Академический Документы

Профессиональный Документы

Культура Документы

U.I.P. System: Submittal Data

Загружено:

naseema1Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

U.I.P. System: Submittal Data

Загружено:

naseema1Авторское право:

Доступные форматы

Submittal Data

________________________________________________________________

U.I.P. system

Below grade applications for pipe with plain ends

Urecons U.I.P. factory insulation piping process and related ISO-9000 quality control procedures assure you of the highest quality product on the market today. This unique, time proven, void free process allows us to visually inspect the urethane foam insulation prior to jacket application. A gray or UV inhibited black polyethylene jacket protects the system once the U.I.P. foam has cured. Application: Urecons standard U.I.P. pre-insulated piping system is suitable for underground chilled water lines in warmer climates underground potable water or sewer lines to prevent freezing in colder regions. 0 0 underground warm water lines to 86 C (185 F) temporary above ground lines (black jacket). Core Pipe: All types of plain end pipe may be factory insulated with the U.I.P. process; refer to the attached pipe manufacturers data sheet for information on the core pipe(s) chosen for this project. Pipe Preparation: Pipe shall be cleaned of surface dust and dirt to insure a positive bond of the foam to the entire pipe surface. The pipes may be treated by sand blasting or the application of a chemical foam-bonding compound if deemed necessary by Urecon. Insulation: Material, rigid polyurethane foam, factory applied. Thickness: as required, refer to accompanying thickness chart. 3 Density: (ASTM D 1622) 35 to 46 kg/m (2.2 to 3.0 3 lbs/ft ). Closed cell content: (ASTM D 2856) 90%,minimum.

Water absorption: (ASTM D 2842) 4.0% by volume . Thermal conductivity: (ASTM C518) 0,020 to 0,026 W/m 0 2 0 C (0.14 to 0.17 Btu in/ft hr F).

System Properties: System compressive strength: (modified ASTM D 1621 with 50 mil jacket) approximately 414 to 552 kPa (60-80 2 lbs/in ), varies with pipe diameter. b) Temperature limitations: 0 0 0 0 in service, -45 to 86 C(-49 to 185 F) 0 0 installation, to -34 C (-30 F) Outer Jacket on Pipe Insulation: The outer protective jacket shall consist of custom blended black polyethylene, 1,27 mm (50 mils) thick, UV inhibited factory applied. The jacket shall have a modified butyl rubber adhesive to ensure positive adhesion to the foam insulation and shall be applied hot in two counterwound and overlapping layers each 0,64 mm (25 mils) thick to ensure a waterproof bond throughout its entire length. Exposed ends of insulation shall be coated with an approved waterproofing sealant prior to leaving the factory, when required. Outer Jacket Characteristics: jacket material: gray or black (UV inhibited ) polyethylene sealant: butyl rubber, resin jacket thickness: 1,27 mm (50 mils) minimum elongation: (ASTM D 1000) 300%, 6 month test tensile strength: (ASTM D-1000) 8,93 kg/cm (38 lbs/in) Plain End Joints: The pipe is provided with the appropriate cut-backs to allow for joining in the field. These are typically: butt-welded steel @ 150mm (6 in.) butt-fused HDPE @ 225mm (9 in.)

Submittal Data, #135 E, March 2004

Page 1 of 2

soldered copper @ 150mm (6 in.) for up to 37mm (1 in.), and 225mm (9 in.) for 50mm (2 in.) and larger. Joint insulation kits consist of a preformed set of urethane or polyisocyanurate foam half shells and adequate butyl mastic tape. width: 100mm (4 in.) or 150mm (6 in.). backing: Low density polyethylene. adhesive: Butyl rubber and resin. thickness: 0,90mm (35 mils).

meets AWWA C-209 standard.

Fittings: May be supplied factory insulated if the fitting has long tangential legs (such as with fabricated Steel fittings) or insulation kits may be provided for field installation. These kits match the thickness of the insulation on the pipe complete with extension legs to suit the cut-back on the pipe. Refer to Urecons Submittal Data for Insulation Kits for details.

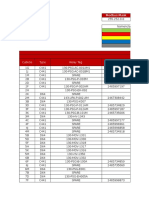

UIP System 25mm (1) Pipe Size In " " 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4" 5" 6" 8" 10" 12" 14" 16" 18" 20" mm 12 19 25 32 38 51 64 76 102 127 152 203 254 305 356 406 457 508 in 3.00 3.35 3.75 4.00 4.25 4.63 5.13 5.75 6.75 8.00 9.00 11.00 13.75 15.70 x x x x OD mm 76 85 95 102 108 118 130 146 171 203 229 279 349 399

X X X X

35mm (1 ) Foam OD mm 28 30 30 30 30 28 28 30 28 30 30 30 38 38 x x x x in 3.67 4.25 4.50 4.50 5.00 5.75 6.13 6.75 7.75 8.75 10.00 12.00 14.00 16.00 17.75 19.75 x x Mm 93 108 114 114 127 146 156 171 197 222 254 305 356 406 450 502

X X

50mm (2) Foam OD mm 36 41 43 36 41 43 41 43 41 41 43 43 41 41 48 48 x x in 5.25 5.25 5.25 5.50 6.13 6.50 6.75 7.75 8.75 10.00 11.00 13.25 15.50 17.50 18.80 21.00 23.00 25.00 mm 133 133 133 140 156 165 171 197 222 254 279 337 394 445 478 533 584 635 in 2.2 2.1 2.1 1.9 2.1 2.1 1.9 2.2 2.2 2.2 2.2 2.3 2.4 2.4 2.4 2.5 2.5 2.5 Foam mm 56 53 53 48 53 53 48 56 56 56 56 58 61 61 61 64 64 64

in 1.1 1.2 1.2 1.2 1.2 1.1 1.1 1.2 1.1 1.2 1.2 1.2 1.5 1.5

X X X XX

In 1.4 1.6 1.7 1.4 1.6 1.7 1.6 1.7 1.6 1.6 1.7 1.7 1.6 1.6 1.9 1.9

X X

Insulate fittings with insulation kits or field poured foam

Plain End Pipe

Factory-Applied Moisture Barrier

Plain End Pipe

PE Jacket

PE Jacket

Polyurethane Foam Insulation Cutback to permit field joining

*Highlighted areas indicate product submitted for this project.

CANADA

1800, av. Bdard St-Lazare-de-Vaudreuil (Qubec) J7T 2G4 Tl.: (450) 455-0961 Fax: (450) 455-0350 E-mail: sales.east@urecon.com 5010-43 Avenue Calmar, Alberta T0C 0V0 Tel: (780) 985-3636 Fax: (780) 985-2466 E-mail: sales.west@urecon.com I S O 9 0 0 1: 2000 Registered Company

UNITED STATES

4185 South US1, Suite 102 Rockledge, Florida 32955 Tel.: (321) 638-2364 Fax: (321) 638-2371 E-mail: sales.usa@urecon.com

Local Representative

WEB SITE: www.urecon.com

Submittal Data, #135 E, March 2004

Page 2 of 2

Вам также может понравиться

- Viewing and Interpretation of RadiographsДокумент30 страницViewing and Interpretation of RadiographsNatrajiОценок пока нет

- Weld Fitting DimensionsДокумент5 страницWeld Fitting DimensionsteguheafОценок пока нет

- Buttweld FittingsДокумент3 страницыButtweld FittingsAshok Kumar100% (1)

- (AL Shabab) : Painting Procedure P-04Документ12 страниц(AL Shabab) : Painting Procedure P-04Omar Nabil80% (5)

- Sproule WR 1200 Perlite TDSДокумент2 страницыSproule WR 1200 Perlite TDSnaseema1Оценок пока нет

- Itp For Storge TankДокумент23 страницыItp For Storge Tanknaseema1Оценок пока нет

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineДокумент7 страницPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1Оценок пока нет

- UAS Engineering & Ship Repair ServicesДокумент1 страницаUAS Engineering & Ship Repair Servicesnaseema1Оценок пока нет

- Kaiflex Specification DomesticДокумент5 страницKaiflex Specification Domesticnaseema1Оценок пока нет

- Kaiflex MasterSpecificationДокумент8 страницKaiflex MasterSpecificationnaseema1Оценок пока нет

- ProcedureДокумент11 страницProcedurePoonam AshwinОценок пока нет

- Insulation InspectionsДокумент1 страницаInsulation Inspectionsnaseema1Оценок пока нет

- Kooltherm PipeДокумент8 страницKooltherm Pipenaseema1Оценок пока нет

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsДокумент1 страницаMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Оценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- Regulationonliftingequipmentprotocol 1 Steditionapril 2010 CsДокумент14 страницRegulationonliftingequipmentprotocol 1 Steditionapril 2010 Csnaseema1Оценок пока нет

- TGN-BC-01 Tack Welding of Reinforcement BarДокумент8 страницTGN-BC-01 Tack Welding of Reinforcement Barnaseema1Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Yugo m59 - 66 RifleДокумент8 страницYugo m59 - 66 Riflestraightshooter100% (1)

- Monthly Ladder Inspection ChecklistДокумент4 страницыMonthly Ladder Inspection ChecklistPeter Sare WolloОценок пока нет

- Lancaster LinksДокумент3 страницыLancaster LinksTiago FerreiraОценок пока нет

- Oct 15 Action Research PLT AgendaДокумент2 страницыOct 15 Action Research PLT Agendaapi-231962429Оценок пока нет

- An 4160Документ8 страницAn 4160aurumstar2000Оценок пока нет

- Item 3 Ips C441u c441r Ieb Main ListДокумент488 страницItem 3 Ips C441u c441r Ieb Main Listcristian De la OssaОценок пока нет

- Boeing Defence Australia LimitedДокумент16 страницBoeing Defence Australia LimitedMitchОценок пока нет

- Fax 283Документ3 страницыFax 283gary476Оценок пока нет

- BAERD GEN-007 Rev CДокумент27 страницBAERD GEN-007 Rev CPaulОценок пока нет

- Ooad Question BankДокумент5 страницOoad Question Bankkhusboo_bhattОценок пока нет

- TX-SMS Remote Programming GuideДокумент2 страницыTX-SMS Remote Programming GuidedjbobyОценок пока нет

- Rotork: Product TrainingДокумент4 страницыRotork: Product TraininghieuОценок пока нет

- Thermodynamics Nozzle 1Документ19 страницThermodynamics Nozzle 1waseemjuttОценок пока нет

- Mohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoДокумент1 страницаMohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoMohiuddin AhmadОценок пока нет

- A White Paper On IExpense Features in R12Документ17 страницA White Paper On IExpense Features in R12Balaji ShindeОценок пока нет

- Premium Protection Synthetic Motor Oils (AMO & ARO)Документ2 страницыPremium Protection Synthetic Motor Oils (AMO & ARO)brian5786Оценок пока нет

- Broadcast Tools Site Sentinel 4 Install Op Manual v2 12-01-2009Документ41 страницаBroadcast Tools Site Sentinel 4 Install Op Manual v2 12-01-2009testeemailОценок пока нет

- Non Domestic Building Services Compliance GuideДокумент76 страницNon Domestic Building Services Compliance GuideZoe MarinescuОценок пока нет

- CV Product C-EtdДокумент6 страницCV Product C-EtdmrmskymanОценок пока нет

- Scan 0001Документ1 страницаScan 0001ochiroowitsОценок пока нет

- Em - 1110 1 1005Документ498 страницEm - 1110 1 1005Sajid arОценок пока нет

- Technical Report Route To IEng GuidanceДокумент11 страницTechnical Report Route To IEng GuidanceECCОценок пока нет

- Procedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0Документ13 страницProcedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0José Angel TorrealbaОценок пока нет

- Introducing Maf and Mef Frameworks: Exploring Managed Addin FrameworkДокумент9 страницIntroducing Maf and Mef Frameworks: Exploring Managed Addin Frameworkkris2tmgОценок пока нет

- Y62 Patrol Full EditionДокумент163 страницыY62 Patrol Full EditionEric Golden100% (8)

- CV - Shakir Alhitari - HR ManagerДокумент3 страницыCV - Shakir Alhitari - HR ManagerAnonymous WU31onОценок пока нет

- Manual Redutores SEWДокумент154 страницыManual Redutores SEWLucas Issamu Nakasone PauloОценок пока нет

- Section 1.0 Typical AMF PANEL Application WiringДокумент2 страницыSection 1.0 Typical AMF PANEL Application WiringMAYUR GENSET100% (4)

- Applichem Case-SCM Sec B Group-2Документ11 страницApplichem Case-SCM Sec B Group-2Ayush RanjanОценок пока нет

- Waste To Wealth Green Potential From Palm Biomass in MalaysiaДокумент9 страницWaste To Wealth Green Potential From Palm Biomass in MalaysiaLai Mei EeОценок пока нет