Академический Документы

Профессиональный Документы

Культура Документы

15500-Fire Protection System

Загружено:

aries82senthilИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

15500-Fire Protection System

Загружено:

aries82senthilАвторское право:

Доступные форматы

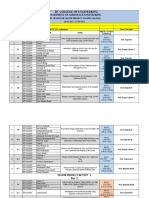

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OW NER.

DIVISION 15 - MECHANICAL

ENGG CERT

SECTION 15500 - FIRE PROTECTION SYSTEMS

PART 1 - GENERAL

1.01 DESCRIPTION OF WORK

IISSUED FOR BIDDING

A. Provide all labor, material, tools, and equipment; fabricate, furnish and install all fire

DESCRIPTION

protection systems complete and in place, including all associated hardware as specified

herein, and as indicated on drawings for a complete and proper installation. Items required

for this work include, but are not necessarily limited to:

1. Fire hose cabinets.

2. Preparations of complete shop drawings for the entire protection systems and

approvals.

JO/EWO

3. All required patent rights satisfaction; and inspections.

4. Connection to site fire main at designated tie-in points outside the building.

05-2006

DATE

5. Protection of materials and protective coatings.

NO.

REV

00

DISCIPLINE 6. Cleaning, testing, and adjusting.

ENGINEER

7. Record Drawings of work installed.

DATE:

PROJECT

ENGINEER

1.02 QUALITY ASSURANCE

DATE:

CERTIFIED A. Codes and Standards: Comply with all applicable codes and standards including, but not

limited to, those listed below:

DATE:

CONSTRUCTION 1. NFPA 14 Standard for Installation of Standpipe and Hose System.

AGENCY

2. Saudi Aramco Engineering Standards (SAES)

DATE:

OPERATIONS

3. SAES-B-017A Firewater System Design

OR

DATE: 4. SAES-B-019C Portable Mobile and Auxiliary Fire Fighting Equipment.

CONTROL NUMBER

VERIFICATION

5. SAES-S-050 Sprinkler and Standpipe Systems in Building

EDSD

6. SAES-S-060 SAUDI ARAMCO Plumbing Code

DATE:

BY:

CERTIFICATION

1.03 SUBMITTALS

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

RTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. _____________________

A. General: In compliance with requirements in Section 15050, and submit the followings

items for Company Representative’s review and approval.

SECTION - 15500

REVISIONCE

CONSTRUCTION

FIRE PROTECTION SYSTEM (15500) DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

OPERATION SUPPORT BUILDING DOC 1

SEA WATER PLANT 496 A BE-215248

00

OF

QURAYYAH SAUDI ARABIA JO / EWO: BI# 10-03451-0001 4

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OW NER.

B. Manufacturer’s Data:

ENGG CERT

1. Complete material list of items proposed to be furnished and installed under this

Section.

2. Manufacturer’s specifications and other data required to demonstrate compliance

with the specified requirements including: catalog numbers, trade names,

illustrations, and descriptive data for each article proposed. All pertinent data for

each articles shall be underlined in each copy of each catalog or brochure in which

IISSUED FOR BIDDING

it is described. Data shall include valves, gauges, risers, trim, sprinkler heads, and

DESCRIPTION

auxiliary equipment.

3. Names and addresses of the service and maintenance organizations nearest the

WORK Sites that readily stocks repair parts.

4. Manufacturer’s recommended installation procedures which, when approved by

SAUDI ARAMCO, shall become the basis for inspecting and accepting or rejecting

actual installation procedures used on the work.

JO/EWO

1.04 PRODUCT DELIVERY, STORAGE AND HANDLING

05-2006

DATE

A. General: Shall be in conformance with Section 15021 Para. 1.04.

PART 2 - PRODUCTS

NO.

REV

00

DISCIPLINE

ENGINEER

2.01 MATERIALS

DATE:

PROJECT

ENGINEER

A. Piping and Fittings

DATE:

1. Provide sleeves at all points where piping passes through walls and floors. Space

CERTIFIED between pipe and sleeves shall be filled with Teflon rope or glass fiber material to

avoid sound transmission and chrome-plated escutcheons shall be provided at floor

DATE: and on each side of wall.

CONSTRUCTION

AGENCY

2. Connect to site fire protection main at designated tie-in points outside of building.

DATE: Extend through foundation wall and up through building at least 6” above floor.

OPERATIONS Provide adapter as required between two different materials.

OR

DATE:

B. Fire Hose Cabinets and Accessories

CONTROL NUMBER

VERIFICATION

1. Cabinets shall include Fire Hose & Nozzle (FH$N) as specified below and a

EDSD

portable Fire Extinguisher (FE-1, without mounting bracket). Cabinets shall be so

designated as to not interfere with the prompt use of the hose valve, the hose and

DATE:

BY:

other requirement within the cabinet at the time of use in fighting a fire. The hose

valve shall be located such that there is at least 25mm between any part of the

CERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

RTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

cabinet and the handle of the valve when the valve is in any position form fully

opened to fully close. Use Larson Model # HCSS3232-R or equal.

(DCC) NO. _____________________

SECTION - 15500

REVISIONCE

CONSTRUCTION

FIRE PROTECTION SYSTEM (15500) DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

OPERATION SUPPORT BUILDING DOC 2

SEA WATER PLANT 496 A BE-215248

00

OF

QURAYYAH SAUDI ARABIA JO / EWO: BI# 10-03451-0001 4

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OW NER.

2. Fire hose cabinets shall be fully recessed type as shown on design drawings. Door

shall be full glass type with tempered glass.

ENGG CERT

3. Materials:

a) Sheet steel for cabinet body shall be cold rolled annealed, stretcher leveled,

bonderized or equivalent treatment and cleaned for the finish specified.

b) Stainless steel for door and frame shall be type 304.

IISSUED FOR BIDDING

c) Glass shall be tempered and meet the requirement of ANSI Z97.1.

DESCRIPTION

4. Construction:

a) Body shall be sheet steel not less than 1.2 mm (18gauge) thick, one piece

full welded with square corners, or seamless front full welded to back and

at corners. Welds shall be continuous in full depth and width dressed

smooth and flush on exposed interior surfaces. Sides shall be blanked or

counter sunk for hardware.

b) Door and frame shall be hollow metal rigid tubular stainless steel

JO/EWO

construction, welded and ground smooth not less than 1.2 mm (18gauge)

thick with attached glass retainers on the inside.

05-2006

DATE

5. Finish:

NO.

REV

00

DISCIPLINE

ENGINEER a) Prime concealed exposed metal surfaces of cabinet body with one

coat of baked enamel primer. Ground smooth exposed surfaces.

DATE:

PROJECT

ENGINEER b) Exposed interior surfaces, in addition to the prime coat, shall have

not less than two coats of baked enamel finish, color shall be white.

DATE:

CERTIFIED

6. Hardware:

DATE:

CONSTRUCTION

a) Cabinets shall have hinges and latch.

AGENCY

b) Hinges shall be continuous stainless steel permitting door to open

DATE:

180 degrees.

OPERATIONS

OR

7. Fire Hose and Nozzle: For installation in FHC

DATE:

CONTROL NUMBER

VERIFICATION

a) Fire Hose shall be 30 meters(100feet) long, 38mm(1 ½ inches) lined

and meet the requirements of SAES-B-019,Section 8.5 and NFPA

EDSD

14, complete with cast brass couplings with threads meeting the

DATE:

requirements of NFPA 1961 & 63. Use Elkhart Model Elk-Lite Hose

BY:

with El khart 328 couplings or equal.

CERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

RTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

b) Nozzle shall be 38mm (1 ½ inch) cast brass adjustable fog nozzle

(DCC) NO. _____________________

capable of complete shutoff, straight stream of any degree of solid

SECTION - 15500

REVISIONCE

CONSTRUCTION

FIRE PROTECTION SYSTEM (15500) DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

OPERATION SUPPORT BUILDING DOC 3

SEA WATER PLANT 496 A BE-215248

00

OF

QURAYYAH SAUDI ARABIA JO / EWO: BI# 10-03451-0001 4

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OW NER.

conical fog. Threads shall meet the requirements of NFPA 194. Use

Elkhart Model L-206T nozzle or equal.

ENGG CERT

c) Hose Rack shall be semi-automatic 38mm (1 ½ inch) on piece

construction, 1.5 mm (16gauge) thick. Rack pins, steel cadmium

plated. Unit shall be red enamel painted and be listed or approved

by Underwriters Laboratories. Use Elkhart Model S-41 or equal.

The following accessories shall be provided with the Hose Rack:

IISSUED FOR BIDDING

DESCRIPTION

1. 50 x 38mm (2 ½ inch) cast brass angle valve, Underwriters

Laboratories approved 150 lb, with threads meeting the

requirements of NFPA 194. Use Elkhart Model U-20 or

equal.

2. 50 mm (2 inch) steel escutcheon plate. Use Elkhart Model

589 or equal.

3. 38 mm (1 ½ inch) cast brass rack nipple. Use Elkhart Model

46-B or equal.

JO/EWO

4. Spanner wrench of malleable iron with cadmium plated fitting

05-2006

DATE

38 mm (1 ½ inch) pin lug or sidewall lug couplings, Spanner

bracket shall be provided.

NO.

REV

00

C. Valves: Valves shall be provided as required by NFPA 13 and of types approved for fire

DISCIPLINE

ENGINEER services. Gate valves shall be flanged clear opening switch check type with flanged

inspection and access cover plate for sizes 100mm(4 inches) and larger. An OS&Y valve

DATE:

shall be provided beneath each alarm valve in each riser when more than one alarm valve is

PROJECT

ENGINEER supplied from the same water supply pipe.

DATE: D. Identification Signs: Properly lettered approved metal signs conforming to NFPA shall be

CERTIFIED

attached to each valve and alarm device.

DATE:

CONSTRUCTION

AGENCY

DATE:

END OF SECTION (15500)

OPERATIONS

OR

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

CERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

RTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. _____________________

SECTION - 15500

REVISIONCE

CONSTRUCTION

FIRE PROTECTION SYSTEM (15500) DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

OPERATION SUPPORT BUILDING DOC 4

SEA WATER PLANT 496 A BE-215248

00

OF

QURAYYAH SAUDI ARABIA JO / EWO: BI# 10-03451-0001 4

EDSD/2616-0399.doc

Вам также может понравиться

- FM Global Property Loss Prevention Data Sheets: List of FiguresДокумент10 страницFM Global Property Loss Prevention Data Sheets: List of FiguresCarlos Oliva LagosОценок пока нет

- Pivot TableДокумент19 страницPivot TablePrince AroraОценок пока нет

- Chronic Kidney DiseaseДокумент15 страницChronic Kidney Diseaseapi-270623039Оценок пока нет

- Lesson 5 Designing and Developing Social AdvocacyДокумент27 страницLesson 5 Designing and Developing Social Advocacydaniel loberizОценок пока нет

- Tender Package Electrical SystemsДокумент221 страницаTender Package Electrical SystemsMohan BabuОценок пока нет

- Cqs Epr Ts Gen PHL 001 Rev 3.0Документ25 страницCqs Epr Ts Gen PHL 001 Rev 3.0Atty AttyОценок пока нет

- Civil Document List: No Document Number Document Title Status DataДокумент12 страницCivil Document List: No Document Number Document Title Status DataMuhammad ZaidОценок пока нет

- Tower 1 and B1&B2 - 29 CommentsДокумент22 страницыTower 1 and B1&B2 - 29 CommentssamehОценок пока нет

- Week 7 Sex Limited InfluencedДокумент19 страницWeek 7 Sex Limited InfluencedLorelyn VillamorОценок пока нет

- Boq For A'sharqiyah UniversityДокумент10 страницBoq For A'sharqiyah UniversitymuthuvelaaОценок пока нет

- Solar Water Heater - ProceedureДокумент13 страницSolar Water Heater - ProceedureSharad MishraОценок пока нет

- Oracle - Prep4sure.1z0 068.v2016!07!12.by - Lana.60qДокумент49 страницOracle - Prep4sure.1z0 068.v2016!07!12.by - Lana.60qLuis AlfredoОценок пока нет

- NEC Cable Tray Sizing ProgramДокумент9 страницNEC Cable Tray Sizing ProgramSimsim GendyОценок пока нет

- Part 23 Fire Fighting & Fire Fighting SystemsДокумент23 страницыPart 23 Fire Fighting & Fire Fighting Systemsmuhannad11061975Оценок пока нет

- Career Level Diagram - V5Документ1 страницаCareer Level Diagram - V5Shivani RaikwarОценок пока нет

- Fire Products CatalogueДокумент8 страницFire Products CatalogueHemalatha KumarОценок пока нет

- ANNEXURE For HVW SPRAY SYSTEM - StandardДокумент1 страницаANNEXURE For HVW SPRAY SYSTEM - StandardVaibhav SawantОценок пока нет

- Electric Pump Acceptence ReportДокумент4 страницыElectric Pump Acceptence ReportNOMANОценок пока нет

- GM479-R0731-000-PR-RP-0003 - 2-Esd PhilosophyДокумент19 страницGM479-R0731-000-PR-RP-0003 - 2-Esd PhilosophySuper 7Оценок пока нет

- 2.12 Construction-Schedule and OperationДокумент4 страницы2.12 Construction-Schedule and OperationScott NewtonОценок пока нет

- P2986-MRP-002 (Dec 12)Документ52 страницыP2986-MRP-002 (Dec 12)tvpham123Оценок пока нет

- Electrical Heat Tracing PDFДокумент10 страницElectrical Heat Tracing PDFdigecaОценок пока нет

- NFPS Compression Project FEED: Page 62 of 122Документ23 страницыNFPS Compression Project FEED: Page 62 of 122Sanjeevi ParthasarathiОценок пока нет

- Water Demand & Spray Nozzle Calculation For 100 KL Horizontal TankДокумент2 страницыWater Demand & Spray Nozzle Calculation For 100 KL Horizontal Tankbecpavan100% (1)

- New Sih Building: Extension of Instrument Room FOR (BI-10-00043-001)Документ25 страницNew Sih Building: Extension of Instrument Room FOR (BI-10-00043-001)John Philip BuntalesОценок пока нет

- Sheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437Документ3 страницыSheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437abdulkidwai2009Оценок пока нет

- NGДокумент10 страницNGbillОценок пока нет

- MMEP Tender - Summary of Suppliers List - Xls Tender - Summary of Suppliers ListДокумент1 страницаMMEP Tender - Summary of Suppliers List - Xls Tender - Summary of Suppliers ListChungNguyenОценок пока нет

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsДокумент6 страницMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92Оценок пока нет

- Glanding: Glands Must Maintain Integrity of EnclosureДокумент11 страницGlanding: Glands Must Maintain Integrity of EnclosureMohamed HamedОценок пока нет

- Richardson Heidegger PDFДокумент18 страницRichardson Heidegger PDFweltfremdheitОценок пока нет

- Hydraulic Calculation FOR Service Water System: I.P.D.C. Project: Shirvan Gas Turbine Power PlantДокумент9 страницHydraulic Calculation FOR Service Water System: I.P.D.C. Project: Shirvan Gas Turbine Power PlantnourfarmajidОценок пока нет

- Overfill Protection System For Tanks Rev1Документ6 страницOverfill Protection System For Tanks Rev1furqan343Оценок пока нет

- Hima OPC Server ManualДокумент36 страницHima OPC Server ManualAshkan Khajouie100% (3)

- Method Statement 01 ESDV 100Документ2 страницыMethod Statement 01 ESDV 100Mohammed AbdallaОценок пока нет

- Functional DesignДокумент17 страницFunctional DesignRajivSharmaОценок пока нет

- Organization and Management Module 3: Quarter 1 - Week 3Документ15 страницOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoОценок пока нет

- Electrical Equipment in Hazardous AreasДокумент8 страницElectrical Equipment in Hazardous AreasMehulkumar PatelОценок пока нет

- VESDA Troubleshooting Guide - Rev05Документ26 страницVESDA Troubleshooting Guide - Rev05Eduardo Diaz PichardoОценок пока нет

- Proposal 4034 AДокумент20 страницProposal 4034 AAbdul AlimОценок пока нет

- 3299 Mom 0004Документ7 страниц3299 Mom 0004Kishore KumarОценок пока нет

- Solberg Ebook 00010 Web PDFДокумент434 страницыSolberg Ebook 00010 Web PDFToretta AdrianОценок пока нет

- SECTION 16120 Conductors and Cables Rev 0Документ49 страницSECTION 16120 Conductors and Cables Rev 0Ahmed HashimОценок пока нет

- Tanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Документ2 страницыTanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Paulo MaresОценок пока нет

- Basic Framework For Submission of Performance-Based SolutionsДокумент83 страницыBasic Framework For Submission of Performance-Based Solutionsahmed abdohОценок пока нет

- 53 TS Fire Protection System For 400kV R1 010108Документ95 страниц53 TS Fire Protection System For 400kV R1 010108girish_motiyani100% (3)

- B2 Project Planning Notes and TipsДокумент29 страницB2 Project Planning Notes and TipsRomeo MarculescuОценок пока нет

- 94-Tmss-01-R0-Automatic Electric Water Heater PDFДокумент14 страниц94-Tmss-01-R0-Automatic Electric Water Heater PDFUtkucan KILIÇОценок пока нет

- Air Foam Chamber: Fire Fighting Equipment Data SheetДокумент8 страницAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaОценок пока нет

- FF BoqДокумент14 страницFF BoqSreenivasa Rahavan VОценок пока нет

- IG 55 CalculationДокумент11 страницIG 55 CalculationNoridhamОценок пока нет

- Disel Pump Acceptance ReportДокумент4 страницыDisel Pump Acceptance ReportNOMAN100% (1)

- Vav HvacДокумент47 страницVav HvacMuraryspotty100% (1)

- Medium Velocity Water Spray (MVWS) System - Electrical4UДокумент16 страницMedium Velocity Water Spray (MVWS) System - Electrical4UkaustavОценок пока нет

- Fire Pump SpecificationДокумент5 страницFire Pump SpecificationThiru AnanthОценок пока нет

- Entrance of VIP: Service Path TarmacДокумент5 страницEntrance of VIP: Service Path TarmacfebousОценок пока нет

- Kidde Fire Protection FM200 GX20 Technical DatasheetsДокумент56 страницKidde Fire Protection FM200 GX20 Technical DatasheetsIndo AprilОценок пока нет

- Appendix3 25113Документ189 страницAppendix3 25113iezohreОценок пока нет

- 2014-0192 QTN r.0 - Technical QuotationДокумент8 страниц2014-0192 QTN r.0 - Technical QuotationShibin SahadevanОценок пока нет

- APMRG1 Series: Packaged Air ConditionersДокумент32 страницыAPMRG1 Series: Packaged Air Conditionerszaid jamaluОценок пока нет

- Volume 1 Fire Protection Systems Testing and Commissioning ProceduresДокумент7 страницVolume 1 Fire Protection Systems Testing and Commissioning ProceduresAbdalrahman AntariОценок пока нет

- Block 3 - SMPL Programming Rev 1Документ103 страницыBlock 3 - SMPL Programming Rev 1Oscar GarciaОценок пока нет

- Itcc Cluster Bms Io PGДокумент9 страницItcc Cluster Bms Io PGuddinnadeemОценок пока нет

- Chilled Water Buffer TankДокумент4 страницыChilled Water Buffer TankThiraviam Ayyappan100% (1)

- 32 Tmss 01Документ35 страниц32 Tmss 01mostafa mansourОценок пока нет

- Precommision Cleaning of Piping SystemsДокумент10 страницPrecommision Cleaning of Piping SystemsElias EliasОценок пока нет

- 2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetДокумент10 страниц2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetSamuel JohnsonОценок пока нет

- Technical Specification - Fire Alarm System - P0 PDFДокумент29 страницTechnical Specification - Fire Alarm System - P0 PDFAbil RajanОценок пока нет

- Edl Electrical - Instrument 25 September 2012Документ36 страницEdl Electrical - Instrument 25 September 2012raih_zenita2807Оценок пока нет

- Saudi Arabian Oil Company: 13.0 Instrumentation and ControlДокумент1 страницаSaudi Arabian Oil Company: 13.0 Instrumentation and ControlParthiban RОценок пока нет

- A Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportДокумент110 страницA Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDeepak SinghalОценок пока нет

- Partes de La Fascia Opteva Y MODULOSДокумент182 страницыPartes de La Fascia Opteva Y MODULOSJuan De la RivaОценок пока нет

- Dialogue Au Restaurant, Clients Et ServeurДокумент9 страницDialogue Au Restaurant, Clients Et ServeurbanuОценок пока нет

- B.SC BOTANY Semester 5-6 Syllabus June 2013Документ33 страницыB.SC BOTANY Semester 5-6 Syllabus June 2013Barnali DuttaОценок пока нет

- Comparitive Study ICICI & HDFCДокумент22 страницыComparitive Study ICICI & HDFCshah faisal100% (1)

- Review1 ScheduleДокумент3 страницыReview1 Schedulejayasuryam.ae18Оценок пока нет

- A Case Study Puga Geothermal System,: OF IndiaДокумент7 страницA Case Study Puga Geothermal System,: OF IndiaPERIKALA TARUNОценок пока нет

- Analizador de Combustion Kigaz 310 Manual EngДокумент60 страницAnalizador de Combustion Kigaz 310 Manual EngJully Milagros Rodriguez LaicheОценок пока нет

- Quick Help For EDI SEZ IntegrationДокумент2 страницыQuick Help For EDI SEZ IntegrationsrinivasОценок пока нет

- AntibioticsДокумент36 страницAntibioticsBen Paolo Cecilia RabaraОценок пока нет

- Ricoh IM C2000 IM C2500: Full Colour Multi Function PrinterДокумент4 страницыRicoh IM C2000 IM C2500: Full Colour Multi Function PrinterKothapalli ChiranjeeviОценок пока нет

- Application of Graph Theory in Operations ResearchДокумент3 страницыApplication of Graph Theory in Operations ResearchInternational Journal of Innovative Science and Research Technology100% (2)

- Android Developer PDFДокумент2 страницыAndroid Developer PDFDarshan ChakrasaliОценок пока нет

- The Homework Song FunnyДокумент5 страницThe Homework Song Funnyers57e8s100% (1)

- Thermally Curable Polystyrene Via Click ChemistryДокумент4 страницыThermally Curable Polystyrene Via Click ChemistryDanesh AzОценок пока нет

- Chemistry: Crash Course For JEE Main 2020Документ18 страницChemistry: Crash Course For JEE Main 2020Sanjeeb KumarОценок пока нет

- Recommendations For Students With High Functioning AutismДокумент7 страницRecommendations For Students With High Functioning AutismLucia SaizОценок пока нет

- Study 107 - The Doctrine of Salvation - Part 8Документ2 страницыStudy 107 - The Doctrine of Salvation - Part 8Jason MyersОценок пока нет

- Career Essay 1Документ2 страницыCareer Essay 1api-572592063Оценок пока нет

- Costbenefit Analysis 2015Документ459 страницCostbenefit Analysis 2015TRÂM NGUYỄN THỊ BÍCHОценок пока нет