Академический Документы

Профессиональный Документы

Культура Документы

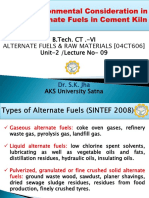

Cement and Lime Kilns: Process Description

Загружено:

mkdo82Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cement and Lime Kilns: Process Description

Загружено:

mkdo82Авторское право:

Доступные форматы

PROCESS INSTRUMENTS

T

H

E

R

M

O

X

A

p

p

l

i

c

a

t

i

o

n

N

o

t

e

www.ametekpi.com

ADVANTAGES OF USING THERMOX ANALYZERS IN

LIME, CEMENT AND OTHER INDUSTRIES WITH ROTARY KILNS

Measure O

2

, Combustibles (CO + H

2

), and Methane

Direct or indirect measurement

Reliable sensor technology

Fast response

Ability to measure oxidizing or close to stoichiometric

Maximize fuel effciency and product quality with reliable fue gas

measurement

Many options allow choice of analyzer style for optimum performance

Cement and Lime Kilns

PROCESS DESCRIPTION

Cement, lime and gypsum manufacturing processes have in common the mixing of inorganic minerals calcined at high

temperatures typically using rotary kilns (vertical kilns are also used).

CEMENT

Regular Portland cements are the

usual products for general concrete

construction. The raw materials,

limestone or chalk, together with

clay or shale are mixed and fed to a

large rotary kiln at temperatures up

to 2600F (1427C). The mix can be

taken through a number of preheater

and precalciner stages before being

charged into the rotary kiln.

Kilns are normally fred with

pulverized coal or gas at one end.

Raw materials are fed to the kiln

at the back end furthest from the

burners. Travelling through the kiln,

the ingredients are progressively

heated. Here fue gas fows in the

opposite direction. The kiln can be

divided into three zones - drying,

calcining and burning. Drying

removes the water from the mix;

calcining drives off the carbon dioxide;

burning sinters and partially fuses

the ingredients into lumps known

as clinkers. These clinkers are then

cooled and pulverized into fne

powder. Some gypsum is used to

control the speed of setting when

water is added. After the kiln, the

fue gas passes through various heat

recovery stages, then to electrostatic

precipitators for fnal clean up before

being discharged to the stack.

Some cement kilns are the

wet slurry type. Slurry of raw

materials is fed directly into the

kiln. The temperature at the inlet is

considerably less than the dry feed

process. Also the kiln is much longer

to allow suffcient time for drying

before calcination. Figure 1 is a

schematic of a typical cement plant.

The tremendously high temperature

sustained by cement kilns and the

long transit time are ideal for the

disposal of material such as tires or

hazardous wastes.

LIME

Lime or quicklime are the common

names for calcium oxide (CaO), a

gray-white powder. Either directly

or indirectly lime and limestone are

used in more industries than any

other natural substance. It is used in

the manufacture of glass, cement,

brick, pulp/paper, steel, aluminum,

magnesium and poultry feed. It also

is used in processing cane and sugar

beet juices. Lime kilns are associated

with every kraft pulp mill and often

used in steel mills.

Since lime is manufactured from

quarried limestone, lime plants are

located near these deposits. The

crushed raw material is fed to a

rotary or vertical kiln where carbon

dioxide is driven off to produce lime.

The use of lime for any particular

process depends on its composition

and physical properties, which are

controlled by the selection of the

limestone and manufacturing process

details. The quality and color affect

the suitability of use and price.

T

H

E

R

M

O

X

2

Kiln operators aim to ensure consistent

product quality along with good fuel

effciency and increased production.

Some reasons for fue gas monitoring

include:

Effciency

In all combustion processes, monitoring

fue gas for oxygen and combustibles

(or CO) allows the process to be

operated more effciently. At the high

operating temperature of kilns, even

a small reduction in excess air gives a

signifcant cost savings which makes

monitoring particularly important.

Product Quality

Maintaining the air/fuel ratio within a

specifc range can be important for

product quality. For example, lime kilns

use coal whenever possible due to the

high temperature and high cost of fring

with natural gas. If the coal has a high

sulfur content, it is necessary to operate

the kiln close to stoichiometric to avoid

contamination of the lime with SO

2

.

This is important for lime used in steel

manufacture or as a neutralizing agent

for SO

2

removal plants.

Safety

Monitoring CO, combustibles and

methane can prevent build-up to the

levels that can cause an explosion in

electrostatic precipitators, bag houses

or ID fans. CH

4

is measured during the

purge and light-off on kilns started up

with natural gas.

Emissions Reduction

Signifcant reduction in emissions

of NOx and other pollutants can

be achieved by maintaining good

combustion control.

Process Optimization and

Control

Reliable fue gas analysis provides

information for effective control of kiln,

preheater, and precalciner conditions.

Emissions Monitoring

Continuous emissions monitoring

systems (CEMS) are required for

reporting emissions but are not normally

used for process optimization.

PRE-HEATER

(OPTIONAL)

PRE-CALCINER

(OPTIONAL)

WET PROCESS DRY PROCESS

SLURRY

MIXING &

BLENDING

DRY

MIXING &

BLENDING

DRYING

ZONE

CALCINING

ZONE

BURNING or

CLINKERING

ZONE

CLINKER

STORAGE

CLINKER

COOLER

PRODUCT

STORAGE

SEPARATOR

FINISHING

MILL

GYPSUM

SHIPMENT

ROTARY KILN

PRECIPITATOR/

DUST REMOVAL

STACK

QUARRYING RAW

MATERIALS

CRUSHING

OPERATIONS

GRINDING

WHY FLUE GAS MONITORING?

Recent advances in sensor technology

combined with alternative methods

of mounting fue gas analyzers have

allowed much more dependable

measurement of oxygen and carbon

monoxide or combustibles in the fue

gas from rotary kilns.

As desirable as it is to measure for the

above reasons, it is also very diffcult

to measure the fue gas in cement

and lime kilns. This is due to the

combination of high temperature, heavy

particulate loading, and the tendency

of the material to aggregate. It is

preferable to measure in the kiln ahead

of the rotary seal so that air leakage

does not affect the reading. This often

necessitates a long probe, typically 9 ft.

(2.7 m), which further compounds the

diffculty. Figure 2 shows a schematic of

the fue gas/burning section of the plant.

Figure 1. Typical Cement Plant

T

H

E

R

M

O

X

3

Oxygen (O

2

)

Zirconium oxide-based oxygen

analyzers can be used either directly

on the fue gas or connected to the

end of a sample conditioning system.

Paramagnetic or fuel cell-based oxygen

analyzers must have a clean dry

sample and therefore can be used only

after a sample conditioning system.

MEASURED GASES

K IL N

ELECTROSTATIC

PRECIPITATOR

OR

BAG HOUSE

S

T

A

C

K

GAS

CONDITIONING

TOWER

PREHEATER

TOWER

STORAGE

SILO

COAL

MILL

FLUE GAS FLOW

FEED FLOW

FUEL

Carbon Monoxide (CO) and

Combustibles (CO+H

2

)

Carbon monoxide analyzers are

infrared and can either be across-

the-stack or at the end of a sample

conditioning system. The across-the-

stack version can be used only after

a sample clean up device such as an

electrostatic precipitator. Combustibles

detectors (CO and H

2

) are typically

catalytic bead and are usually combined

with the oxygen measurement in the

same analyzer. Most analyzers used on

sample conditioning systems are based

on paramagnetic, infrared, ultraviolet

or electrochemical technology and

require a perfectly clean, dry sample

gas. If the sample conditioning system

fails to operate correctly, the cells of

these analyzers become coated or

contaminated and are very expensive

to repair.

Methane (CH

4

)

Neither combustibles nor carbon

monoxide detectors are able to

measure methane, the primary

constituent of natural gas. Before

ignition of a natural gas burner, a

purge and light-off cycle aims to

ensure that no gas is present, but

explosions still occur. An on-line

methane measurement detects the

presence of natural gas before ignition

independently of the purge cycle.

Once the burners are lit, methane

no longer exists - only CO and H

2

.

This measurement can be combined

with oxygen and combustibles in the

WDG-IVCM 3-in-1 analyzer. Due to the

physical nature of gas-fred rotary kilns,

which can channel explosive energy,

methane detection can be of particular

importance.

Figure 2. Flue Gas/Feed Schematic

T

H

E

R

M

O

X

4

There are many different ways of

measuring the fue gas from rotary

kilns. All have been developed by

customers through many years of trial

and error with their own process. The

customer knows the characteristics of

the fue gas temperature, stickiness

of the particulate, corrosivity, fuidity,

and abrasiveness. He or she will

generally know which kind of system

is most likely to survive in the process.

There are as many different solutions

as there are plants. It is important

to work within the framework of the

customers experience. Most customers

prefer to measure at a point ahead of

the rotating seal for precise control of

the kiln fring conditions without errors

caused by the ingress of air from the

seal. However, analysis can be made

at any point between the kiln and the

fnal stack. Direct measurement works

for lower temperature, dry applications

where ceramic is not required and the

particulates do not stick to the probe to

build a large beehive. Making use of

an existing sample system or a by-

pass is preferred for high temperature

applications, although some customers

are measuring directly in the kiln

with varying degrees of success

and maintenance frequency. There

is no single best way to monitor in

kiln applications, but here are some

approaches.

1. Direct Measurement

Direct Measurement Before the

Seal

Direct measurement in the kiln

ahead of the seal is the most diffcult.

Temperatures here are typically 1900

2200F (1038 1204C) on a dry

cement process and 800 1800F

(427 982C) on a wet slurry cement

process or a lime kiln. An insitu can be

used if oxygen-only measurement is

required and the temperature is under

1250F/677C. In many dry cement

kilns, the temperature is high enough

that only water-cooled probes can

survive for extended operation. Some

customers use a type of defector

pipe installed in the process with the

analyzer mounted directly to this. The

METHODS OF FLUE GAS MONITORING

analyzer probe extends almost to the

end of the defector pipe, which is open

in the direction opposite of the gas fow

shielded by the defector. Others use a

standard probe and flter with variable

success rates (see Figure 3, Probe 2).

Direct Measurement After the

Seal

A WDG-HPIIC (O

2

and combustibles,

less than 1875F/1024C) or a WDG-

Insitu (O

2

only, less than 1250F/677C)

can be used in the kiln hood or at any

point in the fue gas fow path between

the kiln and the fnal stack. The

diffculty at the kiln hood is accessibility

for cleaning of the probe and service

of the analyzer. The measurement

in the hood can be infuenced by air

leakage past the rotating seal and

hence many customers prefer to have

a sample taken from before the seal.

However it is often useful to measure

at other points in the process for good

combustion control and comparison.

Both the WDG-Insitu and WDG-HPIIC

are diffusion-based analyzers and can

be used directly in high particulate

applications (see Figure 3, Probes 3

and 4).

Direct Measurement in the

PreHeater

As the temperature is normally cooler

here (less than 1250F/677C), a

WDG-HPIIC or a WDG-Insitu can be

used directly mounted at a suitable

point in the ductwork.

1 WATER WASH PROBE TO SAMPLE SYSTEM

2 WDG-INSITU

3 WDG-HPIIC

4 WDG-HPIIC FLOOR MOUNT

2. Sample Conditioning Systems

A water-cooled probe or an automated/

motorized probe ahead of the seal is

often connected to a sample system

(refer to Figure 3, Probe 1). This

presents the cleaned, cooled fue

gas to a bank of analyzers located in

an analyzer shelter. The analyzers

are oxygen, carbon monoxide and

sometimes carbon dioxide used for

process and combustion control. They

are easily damaged by sample system

upsets and require frequent, if not daily,

calibration.

A separate probe from the fnal

stack is used for continuous emission

monitoring. The gases measured

include oxygen, CO, NOx, and SO

2

.

The Thermox WDG-IVC or WDG-

IVCM can replace the oxygen and CO

analyzers used for process control

on an existing sample system. The

unistrut option allows the analyzer to

be mounted on a wall or panel in a

convenient location.

Figure 3. Various Kiln Measurements

FAN

SAMPLE

FROM KILN

BLOWBACK

AIR INLET

S

A

M

P

L

E

B

O

X

(

a

p

p

r

o

x

.

3

'

x

3

'

x

1

' )

INSPECTION/

CLEANING PORTS

DUCT WORK

8" KILN

WDG-

HPIIC

T

H

E

R

M

O

X

5

3. By-Pass Systems

In a by-pass system, the sample pipe is inserted into

the kiln behind the seal and routed out of the kiln to a

part of the ductwork at a slightly lower pressure. This

causes the sample to fow through the by-pass and the

analyzer can be located at a suitable position. A fan

may be required to assist the fow. A by-pass system

still requires regular maintenance to keep it clean but

the system can be designed with easy access ports.

Figure 4 shows the analyzer mounted vertically on a

larger diameter section of the by-pass. The version

shown in Figure 5 uses a Y-shaped pipe with the

probe mounted horizontally in one of the arms of the Y.

Another approach brings the pipe to a large sample box

upon which the analyzer (or multiple analyzers) can be

mounted (Figure 6).

METHODS OF FLUE GAS MONITORING

AIRPURGE

KILNGAS

FLOOR

ROTARY KILN

4" SAMPLE

GAS PIPE

SAMPLE

FAN

(OPTIONAL)

10" PIPE

BRINGTO

LOWER

PRESSURE

LOCATION

FLOORMOUNT WDG-HPIIC

MOUNTEDTOFLANGE

CLEANING

PORT

Figure 4. By-Pass Vertical Probe

Figure 5. By-Pass Horizontal Probe

Figure 6. By-Pass Sample Box

T

H

E

R

M

O

X

6

ELECTROSTATIC PRECIPITATOR

PROTECTION

For electrostatic precipitator protection, we recommend

the WDG-IVCM, and WDG-HPIICM. Normally the

combustibles high alarms are set to 0.8% at which point

the precipitator or other devices can be shut down.

Since a standard catalytic combustibles detector does

NOT respond to methane, high levels of methane which

may have leaked into the burner chamber at start up

can lead to an explosion. A useful precaution in this

case is to use an analyzer ftted with the additional

methane detector.

RELATED INDUSTRIES WITH KILNS

In addition to cement and lime, rotary kilns are used

for other applications. Some of the applications have

considerable vibration which would damage the

analyzer. A fexible mount, shown in Figure 7, can be

used to minimize the effect of vibration. An antivibration

furnace is also recommended.

SUMMARY

AMETEK/Thermox has a large installed base in rotary kiln measurement in the cement, lime, pulp and paper, steel,

minerals, and waste disposal industries. The Thermox analyzers offer fexibility in design and options and can be

adapted to practically any situation. We will be pleased to advise on your analytical application and invite you to contact

your nearest AMETEK Process Instruments offce for assistance.

FLEXIBLE

MOUNT

ANALYZER ATTACHED TO

FIRM SUPPORT

VIBRATING

PROCESS WALL

PROBE

Figure 7. Flexible Mount

2011, by AMETEK, Inc.

All rights reserved. Printed in the U.S.A.

F-0240 Rev. 2 (0311)

One of a family of innovative process analyzer solutions from AMETEK Process Instruments.

Specifcations subject to change without notice.

150 Freeport Road, Pittsburgh, PA 15238

Ph. +1-412-828-9040, Fax +1-412-826-0399

www.ametekpi.com

T

H

E

R

M

O

X

A

p

p

l

i

c

a

t

i

o

n

N

o

t

e

SALES AND MANUFACTURING:

USA - Delaware

455 Corporate Blvd., Newark DE 19702 Tel: +1-302-456-4400, Fax: +1-302-456-4444

USA - Oklahoma

2001 N. Indianwood Ave., Broken Arrow OK 74012 Tel: +1-918-250-7200, Fax: +1-918-459-0165

CANADA - Alberta

2876 Sunridge Way N.E., Calgary, AB T1Y 7H9 Tel: +1-403-235-8400, Fax: +1-403-248-3550

WORLDWIDE SALES AND SERVICE LOCATIONS:

USA - Texas

Tel: +1-713-466-4900, Fax: +1-713-849-1924

CHINA

Beijing / Tel: 86 10 8526 2111, Fax: 86 10 8526 2141

Chengdu / Tel: 86 28 8675 8111, Fax: 86 28 8675 8141

Guangzhou / Tel: 86 20 8363 4768, Fax: 86 20 8363 3701

Shanghai / Tel: 86 21 5868 5111, Fax: 86 21 5866 0969

FRANCE

Tel: 33 1 30 68 89 20, Fax: 33 1 30 68 89 29

GERMANY

Tel: 49 21 59 91 36 0, Fax: 49 21 59 91 3639

INDIA

Tel: 91 80 6782 3200, Fax: 91 80 6782 3232

SINGAPORE

Tel: 65 6484 2388, Fax: 65 6481 6588

Вам также может понравиться

- Challenges of Welding of Catalyst TubesДокумент16 страницChallenges of Welding of Catalyst TubesTravis SkinnerОценок пока нет

- Q and A Refinery ProcessesДокумент9 страницQ and A Refinery ProcessesnishilgeorgeОценок пока нет

- Kerui XJ650 Rig WorkoverДокумент29 страницKerui XJ650 Rig WorkoverElieser MirandaОценок пока нет

- A Summary Report On FPSO Lessons Learned by OLF - May 2002 PDFДокумент27 страницA Summary Report On FPSO Lessons Learned by OLF - May 2002 PDFAgung Doank Yess100% (1)

- Instrumentation in Cement IndustriesДокумент9 страницInstrumentation in Cement Industriesdina safiri100% (2)

- Cement IndustryДокумент26 страницCement Industryrajeevmenon2003Оценок пока нет

- Coal Quality DeterminationДокумент17 страницCoal Quality DeterminationWulan Dwikusuma Asih100% (1)

- The Versatility of Outotec's Ausmelt Process For Lead ProductionДокумент12 страницThe Versatility of Outotec's Ausmelt Process For Lead ProductionMatthew PrattОценок пока нет

- Hydrogen Technology An OverviewДокумент7 страницHydrogen Technology An Overviewlili_eqОценок пока нет

- Operators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineДокумент8 страницOperators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineKrishnan SanthanarajОценок пока нет

- Installation Akpo FieldДокумент82 страницыInstallation Akpo FieldOkolo ObinnaОценок пока нет

- Argus International LPGДокумент16 страницArgus International LPGreynaldo figueroa guerreroОценок пока нет

- 3 E&P Business LifecycleДокумент34 страницы3 E&P Business Lifecyclesatztg6089Оценок пока нет

- Kiln Control Using Continuous On-Stream XRD: A Proven TechnologyДокумент8 страницKiln Control Using Continuous On-Stream XRD: A Proven TechnologySiti Hanna100% (1)

- Trace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCДокумент6 страницTrace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCgoodcharacter1Оценок пока нет

- Lurgi's MPG Gasification Plus RectisolДокумент12 страницLurgi's MPG Gasification Plus Rectisolmourinho2Оценок пока нет

- Cleaning Furnace CoilsДокумент8 страницCleaning Furnace CoilsMaruthiram100% (1)

- Chemical Cleaning of Steam Generator System by GEДокумент6 страницChemical Cleaning of Steam Generator System by GEBapu612345Оценок пока нет

- Source of Energy in The BiosphereДокумент94 страницыSource of Energy in The BiosphereSamuel YangОценок пока нет

- Tilting Rotary Furnaces KMF Maschinenfabriken GmbH7yiДокумент3 страницыTilting Rotary Furnaces KMF Maschinenfabriken GmbH7yiVijaykumar SharmaОценок пока нет

- Modeling, Control, and Optimization of Natural Gas Processing PlantsОт EverandModeling, Control, and Optimization of Natural Gas Processing PlantsРейтинг: 5 из 5 звезд5/5 (1)

- Coal Mill Gas AnalysisДокумент12 страницCoal Mill Gas AnalysisPaulo VidasОценок пока нет

- Mercury Removal ProcessesДокумент10 страницMercury Removal ProcesseshortalemosОценок пока нет

- High Temperature Syngas Coolers - ccc257 PDFДокумент60 страницHigh Temperature Syngas Coolers - ccc257 PDFAbhijeet SahuОценок пока нет

- Control of Vapor Recovery Units (VRU)Документ8 страницControl of Vapor Recovery Units (VRU)Yasmine ياسمينОценок пока нет

- High-Temperature Technology High-Temperature: PolysiusДокумент4 страницыHigh-Temperature Technology High-Temperature: PolysiusHarsh Vardhan Sharma100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- SS ENERGY LPG AutoGas Station Presentation FinalДокумент17 страницSS ENERGY LPG AutoGas Station Presentation FinalSaeed AwanОценок пока нет

- CEMTEC - Solutions For Gas Analysis in Cement PlantsДокумент16 страницCEMTEC - Solutions For Gas Analysis in Cement PlantsMichael KimОценок пока нет

- 4 - Report On Gas Analysis in Cement Plant PDFДокумент77 страниц4 - Report On Gas Analysis in Cement Plant PDFTin Nguyen0% (1)

- Waste To Energy (WTE)Документ51 страницаWaste To Energy (WTE)Santosh Gopal100% (1)

- Clyde Bergemann PDFДокумент6 страницClyde Bergemann PDFenjineringОценок пока нет

- Lime Kiln Control Using Simple Advanced Pid ControlДокумент4 страницыLime Kiln Control Using Simple Advanced Pid ControlA Sar BanОценок пока нет

- Cement and Lime KilnsДокумент6 страницCement and Lime KilnsbizarropОценок пока нет

- 32 Productivity Increase in A PeirceSmith Convert 153013Документ14 страниц32 Productivity Increase in A PeirceSmith Convert 153013amirlpОценок пока нет

- CHNS Elemental Analysers Technical Brief 29 Tcm18 214833Документ2 страницыCHNS Elemental Analysers Technical Brief 29 Tcm18 214833Aang FebrizalОценок пока нет

- 12safe Even in The DesertДокумент3 страницы12safe Even in The Desertchemical_potentialОценок пока нет

- Petroleum and Petrochemical Waste Reuse in Cement Kilns: Gossman Consulting, IncДокумент11 страницPetroleum and Petrochemical Waste Reuse in Cement Kilns: Gossman Consulting, IncTruong Giang Vo100% (1)

- 2008JUN - Permitting of Alternative Fuels and Raw Materials at Portland Cement Plants Post NSR ReformДокумент8 страниц2008JUN - Permitting of Alternative Fuels and Raw Materials at Portland Cement Plants Post NSR ReformRheza NugrahaОценок пока нет

- Ijfeat: Application of Electrostatic Precipitator in Cement PlantДокумент7 страницIjfeat: Application of Electrostatic Precipitator in Cement PlantElwathig BakhietОценок пока нет

- 2165 5870 1 PBДокумент14 страниц2165 5870 1 PBPrateikMenonОценок пока нет

- Factorial Analysis o F A Cement: Portland Cement Company of Utah, Salt Lake City, Utah 84104, USAДокумент7 страницFactorial Analysis o F A Cement: Portland Cement Company of Utah, Salt Lake City, Utah 84104, USAkingОценок пока нет

- Danieli New Pot Grate Testing Facilities: A Case Study - Ahmsa Pellet PlantДокумент11 страницDanieli New Pot Grate Testing Facilities: A Case Study - Ahmsa Pellet PlantkalaiОценок пока нет

- Delayed Coker Fired Heater Designand Operation Fouling PDFДокумент10 страницDelayed Coker Fired Heater Designand Operation Fouling PDFMajid MohebbifarОценок пока нет

- Application of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaДокумент24 страницыApplication of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaSJ ChuaОценок пока нет

- Inherent MercuryДокумент32 страницыInherent MercuryJoko DewotoОценок пока нет

- Manualul Pentru Incalzire Danfoss - Chapter2Документ20 страницManualul Pentru Incalzire Danfoss - Chapter2valicanОценок пока нет

- Contribution of Filtration and Coalescence To Steam Cracking Furnace Productivity and Emissions ControlДокумент17 страницContribution of Filtration and Coalescence To Steam Cracking Furnace Productivity and Emissions ControlVenkatesan DevendranОценок пока нет

- 6 B.tech. CT - U2-09 Environmental ConsideraДокумент19 страниц6 B.tech. CT - U2-09 Environmental ConsideraSurendra JhaОценок пока нет

- SUPCON Solution For Waste IncineratorДокумент11 страницSUPCON Solution For Waste IncineratorJKKОценок пока нет

- Roller Hearth Kiln - IjoeДокумент6 страницRoller Hearth Kiln - IjoeSunit AroraОценок пока нет

- Esl Ie 81 04 02Документ4 страницыEsl Ie 81 04 02majmor-1Оценок пока нет

- Modeling Identification and Control Od Cement KilnДокумент1 страницаModeling Identification and Control Od Cement KilnmiltoncobaОценок пока нет

- Ammonia-Water Based Thermal Conversion Technology, Applications in WHR For The Cement IndustryДокумент8 страницAmmonia-Water Based Thermal Conversion Technology, Applications in WHR For The Cement IndustrybehnamОценок пока нет

- FGC Group LLC - Consulting & Engineering - Products - Thermal Processing Equipment - Activated Carbon Plant PDFДокумент3 страницыFGC Group LLC - Consulting & Engineering - Products - Thermal Processing Equipment - Activated Carbon Plant PDFCleverSeyramKetekuОценок пока нет

- Lehigh CementДокумент7 страницLehigh CementAhmed ElhosainyОценок пока нет

- Air Pollution Controls1Документ15 страницAir Pollution Controls1prit soniОценок пока нет

- Enotec2 PDFДокумент6 страницEnotec2 PDFamk2009Оценок пока нет

- Helium Leak Detection - Manufactering ColboxДокумент9 страницHelium Leak Detection - Manufactering ColboxhoseinОценок пока нет

- QTI BrochureДокумент4 страницыQTI BrochureccmvanderzandeОценок пока нет

- Advanced Control Schemes For Cement Fabrication Processes: Susana Arad, Victor Arad and Bogdan BoboraДокумент27 страницAdvanced Control Schemes For Cement Fabrication Processes: Susana Arad, Victor Arad and Bogdan BoboraBeben Efendi BenzyОценок пока нет

- Exergy Analysis of Birla Cement Plant Satna: A Case Study: Shrikant Kol, Dr. Alok ChaubeДокумент13 страницExergy Analysis of Birla Cement Plant Satna: A Case Study: Shrikant Kol, Dr. Alok ChaubeRitesh AgrawalОценок пока нет

- LCP Bref 0706197-321Документ125 страницLCP Bref 0706197-321Stevan MilovanovićОценок пока нет

- Condensate Considerations in High Pressure Cogen PlantsДокумент8 страницCondensate Considerations in High Pressure Cogen Plantsaliscribd46Оценок пока нет

- Coal P PДокумент9 страницCoal P Papi-19667371Оценок пока нет

- Ferrous Metallurgical Operations Double SpacingДокумент28 страницFerrous Metallurgical Operations Double SpacingArpit PitaliyaОценок пока нет

- AP Anode Technology v3Документ4 страницыAP Anode Technology v3Anup DalalОценок пока нет

- 333 PDFДокумент26 страниц333 PDFdineshhissarОценок пока нет

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementОт EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementОценок пока нет

- Presentasi Hse Plan Elnusa b1107Документ8 страницPresentasi Hse Plan Elnusa b1107MoresbehmanОценок пока нет

- Design of Renewable Energy Systems-1Документ118 страницDesign of Renewable Energy Systems-1Sameh Haj AliОценок пока нет

- Quifa Block - Prospects I and E - Rubiales Field - Colombia, South AmericaДокумент4 страницыQuifa Block - Prospects I and E - Rubiales Field - Colombia, South AmericaRajesh BarkurОценок пока нет

- Offshore Oil and Gas ActivitiesДокумент23 страницыOffshore Oil and Gas ActivitiesglosafОценок пока нет

- I. Phonetics (1 PT) 1. Choose A Word (A, B, C, D) That Has The Underlined Part Pronounced Differently From The Others. (0.5 PT)Документ6 страницI. Phonetics (1 PT) 1. Choose A Word (A, B, C, D) That Has The Underlined Part Pronounced Differently From The Others. (0.5 PT)Hồng Anh ĐỗОценок пока нет

- MBA (Oil & Gas)Документ2 страницыMBA (Oil & Gas)Anonymous xmhm6BHОценок пока нет

- 3index PDFДокумент22 страницы3index PDFdada jamdarОценок пока нет

- MERC Route Permit Application Pts 1-10 of 10 11-3-15 01Документ281 страницаMERC Route Permit Application Pts 1-10 of 10 11-3-15 01dangatz4763Оценок пока нет

- Final Project Report On Pms in Gail (New) 12345Документ86 страницFinal Project Report On Pms in Gail (New) 12345Pragati Jha100% (2)

- LC News Thursday, 12th January 2012Документ29 страницLC News Thursday, 12th January 2012pigheadponceОценок пока нет

- Process Narrative: Compressed Natural Gas FacilityДокумент4 страницыProcess Narrative: Compressed Natural Gas FacilityArnel MorenoОценок пока нет

- NTPC Dadri Thermal ReportДокумент18 страницNTPC Dadri Thermal ReportRohit Singh100% (2)

- 30 Years of Niobium Steel Development in ChinaДокумент26 страниц30 Years of Niobium Steel Development in ChinaRepública Maternidade Ouro PretoОценок пока нет

- PAS Bahasa Dan Sastra Inggris KELAS XI IPS 2020-2021Документ8 страницPAS Bahasa Dan Sastra Inggris KELAS XI IPS 2020-2021Nopan Al AzizОценок пока нет

- Overall Performance Evaluation of Small Scale LNGДокумент23 страницыOverall Performance Evaluation of Small Scale LNGEbrahim AbdelrahmanОценок пока нет

- IsoДокумент19 страницIsoSiddhant ShahОценок пока нет

- Indi-Kc5g SS PDFДокумент1 страницаIndi-Kc5g SS PDFErick TapiaОценок пока нет

- Vasitars PVT Limited - Pipeline RepairsДокумент12 страницVasitars PVT Limited - Pipeline RepairsPavan_yoyo100% (1)

- Course ContentsДокумент4 страницыCourse Contentswahaj ahmedОценок пока нет

- Energy Future - April - June 2016Документ80 страницEnergy Future - April - June 2016malafatОценок пока нет

- 01 - 01 - SK10 - JXNipponДокумент1 страница01 - 01 - SK10 - JXNipponredevils86Оценок пока нет