Академический Документы

Профессиональный Документы

Культура Документы

CR Standards

Загружено:

alpha_beta480 оценок0% нашли этот документ полезным (0 голосов)

464 просмотров6 страницInternational steel standards.

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документInternational steel standards.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

464 просмотров6 страницCR Standards

Загружено:

alpha_beta48International steel standards.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

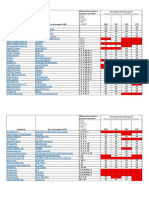

CR Standards (Uncoated & Coated)

Some Important International Standards

Standard for properties of cold rolled

steel strip (chemical composition)

Standard for properties of cold rolled

steel strip (hardness)

Standard for properties of cold rolled

steel strip (bend test)

Thickness tolerances for cold rolled

steel strip (under 23 15/16 inches in

rolled width)

Width tolerances of no. 2 edge (mill

edge) for cold rolled steel strip

(under 23 15 /16 inches in rolled

width)

Width tolerances of no. 3 edge (slit

edge) for cold rolled steel strip

(under 23 15 /16 inches in rolled

width)

Width tolerances of no. 1, 4, 5 and 6

edges rolled steel strip (under 23 15

/16 inches rolled width)

Length tolerances for cold rolled

steel strip (under 23 15/16 inches

rolled width)

ASTM A 109

Camber tolerances for cold steel

strip (under 23 15?16 inches in

rolled width)

ASTM A366

Standard for properties of cold rolled

steel sheets (chemical composition)

A619

Standard for properties of cold rolled

steel sheet (chemical composition)

A620

Standard fort properties of cold

rolled steel strip (chemical

composition)

Thickness tolerances for cold steel

sheet (coils and cut sheet over 12

inches in width)

Thickness tolerances for cold rolled

steel sheet (coils and sheet over 2 to

under 12 inches in width)

Width tolerances for cold rolled steel

sheet (coils and cut sheet over 12

inches in width, not resquared)

Width tolerances for cold rolled steel

sheet (cut sheet/ coils between 2-12

inches in width, 0.014-0.082 in

thickness and over 12 inches in

length, not resquared)

Length tolerances for cold rolled

s2teel sheet (cut sheet/ coils

between 2-12 inches in width 0.014-

0.082 in thickness and over 12

inches in length ,not resquared)

Camber tolerances for cold rolled

steel sheet (cut sheet over 12 inches

in width not resquared)

Camber tolerances for cold rolled

steel sheet (over 2 to under 12

inches in width ,over 0.014yto under

0.08 inches in thickness.)

Flatness tolerances for cold rolled

steel sheet (cut sheet over 12 inches

in width , stretcher leveler finish not

specified)

Flatness tolerances for cold rolled

steel sheet (cut sheet, stretcher

leveler specified)

ASTM A 568

Out-of -square tolerances for cold

rolled steel sheet over 12 inches in

width , not resquared)

DIN 1623 Unified under EN 10130

DIN 1624 DIN standard for properties of cold

rolled steel sheet (carbon steel sheet

and strip with narrow width of under

650 mm)

DIN 1541 Unified under EN 10130

DIN 1544 Thickness tolerance for cold rolled

steel (under 650 mm in rolled width)

Thickness tolerances for cold rolled

steel and strip

Thickness tolerances for cold rolled

steel strip (high yield steel point)

Width tolerances for cold rolled steel

sheet and strip with wide width.

BS EN 10131

Width tolerances for cold rolled strip

(less than 650 mm in width)

Width tolerances for cold rolled steel

strip (under 650 mm in rolled width)

Length tolerances for cold rolled

steel strip (under 650 mm in rolled

width)

Camber tolerances for cold rolled

steel strip (under 650 mm in rolled

width)

Standard properties of cold rolled

steel strip (chemical composition

and mechanical properties

BS EN 10130

Surface finished and surface

roughness of cold rolled steel strip .

Length tolerances for cold rolled

steel sheet

Flatness tolerances for cold rolled

steel sheet

Flatness tolerances for cold rolled

steel sheet (high yield point steel

over 280 to less than 360N/mm

2

)

Chemical composition of cold rolled

carbon steel sheet.

Mechanical properties of cold rolled

steel sheet

Thickness tolerances for cold rolled

steel sheet and strip

Width tolerances for cold rolled steel

and strip with width

Length tolerances for cold rolled

steel sheet

Camber tolerances for cold rolled

steel sheet and strip

ISO 3574

Flatness tolerances for cold rolled

steel sheet

JIS J 3125 Cold rolled superior atmospheric

corrosion resistant steel

JIS J 3133 Decaburised steel sheet and strip for

porcelain enamelling

JIS G 3135 Cold rolled high strength steel sheet

with improved formability for

automobiles structural uses

JIS G 3141 Specification for cold rolled steel

sheet and strip

JIS G 3302 Specification for hot-dip-zinc coated

steel sheet and coils

JIS G 3316 Specification for shapes and

dimension of corrugated sheet

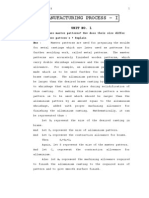

Equivalent Standards

Grade IS 513 JIS G

3141

BS 1449 DIN

1623

ASTM

A366,A366M,A619,A619M,A620,A620M

EN 10130

Commercial

quality

O SPCC CR4 CQ FEP01

Drawing

quality

D SPCD CR3 ST 12,13 CQ FEP03

Deep

drawing

quality

DD SPCE CR2 ST14 DQ FEP03

Extra deep

drawing

quality (Al

Killed, Non

Ageing)

EDD SPCEN CR1 EDDQ FEP04

Extra deep

drawing

quality

(IF Grade)

FEP05

Super extra

deep

drawing

quality

(IF Grade)

FEP06

IS 513

chemical composition

(max permissible limit for each element)

Mechanical properties Hardness max Grade

* (Al

Killed)

C% Mn% P% S% YS (MPA)

MAX

TS (MPA) ELONGATION

% MIN

HRB HR30T

O 0.15 0/60 0.055 0.055 - - - - -

D 0.12 0.50 0.040 0.040 280 270-410 23 65 60

DD 0.10 0/45 0.035 0.035 250 270-310 26 57 55

EDD 0.08 0.40 0.030 0.030 220 270-350 32 50 50

DIN 1623 Part 1 Cold Rolled Sheet and Strip for Cold Forming

St 12* 0.10

280 270-410 28 65 60

St 13* 0.10 240 270-310 34 55 53

St 14* 0.08

210 270-350 38 50 50

CR Standards (Uncoated & Coated) contd.

JIS G 3141 Cold Rolled Carbon Steel Sheet & Strip

TS(MPA) Elongation %, min for thickness(t) in mm

Symbol of class t>=0.25 0.25<=t<0.4 0.4<=t<0.6 0.6<=t<1.0 1.0<=t<1.6 1.6<=t<2.5 2.5

or over

SPCC 270 32 34 36 37 38 39

SPCD 270 34 36 38 39 40 41

SPCE 270 36 38 40 41 42 43

Erichsen Value for thickness in mm

Symbol of class 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6

Remarks

SPCC 7.2 7.8 8.4 8.8 9.1 9.4 9.6 10.0 10-3 10.5 for general use

SPCD 7.6 8.2 8.8 9.2 9.5 9.8 10.0 10.4 10.7 10.9 for deep drawing use

SPCE 8.0 8.6 9.2 9.6 9.9 10.2 10.4 10.8 11.1 11.3 for extra deep drawing

Temper

grad e

Surface

finished

Symbol Hardness

Hr B HV

1/8

hard

dull/bright

finished

SPCC-86/ 8B 50 71 95 130

1/4

hard

dull/bright

finished

SPCC-4D/4B 65 80 115

150

1/2

hard

dull/bright

finished

SPCC-2D/2B 74 89 135

185

full

hard

dull/bright

finished

SPCC-1D/1B 85min 170min

Temper

grade

Surface

finished

symbol

As

annealed

SPCC-A,

SPCD-A,

SPCE-A

Standard

temper

grade

Dull /

Bright

finished

SPCC-SD/SB.

SPCD-SD/SB,

SPCE-SE/SB

Std temp

grade

(when

specified to

guarantee

mechanical

properties)

Dull /

Bright

finished

SPCCT-SD/SB,

SPCEN-SD/SB

JIS G 3135 Cold Rolled High Strength Steel with Improved Formability for Automobile Structural

Use

New Spec.

Conventional

Spec.

Mechanical Properties

YS (MPA) min TS (mpa) min % Elong. min

0.60 mm and

over to under 1.0

mm

1.0 mm and over

to 2.3 mm

inclusive

SPFC 340 SPFC 35 175 340 34 35

SPFC 370 SPFC 38 205 370 32 33

SPFC 390 SPFC 40 235 390 30 31

SPFC 440 SPFC 45 265 440 26 27

SPFC 490 SPFC 50 295 490 23 24

SPFC 540 SPFC 55 325 540 20 21

SPFC 590 SPFC 60 355 590 17 18

SPFC 490Y SPFC 50Y 225 490 24 25

SPFC 540Y SPFC 60Y 245 540 21 22

SPFC 590Y SPFC 80Y 265 590 18 19

SPFC 780Y SPFC 80Y 365 780 13 14

SPFC 980Y SPFC 100Y 490 980 34 35

SPFC 340 SPFC 35H 185 340 34 35

BS 1449 Part 1 Carbon Steel Sheet & Strip

Chemical Composition

(max permissible limit for each

element)

Mechnical Properties

% Elong. min (Original Gauge

Length, Lo)

Grade

C% Mn% P% S% YS (MPA)

min

TS (MPA)

min

50 mm 80 mm 200 mm

CR4 0.12 0.60 0.050 0.050 140 280

CR3 0.10 0.50 0.040 0.040 140 280 34 32 25

CR2 0.08 0.45 0.030 0.035 140 280 36 34 27

CR1 0.08 0,45 0.025 0.03O 140 280 38 36 29

CR34/20 0.15 1.20 0.050 0.050 200 340 29 29 21

CR37/23 0.20 1.20 0.050 0.050 230 270 28 28 20

ASTM A 653 M

Weight (Mass) of Zinc Coating Requirements by Hot Dip Process

Zinc Coated (Galvanised)

Triple Spot test Symbol

Single Spot

Z1100 1100 390 975

Z900 900 316 790

Z700 700 238 595

Z600 600 204 510

Z550 550 190 475

Z500 500 170 425

Zinc Iron Alloy Coated (Galvannealed)

ZF 180 180 60 150

ZF120 120 36 90

Zinc Coated (Galvanised)

Triple Spot test Symbol

Single Spot

Z450 450 154 385

Z350 350 120 300

Z275 275 94 235

Z180 180 60 150

Z120 120 36 90

Z90 90 30 75

Zinc Iron Alloy (Galvannealed)

ZF 75 75 24 60

ZF 001 no.min no.min no min

IS 277 (1992) Weight (Mass) of Zinc Coating Requirements by Hot Dip Process

Class of coating Total 2 sides gm/m

2

CL L 600

CL LL 450

CL LLL 350

CL LV 275

Class of coating Total 2 sides gm/m

2

CL L 220

CL LL 200

CL LLL 180

CL LV 120

JIS G3302

Weight (Mass) of Zinc Coating Requirements by Hot Dip Process

Zinc Coated (Galvanised)

Symbol Triple spot test Total both side

gm/m

2

Single spot test Total both

side gm/m

2

Equivalent

coating

thickness

(mm)

Z06 60 51 0.013

Z08 80 68 0.017

Z10 100 85 0.021

Z12 120 102 0.0260

Z18 180 153 0.040

Zinc Coated (Galvanised)

Symbol Triple spot test Total both side

gm/m

2

Single spot test Total both

side gm/m

2

Equivalent

coating

thickness

(mm)

Z22 220 187 0.043

Z25 250 213 0.049

Z27 275 234 0.054

Z35 350 298 0.064

Z45 450 383 0.080

Z60 600 510 0.102

Zinc Iron Alloy Coated (Galvannealed)

Symbol Triple spot test Total both side

gm/m

2

Single spot test Total both

side gm/m

2

Equivalent

coating

thickness

(mm)

F04 40 34 0.008

F04 60 51 0.13

F08 80 68 0.017

F10 100 85 0.021

F12 120 102 0.026

F18 180 153 0.034

Data and information provided are approximate and not for engineering/design use.

Вам также может понравиться

- Mil S 22698CДокумент40 страницMil S 22698CJeff95TAОценок пока нет

- Astm e 2218 - 02Документ15 страницAstm e 2218 - 02Jaime Rafael Patron PrioloОценок пока нет

- ASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtДокумент17 страницASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtMalaz Abdul JalilОценок пока нет

- Injection Moulding Process ExplainedДокумент24 страницыInjection Moulding Process ExplainedAbdulRehman Ahmed SoomroОценок пока нет

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentДокумент2 страницыSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Sheet Metal WorkingДокумент26 страницSheet Metal Workingvelavansu0% (1)

- Automotive Gray Iron Castings: Standard Specification ForДокумент5 страницAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezОценок пока нет

- QQ N 290aДокумент17 страницQQ N 290aBryan MartinezОценок пока нет

- A 247 - 17 PDFДокумент13 страницA 247 - 17 PDFأسامة وحيد الدين رمضانОценок пока нет

- Aerospace Material SpecificationДокумент6 страницAerospace Material Specificationvsraju2Оценок пока нет

- Kaiser Aluminum Soft Alloy Tube PDFДокумент31 страницаKaiser Aluminum Soft Alloy Tube PDFgerrzen64Оценок пока нет

- Atlas Aluminium Datasheet 3003 Rev Oct 2013Документ3 страницыAtlas Aluminium Datasheet 3003 Rev Oct 2013PrakashОценок пока нет

- Astm B111Документ9 страницAstm B111mmlingОценок пока нет

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39От EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Рейтинг: 5 из 5 звезд5/5 (1)

- CNC Programming Tutorials Examples G and M Codes Programming Tutorial Example Code For Beginner To Advance Level CNC Machinist PDFДокумент302 страницыCNC Programming Tutorials Examples G and M Codes Programming Tutorial Example Code For Beginner To Advance Level CNC Machinist PDFSanjai RohanОценок пока нет

- Material Specification: Specification: Revision Date: Revision LevelДокумент2 страницыMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Pump PresentationДокумент206 страницPump Presentationalpha_beta48100% (2)

- CWI Qustion BankДокумент35 страницCWI Qustion Bankprabhu100% (1)

- Aisi 1008Документ2 страницыAisi 1008GANESH GОценок пока нет

- Comaparação A572 G50-A992Документ4 страницыComaparação A572 G50-A992Tiago CastelaniОценок пока нет

- 701 Steel InclusionRating DIN-50602 PDFДокумент1 страница701 Steel InclusionRating DIN-50602 PDFbiancogallazzi0% (1)

- Supraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilДокумент2 страницыSupraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilHugo RodriguezОценок пока нет

- KilnOpBasics - ManufProcess OverviewДокумент31 страницаKilnOpBasics - ManufProcess OverviewmustafОценок пока нет

- JIS G4801 SUP10 Steel GuideДокумент2 страницыJIS G4801 SUP10 Steel GuideĐình Sỹ TTPОценок пока нет

- JIS C 3406 (1971) - Auto CablesДокумент1 страницаJIS C 3406 (1971) - Auto CablesBrandon BroОценок пока нет

- Tata Steel - YMPRESS S500MC - Data SheetДокумент2 страницыTata Steel - YMPRESS S500MC - Data SheetpnagarajjОценок пока нет

- Astm A659-18Документ3 страницыAstm A659-18Ryan ZhangОценок пока нет

- 521+technical Data Sheet V-6Документ2 страницы521+technical Data Sheet V-6TeenTeen GaMingОценок пока нет

- Bearing Steel Material Specification Sheet SAE52100Документ1 страницаBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryОценок пока нет

- Extrusion Fig Q A AnalysisДокумент13 страницExtrusion Fig Q A AnalysisRavinder AntilОценок пока нет

- The Current State of Worldwide Standards of Ductile IronДокумент8 страницThe Current State of Worldwide Standards of Ductile IronN.PalaniappanОценок пока нет

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsДокумент4 страницыA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterОценок пока нет

- Sfa-5.7Документ10 страницSfa-5.7vannie_yundaОценок пока нет

- Ansteel Product CatalogueДокумент13 страницAnsteel Product Cataloguerashid isaarОценок пока нет

- AluminizedДокумент4 страницыAluminizedmarkengineerОценок пока нет

- 2370 Ed1 ENДокумент5 страниц2370 Ed1 ENanhthoОценок пока нет

- Ferrous Metals: General Grade Cast IronsДокумент8 страницFerrous Metals: General Grade Cast IronskkamalakannaОценок пока нет

- Hot Dip Galvanizing For FastenersДокумент3 страницыHot Dip Galvanizing For FastenersIrwin CastroОценок пока нет

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Документ5 страницSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiОценок пока нет

- Aisi 1010 Carbon Steel (Uns g10100)Документ5 страницAisi 1010 Carbon Steel (Uns g10100)spiderblackОценок пока нет

- Is Phosphorus Bad For SteelДокумент19 страницIs Phosphorus Bad For SteelKarun Dev100% (1)

- 701 Steel InclusionRating DIN-50602Документ1 страница701 Steel InclusionRating DIN-50602ksathisОценок пока нет

- Is 209 - 1992 Zinc Ingot - SpecificationДокумент5 страницIs 209 - 1992 Zinc Ingot - SpecificationRam NiwasОценок пока нет

- SWRCH18A Steel DatasheetДокумент2 страницыSWRCH18A Steel DatasheetHari SuthanОценок пока нет

- Nisshin Cold-Rolled Special Steel GuideДокумент28 страницNisshin Cold-Rolled Special Steel GuideekopujiantoeОценок пока нет

- 30 CR Ni Mo 8Документ2 страницы30 CR Ni Mo 8Amy GriffinОценок пока нет

- Carbide Banding - Effect On FatigueДокумент15 страницCarbide Banding - Effect On FatigueSteve Green100% (1)

- WSS M1P94 AДокумент9 страницWSS M1P94 AAleks SenaОценок пока нет

- Laser WeldingДокумент11 страницLaser WeldingnkalaiОценок пока нет

- Isothermal Heat Treatment PDFДокумент6 страницIsothermal Heat Treatment PDFsmani170Оценок пока нет

- A 1031 - 04 Qtewmze - PDFДокумент4 страницыA 1031 - 04 Qtewmze - PDFqueno1Оценок пока нет

- BS3468 Austenitic Cast Iron Material SpecificationsДокумент2 страницыBS3468 Austenitic Cast Iron Material SpecificationsPanchoMiyamotoОценок пока нет

- Aluminum Stock CatalogДокумент4 страницыAluminum Stock Catalogsav33Оценок пока нет

- 6061 Aluminum Sheet SuppliersДокумент7 страниц6061 Aluminum Sheet Supplierssanghvi overseas incОценок пока нет

- Aisi 1018Документ1 страницаAisi 10188085roОценок пока нет

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Документ5 страницTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺Оценок пока нет

- A493 00 PDFДокумент3 страницыA493 00 PDFJohano AraújoОценок пока нет

- ASTM A1011 steel sheet & strip standardДокумент1 страницаASTM A1011 steel sheet & strip standardotaviossОценок пока нет

- Silicon Nitride Ceramic Ball Bearings Properties Advantages and ApplicationsДокумент9 страницSilicon Nitride Ceramic Ball Bearings Properties Advantages and ApplicationsAbdul RozaqОценок пока нет

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFДокумент16 страницA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrОценок пока нет

- Oleum Leakage-Case StudyДокумент14 страницOleum Leakage-Case Studyalpha_beta48Оценок пока нет

- News Vol3 I7 JulДокумент4 страницыNews Vol3 I7 JulSonal GuptaОценок пока нет

- Technical ClassДокумент58 страницTechnical Classalpha_beta48Оценок пока нет

- Surface Area of Common SolidsДокумент17 страницSurface Area of Common Solidsalpha_beta48Оценок пока нет

- NPTДокумент6 страницNPTthailanОценок пока нет

- Brazing: Brazing Is A Metal-Joining Process in Which Two or More Metal ItemsДокумент23 страницыBrazing: Brazing Is A Metal-Joining Process in Which Two or More Metal ItemsR Hari Hara SОценок пока нет

- Formato de Troca de Arquivo Suportado Por Software CAMДокумент2 страницыFormato de Troca de Arquivo Suportado Por Software CAMJonatas PietrОценок пока нет

- Soft vs hard tooling for molding processesДокумент17 страницSoft vs hard tooling for molding processesSurya Raghavendar100% (1)

- Manufacturing Process 1 by DV ShirbhateДокумент134 страницыManufacturing Process 1 by DV ShirbhateDIPAK VINAYAK SHIRBHATE100% (4)

- 0030 KM Modular Quick#3C6B7Документ324 страницы0030 KM Modular Quick#3C6B7sugusdez18Оценок пока нет

- Heat Treatment QuestionsДокумент6 страницHeat Treatment QuestionsSleepy PandaОценок пока нет

- Fusing AgentДокумент1 страницаFusing AgentHarshal ThakreОценок пока нет

- Blastrite BeadsДокумент1 страницаBlastrite BeadsAsad AhmedОценок пока нет

- Casting in AviationДокумент32 страницыCasting in AviationJCОценок пока нет

- Kennametal - Tungsten Carbide Composite Brazing Rods DatasheetДокумент1 страницаKennametal - Tungsten Carbide Composite Brazing Rods DatasheetsakthiОценок пока нет

- Manufacturing Technology: Unit - IДокумент12 страницManufacturing Technology: Unit - Iapi-271354682Оценок пока нет

- IENG 475 - Lathe OperationsДокумент27 страницIENG 475 - Lathe OperationsJohn VincentОценок пока нет

- Electroless Nickel Plating On Abs Plastic by Using Environmentally Friendly Chemicals (#350219) - 379925Документ8 страницElectroless Nickel Plating On Abs Plastic by Using Environmentally Friendly Chemicals (#350219) - 379925miguelin9169Оценок пока нет

- Scheda Tecnica Spray Zincato 0893114113ztd02Документ2 страницыScheda Tecnica Spray Zincato 0893114113ztd02Samuel Chiappara100% (1)

- Heat Treatment Objectives and ProcessesДокумент6 страницHeat Treatment Objectives and ProcessesAdaitaChowdhury100% (1)

- Matrial and EquipmentДокумент2 страницыMatrial and EquipmentJymaer GeromoОценок пока нет

- Lec 10 Commonly Used FurnacesДокумент35 страницLec 10 Commonly Used FurnacesSakunaPappuОценок пока нет

- Design Guide: Sheet Metal FabricationДокумент12 страницDesign Guide: Sheet Metal FabricationSanatan ChoudhuryОценок пока нет

- Unusual, Given The Brittle Nature of Most Cast Iron.: Electrode SelectionДокумент2 страницыUnusual, Given The Brittle Nature of Most Cast Iron.: Electrode SelectionparmindersinОценок пока нет

- PAMДокумент5 страницPAMSuresh DorairajОценок пока нет

- Die Maintenance. Die Repair.Документ9 страницDie Maintenance. Die Repair.zfrlОценок пока нет

- Stavax ESR PH-ENДокумент12 страницStavax ESR PH-ENChetan SharmaОценок пока нет

- Rolling ProcessДокумент0 страницRolling ProcesscosmiclatteОценок пока нет

- Standard Practice For Preparation of Cold-Rolled Steel Panels For Testing Paint, Varnish, Conversion Coatings, and Related Coating ProductsДокумент3 страницыStandard Practice For Preparation of Cold-Rolled Steel Panels For Testing Paint, Varnish, Conversion Coatings, and Related Coating Productsjgómez_510704Оценок пока нет

- 400 Bad Request 400 Bad Request Nginx/1.2.9Документ1 страница400 Bad Request 400 Bad Request Nginx/1.2.9muthuswamy77Оценок пока нет