Академический Документы

Профессиональный Документы

Культура Документы

Executive Summary

Загружено:

navinchopra1986Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Executive Summary

Загружено:

navinchopra1986Авторское право:

Доступные форматы

EXECUTIVE SUMMARY

The electrical and electronic waste (e-waste) is one of the fastest growing waste

streams in the world. The increasing “market penetration” in developing

countries, “replacement market” in developed countries and “high obsolescence

rate” make e-waste as one of the fastest growing waste streams. Environmental

issues and trade associated with e-waste at local, transboundary and

international level has driven many countries to introduce interventions.

In accordance with the National Environmental Policy (NEP) and to address

sustainable development concerns, there is a need to facilitate the recovery

and/or reuse of useful materials from waste generated from a process and/or

from the use of any material thereby, reducing the wastes destined for final

disposal and to ensure the environmentally sound management of all materials.

The NEP also encourages giving legal recognition and strengthening the informal

sectors system for collection and recycling of various materials. In particular

considering the high recyclable potential of e-waste such wastes should be

subject to recycling in an environmentally sound manner.

E-waste comprises of wastes generated from used electronic devices and house

hold appliances which are not fit for their original intended use and are destined

for recovery, recycling or disposal. Such wastes encompasses wide range of

electrical and electronic devises such as computers, hand held cellular phones,

personal stereos, including large household appliances such as refrigerators, air

conditioners etc. E-wastes contain over 1000 different substances many of which

are toxic and potentially hazardous to environment and human health, if these

are not handled in an environmentally sound manner.

The growth of e-waste has significant economic and social impacts. The increase

of electrical and electronic products, consumption rates and higher obsolescence

rate leads to higher generation of e-waste. The increasing obsolescence rate of

electronic products also adds to the huge import of used electronics products.

The e-waste inventory based on this obsolescence rate in India for the year 2005

has been estimated to be 1,46,180 tonnes which is expected to exceed 8,00,000

tonnes by 2012.

The objective of these Guidelines is to provide guidance for identification of various

sources of waste electrical and electronic equipments (e-waste) and prescribed

procedures for handling e-waste in an environmentally sound manner.

These Guidelines shall apply to all those who handle e-waste which includes the

generators, collectors, transporters, dismantlers, recyclers and stakeholders of

e-wastes irrespective of their scale of operation.

In India, there are no specific environmental laws or Guidelines for e-waste.

None of the existing environmental laws have any direct reference to electronic

waste or refer to its handling as hazardous in nature. However several provisions

of these laws may apply to various aspects of electronic wastes. Since e-waste

or its constituents fall under the category of ‘hazardous” and “non hazardous

waste”, they shall be covered under the purview of “The Hazardous Waste

Management Rules, 2003”.

Composition of e-waste is very diverse and differs in products across different

categories. Broadly, it consists of ferrous and non-ferrous metals, plastics, glass,

wood & plywood, printed circuit boards, concrete and ceramics, rubber and other

items. Iron and steel constitutes about 50% of the e-waste followed by plastics

(21%), non ferrous metals (13%) and other constituents. Non-ferrous metals

consist of metals like copper, aluminium and precious metals ex. silver, gold,

platinum, palladium etc. The presence of elements like lead, mercury, arsenic,

cadmium, selenium, and hexavalent chromium and flame retardants beyond

threshold quantities in e-waste classifies them as hazardous waste.

The e-waste inventory based on this obsolescence rate and installed base in

India for the year 2005 has been estimated to be 146180.00 tonnes. This is

expected to exceed 8,00,000 tonnes by 2012. There is a lack of authentic and

comprehensive data on e-waste availability for domestic generation of e-waste

and the various State Pollution Control Boards have initiated the exercise to

collect data on e-waste generation.

Sixty-five cities in India generate more than 60% of the total e-waste generated in

India. Ten states generate 70% of the total e-waste generated in India.

Maharashtra ranks first followed by Tamil Nadu, Andhra Pradesh, Uttar Pradesh,

West Bengal, Delhi, Karnataka, Gujarat, Madhya Pradesh and Punjab in the list

of e-waste generating states in India. Among top ten cities generating e-waste,

Mumbai ranks first followed by Delhi, Bangalore, Chennai, Kolkata, Ahmedabad,

Hyderabad, Pune, Surat and Nagpur.

Under Rule 3, “Definitions”, E-waste can be defined as “Waste Electrical and

Electronic Equipment including all components, sub assemblies and their

fractions except batteries falling under Schedule 1, Schedule 2 and Schedule 3”

of these rules.

There is an increasing trend in the reduction in the use of hazardous substances

such as lead, cadmium, mercury, polychlorinated biphenyls (pcbs) and other

toxic and hazardous substances for which safe substitutes have been found.

Many countries have adopted the RoHS regulations in the manufacture of

electrical and electronic equipments.

The Extended Producer Responsibility (EPR) is an environment protection

strategy that makes the producer responsible for the entire life cycle of the

product, especially for take back, recycle and final disposal of the product. Thus

the producers’ responsibility is extended to the post-consumer stage of the

product life cycle. This needs to be included in the legislative framework making

EPR a mandatory activity associated with the production of electronic and

electrical equipments over a period of time.

Environmentally sound E-waste treatment technology was identified at three

levels. The first level included decontamination, dismantling and segregation.

The second level included shredding and four special treatment processes like

electromagnetic separation, eddy current separation, CRT breaking and

treatment and density separation using water. The 3rd level treatment included

recovery of metals and disposal of hazardous E-waste fractions including plastics

with flame retardants, CFCs, capacitors, Mercury, lead and other items.

All the three levels of e-waste treatment are based on material flow. The material

flows from 1st level to 3rd level treatment. Each level treatment consists of unit

operations, where e-waste is treated and out put of 1st level treatment serves as

input to 2nd level treatment. After the third level treatment, the residues are

disposed of either in TSDF or incinerated. The efficiency of operations at first and

second level determines the quantity of residues going to TSDF or incineration.

The details of the type of treatment technology to be put in place are given in

Chapter – VI.

The establishment of E-waste Recycling & Treatment Facility shall be in line with

the existing Guidelines/best practices/requirements in India for establishing and

operating “Recycling and Treatment and Disposal Facilities” for hazardous

wastes. Such facilities shall be set up in the organized sector. However, the

activities presently operating in the informal sector need to be upgraded to

provide a support system for the integrated facility. This would enable to bring the

non-formal sector in the main stream of the activity and facilitate to ensure

environmental compliances.

The procedures for setting up & management of e-waste facility shall include

licenses from all appropriate governing authorities such as environmental

clearance, recycler registration from Central Pollution Control Board under HW

Rules, obtaining of consents under water act, Air act and authorization from the

state pollution control board.

These Guidelines are reference document for the management, handling and

disposal of e-wastes. These are intended to provide guidance and broad outline,

however, the specific methods of treatment and disposal for specific wastes

needs to be worked out according to the hazard/risk potential of the waste under

question. These Guidelines provide the minimum practice required to be followed in

the management of e-wastes and the State Department of Environment or State

Pollution Control Board may prescribe more stringent norms as deemed necessary.

Вам также может понравиться

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFRonald ValenciaОценок пока нет

- The Healthy PC. Preventive Care and Home Remedies For Your Computer - Carey Holzman PDFДокумент257 страницThe Healthy PC. Preventive Care and Home Remedies For Your Computer - Carey Holzman PDFLeonardoMartinОценок пока нет

- TIA Workshop ITBДокумент48 страницTIA Workshop ITBFirman Suhendra100% (1)

- Cost AnalysisДокумент81 страницаCost AnalysisPuneeth PaviОценок пока нет

- 015 VT PumpsДокумент32 страницы015 VT PumpsZainul Abdin100% (1)

- 220v DC Lead Acid BatteryДокумент22 страницы220v DC Lead Acid Batterynavinchopra1986Оценок пока нет

- Sampling Procedure and Tables For InspectionДокумент43 страницыSampling Procedure and Tables For InspectionAnonymous AoTZuNvxОценок пока нет

- The Relevance of YS/UTS RatioДокумент21 страницаThe Relevance of YS/UTS RatiocarrespmОценок пока нет

- Hospital Management Information SystemДокумент47 страницHospital Management Information SystemNisarg100% (1)

- Workover Kill Fluid Density CalculationДокумент3 страницыWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- Palfinger PK 15500 Load ChartДокумент2 страницыPalfinger PK 15500 Load ChartD Chandra Sekhar100% (2)

- Project Report ON E-Waste: Bachelor of Business AdministrationДокумент30 страницProject Report ON E-Waste: Bachelor of Business AdministrationDimple GolaitОценок пока нет

- FiltrationДокумент99 страницFiltrationnavinchopra1986100% (1)

- Session Plan CarpentryДокумент8 страницSession Plan Carpentrymark abayonОценок пока нет

- Technical Specs Distribution BoardsДокумент55 страницTechnical Specs Distribution Boardsnavinchopra1986Оценок пока нет

- E Waste ManagementДокумент42 страницыE Waste Managementrit workОценок пока нет

- E WasteДокумент47 страницE WasteGeorge Dlima67% (9)

- Appendix I - AirДокумент155 страницAppendix I - AirTown of Colonie LandfillОценок пока нет

- Career Development PlanДокумент5 страницCareer Development Planapi-317247630Оценок пока нет

- Project Report of SHREYA (E - WASTE RECYCLING)Документ25 страницProject Report of SHREYA (E - WASTE RECYCLING)Shreya Dikshit100% (2)

- Wipro - Wikipedia, The Free EncyclopediaДокумент6 страницWipro - Wikipedia, The Free EncyclopediaSasidhar ReddyОценок пока нет

- Business Communication Assignment: Topic: Modern Communication MethodДокумент8 страницBusiness Communication Assignment: Topic: Modern Communication MethodRigio GameplayОценок пока нет

- A Financial System Refers To A System Which Enables The Transfer of Money Between Investors and BorrowersДокумент8 страницA Financial System Refers To A System Which Enables The Transfer of Money Between Investors and BorrowersAnu SingalОценок пока нет

- Principles of ManagementДокумент36 страницPrinciples of ManagementNISTHA KUMARIОценок пока нет

- Business Analytics AssignmentДокумент6 страницBusiness Analytics AssignmentCindy GabayeronОценок пока нет

- Bharti AirtelДокумент25 страницBharti AirtelSai VasudevanОценок пока нет

- Wipro CSR PapersДокумент35 страницWipro CSR PapersShashank Batra100% (2)

- Assignment: Organizational Behavior MGT 3124Документ10 страницAssignment: Organizational Behavior MGT 3124Shakil KhanОценок пока нет

- Approach and Methodology - Digital India ProgrammeДокумент1 страницаApproach and Methodology - Digital India ProgrammeArun KumarОценок пока нет

- Case Study On Green HRMДокумент2 страницыCase Study On Green HRMAmit Aggarwal100% (1)

- A Project On CSR Activities of TCSДокумент13 страницA Project On CSR Activities of TCSshkarekar33% (3)

- PDFДокумент111 страницPDFParas JainОценок пока нет

- Coca Cola Project ReportДокумент81 страницаCoca Cola Project ReportgoswamiphotostatОценок пока нет

- Reliance CommunicationsДокумент120 страницReliance CommunicationsMadhav LavaniaОценок пока нет

- Recruitment and Selection at Reliance LICДокумент66 страницRecruitment and Selection at Reliance LICRohit KashyapОценок пока нет

- WastewatertreatmentdesignreportfДокумент49 страницWastewatertreatmentdesignreportfapi-314633288Оценок пока нет

- FMCG Meaning Fast Moving Consumer GoodsДокумент4 страницыFMCG Meaning Fast Moving Consumer GoodsSustain FitnessОценок пока нет

- Organisational Study at DELTA FINALДокумент48 страницOrganisational Study at DELTA FINALThamiz RaihanОценок пока нет

- Delhi The Pollution Capital of India: by Sagar LadhwaniДокумент32 страницыDelhi The Pollution Capital of India: by Sagar LadhwaniRajsree RasmitaОценок пока нет

- Research MethodologyДокумент58 страницResearch MethodologyAbhishek SinghОценок пока нет

- Completed Project IMT A Study On Recycling and Management of Electronic Waste in India - A Case Study of Namo E-Waste Management Ltd. 22 Aug 2020Документ60 страницCompleted Project IMT A Study On Recycling and Management of Electronic Waste in India - A Case Study of Namo E-Waste Management Ltd. 22 Aug 2020Mohd Anas KhanОценок пока нет

- Difference Between Planning Commission and NITI Aayog MMДокумент2 страницыDifference Between Planning Commission and NITI Aayog MMAastha Gupta80% (5)

- Bank Reconciliation Statement Class 11 NotesДокумент10 страницBank Reconciliation Statement Class 11 NotesAshna vargheseОценок пока нет

- E-Waste Management in Vit: A Mini Project Report Submitted in Partial Fulfilment of TheДокумент21 страницаE-Waste Management in Vit: A Mini Project Report Submitted in Partial Fulfilment of TheSimranjeet ChawlaОценок пока нет

- Problems of Women Education in India A Case Study of Mangalagiri Mandal in Guntur District of A.PДокумент5 страницProblems of Women Education in India A Case Study of Mangalagiri Mandal in Guntur District of A.PEditor IJTSRDОценок пока нет

- Make My TripДокумент9 страницMake My TripPrasanth Cool0% (1)

- Human Capital Formation in India - Notes & Video LinkДокумент7 страницHuman Capital Formation in India - Notes & Video LinkArnav KhandelwalОценок пока нет

- Idea Customer Satisfaction ReportДокумент85 страницIdea Customer Satisfaction Reportjkd4550% (6)

- By Mariyam Habibullah M.Sc. F.P.P (II) Roll No. 07: 100% Sin. 0% GuiltДокумент17 страницBy Mariyam Habibullah M.Sc. F.P.P (II) Roll No. 07: 100% Sin. 0% GuiltMaryam HabibullahОценок пока нет

- Sarrus RuleДокумент1 страницаSarrus Ruledwarika2006Оценок пока нет

- Special Purpose DiodesДокумент4 страницыSpecial Purpose DiodesArvinALОценок пока нет

- Demonetization Kicks in - India Is Reacting: 8, 2016 Midnight. This Scheme Has ReceivedДокумент9 страницDemonetization Kicks in - India Is Reacting: 8, 2016 Midnight. This Scheme Has ReceivedShiny SОценок пока нет

- Project On Environmental ScienceДокумент23 страницыProject On Environmental SciencejanhaviОценок пока нет

- Project Research (E Commerce)Документ29 страницProject Research (E Commerce)NitinKishan Sharma100% (1)

- Impact On Plastic Ban Problem Face by Small ShopkeepersДокумент40 страницImpact On Plastic Ban Problem Face by Small ShopkeepersNachiket NeveОценок пока нет

- Effect of Stock Market On Indian EconomyДокумент28 страницEffect of Stock Market On Indian Economyanshu009767% (3)

- Harish Mba ProjectДокумент72 страницыHarish Mba ProjectchaluvadiinОценок пока нет

- Impact-of-E-Commerce-in-Indian Economy Case Study PDFДокумент13 страницImpact-of-E-Commerce-in-Indian Economy Case Study PDFakthaks14Оценок пока нет

- Hed Cia 3Документ6 страницHed Cia 3ARYAN GARG 19212016Оценок пока нет

- Dabour Project123Документ76 страницDabour Project123Deepak SinghalОценок пока нет

- "People, Not Buildings, Make A Company Successful." - AnonymousДокумент65 страниц"People, Not Buildings, Make A Company Successful." - Anonymoussonabeta07Оценок пока нет

- Business EnvironmentДокумент20 страницBusiness EnvironmentShubham MishraОценок пока нет

- Clean India-Green IndiaДокумент9 страницClean India-Green IndiaDeepakОценок пока нет

- Cashless Economy and Comparative Analysis of India and SwedenДокумент8 страницCashless Economy and Comparative Analysis of India and SwedenAshutosj AKОценок пока нет

- Report On "Production Management"Документ15 страницReport On "Production Management"Zannatun NayeemОценок пока нет

- A Study On Effects of Demonetization On Rural Economy/ Small and Micro Business/ Rural HouseholdsДокумент6 страницA Study On Effects of Demonetization On Rural Economy/ Small and Micro Business/ Rural HouseholdsSetu AhujaОценок пока нет

- Factors Influencing Indian Supply ChainsДокумент11 страницFactors Influencing Indian Supply ChainsGourav SihariyaОценок пока нет

- Project Report On Digiworld at MumbaiДокумент77 страницProject Report On Digiworld at Mumbaisantosh888888Оценок пока нет

- Ratio AnalysisДокумент48 страницRatio AnalysiskeerthiОценок пока нет

- Case 4.5Документ2 страницыCase 4.5Jagadish TangiralaОценок пока нет

- Hospital Management Mba ProjectДокумент69 страницHospital Management Mba ProjectSrk SivaramakrishnanОценок пока нет

- Amul ProjectДокумент120 страницAmul ProjectrobanabangbangОценок пока нет

- Minor Project Report On Air Pollution in Delhi NCR Causes and Solutions.Документ21 страницаMinor Project Report On Air Pollution in Delhi NCR Causes and Solutions.Gopesh kumar Acharya100% (1)

- Global and Indian Scenario of E-Waste Management: A ReviewДокумент7 страницGlobal and Indian Scenario of E-Waste Management: A ReviewJhanvi DesaiОценок пока нет

- Handbook For Setting Up of An E-Waste Recycling FacilityДокумент35 страницHandbook For Setting Up of An E-Waste Recycling FacilitySachinSharmaОценок пока нет

- Municipal Corporation of Greater Mumbai: DeskjetДокумент4 страницыMunicipal Corporation of Greater Mumbai: Deskjetnavinchopra1986Оценок пока нет

- CSD Application FormДокумент10 страницCSD Application FormMushtaq MalikОценок пока нет

- Total Quality Management: ConceptualizationДокумент14 страницTotal Quality Management: ConceptualizationdnyaneshwarlpradhanОценок пока нет

- 1250 1500kva PDFДокумент4 страницы1250 1500kva PDFnavinchopra1986Оценок пока нет

- Jai Balaji Limit SwitchesДокумент2 страницыJai Balaji Limit Switchesnavinchopra1986Оценок пока нет

- Project Management and Organisational StrategyДокумент12 страницProject Management and Organisational StrategyfgdgdfgdfgОценок пока нет

- Supplier Selection ChecklistДокумент12 страницSupplier Selection ChecklistTan Zhang100% (1)

- Quick Guide To Project Management PDFДокумент23 страницыQuick Guide To Project Management PDFZaina AhmedОценок пока нет

- Program Management StudyДокумент19 страницProgram Management Studynavinchopra1986Оценок пока нет

- Rapid Assessment and Recovery of Troubled Projects PDFДокумент20 страницRapid Assessment and Recovery of Troubled Projects PDFHolly MurrayОценок пока нет

- Successfully Deploy Productivity SoftwareДокумент9 страницSuccessfully Deploy Productivity Softwarenavinchopra1986Оценок пока нет

- Mco Mib ReportДокумент118 страницMco Mib Reportamishatandon100% (2)

- Earthing 1Документ9 страницEarthing 1renjithas2005Оценок пока нет

- Eight Key Factors For Project MGMTДокумент3 страницыEight Key Factors For Project MGMTypraviОценок пока нет

- Internal Customer SatisfactionДокумент23 страницыInternal Customer Satisfactionnavinchopra1986Оценок пока нет

- Doe Fundamentals Handbook: Electrical Science Volume 3 of 4Документ126 страницDoe Fundamentals Handbook: Electrical Science Volume 3 of 4navinchopra1986Оценок пока нет

- Figure 6 1Документ1 страницаFigure 6 1navinchopra1986Оценок пока нет

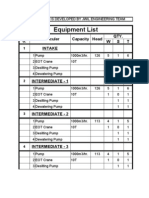

- Equipment List: Particuler Capacity Head Qty. W S T Intake SR.N oДокумент3 страницыEquipment List: Particuler Capacity Head Qty. W S T Intake SR.N onavinchopra1986Оценок пока нет

- Fig 2-6Документ1 страницаFig 2-6navinchopra1986Оценок пока нет

- Essential Knowledge For Instrumentation EngineerДокумент1 страницаEssential Knowledge For Instrumentation Engineernavinchopra1986Оценок пока нет

- Plunger Pump Service Manual: Installation and Start-Up InformationДокумент6 страницPlunger Pump Service Manual: Installation and Start-Up InformationDark CenobiteОценок пока нет

- ABB - AppNotes - 2.2 - 1HC0138868 EN AAДокумент8 страницABB - AppNotes - 2.2 - 1HC0138868 EN AADeoudrafОценок пока нет

- Instalación Sensor RPM TurboДокумент13 страницInstalación Sensor RPM TurboLuis Herrera MarinОценок пока нет

- Principles of Accounting, Volume 2: Managerial AccountingДокумент59 страницPrinciples of Accounting, Volume 2: Managerial AccountingVo VeraОценок пока нет

- 3BSE035980-600 A en System 800xa Control 6.0 AC 800M Configuration PDFДокумент580 страниц3BSE035980-600 A en System 800xa Control 6.0 AC 800M Configuration PDFWaqas AnjumОценок пока нет

- BK Report and ProjectДокумент55 страницBK Report and ProjecttesfuОценок пока нет

- Ductle Iron Spec1Документ8 страницDuctle Iron Spec1윤병택Оценок пока нет

- OpenJDK Vs Oracle JDKДокумент2 страницыOpenJDK Vs Oracle JDKkuzzuloneОценок пока нет

- 390 Track Bolt M0079195Документ2 страницы390 Track Bolt M0079195joshpbenzОценок пока нет

- Terminal - Exam - Section 4A-4B - Signal & System FA14 COMSATДокумент3 страницыTerminal - Exam - Section 4A-4B - Signal & System FA14 COMSATAli RazaОценок пока нет

- NDT NablДокумент3 страницыNDT NablPrabir KumarОценок пока нет

- Network Management Card - Installation Manual - EngДокумент30 страницNetwork Management Card - Installation Manual - EngZunaira ShafiОценок пока нет

- Report For Neha Lem ArchitectureДокумент17 страницReport For Neha Lem ArchitecturewafasaОценок пока нет

- Dutypoint BrochureДокумент24 страницыDutypoint Brochuremh wОценок пока нет

- Eco ProductsДокумент3 страницыEco Productssreekutty A SОценок пока нет

- Arco Solar Inc.: Case Analysis OnДокумент12 страницArco Solar Inc.: Case Analysis OnAnish RajОценок пока нет

- Ms 95-2018 Solved AssignmentДокумент15 страницMs 95-2018 Solved AssignmentPramod ShawОценок пока нет

- Quality Related QuestionsДокумент22 страницыQuality Related QuestionsHotPriyu OnlyforgalsОценок пока нет