Академический Документы

Профессиональный Документы

Культура Документы

Installation Booklet 1

Загружено:

Camhoa NguyenИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Installation Booklet 1

Загружено:

Camhoa NguyenАвторское право:

Доступные форматы

Tasman and Norfolk Retaining Wall

Evaluation and Installation Guide

A INE

S

BAINES

MASONRY

Tel: (02) 4631 1383 Fax: (02) 4631 1402 info@bainesmasonry.com.au www.bainesmasonry.com.au

900 Wilton Road (P.O. Box 89) Appin NSW 2560

Tasman and Norfolk are registered trade marks of Baines Masonary Blocks Pty Ltd and are used under licence.

A INE

S

BAINES

MASONRY

Norfolk and Tasman block retaining wall systems are proven Segmental Retaining Wall Systems (SRWS) designed and manufactured in Australia for Australian conditions. The unique characteristics of the Norfolk and Tasman systems ensure construction of any wall will be durable and strong for both residential and commercial projects. The aesthetic value of the split face (rock face) finished texture coupled with natural Australian colour tones means the Norfolk and Tasman systems when installed, enhance any landscaped environment - which means, to you, a sensational looking space that blends to the natural surroundings adding value and usability to your property. Both the Norfolk and Tasman SRW systems have undergone extensive testing (field and lab) in the most state of art testing facility by the most experienced staff in Australia. The results both systems achieved, at worse, were equal to but in most cases, bettered the majority of segmental retaining wall products produced worldwide . Skilled Architects, Engineers and Designers time and time again prefer the qualities both systems offer: Positive connection, no pins or plastic connectors that may not be used. Snug fitting connections, very little movement once blocks are correctly installed. A professionally designed user friendly software package that is a guide for your engineer to confirm Australian Standard (AS/NZ 4678) verification. Imitation is the highest form of compliment - Not a truer word has been spoken in regards to the Norfolk and Tasman Segmental Retaining Wall Systems. Many of our competitors will offer you products of similar shape and colour, but due to legal reasons they cannot duplicate the superior locking connection of both systems. Our product quality and our superior, unique, system design is your piece of mind that you are investing in the best segmental retaining wall system in Australia. It is the original and the best!

Tasman and Norfolk are registered trade marks of Baines Masonary Blocks Pty Ltd and are used under licence. 3

A INE

S

BAINES

MASONRY

Tasman and Norfolk Retaining Wall Evaluation and Installation Guide

Tasman and Norfolk Retaining Wall Evaluation and Installation Guide

This installation guide demonstrates the basics on how to construct A. Segmental Concrete Gravity Retaining Walls up to 900mm high (Gravity) B. Segmental Concrete Reinforced Soil Retaining Walls over 1 metre high (Reinforced)

C. Segmental Concrete Gravity Retaining Walls with Nofines Concrete over 1 metre high (No-fines Concrete) This is a guide only, to help determine whether a gravity, soil reinforced or no-fines concrete retaining wall is the most appropriate for your situation, and the preparation necessary to achieve the end result. This guide is not a design manual for soil reinforced or no-fines concrete retaining walls. The information provided in no way replaces the services of professional consultants on a particular project. No liability can therefore be accepted by Baines Masonry. STEP 1. Wall Height: Determine the maximum wall height. (see figure 1)

Wall Height

Figure 1. Maximum Wall Height

STEP 2. Decide on A. Gravity retaining wall B. Soil reinforced retaining wall C. No-fines concrete retaining wall A. Segmental Concrete Gravity Retaining Wall. There are two types of gravity retaining walls: Type A1 Norfolk which can be constructed up to 900mm high and Type A2 Tasman which can be constructed up to 660mm high for straight walls and 860mm for serpentine walls.

A INE

S

BAINES

MASONRY

A1 - Norfolk

The maximum permissible height for both straight and serpentine Norfolk retaining walls is 900mm (4 blocks at 180mm plus one capping block at 180mm). Norfolk retaining walls supporting up to 800 mm of soil, should comply with the following specification. Norfolk walls intended to support higher embankments must comply with AS 4678 Earth Retaining Structures and the advice of a competent civil engineer should be sought. The following limitations comply with the requirements of Concrete Masonry Association of Australia Manual MA53 Segmental Concrete Gravity Retaining Walls Appendix E. This design may be used to determine the permissible height of retaining walls satisfying the following criteria. For retaining walls outside these criteria, the design shall be determined using engineering analysis similar to that shown in the worked example, Appendix A, by qualified and experienced civil or structural engineers with a comprehensive working knowledge of soil mechanics and structural analysis and design.

The limits of application are as follows:

All retaining walls shall comply with AS 4678 Structure Classification A (Available from SAI Global Publishing www.sai-global.com) Permissible height for both straight and serpentine walls is 900 mm (4 blocks at 180 mm plus one capping block at 180 mm) All retaining walls are designed for level backfill. If the backfill has a slope greater than 1 in 8, engineering advice should be sought. This design does not apply to terraced retaining walls This design is not suitable for imposed loads. If imposed loads are expected, the retaining wall should be designed by engineering analysis similar to that in the worked example, in CMAA Manual MA53 Appendix A (Available from The Concrete Masonry Association of Australia. www.cmaa.com.au ) This design is not suitable for situations of excessive water run-off This design applies to retaining walls with a compacted crushed rock levelling pad, 600 mm wide x 150 mm deep. (The addition of portland cement is recommended to avoid erosion over the long term

Details of the Norfolk System

Block height Block length Block depth (into the embankment) Block weight Capping block weight Setback distance per block Wall slope Infill behind and within the facing blocks Bearing pad Drainage pipe 180 mm (plus 10mm tab height) 390 mm 190 mm 18.5 kg 21.5 kg 55 mm 17 degrees (55 in 180) Compacted 10 to 20 mm crushed rock aggregate Compacted 10 to 20 mm crushed rock aggregate 100 mm diameter PVC agricultural pipe with sock

200m (MIN m .)

Level or 1 in 8 MAX 1 Top Soil Optional Capping Unit

Notes

Structure Classification A retaining structures under 800 mm high are outside the scope of AS 4678. The criteria for Norfolk gravity retaining walls under 800mm is based on MA53 of the Concrete Masonry Association of Australia. For all retaining walls it is the owners responsibility to determine if council approval is required, irrespective of height or site conditions.

Norfolk Blocks

Norfolk Blocks Free Draining Layer

Retained Soil

Norfolk Block

Norfolk Cap

100mm Slotted PVC Pipe Bearing Pad Compacted Foundation

Figure 2. Norfolk Straight and Curved or Serpentine Garvity Walls up to 900mm

A INE

S

Norfolk Blocks

BAINES

MASONRY

A2 - Tasman

The maximum permissible height for straight Tasman retaining walls is 660mm (three courses and one cap) and serpentine Tasman retaining walls is 860mm (four courses and on cap). Tasman walls intended to support higher embankments must comply with AS 4678 Earth Retaining Structures and the advice of a competent civil engineer should be sought. The following limitations comply with the requirements of Concrete Masonry Association of Australia Manual MA53 Segmental Concrete Gravity Retaining Walls Appendix E. This design may be used to determine the permissible height of retaining walls satisfying the following criteria. For retaining walls outside these criteria, the design shall be determined using engineering analysis similar to that shown in the worked example, Appendix A, by qualified and experienced civil or structural engineers with a comprehensive working knowledge of soil mechanics and structural analysis and design.

Optional Capping Unit Top Soil Norfolk Blocks Drainage Layer

200mm (MIN.)

Geotextile Back ll / Retained Soil 100mm AG-Pipe Bearing Pad Compacted Foundation

Figure 4 Tasman Straight Gravity Retaining Walls up to 660mm High

The limits of application are as follows:

All retaining walls shall comply with AS 4678 Structure Classification A (Available from SAI Global Publishing www.sai-global.com/) Permissible height for straight walls is 660mm (three courses and one cap) and serpentine walls is 860mm (four courses and one cap) All retaining walls are designed for level backfill. If the backfill has a slope greater than 1 in 8, engineering advice should be sought. This design does not apply to terraced retaining walls. This design is not suitable for imposed loads. If imposed loads are expected, the retaining wall should be designed by engineering analysis similar to that in the worked example, in CMAA Manual MA53 Appendix A (Available from The Concrete Masonry Association of Australia. www.cmaa.com.au ) This design is not suitable for situations with excessive water run-off. This design applies to retaining walls with a compacted crushed rock levelling pad, 600 mm wide x 150 mm deep. (The addition of portland cement is recommended to avoid erosion over the long term

Details of the Tasman System

Block height Block length Block depth (into the embankment) Block weight Capping block weight Setback distance per block Wall slope Infill behind and within the facing blocks Bearing pad Drainage pipe 200 mm (plus 10 mm tab height) 390 mm 225 mm 23.5 kg 12 kg 10 mm 3 degrees (10 in 225) Compacted 10 to 20 mm crushed rock aggregate Compacted 10 to 20 mm crushed rock aggregate 100 mm diameter PVC agricultural pipe with sock

Optional Capping Unit Top Soil Compacted Clay Drainage Layer

Notes

Structure Classification A retaining structures under 800 mm high are outside the scope of AS 4678. The criteria for Tasman gravity retaining walls is based on MA53 of the Concrete Masonry Association of Australia. For all retaining walls it is the owners responsibility to determine if council approval is required, irrespective of height or site conditions.

Geotextile

200mm (MIN.)

Back ll / Retained Soil

100mm AG-Pipe Bearing Pad Compacted Foundation

Figure 3 Tasman Curved and Serpentine Gravity Retaining Walls up to 860mm High

A INE

S

BAINES

MASONRY

Installing Segmental Concrete Gravity Retaining Walls A1 and A2

Step 1 Check Compliance

Check with your local council to ensure all local Building Codes are complied with.

Step 5 Drainage and Backfill

Place 100 mm diameter PVC agricultural pipe with sock behind the wall, with a 1 in 100 fall. Backfill behind the courses of blocks to a width of approx. 200mm - 300mm using 10 - 20 mm free draining material (eg crushed rock aggregate / blue metal). Ensure each block is also well filled with free-draining material.

Step 2 Foundation

The foundation material, (the natural soil or rock material under retaining walls) shall be compacted by several passes of a mechanical plate vibrator. Where there are significant variations of foundation material or compaction, soft spots, or where there is ponding of ground water, the material shall be removed, replaced and compacted in layers not exceeding 150 mm. Trenches shall be dewatered and cleaned prior to construction, such that no softened or loosened material remains.

Step 6 Laying Additional Courses

Lay the next course and subsequent courses to a string line following the same procedure, as outlined in step 4, cleaning the top of the blocks, filling the block cores and backfilling behind the blocks to a maximum of one block high, at a time. (As per step 5)

Step 3 Bearing Pad

The facing shall be built on a bearing pad, not less than 150 mm thick, consisting of one of the following options: Compacted crushed rock, wellgraded and of low plasticity (without clay content), compacted by a plate vibrator; Cement-stabilized crushed rock, with an additional 5% by mass of GP Portland cement thoroughly mixed, moistened and compacted by a plate vibrator; or Lean-mix concrete with a compressive strength of not less than 15 MPa.

Step 7 Capping Units

When a Norfolk capping block is laid as the final course no adhesive fixing is necessary. If using a Tasman cap on either Norfolk or Tasman walls the capping block shall be fixed by Mason Bond adhesive

Step 4 First Course

Spread 25mm of metal dust with an additional 5% by mass of GP Portland cement over the compacted base. The first course is now bedded into the metal dust. The use of a level and string line is recommended to ensure the first course is laid correctly. Ensure each block is also well filled with free-draining material. (eg crushed rock aggregate / blue metal).

Note: The criteria for Norfolk and Tasman Gravity Retaining walls are based on MA53 of the Concrete Masonry Association of Australia

Tasman Blocks

Tasman Block

Tasman Cap

A INE

S

1 20

BAINES

MASONRY

Installing Tasman Segmental Concrete Reinforced Soil Retaining Wall B

Step 1 Check Compliance

Check with your local council to ensure all local Building Codes are complied with.

Step 4 Bearing Pad

The facing shall be built on a bearing pad, as per engineers advice, consisting of one of the following options: Compacted crushed rock, well-graded and of low plasticity (without clay content), compacted by a plate vibrator; Cement-stabilized crushed rock, with an additional 5% by mass of GP Portland cement thoroughly mixed, moistened and compacted by a plate vibrator; or Lean-mix concrete with a compressive strength of not less than 15 MPa.

Step 2 For walls up to 3m high

Engage a qualified civil engineer with a comprehensive working knowledge of soil mechanics and structural analysis and design. The design should comply with AS 4678 Earth Retaining Structures (A detailed engineering software design and specification disc is available from Baines Masonry). Walls over 3m high must be designed by a qualified and experienced civil or structural engineer with a comprehensive working knowledge of soil mechanics and structural analysis and design, using the design software available from Baines Masonry. It may be a council requirement to have the retaining wall certified and supervised by a civil or structural engineer.

Optional capping unit Top course and capping xed with two-part epoxy adhesive Drain (minimum 1 in 100 fall) to permanent stormwater system 150 min. compacted clay or similar to seal surface Excavation line Geogrids in rst and last course and each second course (maximum three courses) Retained soil Tasman blocks Bearing pad 200 200 In ll material as per speci cation Drainage ll placed in layers Compacted foundation material 600 Slotted PVC ag. pipe at minimum 1 in 100 fall. Position pipe as close to wall as practical, allowing for fall

Step 5 Drainage, Backfill and the First Course

Ensure the first course is embedded below the finished ground level. Place 100 mm diameter PVC agricultural pipe with sock behind the wall, with a 1 in 100 fall. The agricultural pipe should be connected to a PVC stormwater pipe and brought through the front of the wall at intervals not exceeding 30m. It should be connected to a PVC stormwater system at the lower end of each run, where practical, and must drain positively away from the base of the retaining wall. Backfill behind the courses of blocks to a width of not less than 300mm using 10-20 mm free draining material (eg crushed rock aggregate / blue metal). Ensure each block is also well filled with free-draining material. Back fill behind the drainage layer with the specified backfill in a maximum of 200mm layers. Compaction rate of 95% must be achieved (use only hand operated plate compactors close to the wall). Soft or wet clay must not be used to backfill. The use of a level and string line is recommended to ensure the first course is laid correctly.

Minimum fall 1 in 100

Step 3 Foundation

The foundation material shall be compacted by several passes of a mechanical plate vibrator. Where there are significant variations of foundation material or compaction, soft spots, or where there is ponding of ground water, the material shall be removed, replaced and compacted in layers as per engineers advice. Trenches shall be dewatered and cleaned prior to construction, such that no softened or loosened material remains. See example.

A INE

S

BAINES

MASONRY

Step 6 Laying Geogrid

Clean any debris from the top of the block wall to ensure the next block and or the geogrid layer sits perfectly. Roll the geogrid perpendicular to the wall, pull tight, stake in place and cut to the required length. Ensure that the geogrid sits within 15mm of the face of the block, so that the purpose made connecting lugs can interlock. Butt join the geogrid along the length of the wall. Place the next course on top of the geogrid. Baines Masonry recommends and supplies Fortrac Geogrid Manufactured by Huesker Inc

Step 8 Capping

The capping block shall be fixed by Mason Bond adhesive

MASON BOND is a moisture cure, polyurethane adhesive formulated to permanently bond concrete masonry block structures. MASON BOND meets the requirements of the International Code Council (ICC) A362 and is recognised as an alternative to mortar in ICCs Evaluation Services Report 1968 Build your walls with MASON BOND masonry adhesive instead of mortar and youll save TIME & MONEY.

WHY ?

Simple to apply Sets quickly Complete your masonry project in HALF the time - thats a 50% labour reduction! No trowelling, no premixing no waiting! 3.5 times stronger than mortar 80% less water penetration Economical

Step 9 Surface Drainage Step 7 Laying Additional Courses

Lay the next course and subsequent courses to a string line following the procedures outlined previously i.e. Clean any debris from the top of the block wall to ensure the next block and or the geogrid layer sits perfectly. Backfill behind the course of blocks to a width of not less than 300mm using 10-20 mm free draining material (eg crushed rock aggregate / blue metal). Ensure each block is also well filled with free-draining material. Back fill behind the drainage layer with the specified backfill in a maximum of 200mm layers. Compaction rate of 95% must be achieved (use only hand operated plate compactors close to the wall). Soft or wet clay must not be used to backfill. The whole of the disturbed fill surface should be sealed by at least 150mm of compacted clay and properly drained. Alternative means, such as bentonite layers or PVC membranes may be employed, provided they do not introduce potential slip planes into the surface material.

A INE

S

1 20 2H* bp

BAINES

MASONRY

Installing Tasman No-fines Concrete Retaining Walls C

Step 1 Check Compliance

Check with your local council to ensure all local Building Codes are complied with.

Step 3 Foundation

The foundation material shall be compacted by several passes of a mechanical plate vibrator. Where there are significant variations of foundation material or compaction soft spots, or where there is ponding of ground water, the material shall be removed, replaced and compacted in layers as per engineers advice. Trenches shall be dewatered and cleaned prior to construction, such that no softened or loosened material remains. See example.

Step 2 For walls up to 3m high

Engage a qualified civil engineer with a comprehensive working knowledge of soil mechanics and structural analysis and design. The design should comply with AS 4678 Earth Retaining Structures (A detailed engineering software design and specification disc is available from Baines Masonry) Walls over 3m high must be designed by a qualified and experienced civil or structural engineer with a comprehensive working knowledge of soil mechanics and structural analysis and design, using the design software available from Baines Masonry. It may be a council requirement to have the retaining wall certified and supervised by a civil or structural engineer.

Drain (min. 1 in 100 fall) to permanent stormwater system Optional capping unit Minimum fall 1 in 100 150 min. compacted clay or similar to seal surface

Step 4 Bearing Pad

The facing shall be built on a bearing pad, as per engineers advice, consisting of one of the following options: Compacted crushed rock, well-graded and of low plasticity (without clay content), compacted by a plate vibrator; Cement-stabilized crushed rock, with an additional 5% by mass of GP Portland cement thoroughly mixed, moistened and compacted by a plate vibrator; or Lean-mix concrete with a compressive strength of not less than 15 MPa.

Excavation line No- nes concrete Retained soil Slotted PVC ag. pipe at min. 1 in 100 fall Compacted foundation material

Tasman blocks

H* bp

Step 5 Drainage, Backfill and the First Course

Place 100 mm diameter PVC agricultural pipe with sock behind the wall, with a 1 in 100 fall. The agricultural pipe should be connected to a PVC stormwater pipe and brought through the front of the wall at intervals not exceeding 30m. It should be connected to a PVC stormwater system at the lower end of each run, where practical, and must drain positively away from the base of the retaining wall. Backfill behind the course of blocks to a width of not less than 300mm using no-fines concrete. Ensure each block is also well filled with no-fines concrete. Back fill behind the drainage layer with the specified backfill in a maximum of 200mm layers. Compaction rate of 95% must be achieved (use only hand operated plate compactors close to the wall). Soft or wet clay must not be used to backfill. The use of a level and string line is recommended to ensure the first course is laid correctly.

Bearing pad

B*

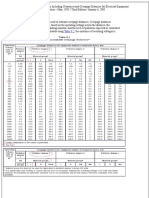

* See Design Tables 1 and 2 for values

Specification of No-fines Concrete infill No-fines concrete shall be free-draining, allowing water to pass readily through it to the drainage system. No-fines concrete shall have a bulk density not less than 1800kg/m and an aggregate to GP cement ratio not greater than 6:1 (by volume).

10

A INE

S

BAINES

MASONRY

Step 6 Laying Additional Courses

Lay the next course and subsequent courses to a string line following the procedures outlined previously i.e. Clean any debris from the top of the block wall to ensure the next block sits perfectly. Backfill behind the course of blocks to a width of not less than 300mm using no-fines concrete. Ensure each block is also well filled with no-fines concrete. Back fill behind the drainage layer with the specified backfill in a maximum of 200mm layers. Compaction rate of 95% must be achieved (use only hand operated plate compactors close to the wall). Soft or wet clay must not be used to backfill.

Step 7 Capping

The capping block shall be fixed by Mason Bond adhesive

Step 8 Surface Drainage

The whole of the disturbed fill surface should be sealed by at least 150mm of compacted clay and properly drained. Alternative means such as bentonite layers or PVC membranes may be employed, provided they do not introduce potential slip planes into the surface material.

Internal and External Half Tasman Caps Cutting Details*

Internal Corner Caps External Corner Caps

Cut Line

Finished Corner

Cut Line

Finished Corner * Not available in all regions

11

A INE

S

BAINES

MASONRY

Tasman

Corners

Tasman corners are built by fixing the purpose made corner blocks alternately to each course using adhesive. Allowances should be made for a 10mm step back per course. Lugs must be removed from the Tasman Blocks to ensure that the corner block fits evenly. A maximum height of one metre is recommended when using corner blocks. Curved corners is the preferred method of corner construction.

Curves

Curves and serpentine walls are easy to construct and the best guide is to lay out a garden hose and follow the profile. Be conscious that the length of courses will vary for a concave or convex wall. With fewer blocks per lineal metre of a convex, and more blocks per lineal metre when the wall is concave. For convex curved walls knock the back fin off the block with a hammer. For concave walls simply position blocks. The minimum radius for the top course of Tasman half blocks is 650mm and Tasman blocks is 1300mm. Adjust lower courses allowing for 10mm step back. Always keep the front of the blocks tightly together.

Steps

Steps must be built according to the local building code, so always check with your local building authority for the minimum requirements before commencing.

First Course

First Course

Prepare Surface

Additional Courses

Additional Courses

Install blocks

Capping 12

Capping

Capping

A INE

S

BAINES

MASONRY

Norfolk

Corners

Due to the setback of the Norfolk, 90 corners are difficult to construct, but not impossible. You may have to remove the lugs and fix using a construction adhesive, allowing 55mm for the set back of the block. Additional cutting of the blocks may be required. Curved corners are easy to construct and the best guide is to lay out a garden hose and follow the profile. Be conscious that the length of courses will vary for a concave or convex wall. With fewer blocks per lineal metre of convex wall, and more blocks per lineal metre when the wall is concave.

First Course

Curves

Curves and serpentine walls are easy to construct and the best guide is to lay out a garden hose and follow the profile. Be conscious that the length of courses will vary for a concave or convex wall. With fewer blocks per lineal metre of a convex, and more blocks per lineal metre when the wall is concave. The minimum diameter of the top course of the Norfolk wall is 1900mm (internal dimension). Adjust lower courses allowing for 55mm step back. Always keep the front of the blocks tightly together.

Additional Courses

Capping

13

A INE

S

BAINES

MASONRY

Glossary

Gravity Retaining Walls Gravity retaining walls depend on the weight of their mass to resist pressures from behind and will often have a slight batter set back, to improve stability by leaning back into the retained soil. Soil Reinforced Retaining Walls Soil reinforced retaining walls incorporate geogrids into the soil structure to create a segmental concrete reinforced soil structure. Such systems can be constructed several metres high and accommodate significant loads. No-Fines Concrete Retaining Wall No-fines concrete retaining walls use no-fines concrete as a mass behind the concrete facing units to reinforce the soil structure to create a segmental concrete reinforced soil structure. Such systems can be constructed several metres high and accommodate signifcant loads. Serpentine Wall The serpentine wall derives its name from its curving shape, which is in the form of a snake. Geogrids Layers of metal or plastic material, which when constructed in horizontal planes in a soil mass, strengthen the soil. The most common geogrids are open mesh consisting of polyester, highdensity polyethene, polyproplene or steel. Infill Material The soil material, placed behind the retaining wall facing and strengthened by the geogrids. Foundation The natural soil or rock material under a retaining wall. Bearing Pad The pad the Tasman or Norfolk blocks are built on. Drainage Fill The crushed rock, gravel or similar material placed behind a retaining wall to convey groundwater away from the wall foundations. It is commonly used in conjunction with other drainage media, such as agricultural pipes.

14

Client Site Ph Fax

A INE

S

BAINES

MASONRY

Date

this drawing is indicative only and is not to scale unless otherwise stated

15

A INE

S

BAINES

MASONRY

Supplier:

This manual is intended to be a guide to determine the most appropriate type of segmental concrete retaining wall and the procedure for installation. This is not a design manual for soil reinforced or no-fines concrete retaining walls. Tasman and Norfolk are registered trade marks of Baines Masonary Blocks Pty Ltd and are used under licence. Baines Masonry is a member of the Concrete Masonry Association of Australia. www.cmaa.com.au The information provided in no way replaces the services of professional consultants on a particular project. No liability can therefore be accepted by Baines Masonry.

16

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Shoring JackДокумент8 страницShoring Jackmikeroack_11100% (1)

- Sydney 05 5 2013Документ7 страницSydney 05 5 2013Camhoa NguyenОценок пока нет

- PrivacyДокумент1 страницаPrivacyCamhoa NguyenОценок пока нет

- BID BUY SOLDДокумент28 страницBID BUY SOLDCamhoa NguyenОценок пока нет

- Sydney 11 05 2013Документ8 страницSydney 11 05 2013Camhoa NguyenОценок пока нет

- Owner's ManualДокумент64 страницыOwner's ManualAnkit BhatiaОценок пока нет

- Reference: Frank MonaghanДокумент20 страницReference: Frank MonaghanIeeeChannaОценок пока нет

- Bridge ConstructionДокумент101 страницаBridge ConstructionMuhammad Nashrul FikriОценок пока нет

- R50 Guide Notes For Bituminous Surfacing Specifications June 11Документ46 страницR50 Guide Notes For Bituminous Surfacing Specifications June 11qazalbash1109588Оценок пока нет

- Mantri Metro-Residential Commercial Station Projects AnalysisДокумент2 страницыMantri Metro-Residential Commercial Station Projects AnalysisraviОценок пока нет

- Thornel T300 052112 PDFДокумент2 страницыThornel T300 052112 PDFDavid CoutinhoОценок пока нет

- Sprinkler 2 01 2021Документ2 страницыSprinkler 2 01 2021rajaОценок пока нет

- A743A743MДокумент7 страницA743A743MAnonymous ggwJDMh8Оценок пока нет

- AMERONДокумент343 страницыAMERONrajeshn1100% (1)

- Table 7-3 UPC DFUДокумент4 страницыTable 7-3 UPC DFUAhmed OsmanОценок пока нет

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Документ1 страницаMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- Glass To Metal Sealing OverviewДокумент3 страницыGlass To Metal Sealing OverviewbusybusybusyОценок пока нет

- Burtrand Lee, Sridhar Komarneni - 2005 - Chemical Processing of CeramicsДокумент737 страницBurtrand Lee, Sridhar Komarneni - 2005 - Chemical Processing of Ceramicsvanessa santanaОценок пока нет

- Q1 Day 1-3 Enrichment ActivitiesДокумент3 страницыQ1 Day 1-3 Enrichment ActivitiesAngelica N. HilarioОценок пока нет

- Reinforced concrete beam and floor slab detailsДокумент1 страницаReinforced concrete beam and floor slab detailsRbcabajes ButalonОценок пока нет

- How Does Contact With Aluminum Affect Concrete - Concrete Construction MagazineДокумент1 страницаHow Does Contact With Aluminum Affect Concrete - Concrete Construction MagazineHerdisОценок пока нет

- VRV4 0215 AДокумент96 страницVRV4 0215 ATiam Yee YongОценок пока нет

- SIM (3) - EIM 10-CMG - Week 4-5 - Q1Документ12 страницSIM (3) - EIM 10-CMG - Week 4-5 - Q1Genelyn NarcisoОценок пока нет

- UL 840 Third Edition January 2005 Section 9 Creepage DistancesДокумент4 страницыUL 840 Third Edition January 2005 Section 9 Creepage DistancesRobert LegaultОценок пока нет

- EDI FlexAir Threaded Spec SheetДокумент2 страницыEDI FlexAir Threaded Spec Sheetomega AlfaОценок пока нет

- Fatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxДокумент18 страницFatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxSWAPNIL PATILОценок пока нет

- MATERIALSДокумент44 страницыMATERIALSnadyaОценок пока нет

- L (73) 25 Unit Type 'G' Typical Kitchen Elevation (Option 02)Документ1 страницаL (73) 25 Unit Type 'G' Typical Kitchen Elevation (Option 02)Jeremiah MangeniОценок пока нет

- 28 Transmission Lines and CablesДокумент7 страниц28 Transmission Lines and CablesIlyas HussainОценок пока нет

- MOR and Modes of Failure of BeamsДокумент9 страницMOR and Modes of Failure of Beamsward dhapakhelОценок пока нет

- Composite in Marine ApplicationsДокумент12 страницComposite in Marine ApplicationsJithin Devan PadincharayilОценок пока нет

- Axial capacity of circular concrete-filled tube columnsДокумент20 страницAxial capacity of circular concrete-filled tube columnsMona MahmoudОценок пока нет

- Water Migration in Xlpe CableДокумент4 страницыWater Migration in Xlpe CableSISWANTOОценок пока нет

- Hands-On Workshop Manual On Etabs: BY4 D DesignДокумент18 страницHands-On Workshop Manual On Etabs: BY4 D DesignEr Prakhar Pagaria JainОценок пока нет

- Mems Lecture PlanДокумент2 страницыMems Lecture PlanMahesh Kumar K BОценок пока нет