Академический Документы

Профессиональный Документы

Культура Документы

Technical Challenge of Quator Gas LNG Project

Загружено:

thawdarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Technical Challenge of Quator Gas LNG Project

Загружено:

thawdarАвторское право:

Доступные форматы

Paper PS2-1

TECHNICAL CHALLENGES DURING THE ENGINEERING PHASES OF THE QATARGAS II LARGE LNG TRAINS

Victor Chavez Overall Technical Lead, Qatargas II Stephen Wright Process Engineering Lead, Qatargas II Mansoor Al-Marzooqi ESU Division Manager, Qatargas II Kenji Nagahama CTJV Lead Process Engineer Chiyoda Dennis Atwood Principal Human Factors Engineer RRS Engineering Yu-Nan Liu LNG Technical Director Air Products and Chemicals, Inc.

ABSTRACT The Qatargas II LNG Project (QG II) is a 'full supply chain' LNG joint venture that will set new benchmarks for LNG production. The project will expand the existing Qatargas LNG facility at Ras Laffan, Qatar with the addition of two LNG trains, each with an LNG production capacity of approximately 7.8 million tonne per annum (MTA), with production starting in 2008. Feed gas will come from Qatars North Field, which is the largest non-associated gas field in the world. The onshore gas processing plant will extract LPGs (propane and butane) from the feed gas, and then produce a lean LNG that will be shipped to the United Kingdom using new, larger LNG transportation ships. The LPG extracted from the feed gas will be fractionated at Ras Laffan and exported as separate products. A new LNG receiving terminal that is being built in the UK will regasify the LNG and send out sales gas into the U. K. national gas transmission system. The Qatargas II Project Team has developed a design for the onshore facilities at Ras Laffan that maximizes shareholder value by applying a combination of existing and new technologies. Economies of scale require the latest generation of LNG production facilities to be larger than ever. These large plants are designed with facilities and equipment that dwarf those in plants that are but a few years old. New designs create new challenges for the people who must operate and maintain them. This paper describes some of the technical challenges encountered during the engineering phases of the Qatargas II LNG onshore development facility, which is being developed as a joint venture between Qatar Petroleum and ExxonMobil. It describes the measures taken to overcome these technology changes, including the first application of the Air Products AP-XTM LNG technology. It also reviews the Human Factors challenges inherent with the increase in facility scale and the solutions implemented in the detailed design phase.

PS2-1.1

Paper PS2-1

1. INTRODUCTION The world demand for natural gas has renewed interest in the production and transportation of Liquefied Natural Gas (LNG) from resource rich areas in Africa and the Middle East to customers in Europe and the Americas. Qatar has taken the lead to meet this challenge with a vision of becoming the largest LNG producer in the world (80 MTA by 2010) through the continued development of the North Field, the largest nonassociated gas reservoir in the world. This vision will become a reality through the development of the worlds largest LNG trains which was initiated in a joint venture between Qatar Petroleum and ExxonMobil. Ownership of this joint venture company, Qatargas II, has recently been expanded to include a third partner, Total. Economies of scale require the latest generation of LNG production facilities to be larger than ever. These large plants are designed with facilities and equipment that dwarf those in plants that are but a few years old. New designs create new challenges for the people who must operate and maintain them. This paper describes some of the technical challenges encountered during the engineering phases of the Qatargas II LNG onshore development. It describes the measures taken to overcome these technology changes, including the first application of the Air Products AP-XTM LNG technology. It also reviews the Human Factors challenges inherent with the increase in facility scale and the solutions implemented in the detailed design phase. 2. BACKGROUND The Qatargas II Project is located at Ras Laffan Industrial City, on the northwest coast of the State of Qatar. Ras Laffan has two LNG facilities: Qatargas and RasGas. The existing Qatargas plant consists of three LNG trains, each with a capacity of 3.2 MTA. The combined capacity of the existing plant is 9.6 MTA. The Qatargas II onshore project is a two train expansion (Trains 4 & 5) to the existing Qatargas plant (Trains 1, 2, & 3). The ownership in Train 4 is Qatar Petroleum 70% and ExxonMobil 30% while the ownership in Train 5 is Qatar Petroleum 65%, ExxonMobil 18.3% and Total 16.7%. Presently, the project is well into the construction phase. Train 4 is scheduled to start LNG Production in early 2008 and Train 5 will follow approximately 9 months later. The EPC contractor is a joint venture between Chiyoda Corporation of Japan and Technip France (CTJV). The Qatargas II project is unique in the industry because of its large scale and the agreed commercial scope between shareholders. Rather than developing a plant for longterm, firm sales contracts, the QGII venture is developing the full supply chain for exterminal sales into an open market. The integrated projects to produce, export, and sell LNG and LPG includes: Offshore production platforms and pipelines Onshore gas treating, LPG recovery and LNG facilities Large LNG (LLNG) ships, LNG re-gasification terminal at South Hook in Wales, UK

PS2-1.2

Paper PS2-1

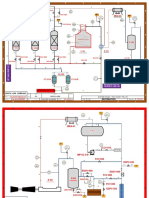

The LNG14 paper "QATARGAS II: FULL SUPPLY CHAIN OVERVIEW" (Ref. 3) provides an overview of the project, with particular focus on the large train technologies that will be implemented. 2.1 Overall Process Flow Scheme

SINGLE TRAIN

09

TO OTHER TRAIN

SULFUR RECOVERY

06

SULFUR

REFRIGERATION (C3, MR, N2)

OFFSHORE PRODUCTION

31

02

03

INLET FACILITY

ACID GAS REMOVAL

DEHYDRATION MERCAPTAN REMOVAL

04

05

08

NGL RECOVERY

LIQUEFACTION

NITROGEN REJECTION

LNG

07

FRACTIONATION C3, C4 TREATING

PROPANE

BUTANE PLANT CONDENSATE

32

CONDENSATE TREATING

FIELD CONDENSATE

3. AIR PRODUCTS AP-XTM LIQUEFACTION TECHNOLOGY 3.1 Selection of Air Products AP-XTM Technology

In 2001, ExxonMobil began a study to evaluate the largest feasible LNG train size that could be achieved with proven LNG technologies (Ref. 1). One of the constraints imposed on the study was setting a maximum spiral wound heat exchanger (SWHE) diameter of 5 meters (16.5 feet) based on manufacturing limits at that time. The study yielded a maximum train size of about 5.5 MTA. This result did not offer a significant

PS2-1.3

Paper PS2-1

step-out from the LNG trains already in existence (e.g. RasGas Trains 3, 4, and 5 at 4.7 MTA each). Several other technologies that could produce greater than 5.5 MTA were evaluated. Air Products AP-XTM Hybrid Process, for which Air Products was awarded a US patent in November 2001 (Ref. 2), was selected for further development. The key feature of the AP-XTM Hybrid Process is that it adds a third refrigeration cycle (nitrogen) to the conventional Air Products C3MR design. The reasons that Air Products AP-XTM Hybrid Process was selected over other technologies were: Offered the potential to increase train sizes beyond current limitations Combines proven C3MR technology with proven Nitrogen Expansion refrigeration technology used in air separation plants Design could be built utilizing existing equipment (e.g. liquefaction exchanger size within proven 15 foot diameter) New equipment technology offers opportunity to optimize design and possibly consider further increases in train sizes or reduce cost

ExxonMobil then embarked on an intensive, multi-discipline, multi-company study to turn Air Products patented process concept into a comprehensive engineering design. These further studies concluded that the AP-X technology was robust and that its pursuit would produce significant economies of scale. Qatargas II would be the first commercial application of this technology. Below is a simplified overall process flow diagram utilizing the AP-X process:

Nitrogen Rejection Expander / Compressor

E C

LNG

SUBCOOLER PROPANE COMPRESSORS

PROPANE CHILLER & SMALL EXPANDER

PRE-COOLING: PROPANE SYSTEM (Four Pressure Levels)

COLD BOX

SWEET GAS

DEHYDRATION

NGL RECOVERY

NITROGEN COMPRESSOR

NITROGEN REFRIGERATION SYSTEM MAIN HEAT EXCHANGER

PROPANE-PLUS TO FRACTIONATION MIXED REFRIGERANT COMPRESSORS

PS2-1.4

Paper PS2-1

3.2

Designed for Operational Flexibility

With three separate refrigerant loops, the AP-X technology permits operational flexibility to maximize production during seasonal temperature changes. This can be accomplished by shifting the refrigeration load among the three refrigeration loops to adjust plant capacity and optimize fuel gas balance. The refrigeration power load of the three refrigeration loops can be changed easily by adjusting some operating variables: Propane Refrigerant Circuit - The major control variable for the propane (C3) system is compressor speed. Since the C3 compressor discharge pressure is set by the C3 condensing temperature, the C3 compressor speed is used to control the LLP C3 compressor stage pressure, which produces temperature changes of the feed gas and MR entering the main cryogenic heat exchanger (MCHE). Mixed Refrigerant (MR) - Control of the MR system is based on maintaining the desired LNG temperature exiting the MCHE by controlling the overall flow rate at an adjusted MR composition with a constant MR compressor speed. Changing the refrigeration load in the MR system can be accomplished by changing the mass flow rate of the total MR circulation or adjusting the MR composition. The overall inventory in the system and the MR compressor speed can also be used to adjust the overall MR refrigeration system load. Nitrogen - The major control variables for the nitrogen refrigeration loop are: N2 recycle compressor speed, N2 inventory in the system, and flow with the N2 Companders1. The inlet guide vanes of the Companders1 can be adjusted to vary the refrigeration load of the nitrogen system.

The Qatargas II liquefaction unit is designed to maintain the same production capacity throughout the year up to a design ambient temperature of 43oC (Ref. 3). To maintain the same design rate, it is expected that the C3 compressor speed will be adjusted to supply maximum precooling. The MR and N2 suction and discharge pressures and their respective compressor speeds and inventories may be adjusted to achieve the production objectives. To maximize production of the liquefaction unit, the C3 compressor speed will be increased to provide maximum precooling, the starter-helper motor for the MR compressor will be in the helper mode, and the MR inventory will be adjusted to provide additional refrigeration. Similarly, the N2 system inventory and compressor speed may be increased to supply the necessary refrigeration required to subcool the LNG to its required temperature for plant fuel balance when the plant is in the maximum production mode. In the event of a need to operate the plant at less than the maximum production rate, the refrigerant compressor-driver sets may be operated at lower speed, or the compressors can be put on recycle. It is expected that the C3 compressor may be on recycle at about 80% of design capacity or lower. The MR compressor may be operated at about 50% of design capacity without going into recycle. For some long term turndown operations, it

Companders is the Air Products name for Compressor-Loaded-Expanders

PS2-1.5

Paper PS2-1

may be beneficial to reduce the MR and N2 inventories in the respective refrigeration loops. 3.3 Lean and Rich LNG Production

Early on it was recognized that the markets targeted by the Qatargas II project, i.e. the Atlantic Basin (mainly the UK and US), have a preference for lower heating value gas than has been traditionally been produced from Qatar for sale to the Pacific Basin (mainly Japan, Korea, and India). Also flexibility to produce spot cargoes for the Pacific Basin needed to be maintained. Various methods to meet the Atlantic Basin preference were evaluated such as Pipeline Gas Blending, Air Injection, Nitrogen Injection, and NGL stripping to various degrees in both Qatar and at the LNG terminal sites. The results of that evaluation were that NGL would be extracted and sold from Qatar. NGL extraction within the Qatargas II Project will be achieved prior to liquefaction using the Single Column Overhead Recycle (SCORE) process technology, licensed by Ortloff Engineers, Ltd. The SCORE process has been designed to achieve 99% propane recovery. After NGL extraction, the residual lean feed gas is compressed to high pressure for efficient operation of the liquefaction process. A key challenge of the design has been to ensure a high level of reliability and flexibility in this unit. This has been achieved by using a 3 x 50% NGL turbo-expander configuration and the application of a steam turbine driver for the lean gas recompressor. The steam turbine will provide a long run time between maintenance cycles and significant speed flexibility. Depending on the heating value required by the gas markets, the LNG composition can be adjusted by modifying the operation of the NGL recovery unit to increase or decrease the level of heavier components in the feed gas to the refrigeration and liquefaction sections. The Qatargas II design includes the ability to re-inject subcooled propane into a slipstream of the lean LNG, thereby allowing production of a rich LNG product while continuing to produce a lean LNG product.

4. APPLICATION OF GE FRAME 9E GAS TURBINES It was clear that these large scale trains would require significant compression power, in the range of 280 MW per train. Using the current industry standard GE Frame 7EA gas turbines, four units would be required per train. This scale up also challenged compressor vendors to produce very large refrigeration compressors with impellers nearly 2 meters in diameter, which are not well suited for the running speed of 3,600 rpm. The Frame 9E was the ideal mechanical driver for these compression trains as they can provide 123 MW of power at ISO rating and 3000 rpm, a speed within compressor capabilities. Because the Frame 9E had never been applied in LNG mechanical driver service, a significant qualification effort was undertaken to adapt it from fixed speed power generation service to variable speed mechanical drive service (Ref. 7).

PS2-1.6

Paper PS2-1

In addition, considerable effort was concentrated on reducing plant emissions through the qualification and use of Dry Low NOx (DLN) burner technology suitable for the low BTU fuel gas produced as a byproduct of the liquefaction process. Even at fuel gas N2 concentrations up to 38%, the Frame 9E demonstrated reliable operation while achieving less than 25 ppmv NOx emissions. Further improvements to efficiency required a solution to address the impact of diurnal and seasonal ambient temperature variations on the gas turbine power output. This requirement was accomplished through the development of a unique, variable-speed, starter motor / helper motor / generator. The motor/generator enables pressurized starting of the compressors, ensures adequate power for refrigeration compression, and exports surplus power as electricity into the plant grid to fully utilize the capability of the gas turbine. This enables Flat LNG production year round and power sharing between compressor strings, while minimizing the need for stand-alone gas turbines for power generation.

5. STRINGENT ENVIRONMENTAL CONSTRAINTS The State of Qatar has stringent environmental regulations. This requires high sulfur recovery from the feed gas to satisfy the SOx and NOx limits on gas turbine and fired heaters flue gas emissions. The sulfur (SO2) emissions limits require a high sulfur recovery (better than 99%). This led to production of a commercial-quality liquid sulfur product by the following design scheme: Acid gas removal using the BASF activated MDEA (aMDEAR) process. Mercaptans removal is accomplished using molecular sieves in a process licensed by UOP. The spent molecular sieve regeneration gas is treated using a Chilled SELEXOLTM process also licensed by UOP, which reduces total sulfur in the spent regeneration gas to below 50 ppmv. This spent regeneration gas feeds the fuel gas system. Sulfur recovery is accomplished using a 2-stage Claus process designed by Lurgi. The H2S-laden acid gas from the aMDEAR and the mercaptan-laden acid gas from the Selexol unit are enriched upstream of the Claus Unit, and the Claus tail-gas is hydrogenated and then further treated in a Tail Gas Treating unit. Both the Acid Gas Enrichment and Tail Gas Treating Units use the ExxonMobil Flexsorb-SE Plus process. The major challenge has been to ensure that the design is robust to meet the sulfur recovery requirements for the range of expected sulfur species in the feed gas to the plant.

6. COST EFFECTIVE DESIGN OF THE GAS TREATING SYSTEM Early studies concluded that a LNG train sized at around 8 MTA could significantly reduce the unit cost of LNG production through economy of scale. This LNG train size would require a feed gas rate of about 1.5 billion SCFD. In order to achieve the economy of scale, a single-vessel configuration concept was developed for major equipment rather than splitting the flow through two or more units in parallel. Consequently,

PS2-1.7

Paper PS2-1

accomplishing a single-vessel gas treating absorber for this feed gas rate of 1.5 billion SCFD was a special challenge. Various leading acid gas removal technologies were studied during the FEED phase of the project. As a result of the study, the BASF aMDEAR process was selected based on: having a proven track record, the possibility of a single absorber design within the feasibility fabrication, and competitive cost. The aMDEAR process is used to remove H2S, CO2 and COS. Other sulfur compounds (mercaptans) are removed from the feed gas using molecular sieves. The molecular sieve process is licensed by UOP and has a dual role of dehydration and mercaptans removal.

7. HUMAN FACTORS DESIGN CHALLENGES FOR SAFETY, MAINTENANCE, AND OPERATIONS There are many significant challenges to design an LNG train of this magnitude. Extensive 3D modeling was used during the development of this project to develop a design that encompasses the key human factors in the design. A significant effort was devoted to the development of the human factors specification. This involved the collaboration of project, operations, and contractor personnel and a human factors specialist. Furthermore, at the start of detailed design, training sessions were held with the various contractor disciplines (piping, mechanical, electrical, instruments and safety) to ensure the specification was clear for incorporation into the design. A few examples are detailed below: 7.1 Safety Escape Routes

Large line diameters and valves up to 2896 MM (114 inches) in size required the provision of platforms for operations and maintenance access. The challenge for the designers was to ensure that the platforms did not create dead-ends that could trap a worker in the event of a fire or release, and to ensure that large platforms were provided with proper escape routes. NFPA (ref. 6) codes were met or exceeded. For example, an additional means of egress was provided if the walking distance from any location on a platform to a primary escape route exceeded 5.0 meters (16 feet) or if a dead-end exceeded 5.0 meters. 7.2 Adjustment to the Anthropometry of Local Process Workers

It is important to design and construct process plants to accommodate the characteristics of the user population (Attwood et al. 2003, ref. 4). Typically, the design of facilities and equipment is based on the extremes of the working population. Head clearance, for example, is determined from the heights of the tallest workers, and the limits of overhead reach are determined from height of the shortest workers. Data from Qatargas I was used to determine the characteristics of the plant working population. Jurgens et al (1990, ref. 5) published a report through the International Labour Office that provided data on nineteen (19) ergonomically important body measurements for groups which included each of the nationalities of workers in the Qatargas plant.

PS2-1.8

Paper PS2-1

Specifications developed from the data above provided a design safety margin. For example, overhead clearance was set at 2032mm (80 inches). 7.3 Access to and Operation of Manual Valves

Process and non-process lines alike in this plant are typically large, with diameters up to 2896 mm (114 inches). The valves that control flow through these lines are also large and their operation and maintenance required special consideration. Human Factors Engineering (HFE) specifications for Qatargas II limited the maximum valve wheel rim force to 356 N (80 lbf) and the maximum number of turns from fully open to fully closed to 40. Geared operators that are used to reduce the rim force required to operate a valve to 356 N or less would require many more turns than are allowed and could take over an hour to fully close or open the valve. Consequently, if valves exceeded HFE operations specifications they were required to be motor driven, or to be equipped with a portable, hand-operated, power assist. 7.4 Access to Control Valves

Like the manual valves, control valves in this project are also large and present special problems for maintenance access. Many control valves require access to hand jacks for manual operation and for maintenance of instrumentation. It was necessary to develop an access strategy for each of the eight different types and sizes of control valves that are used in the plant. In some cases, access to the valve is from one side and could be accomplished with a simple platform. In other cases, access was necessary from two sides and required more complex platforms and crossovers. 7.5 Vertical Transport Equipment

Pipe racks on this project are as much as 27 meters (89 feet) high. Consequently, access for people and equipment to the tops of pipe racks requires special consideration. Similar to other process plants, most of the safety-related equipment is on the top of the pipe rack, as are air-fin coolers. Each requires a high maintenance effort, either because

PS2-1.9

Paper PS2-1

of scheduled maintenance requirements or the potential for failure (e.g. motors and belts for air-fin coolers). While there were no formal HFE specifications for the use of vertical transport equipment, it quickly became obvious that special arrangements would be necessary. With over 450 process safety valves (PSVs) located at the top of structures, each of them requiring routine maintenance, the use of large ground-based mobile cranes was seen as an impediment to maintenance. Careful evaluation of small portable cranes sometimes combined with portable carts concluded they were suitable for maintenance at high level structures such as the top of the pipe rack. The cranes are small enough to negotiate the narrow passages on top of the pipe rack, and, can be combined with a davit or fixed crane to lower the valves to a staging space, at grade, for PSV pick up and repair.

8. CONCLUSION This paper has described a few of the many design challenges that have been encountered in the development of the Qatargas II project. The design of the large Qatargas II trains has been an extraordinary undertaking which has presented many challenges over the last 3 years. Meeting these challenges has been made possible by the teamwork and cooperation of many outstanding people around the world, representing the leading companies in their respective fields.

9. REFERENCES 1. S. Wright, P.W. Sibal, Technology Challenges for a New Generation of UltraLarge LNG Trains. APCI Owners Seminar, September 2006, Hershey, Pennsylvania, Air Products US Patent 6,308,531 for the Hybrid Cycle (Trade mark AP-XTM) Thompson, G.R., Adams, J. B., Hammadi Ali, Kaabi, S. A., Sibal, P.W,, Qatargas 2 Fuel Supply Chain Overview, LNG 14 Conference, Doha, Qatar Attwood, D.A., Deeb, J.M, and Danz-Reece, M.E., Ergonomic Solutions for the Process Industries. Gulf Professional Publishing (Elsevier), Burlington, MA, 2003. Jurgens, H.W., Aune, I. A., and Pieper, U. International Data on Anthropometry. Occupational Safety and Health Series No. 65, International Labour Office, Geneva, 1990 NFPA 101B: Code for Means of Egress for Buildings and Structures, 2002 Edition National Fire Protection Association. Roy Salisbury et al, Design, Manufacture, and Test Campaign of the Worlds Largest LNG Refrigeration Compressor Strings, LNG 15, April 2007.

2. 3. 4. 5.

6. 7.

PS2-1.10

Вам также может понравиться

- Microsoft Word - LNG Large Scale Background Paper Oct2006 PDFДокумент58 страницMicrosoft Word - LNG Large Scale Background Paper Oct2006 PDFGeoffreyHunter100% (3)

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- Compreesor EfficiencyДокумент16 страницCompreesor EfficiencyHarindharan JeyabalanОценок пока нет

- Fantastic Magazine of KnowledgeДокумент44 страницыFantastic Magazine of KnowledgeRajan BalkiОценок пока нет

- CHART Cold Box Installation Operation and Maintenance PDFДокумент16 страницCHART Cold Box Installation Operation and Maintenance PDFBrinto VargheseОценок пока нет

- Arun LNG PlantДокумент6 страницArun LNG Planthortalemos100% (1)

- Significance of 3% PSV Inlet Line Pressure LossДокумент8 страницSignificance of 3% PSV Inlet Line Pressure LossKannanGKОценок пока нет

- PerfoEvaluation CentrifugalCompressor WetComprДокумент0 страницPerfoEvaluation CentrifugalCompressor WetComprHussain NouriОценок пока нет

- D 103eДокумент19 страницD 103eCivil FriendОценок пока нет

- Steam TurbinesДокумент45 страницSteam TurbinesFadoooll100% (2)

- LNG-simulator ManualДокумент364 страницыLNG-simulator ManualKostya MukhinОценок пока нет

- Flare Gas Recovery - Olefin Plants PDFДокумент5 страницFlare Gas Recovery - Olefin Plants PDFChem.EnggОценок пока нет

- 7-LNG Large Capacity Single Train AP-X Hybrid LNG ProcessДокумент9 страниц7-LNG Large Capacity Single Train AP-X Hybrid LNG ProcesshfОценок пока нет

- CSP-How To Properly Test Materials Performances?: Sebastien Viale, PH.DДокумент41 страницаCSP-How To Properly Test Materials Performances?: Sebastien Viale, PH.DkikorrasОценок пока нет

- 30M - ConocoPhillips Optimized CascadeДокумент11 страниц30M - ConocoPhillips Optimized CascadeX-Titan Wan de Pirates100% (1)

- UOP - Cat PaperДокумент0 страницUOP - Cat Paperbinapaniki6520Оценок пока нет

- Hydroprocessing Reactor and Process Design To Optimize Catalyst Performance PDFДокумент18 страницHydroprocessing Reactor and Process Design To Optimize Catalyst Performance PDFJupichi TMОценок пока нет

- Bahx IomДокумент54 страницыBahx IomIsaac Flores100% (1)

- Engineering Encyclopedia: Mass and Energy Balance Preparation and UseДокумент33 страницыEngineering Encyclopedia: Mass and Energy Balance Preparation and UseLogeswaran AppaduraiОценок пока нет

- Age10506 PDFДокумент29 страницAge10506 PDFrichard nagilusОценок пока нет

- UOP CCR PlatformingДокумент3 страницыUOP CCR PlatformingRodrigo PerezОценок пока нет

- Off-Design Performance of GTs Without Compressor or Turbine Maps (Thesis)Документ276 страницOff-Design Performance of GTs Without Compressor or Turbine Maps (Thesis)andres_old_condeОценок пока нет

- Uop 666Документ5 страницUop 666jrlr65Оценок пока нет

- LNG Shipping Session I - LNG Small Scale Distribution-Michael Lutz - Linde AGДокумент17 страницLNG Shipping Session I - LNG Small Scale Distribution-Michael Lutz - Linde AGPawan Chaturvedi100% (1)

- PTQ 2009Документ60 страницPTQ 2009Ale SanzОценок пока нет

- Maximising Heat Exchanger CleaningДокумент4 страницыMaximising Heat Exchanger CleaningAlexОценок пока нет

- A Brief Review of Para-Xylene Oxidation To Terephthalic Acid As A Model of Primary C-H Bond ActivationДокумент12 страницA Brief Review of Para-Xylene Oxidation To Terephthalic Acid As A Model of Primary C-H Bond ActivationleniucvasileОценок пока нет

- FOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects DivisionДокумент2 страницыFOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects DivisionBilel MahjoubОценок пока нет

- LNG Technology SelectionДокумент9 страницLNG Technology SelectionWayne MonneryОценок пока нет

- Alkylation Technology StudyДокумент41 страницаAlkylation Technology StudyGabriel ManavellaОценок пока нет

- Heat Exchanger & Furnace Operations and ControlsДокумент6 страницHeat Exchanger & Furnace Operations and Controlsnilesh_092Оценок пока нет

- Combustion Gas TurbinesДокумент33 страницыCombustion Gas Turbinesgavski100% (3)

- Cep 202107 Optimize-ReboilerДокумент11 страницCep 202107 Optimize-Reboilerammar fahmiОценок пока нет

- A High Capacity Floating LNG Design by Barend - PekДокумент15 страницA High Capacity Floating LNG Design by Barend - PekShaka Shalahuddin Shantika PutraОценок пока нет

- Dynamic Simulation LNG ProcessesДокумент4 страницыDynamic Simulation LNG ProcessessppramОценок пока нет

- Evolution of Liquefaction Technical PaperДокумент5 страницEvolution of Liquefaction Technical Paperكريم منيبОценок пока нет

- Hydrocarbon Processing 2019-03Документ88 страницHydrocarbon Processing 2019-03Quang Huy BùiОценок пока нет

- LNG NewДокумент8 страницLNG NewdensandsОценок пока нет

- LNG Vaporisers Technologies Onshore LNG Terminals 1610376799Документ11 страницLNG Vaporisers Technologies Onshore LNG Terminals 1610376799lpczyfansОценок пока нет

- Autoclave LDPE EVAДокумент42 страницыAutoclave LDPE EVAtatarey79100% (1)

- Parallel Compressor Load SharingДокумент2 страницыParallel Compressor Load Sharingejzuppelli8036Оценок пока нет

- Wet Gas CompressionДокумент122 страницыWet Gas CompressionMSОценок пока нет

- Li 2014Документ10 страницLi 2014ArunОценок пока нет

- LNG Plant Cost Optimization 2000Документ28 страницLNG Plant Cost Optimization 2000gonzalo_montero_1100% (2)

- 30G - The Cryogenic Heat ExchangerДокумент7 страниц30G - The Cryogenic Heat ExchangerPutu Indra MahatrisnaОценок пока нет

- Ruby Terminal Handbook Revision 6 (July 2010)Документ51 страницаRuby Terminal Handbook Revision 6 (July 2010)Eng Hui YeoОценок пока нет

- Refinery Power Failures - Causes Costs and SolutionsДокумент14 страницRefinery Power Failures - Causes Costs and SolutionsPradeep SinghОценок пока нет

- Simulation, Optimal Operation and Self Optimisation of Tealarc LNG Plant (2009)Документ48 страницSimulation, Optimal Operation and Self Optimisation of Tealarc LNG Plant (2009)Yang Gul LeeОценок пока нет

- New Technologies For LNGДокумент25 страницNew Technologies For LNGJuan Carlos TaboadaОценок пока нет

- 2012 PTQ q3Документ146 страниц2012 PTQ q3Osvaldo OmarОценок пока нет

- Simulation Reciprocating Compressor in HYSYSДокумент4 страницыSimulation Reciprocating Compressor in HYSYSLenaldy Nuari GarnokoОценок пока нет

- 30B - Liquefaction Processes FundamentalsДокумент31 страница30B - Liquefaction Processes FundamentalsPutu Indra MahatrisnaОценок пока нет

- Start-Up and Operation of GE Frame 9EДокумент23 страницыStart-Up and Operation of GE Frame 9Efazzlie100% (2)

- Execution of LNG Mega TrainsДокумент8 страницExecution of LNG Mega TrainsMelvin MagbanuaОценок пока нет

- Scale UpДокумент4 страницыScale UpMohamed RadwanОценок пока нет

- Cyprus LNG Terminal EngДокумент12 страницCyprus LNG Terminal Engapi-252576407100% (1)

- Emailing 1871Документ8 страницEmailing 1871Adrian YongОценок пока нет

- Ge LNGДокумент28 страницGe LNGRoozbeh P100% (1)

- Ps2 3 KHДокумент14 страницPs2 3 KHBranden933Оценок пока нет

- Sphere FailureДокумент6 страницSphere Failureshivendra99100Оценок пока нет

- Hazop Procedures Kenny Sample PDFДокумент178 страницHazop Procedures Kenny Sample PDFthawdar100% (1)

- Hose & Coupling Failure Rate - Uk HseДокумент59 страницHose & Coupling Failure Rate - Uk HsethawdarОценок пока нет

- NORSOK Standard Jacket PipesДокумент28 страницNORSOK Standard Jacket PipesvuongОценок пока нет

- Engineering Layout of Fuel Tanks in A Tank Farm - J of LPДокумент7 страницEngineering Layout of Fuel Tanks in A Tank Farm - J of LPthawdarОценок пока нет

- HAZOP TrainingДокумент131 страницаHAZOP Trainingtamilnaduchennai100% (14)

- Reverse Circulation Pump PDFДокумент4 страницыReverse Circulation Pump PDFthawdarОценок пока нет

- f00145 PDFДокумент10 страницf00145 PDFthawdarОценок пока нет

- Safe Design Structures-AU CodeДокумент27 страницSafe Design Structures-AU CodethawdarОценок пока нет

- Cooling Tower Thermal DesignДокумент106 страницCooling Tower Thermal Designxuense100% (4)

- f00140 PDFДокумент16 страницf00140 PDFthawdarОценок пока нет

- Gas Line Purging - LPBДокумент8 страницGas Line Purging - LPBthawdarОценок пока нет

- H2Safe LLC Has A Patent On Technology For Safer StorageДокумент1 страницаH2Safe LLC Has A Patent On Technology For Safer StoragethawdarОценок пока нет

- Calculating RiskДокумент13 страницCalculating RisklaharОценок пока нет

- Understand Heat Flux Limitations On Reboiler Design PDFДокумент10 страницUnderstand Heat Flux Limitations On Reboiler Design PDFthawdarОценок пока нет

- Flare TypeДокумент44 страницыFlare TypeBre WirabumiОценок пока нет

- Canned Motor Agitator Catalogues PDFДокумент58 страницCanned Motor Agitator Catalogues PDFthawdarОценок пока нет

- Qra Version FДокумент60 страницQra Version Fbukaro85Оценок пока нет

- A Guide For Flexible Fire Sealing - MCL UnitexДокумент26 страницA Guide For Flexible Fire Sealing - MCL UnitexHanWee LowОценок пока нет

- Steam Trap Sizing Best Practice PDFДокумент5 страницSteam Trap Sizing Best Practice PDFthawdarОценок пока нет

- Canned Motor Pumps in Refinery PDFДокумент2 страницыCanned Motor Pumps in Refinery PDFthawdarОценок пока нет

- Effect of Water Mist On A Confined BlastДокумент12 страницEffect of Water Mist On A Confined BlastthawdarОценок пока нет

- Selecting The Proper Flare System PDFДокумент6 страницSelecting The Proper Flare System PDFjdgh1986100% (1)

- 3 K Constant PDFДокумент1 страница3 K Constant PDFthawdarОценок пока нет

- High Viscosity 2 Phase FlowДокумент8 страницHigh Viscosity 2 Phase FlowPrateechee NaikОценок пока нет

- Gas Line Purging - LPBДокумент8 страницGas Line Purging - LPBthawdarОценок пока нет

- Interview NTD Full TranscriptДокумент9 страницInterview NTD Full TranscriptthawdarОценок пока нет

- Assessment of Vapour Cloud Explosion RiskДокумент53 страницыAssessment of Vapour Cloud Explosion Riskthawdar100% (1)

- Comparsion of Risk Analysis and Preparing TemplateДокумент44 страницыComparsion of Risk Analysis and Preparing TemplatethawdarОценок пока нет

- Assessment of Domino Efect - QRA ApproachДокумент6 страницAssessment of Domino Efect - QRA ApproachthawdarОценок пока нет

- Storage and Wholesale of LPG in Cylinders RegisterДокумент7 страницStorage and Wholesale of LPG in Cylinders RegisterNyasimi GeoffreyОценок пока нет

- Proses Pengolahan GasДокумент66 страницProses Pengolahan GasWahyu HaryadiОценок пока нет

- Workflow EngineeringДокумент12 страницWorkflow EngineeringbayuОценок пока нет

- Mq2-Sensitivity Chars Withlog WithgraphДокумент7 страницMq2-Sensitivity Chars Withlog WithgraphAnil NaikОценок пока нет

- Off Brochure Petronas-Flng LR PDFДокумент8 страницOff Brochure Petronas-Flng LR PDFDak Kaiz100% (1)

- Oil 1Документ1 страницаOil 1Edwin ZachariaОценок пока нет

- The Pioneer 158 - EnglishДокумент34 страницыThe Pioneer 158 - EnglishMuhammad AfzaalОценок пока нет

- Gas & Condensate Production Facility Block DiagramДокумент5 страницGas & Condensate Production Facility Block DiagramAswin TrisaktiОценок пока нет

- LNG TechnologyДокумент52 страницыLNG TechnologykjfensОценок пока нет

- Gail - Company ProfileДокумент20 страницGail - Company ProfilesrinОценок пока нет

- NGL Extraction TechnologiesДокумент7 страницNGL Extraction Technologiescbba2310% (1)

- Presentation To CMDДокумент30 страницPresentation To CMDprati gumrОценок пока нет

- Natural Gas Processing - 2010Документ44 страницыNatural Gas Processing - 2010Ahmed Khamees Shatla100% (1)

- LNG - 2007 Carrier FleetДокумент3 страницыLNG - 2007 Carrier FleetmartctjОценок пока нет

- Line List MasterДокумент165 страницLine List MasteravaisharmaОценок пока нет

- Perenco - Oil and Gas - A Leading Independent Exploration and Production CompanyДокумент3 страницыPerenco - Oil and Gas - A Leading Independent Exploration and Production CompanyCHO ACHIRI HUMPHREYОценок пока нет

- Flow Diagrams PDFДокумент8 страницFlow Diagrams PDFbeshoy naseefОценок пока нет

- Derivatives Info Kit 04 May, 2020: Index / ScripДокумент81 страницаDerivatives Info Kit 04 May, 2020: Index / ScripPrem SagarОценок пока нет

- Ministry of Energy: Myanma Petrochemical EnterpriseДокумент26 страницMinistry of Energy: Myanma Petrochemical EnterprisehtutsweОценок пока нет

- Hook Up Wokshop P&ID Mark Up - 05 Jul 19Документ18 страницHook Up Wokshop P&ID Mark Up - 05 Jul 19gusyahri001Оценок пока нет

- Summary of Oil and Gas in IndonesiaДокумент5 страницSummary of Oil and Gas in IndonesiasynolaОценок пока нет

- MG9 10BMДокумент17 страницMG9 10BMAlfred FerrerОценок пока нет

- City Gas Distribution in IndiaДокумент16 страницCity Gas Distribution in Indiadeepankarchaudhary20100% (1)

- Reservoir ManagementДокумент2 страницыReservoir ManagementShah JeeОценок пока нет

- GTL TechnologyДокумент2 страницыGTL Technologymmsardar76Оценок пока нет

- Technodyne International Limited: Refrigerated Project ListДокумент3 страницыTechnodyne International Limited: Refrigerated Project ListSir AlaaОценок пока нет

- Morgan Stanley OilДокумент19 страницMorgan Stanley Oilephraim_tammyОценок пока нет

- 4 1620 Ignatius Tenny WibowoДокумент18 страниц4 1620 Ignatius Tenny Wibowopuput utomoОценок пока нет

- LPG in World Markets Jan 2016 PDFДокумент32 страницыLPG in World Markets Jan 2016 PDFJcoveОценок пока нет

- Lista Base Instalada LATAM FLESANДокумент19 страницLista Base Instalada LATAM FLESANWiliam SeguraОценок пока нет