Академический Документы

Профессиональный Документы

Культура Документы

RP12E Toc PDF

Загружено:

황산악Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RP12E Toc PDF

Загружено:

황산악Авторское право:

Доступные форматы

Abstract

Process Economics Program Report 12E

LINEAR ALPHA OLEFINS

(December 2008)

This report updates the Process Economics Program technical and economic appraisal of

linear alpha olefin technologies for Shell, Chevron, Ineos, IFP (Institut Francais du Patrole) and

UOP that were last examined in PEP Report 12D (June 2001). In addition, the following new

technologies are evaluated in detailed fashion as customary in the PEP:

SABIC/Linde LAO technology (alpha-SABLINTM)

DuPont LAO technology (VersipolTM)

Shell uses a liganded nickel catalyst system for ethylene oligomerization compared with

Chevron and Ineos, which employ a Ziegler catalyst. IFPs AlphaSelectTM targets the maximizing

of alpha olefin production in the C4C10 range using zirconium-based catalysts. The UOP/Union

Carbides Linear-1TM technology, like Shell, is founded on liganded nickel compounds and,

although focusing on producing C4C10 alpha olefins, can produce the detergent-grade alpha

olefins as well.

SABIC (Saudi Arabia Basic Industries Corporation) is a new entrant in the field of LAO

production business. It recently commercialized a technology jointly with Linde by commissioning

a 150,000 TPA LAO plant In Saudi Arabia. The SABIC/Linde technology is commercially branded

as alpha-SABLIN technology. Like other three main licensors, the SABIC/Linde technology can

also produce all types of LAO products. Additionally, the technology can be operated under

specific catalytic conditions to produce specific ranges (including narrow-range) of the LAO

product also. The technology is based upon a proprietary zirconium based catalyst used in

conjunction with an aluminium alkyl cocatalyst. The current report presents a detailed technoeconomic evaluation of the alpha-SABLIN technology.

DuPonts LAO technology (offered for licensing) is commercially known as Versipol. The

technology has not yet found an application in the form of a plant. DuPont catalyst is comprised

of an iron complex of a selected diimine of a 2,6-diacylpyridine or 2,6-pyridinedicarboxaldehyde.

The catalyst, which is inert at the ambient conditions of reaction, is activated for oligomerization

by an alkylaluminum compound. This technology has also been analyzed in detail.

This report also presents a detailed technical review of the major LAO technologies (Shell,

Chevron-Phillip, Ineos, IFP, UOP, SABIC/Linde, DuPont and Exxon) based upon their patents

issued in the last seven or eight years.

SRI Consulting

PEP Report 12E

SRI Consulting

Report No. 12E

LINEAR ALPHA OLEFINS

by SYED NAQVI

December 2008

A private report by the

PROCESS ECONOMICS PROGRAM

Menlo Park, California 94025

SRIC agrees to assign professionally qualified personnel to the preparation of the

Process Economics Programs reports and will perform the work in conformance with generally

accepted professional standards. No other warranties expressed or implied are made. Because

the reports are of an advisory nature, neither SRIC nor its employees will assume any liability for

the special or consequential damages arising from the Clients use of the results contained in the

reports. The Client agrees to indemnify, defend, and hold SRIC, its officers, and employees

harmless from any liability to any third party resulting directly or indirectly from the Clients use of

the reports or other deliverables produced by SRIC pursuant to this agreement

For detailed marketing data and information, the reader is referred to one of the SRI

Consulting programs specializing in marketing research. THE CHEMICAL ECONOMICS

HANDBOOK Program covers most major chemicals and chemical products produced in the

United States and the WORLD PETROCHEMICALS PROGRAM covers major hydrocarbons and

their derivatives on a worldwide basis. In addition the SRIC DIRECTORY OF CHEMICAL

PRODUCERS services provide detailed lists of chemical producers by company, product, and

plant for the United States, Western Europe, Canada, and East Asia, South America and Mexico.

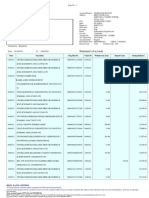

CONTENTS

INTRODUCTION ........................................................................................................

1-1

SUMMARY .................................................................................................................

2-1

COMMERCIAL STATUS ............................................................................................

2-1

INDUSTRIAL PRODUCERS/LICENSORS ................................................................

2-2

LINEAR ALPHA OLEFINS TECHNOLOGIES............................................................

2-2

Shell Higher Olefins Process for Linear Alpha and Internal Olefins...........................

2-3

Chevron Linear Alpha Olefins Process ......................................................................

2-4

Ineos Linear Alpha Olefins Process ...........................................................................

2-5

SABIC/Linear Alpha Olefins Technology (alpha-SABLIN) .........................................

2-6

DuPont Linear Alpha Olefins Technology (Versipol)..................................................

2-7

Institut Francais du Petrole (IFP) LAO Technology (AlphaSelect).............................

2-7

UOP/UCC Linear Alpha Olefins Technology (Linear-1) .............................................

2-9

Exxon Linear Alpha Olefins Technology ....................................................................

2-10

PROCESS ECONOMICS...........................................................................................

2-11

INDUSTRY STATUS..................................................................................................

3-1

CAPACITY, PRODUCTION, AND CONSUMPTION .................................................

3-2

TECHNICAL REVIEW................................................................................................

4-1

TECHNICAL REVIEW ................................................................................................

4-2

Shell Higher Olefins Process for Linear Alpha and Internal Olefins...........................

4-2

Shell Current Research on Oligomerization Catalysts & Process .......................

4-3

Chevron Linear Alpha Olefins Process ......................................................................

4-7

Chevron Current Research on Oligomerization Catalysts & Process..................

4-9

Ineos Linear Alpha Olefins Process ...........................................................................

4-11

Ineos Current Research on Oligomerization Catalysts & Process ......................

4-14

Institut Francais du Petrole (IFP) LAOs Technology (AlphaSelectTM)........................

4-16

IFP Current Research on Oligomerization Catalysts & Process..........................

4-18

SRI Consulting

iii

PEP Report 12E

CONTENTS (Continued)

UOP/UCC Linear Alpha Olefins Technology (Linear-1) .............................................

4-21

UOP/UCC Current Research on Oligomerization Catalysts & Process...............

4-22

SABIC/Linde Linear Alpha Olefins Technology (alpha-Sablin) ..................................

4-25

SABIC/Linde Current Research on Oligomerization Catalysts & Process...........

4-25

DuPont Linear Alpha Olefins Technology (Versipol)..................................................

4-27

Exxon Linear Alpha Olefins Technology ....................................................................

4-28

Exxon Current Research on Oligomerization Catalysts & Process .....................

4-29

SABIC-LINDE LINEAR ALPHA OLEFINS PROCESS .............................................

5-1

PROCESS DESCRIPTION ........................................................................................

5-2

Section 100 - Ethylene Oligomerization .....................................................................

5-2

Section 200 - Alpha Olefins Separation .....................................................................

5-4

PROCESS DISCUSSION...........................................................................................

5-15

Materials of Construction............................................................................................

5-16

Process Waste Effluents ............................................................................................

5-16

COST ESTIMATES ....................................................................................................

5-17

Fixed-Capital Costs ....................................................................................................

5-17

Production Costs ........................................................................................................

5-18

DUPONT LINEAR ALPHA OLEFINS PROCESS .....................................................

6-1

PROCESS DESCRIPTION ........................................................................................

6-2

Section 100 - Ethylene Oligomerization .....................................................................

6-2

Section 200 - Alpha Olefins Separation .....................................................................

6-3

PROCESS DISCUSSION...........................................................................................

6-15

Materials of Construction............................................................................................

6-15

Process Waste Effluents ............................................................................................

6-16

COST ESTIMATES ....................................................................................................

6-16

Fixed-Capital Costs ....................................................................................................

6-16

SRI Consulting

iv

PEP Report 12E

CONTENTS (Concluded)

Production Costs ........................................................................................................

6-17

IFP & UOP LINEAR ALPHA OLEFINS PROCESSES .............................................

7-1

COST ESTIMATES ....................................................................................................

7-8

Fixed-Capital Costs ....................................................................................................

7-8

Production Costs ........................................................................................................

7-8

COST ESTIMATES ....................................................................................................

7-21

Fixed-Capital Costs ....................................................................................................

7-21

Production Costs ........................................................................................................

7-21

PROCESS ECONOMICS OF SHELL, CHEVRON AND INEOS LINEAR ALPHA

OLEFINS TECHNOLOGIES ......................................................................................

8-1

APPENDIX A: PATENT SUMMARY TABLES..................................................................

A-1

APPENDIX B: DESIGN AND COST BASES ....................................................................

B-1

APPENDIX C: CITED REFERENCES...............................................................................

C-1

APPENDIX D: PATENT REFERENCES BY COMPANY..................................................

D-1

APPENDIX E: PROCESS FLOW DIAGRAM ....................................................................

E-1

SRI Consulting

PEP Report 12E

FIGURES

4.1

Ineos Linear Alpha Olefins Process

Poisson Product Distribution for Various Values of X ........................................... 4-13

5.1

SABIC-Linde Linear Alpha-Olefins Process

Flow Diagram ........................................................................................................ E-3

5.2

SABIC-Linde Linear Alpha Olefins Process

Net Production Cost and Product Value as a Function of Ethylene Price ............ 5-23

5.3

SABIC-Linde Linear Alpha Olefins Process

Product Operating Level and Plant Capacity ........................................................ 5-24

6.1

DuPont Linear Alpha-Olefins Process

Flow Diagram ........................................................................................................ E-7

6.2

DuPont Linear Alpha Olefins Process

Net Production Cost and Product Value as a Function of Ethylene Price ............ 6-22

6.3

DuPont Linear Alpha Olefins Process

Product Value as a Function of Plant Operating Level and Plant Capacity.......... 6-23

7.1-A

IFP Linear Alpha Olefins Process

Net Production Cost and Product Value as a Function of Ethylene Price ............ 7-14

7.1-B

UOP Linear Alpha Olefins Process

Net Production Cost and Product Value as a Function of Ethylene Price ............ 7-27

SRI Consulting

vi

PEP Report 12E

TABLES

2.1

Major World Producers of Linear Alpha Olefins .................................................... 2-2

2.2

Commercial Linear Alpha Olefins Technologies

Total Capital Investment........................................................................................ 2-12

2.3

Linear Alpha Olefins Technologies (In Ready-State for Commercialization)

Total Capital Investment........................................................................................ 2-13

2.4

Commerical Linear Alpha Olefins Technologies

Production Costs ................................................................................................... 2-15

2.5

Linear Alpha Olefins Technologies (In Ready-State for Commercialization)

Production Costs ................................................................................................... 2-16

3.1

World Supply/Demand for Linear Alpha Olefins by Region .................................. 3-2

3.2

World Producers of Linear Alpha Olefins .............................................................. 3-3

3.3

Major World Producers of Linear Alpha Olefins .................................................... 3-4

3.4

Linear Alpha Olefins Consumption Breakdown in Major Areas ............................ 3-4

5.1

SABIC-Linde Linear Alpha Olefins Process

Design Bases ........................................................................................................ 5-5

5.2

SABIC-Linde Linear Alpha Olefins Process

Stream Flows......................................................................................................... 5-7

5.3

SABIC-Linde Linear Alpha Olefins Process

Major Equipment ................................................................................................... 5-11

5.4

SABIC-Linde Linear Alpha Olefins Process

Utilities Summary................................................................................................... 5-14

5.5

SABIC-Linde Linear Alpha Olefins Process

Total Capital Investment........................................................................................ 5-19

5.6

SABIC-Linde Linear Alpha Olefins Process

Capital Investment by Section ............................................................................... 5-20

5.7

SABIC-Linde Linear Alpha Olefins Process

Production Costs ................................................................................................... 5-21

6.1

DuPont Linear Alpha Olefins Process

Design Bases ........................................................................................................ 6-5

6.2

DuPont Linear Alpha Olefins Process

Stream Flows......................................................................................................... 6-7

6.3

DuPont Linear Alpha Olefins Process

Major Equipment ................................................................................................... 6-11

SRI Consulting

vii

PEP Report 12E

TABLES (Continued)

6.4

DuPont Linear Alpha Olefins Process

Utilities Summary................................................................................................... 6-14

6.5

DuPont Linear Alpha Olefins Process

Total Captial Investment........................................................................................ 6-18

6.6

DuPont Linear Alpha Olefins Process

Capital Investment by Section ............................................................................... 6-19

6.7

DuPont Linear Alpha Olefins Process

Production Costs ................................................................................................... 6-20

7.1-A

IFP Linear Alpha Olefins Process

Design Bases ........................................................................................................ 7-2

7.2-A

IFP Linear Alpha Olefins Process

Major Equipment ................................................................................................... 7-4

7.3-A

IFP Linear Alpha Olefins Process

Utilities Summary................................................................................................... 7-7

7.4-A

IFP Linear Alpha Olefins Process

Total Capital Investment........................................................................................ 7-10

7.5-A

IFP Linear Alpha Olefins Process

Capital Investment by Section ............................................................................... 7-11

7.6-A

IFP Linear Alpha Olefins Process

Production Costs ................................................................................................... 7-12

7.1-B

UOP Linear Alpha Olefins Process

Design Bases ........................................................................................................ 7-15

7.2-B

UOP Linear Alpha Olefins Process

Major Equipment ................................................................................................... 7-17

7.3-B

UOP Linear Alpha Olefins Process

Utilities Summary................................................................................................... 7-20

7.4-B

UOP Linear Alpha Olefins Process

Total Capital Investment........................................................................................ 7-23

7.5-B

UOP Linear Alpha Olefins Process

Capital Investment by Section ............................................................................... 7-24

7.6-B

UOP Linear Alpha Olefins Process

Production Costs ................................................................................................... 7-25

8.1

Commercial Linear Alpha Olefins Technologies

Total Capital Investment........................................................................................ 8-2

SRI Consulting

viii

PEP Report 12E

TABLES (Concluded)

8.2

Linear Alpha Olefins Technologies (In Ready-State for Commercialization)

Total Capital Investment........................................................................................ 8-3

8.3

Commercial Linear Alpha Olefins Technologies

Production Costs ................................................................................................... 8-4

8.4

Linear Alpha Olefins Technologies (In Ready-State for Commercialization)

Production Costs ................................................................................................... 8-5

SRI Consulting

ix

PEP Report 12E

Вам также может понравиться

- Gap Analysis ReportДокумент62 страницыGap Analysis ReportSAYED91% (23)

- ISO 14001 Step by Step - A practical guide: Second editionОт EverandISO 14001 Step by Step - A practical guide: Second editionРейтинг: 5 из 5 звезд5/5 (1)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsОт EverandModeling, Control, and Optimization of Natural Gas Processing PlantsРейтинг: 5 из 5 звезд5/5 (1)

- Class Action Lawsuit Against Johnson & JohnsonДокумент49 страницClass Action Lawsuit Against Johnson & JohnsonAnonymous GF8PPILW575% (4)

- BLCTE - MOCK EXAM II With Answer Key PDFДокумент20 страницBLCTE - MOCK EXAM II With Answer Key PDFVladimir Marquez78% (18)

- Linear Low Density PolyethyleneДокумент12 страницLinear Low Density PolyethylenedaempiОценок пока нет

- RP44B TocДокумент13 страницRP44B TocPiespi PitwomОценок пока нет

- 14041Документ8 страниц14041mohanspathak0% (1)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersОт EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersРейтинг: 4.5 из 5 звезд4.5/5 (2)

- STEPANOLDCFASNДокумент2 страницыSTEPANOLDCFASNYole IstaОценок пока нет

- MahderДокумент44 страницыMahdermerryzeseОценок пока нет

- Algae FuelДокумент79 страницAlgae FuelZain AliОценок пока нет

- Ácido Acrilico A Partir Da Glicerina IhsДокумент18 страницÁcido Acrilico A Partir Da Glicerina IhsLiège Costa0% (1)

- Report PreviewДокумент79 страницReport PreviewainilubisОценок пока нет

- ButadieneДокумент10 страницButadienearmanОценок пока нет

- 201105151926340.nexant Industry Report 2011Документ40 страниц201105151926340.nexant Industry Report 2011yudhie_7Оценок пока нет

- Health and Safety ManualДокумент19 страницHealth and Safety ManualClarkFedele27100% (1)

- RW2011-15 Toc 183749110917062932Документ6 страницRW2011-15 Toc 183749110917062932Dwi AgungОценок пока нет

- Marketing Plan For A New Product Table of Contents Title Page NoДокумент23 страницыMarketing Plan For A New Product Table of Contents Title Page NoTarandeep SinghОценок пока нет

- SolventInjection RiskAssessmentДокумент38 страницSolventInjection RiskAssessmentFoued DridiОценок пока нет

- Propylene E21a BДокумент108 страницPropylene E21a BMaría Belén JaureguiОценок пока нет

- Process Safety Event PSE Reporting Gui-334210Документ45 страницProcess Safety Event PSE Reporting Gui-334210Abdullah AlbusaidiОценок пока нет

- Op188 9510Документ86 страницOp188 9510A MahmoodОценок пока нет

- Carbonyl Sulfide (COS) Removal From Propane GPAДокумент53 страницыCarbonyl Sulfide (COS) Removal From Propane GPAshitals_18100% (1)

- Guideline Lease Lighting Final062012Документ40 страницGuideline Lease Lighting Final062012Kuljinder VirdiОценок пока нет

- GreenChill Best Practices GuidelineДокумент50 страницGreenChill Best Practices Guidelinezzingenieros pruebaОценок пока нет

- Guide For Designated Pipeline Sections in High-Impact Areas: Best Management PracticeДокумент15 страницGuide For Designated Pipeline Sections in High-Impact Areas: Best Management PracticeaaaОценок пока нет

- IWR 0334 Ed01 - Altitude AER 8.5 - OmniPCXEnterpriseR12.3Документ116 страницIWR 0334 Ed01 - Altitude AER 8.5 - OmniPCXEnterpriseR12.3Asnake TegenawОценок пока нет

- Process Economics Program: ChemicalДокумент9 страницProcess Economics Program: ChemicalRamadan AhmedОценок пока нет

- Audit Shell Gore BayДокумент24 страницыAudit Shell Gore BayMOHAMED ASHRAFXIОценок пока нет

- Acrylic Acid E11a BДокумент106 страницAcrylic Acid E11a BMubarak PatelОценок пока нет

- EATCO - Suez Petrochemicals Complex - Gas To Polyolefins IIДокумент180 страницEATCO - Suez Petrochemicals Complex - Gas To Polyolefins IIAndrzej SzymańskiОценок пока нет

- Solenoid Valve Maintenance Guide - Revision of NP - 7414Документ174 страницыSolenoid Valve Maintenance Guide - Revision of NP - 7414Sebastião Jorge dos SantosОценок пока нет

- HAZOP & Operability Study (Hazop) : ProceduresДокумент32 страницыHAZOP & Operability Study (Hazop) : ProceduresBakri IsmailОценок пока нет

- Baseline Guide Volume 2 Oral Solid Dosage Forms (Third Edition)Документ237 страницBaseline Guide Volume 2 Oral Solid Dosage Forms (Third Edition)nouralhudahullielОценок пока нет

- STRATEGY AND INNOVATION (Repaired)Документ30 страницSTRATEGY AND INNOVATION (Repaired)Uzodinma Victor .nОценок пока нет

- Palsar User GuideДокумент69 страницPalsar User GuideVladimirodipostovОценок пока нет

- Radilon® ENG 2020Документ28 страницRadilon® ENG 2020phu nghiaОценок пока нет

- PEL PakistanДокумент67 страницPEL PakistanK.K.100% (4)

- IOGP 2015pДокумент92 страницыIOGP 2015pAmmar MarОценок пока нет

- 1126HSE-2001 EngДокумент52 страницы1126HSE-2001 EngMohamed HadjkacemОценок пока нет

- APPEA Lifitng and Rigging Guidelines PDFДокумент109 страницAPPEA Lifitng and Rigging Guidelines PDFJosua Sahat Parulian SinagaОценок пока нет

- Attachment Report KPC Ps28 MR Peter Baraza PDFДокумент21 страницаAttachment Report KPC Ps28 MR Peter Baraza PDFIshmael MakhembuОценок пока нет

- Iso 6785 2001 SalmonellaДокумент30 страницIso 6785 2001 SalmonellaAngeles SuarezОценок пока нет

- Internship Report: Maintenance DepartmentДокумент13 страницInternship Report: Maintenance DepartmentMuhammad Salman AttariОценок пока нет

- Ethanol Guidebook For DesignДокумент67 страницEthanol Guidebook For DesignSRINIVASAN TОценок пока нет

- 06 - Troubleshooting of Distillation Columns Using Aspen Plus - Aritra - RILДокумент19 страниц06 - Troubleshooting of Distillation Columns Using Aspen Plus - Aritra - RILCal100% (1)

- Audit Cal TexДокумент27 страницAudit Cal TexMOHAMED ASHRAFXIОценок пока нет

- AP-907-001 Procedure Process DescriptionДокумент66 страницAP-907-001 Procedure Process DescriptionWilliam S. Poisson100% (1)

- Installation, Operation and Maintenance Manual: Rotoclone LVNДокумент23 страницыInstallation, Operation and Maintenance Manual: Rotoclone LVNbertan dağıstanlıОценок пока нет

- Adam IT ReportДокумент36 страницAdam IT Reportadamskilachi1Оценок пока нет

- Process Safety Events-2011 & 2012 DataДокумент28 страницProcess Safety Events-2011 & 2012 DataRichard BaileyОценок пока нет

- ISO 10005 2005 Quality Management Systems - Guidelines For Quality PlansДокумент30 страницISO 10005 2005 Quality Management Systems - Guidelines For Quality PlansTaniaTapiaОценок пока нет

- GTL Technology Small Scale - by V.wanДокумент11 страницGTL Technology Small Scale - by V.wanDebye101Оценок пока нет

- AMPHOSOL1CДокумент2 страницыAMPHOSOL1CJosé Manuel Martínez cedilloОценок пока нет

- Heavy Oil HydrotreatingДокумент15 страницHeavy Oil HydrotreatingSIMON LIUОценок пока нет

- Location and Layout of Dawlance and PellДокумент30 страницLocation and Layout of Dawlance and Pellmaliksuuny0% (1)

- Engineering Encyclopedia: Introduction To Environmental AwarenessДокумент21 страницаEngineering Encyclopedia: Introduction To Environmental Awarenesscvg ertdОценок пока нет

- The Operating Experience of Nitrophosphate Plant PDFДокумент6 страницThe Operating Experience of Nitrophosphate Plant PDFasad100% (1)

- IGFC Techno-EconomicДокумент177 страницIGFC Techno-EconomicKylo RenОценок пока нет

- Solvency PPTДокумент1 страницаSolvency PPTRITU SINHA MBA 2019-21 (Kolkata)Оценок пока нет

- The History of Oil Pipeline RegulationДокумент20 страницThe History of Oil Pipeline Regulationsohail1985Оценок пока нет

- Hearing Committee On Environment and Public Works United States SenateДокумент336 страницHearing Committee On Environment and Public Works United States SenateScribd Government DocsОценок пока нет

- SSRДокумент38 страницSSRsudarsancivilОценок пока нет

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceДокумент3 страницыStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceHiten AhirОценок пока нет

- Sun Server X3-2 (Formerly Sun Fire X4170 M3) : Installation GuideДокумент182 страницыSun Server X3-2 (Formerly Sun Fire X4170 M3) : Installation GuideFrancisco Bravo BustamanteОценок пока нет

- In The Supreme Court of India Criminal Appellate JurisdictionДокумент8 страницIn The Supreme Court of India Criminal Appellate JurisdictionSheetalОценок пока нет

- United States of America Ex Rel. Maria Horta v. John Deyoung, Warden Passaic County Jail, 523 F.2d 807, 3rd Cir. (1975)Документ5 страницUnited States of America Ex Rel. Maria Horta v. John Deyoung, Warden Passaic County Jail, 523 F.2d 807, 3rd Cir. (1975)Scribd Government DocsОценок пока нет

- Aurora Pump VT (FM) PDFДокумент30 страницAurora Pump VT (FM) PDFRizalОценок пока нет

- 10 FixedAsset 21 FixedAsset InitSettingsДокумент32 страницы10 FixedAsset 21 FixedAsset InitSettingsCrazy TechОценок пока нет

- Financial Accounting Module 2Документ85 страницFinancial Accounting Module 2paul ndhlovuОценок пока нет

- The PassiveДокумент12 страницThe PassiveCliver Rusvel Cari SucasacaОценок пока нет

- 5000 English Frequency WordsДокумент234 страницы5000 English Frequency WordsAlice Turnbull100% (1)

- PO-12 - F - 06 1 PA GE 2/ NU MPA GES 2: Învăţământ UniversitarДокумент3 страницыPO-12 - F - 06 1 PA GE 2/ NU MPA GES 2: Învăţământ UniversitarElena FilipОценок пока нет

- Intellectual Property and Domain Name Dispute Resolution in Arbitration in Malaysia - A Practical GuideДокумент29 страницIntellectual Property and Domain Name Dispute Resolution in Arbitration in Malaysia - A Practical GuideDBОценок пока нет

- 101, Shubham Residency, Padmanagar PH ., Hyderabad GSTIN:36AAFCV7646D1Z5 GSTIN/UIN: 36AAFCV7646D1Z5 State Name:, Code: Contact: 9502691234,9930135041Документ8 страниц101, Shubham Residency, Padmanagar PH ., Hyderabad GSTIN:36AAFCV7646D1Z5 GSTIN/UIN: 36AAFCV7646D1Z5 State Name:, Code: Contact: 9502691234,9930135041mrcopy xeroxОценок пока нет

- Farm Animal Fun PackДокумент12 страницFarm Animal Fun PackDedeh KhalilahОценок пока нет

- Letter of Recommendation SchelieДокумент1 страницаLetter of Recommendation Schelieapi-237542168Оценок пока нет

- Chapter 2 Quiz - Business LawДокумент3 страницыChapter 2 Quiz - Business LawRayonneОценок пока нет

- Evolution of Indian Financial SystemДокумент2 страницыEvolution of Indian Financial SystemvivekОценок пока нет

- Service Bulletin 7001Документ14 страницService Bulletin 7001carlosОценок пока нет

- hp6 Final DraftДокумент12 страницhp6 Final Draftapi-389022882Оценок пока нет

- Ethics and Truths in Indian Advertising PDFДокумент2 страницыEthics and Truths in Indian Advertising PDFTrevorОценок пока нет

- 1788-10 Series 310 Negative Pressure Glove Box ManualДокумент10 страниц1788-10 Series 310 Negative Pressure Glove Box Manualzivkovic brankoОценок пока нет

- People v. Calma (Opinion)Документ3 страницыPeople v. Calma (Opinion)Peter Joshua OrtegaОценок пока нет

- Conflict Management HandbookДокумент193 страницыConflict Management HandbookGuillermo FigueroaОценок пока нет

- Godines vs. Court of AppealsДокумент3 страницыGodines vs. Court of AppealsTinersОценок пока нет

- Caf 1 Ia ST PDFДокумент270 страницCaf 1 Ia ST PDFFizzazubair rana50% (2)