Академический Документы

Профессиональный Документы

Культура Документы

CB506 - EN High Performance Decanter Westfalia

Загружено:

LTE002Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CB506 - EN High Performance Decanter Westfalia

Загружено:

LTE002Авторское право:

Доступные форматы

High Performance Economical

Mechanical Separation Division

Westfalia Separator Food Tec

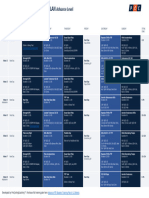

The specs at a glance

3600

2600 2800

Take the Best Separate the Rest

Beer recovery from surplus yeast and tank bottoms

Technical data

Bowl Diameter L/D ratio Speed g-force Motor Rating Speed at 50 Hz Speed at 60 Hz Secondary motor 500 mm 4 max. 3600 min-1 max. 3620

0 12

55 90 kW 3000 min-1 3600 min-1 15 kW

Capacity

Comparison capacity 68,000 l/h

Weights and shipping data

Weight Decanter without motor and auxiliaries Motor (45/110 kW) Motor control net 6500 kg net 340/950 kg net 250 kg

Case for housing with bowl Drive and auxiliaries Dimensions (LxWxH) 3700 x 1550 x 2050 mm Shipping volume 11.8 m3

The comparison capacity is based on different decanters of Westfalia Separator and is below the max. throughput capacity. The effective capacity depends on the clarifiability of the feed mixture, the solids loading in the feed, the admissible residual moisture in the discharged solids and the admissible solids content in the clarified liquid. The machine can be largely adapted to these conditions and requirements.

Highperformance decanter type CB 506

Westfalia Separator Food Tec GmbH

Take the Best Separate the Rest

A company of mg technologies group

Westfalia Separator Food Tec GmbH Werner-Habig-Strae 1 D-59302 Oelde (F.R. Germany) Tel.: +49 (0) 25 22/77-0 Fax: +49 (0) 25 22/77-20 89 Internet: www.westfalia-separator.com E-Mail: info@gea-westfalia.de

9997-0879-000/0901 EN BA

Subject to modification

Printed in Germany

Continuous Efficient

Decanters in Breweries

Decanters are horizontal scroll centrifuges with a cylindrical-conical solid-wall bowl. They are used for the continuous separation of solids from suspensions, clarification of liquids as well as concentration of solids. The new type CB 506 decanter was developed specially for application in breweries. To meet the high requirements of brewing operations, numerous new design developments were realised.

Low wear without mechanical gaskets

Mechanical gaskets are superfluous due to the hydrohermetic non-contacting sealing arrangement. This makes cleaning the decanter much easier and service intervals are longer.

lowmeter

eer

No oxygen pickup due to hydrohermetic seal

Hydrohermetic sealing of the bowl inner chamber prevents oxygen intake into the product during the clarifying process in the decanter.

Optimum solids concentration Full CIP-capability through hygienic design

Optimum integration of the machine in the CIP system of the brewery is possible. Surface quality and gasket dimensions have been optimised to satisfy the high hygiene demands of our customers. Optimum solids concentration is assured by the 2-gear drive for regulating the differential speed. Solids discharge is in a closed system with the possibility of solids recycling.

B 506

Low energy design

The energy consumption has been reduced to a minimum by modifying the inner centripetal pump, reducing the diameter for the solids discharge and opti mising the scroll.

elling yeast

No CO2 loss through blanketing with CO2

The decanter has been designed so that the bowl inner chamber can be permanently blanketed with CO2. On the one hand, this prevents the release of CO2 while, on the other hand, the pressure blanketing can be utilised to support solids discharge from the machine.

Our Features. Your Benefits 20 40 hl/h feed volume Oxygen intake 0 mg/l Fluctuating solids concentrations in the feed between 0 70% by vol. can be processed without dilution Solids concentration in the clear phase < 0.1% for fresh yeast Solids concentration 24 27% DS High economy in comparison to competing technologies Short payback time Continuous operation Short processing times.

Space-saving top-mounted drive

The "tunnel" design makes possible the space-saving arrangement of the drive unit.

Вам также может понравиться

- Sample Minutes of MeetingДокумент3 страницыSample Minutes of MeetingMohamad AzmeerОценок пока нет

- 007: The Stealth Affair ManualДокумент11 страниц007: The Stealth Affair Manualcodigay769Оценок пока нет

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingОт EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingРейтинг: 5 из 5 звезд5/5 (3)

- CentrifugeДокумент2 страницыCentrifugerachma tiaОценок пока нет

- R996B - EnglishДокумент20 страницR996B - EnglishHelio RibeiroОценок пока нет

- AVR On Load Tap ChangerДокумент39 страницAVR On Load Tap ChangerInsan Aziz100% (1)

- Westfalia Separator Ecod DecantersДокумент6 страницWestfalia Separator Ecod DecantersPro.MechanicОценок пока нет

- SPT High Efficiency Phase Separation Internals BrochureДокумент8 страницSPT High Efficiency Phase Separation Internals BrochurefunctionlakeОценок пока нет

- Vacuum Truck SDC-100Документ2 страницыVacuum Truck SDC-100YossiAprianiОценок пока нет

- Gr. 7 Math LM (Q1 To 4)Документ260 страницGr. 7 Math LM (Q1 To 4)Billy Ray C. Castro67% (3)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisОт EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisРейтинг: 5 из 5 звезд5/5 (1)

- Cane PreparationДокумент2 страницыCane PreparationOmar Ahmed ElkhalilОценок пока нет

- High Efficiency Phase Separation Internals BrochureДокумент8 страницHigh Efficiency Phase Separation Internals BrochurePoncho RmzОценок пока нет

- Product Guide GEA Brewery Systems: Engineering For A Better WorldДокумент24 страницыProduct Guide GEA Brewery Systems: Engineering For A Better WorldJose Luis ChapasОценок пока нет

- Rieter - Card C 60Документ8 страницRieter - Card C 60Marathi VideoОценок пока нет

- Industrial Washing MachineДокумент10 страницIndustrial Washing MachineDiêm Công ViệtОценок пока нет

- Appendix 3 FinalДокумент96 страницAppendix 3 FinalMehedi IslamОценок пока нет

- Quench Tower 2Документ16 страницQuench Tower 2achillesntroy100% (2)

- RH6.5 ProspektДокумент14 страницRH6.5 ProspektEslam FaroukОценок пока нет

- Sugar Technology: Technologie GMBHДокумент8 страницSugar Technology: Technologie GMBHBala MuruganОценок пока нет

- Commercial Offer About The PET Washing Line, Capacity 1000 KG/HДокумент13 страницCommercial Offer About The PET Washing Line, Capacity 1000 KG/HAnkitОценок пока нет

- Cat 323D3: Hydraulic ExcavatorДокумент4 страницыCat 323D3: Hydraulic ExcavatorVivek joshiОценок пока нет

- Wheel Loader L 586: Product InformationДокумент16 страницWheel Loader L 586: Product InformationcraigОценок пока нет

- Biomass To Ethanol ProcessДокумент132 страницыBiomass To Ethanol ProcessLTE002Оценок пока нет

- Lemitec Decanter MD60 MD80Документ4 страницыLemitec Decanter MD60 MD80groelantsОценок пока нет

- Sense and NonsenseДокумент263 страницыSense and NonsenseAbdulRehmanKhilji100% (1)

- Sulphonation (Ballestra)Документ20 страницSulphonation (Ballestra)cortezt100% (3)

- 1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivДокумент8 страниц1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivelcarpaneziОценок пока нет

- 12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFДокумент16 страниц12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFadamajaks1985100% (2)

- Reineveld CentrifugeДокумент12 страницReineveld CentrifugeI. Murali KrishnaОценок пока нет

- 3022 B4ce78acДокумент12 страниц3022 B4ce78acmmkattaОценок пока нет

- Presentación ILPRAДокумент45 страницPresentación ILPRAjohanpataОценок пока нет

- De Oiler WEMCOДокумент6 страницDe Oiler WEMCONicolas RehОценок пока нет

- Decanters Disc Stack, Belt Presses, BreweriesДокумент12 страницDecanters Disc Stack, Belt Presses, BreweriesMurali Krishna IndanaОценок пока нет

- DX-250 Data SheetДокумент1 страницаDX-250 Data SheetbehzadОценок пока нет

- Brewing Technology From BriggsДокумент14 страницBrewing Technology From BriggsDuy NguyenОценок пока нет

- Dunham Bush WCOXДокумент24 страницыDunham Bush WCOXWidya PutraОценок пока нет

- Cat 320D3: Hydraulic ExcavatorДокумент4 страницыCat 320D3: Hydraulic ExcavatorVivek joshiОценок пока нет

- Pumps and Grinders For Sludge Transfer E10326Документ4 страницыPumps and Grinders For Sludge Transfer E10326A7mad Sale7Оценок пока нет

- CPC Pumps BrochureДокумент8 страницCPC Pumps BrochureRosa SparksОценок пока нет

- Broadbent Sugar Centrifugal BrochureДокумент0 страницBroadbent Sugar Centrifugal BrochureHossam Mohamed KandilОценок пока нет

- Turbodry®: Agitated Vacuum Pan DryerДокумент5 страницTurbodry®: Agitated Vacuum Pan DryerCak Eko SusiloОценок пока нет

- DFML High-Speed MixerДокумент6 страницDFML High-Speed MixerherumahasiswaОценок пока нет

- Multi-Swt Sde Sse Am04-207Документ6 страницMulti-Swt Sde Sse Am04-207Wayne NefdtОценок пока нет

- CM20201120-dc52b-ce675 CataДокумент16 страницCM20201120-dc52b-ce675 CataSebastian Quezada RamosОценок пока нет

- Bertoli Corporate 2015 en Rev1Документ30 страницBertoli Corporate 2015 en Rev1Andres GarcíaОценок пока нет

- Dynamic HPHT System - FANNДокумент3 страницыDynamic HPHT System - FANNPaola Olivares SanchezОценок пока нет

- Spinning Cone Column Boosts Beer QualityДокумент4 страницыSpinning Cone Column Boosts Beer QualityvsrinivasanchemОценок пока нет

- Basket Centrifugesand REFLUXClassiferspjohau 120413 EMAILДокумент7 страницBasket Centrifugesand REFLUXClassiferspjohau 120413 EMAILJoshua RobinsonОценок пока нет

- CPC Pumps Corporate BrochureДокумент8 страницCPC Pumps Corporate BrochureArdiBarkahОценок пока нет

- Hob ArtДокумент8 страницHob ArtonezienОценок пока нет

- Case CX350B Specifications - 5 - 1Документ20 страницCase CX350B Specifications - 5 - 1Ulises Erica Mendez DufourОценок пока нет

- Rotare Vane PumpsДокумент10 страницRotare Vane PumpsZoran DjurdjevicОценок пока нет

- NETZSCH MasterMill ENДокумент8 страницNETZSCH MasterMill ENاحمد عدنانОценок пока нет

- Tetra Pak Homogenizer 500: Homogenizer or High Pressure Pump For Liquid Food ApplicationsДокумент4 страницыTetra Pak Homogenizer 500: Homogenizer or High Pressure Pump For Liquid Food ApplicationsKhánh HồОценок пока нет

- Plastics Processing TechnologyДокумент31 страницаPlastics Processing TechnologyFrancisco PiñaОценок пока нет

- Haus Environmental EngДокумент16 страницHaus Environmental EngVishartan NayeemuddinОценок пока нет

- Wb213e Pusher Centrifuge SHSДокумент12 страницWb213e Pusher Centrifuge SHSdanielmercadoiqОценок пока нет

- Hybrid Separation - Centrifugation & Cross-Flow Filtration: Westfalia Separator Food TecДокумент8 страницHybrid Separation - Centrifugation & Cross-Flow Filtration: Westfalia Separator Food TecbanerjeeamlanОценок пока нет

- A 924 C Wheeled Excavators A 914 CДокумент32 страницыA 924 C Wheeled Excavators A 914 Coleg-spb50% (4)

- JMT ExtensaДокумент3 страницыJMT ExtensaUgur SahinОценок пока нет

- CD 500 CentrifugeДокумент2 страницыCD 500 Centrifugesaa6383Оценок пока нет

- BSISpecsДокумент2 страницыBSISpecserikraymondpetersenОценок пока нет

- Hidrostal Submersible Immersible PDFДокумент8 страницHidrostal Submersible Immersible PDFariyamanjulaОценок пока нет

- Marine: Highest Level of International ApprovalДокумент4 страницыMarine: Highest Level of International ApprovalddadaraОценок пока нет

- ZH - 2005 RCДокумент99 страницZH - 2005 RCLTE002Оценок пока нет

- Soil WashingДокумент19 страницSoil WashingLTE002Оценок пока нет

- Cal Methodology - Energy Saving - Electrical - HouseholdДокумент15 страницCal Methodology - Energy Saving - Electrical - HouseholdLTE002Оценок пока нет

- High PerformanceДокумент3 страницыHigh PerformanceLTE002Оценок пока нет

- Simulation of High-Speed FillingДокумент13 страницSimulation of High-Speed FillingLTE002Оценок пока нет

- Trigger Sprayer Dynamic Systems ModelДокумент5 страницTrigger Sprayer Dynamic Systems ModelLTE002Оценок пока нет

- Paper - 84 Magnetic FormingДокумент8 страницPaper - 84 Magnetic FormingLTE002Оценок пока нет

- 49 Structure Porosity of Flocculated ADДокумент8 страниц49 Structure Porosity of Flocculated ADLTE002Оценок пока нет

- Paper - 5 Noise MinimizationДокумент5 страницPaper - 5 Noise MinimizationLTE002Оценок пока нет

- Financial Statements Ias 1Документ34 страницыFinancial Statements Ias 1Khalid AzizОценок пока нет

- CV (Martin A Johnson)Документ7 страницCV (Martin A Johnson)kganesanОценок пока нет

- Pulsating Heat Pipe ReportДокумент65 страницPulsating Heat Pipe ReportIdul Azharul HoqueОценок пока нет

- Led Matrix A-788bsДокумент5 страницLed Matrix A-788bsjef fastОценок пока нет

- Tcs IntroДокумент12 страницTcs IntroRomi.Roy1820 MBAОценок пока нет

- JICA Helmya DCC Building FFДокумент4 страницыJICA Helmya DCC Building FFMuhammad ElbarbaryОценок пока нет

- Application of Geosynthetics in Pavement DesignДокумент7 страницApplication of Geosynthetics in Pavement DesignAnonymous kw8Yrp0R5rОценок пока нет

- Ecological Building: Term Project For ME 599Документ32 страницыEcological Building: Term Project For ME 599Junaid AnwarОценок пока нет

- Booklet The 8th JAKINUДокумент20 страницBooklet The 8th JAKINUsamuelionardiОценок пока нет

- Description Features: Maximizing IC PerformanceДокумент1 страницаDescription Features: Maximizing IC Performanceledaurora123Оценок пока нет

- V3 Tool Installation GuideДокумент13 страницV3 Tool Installation GuideLeonardo Floresta NascimentoОценок пока нет

- DrosteДокумент4 страницыDrosteapi-478100074Оценок пока нет

- FTP Booster Training Plan OverviewДокумент1 страницаFTP Booster Training Plan Overviewwiligton oswaldo uribe rodriguezОценок пока нет

- Plastics Library 2016 enДокумент32 страницыPlastics Library 2016 enjoantanamal tanamaОценок пока нет

- Imamsha Maharaj Na Parcha NewДокумент16 страницImamsha Maharaj Na Parcha NewNARESH R.PATELОценок пока нет

- December 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y PДокумент24 страницыDecember 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y Pwpp8284Оценок пока нет

- Seminar ReportДокумент15 страницSeminar ReportNipesh MAHARJANОценок пока нет

- English Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020Документ11 страницEnglish Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020ABEER RATHIОценок пока нет

- Forms of Organizing Activity Games, Methodology of Conducting Activity Games in Physical Education LessonsДокумент4 страницыForms of Organizing Activity Games, Methodology of Conducting Activity Games in Physical Education LessonsAcademic JournalОценок пока нет

- Pte Lastest QuestionsДокумент202 страницыPte Lastest QuestionsIelts Guru ReviewОценок пока нет

- Operaton Q. PДокумент47 страницOperaton Q. PPravin KeskarОценок пока нет

- Jesoc5 1 PDFДокумент15 страницJesoc5 1 PDFfaisal3096Оценок пока нет

- AAR Safety Fact SheetДокумент2 страницыAAR Safety Fact Sheetrogelio mezaОценок пока нет

- Odt Article - Djo - Virtual Population Analysis Improves Orthopedic Implant Design 1 PDFДокумент3 страницыOdt Article - Djo - Virtual Population Analysis Improves Orthopedic Implant Design 1 PDFDragana RajicОценок пока нет