Академический Документы

Профессиональный Документы

Культура Документы

ClassI Division and Zone Protection Methods and Standards

Загружено:

Herbert TuckerАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ClassI Division and Zone Protection Methods and Standards

Загружено:

Herbert TuckerАвторское право:

Доступные форматы

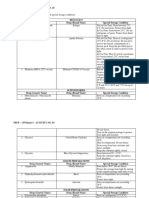

Class I protection method & standards summary (flammable gases, vapors or liquids)

Class I, Division 1 and 2 Protection Methods Applicable Certification Documents Area Protection Methods USA Division 1 Explosionproof enclosures Explosionproof motors and generators Explosionproof industrial control equipment Explosionproof portable lighting units Explosionproof flashlights and lanterns Explosionproof heaters Explosionproof lighting fixtures Explosionproof circuit breakers and enclosures Explosionproof outlet boxes and fittings Explosionproof switches Explosionproof valves Explosionproof receptacle-plug combinations Explosionproof sewage pumps Explosionproof MC cables and sealing fittings UL 1203 UL 674 UL 698 UL 781 UL 783 UL 823 UL 844 UL 877 UL 886 UL 894 UL 1002 UL 1010 UL 1207 UL 2225 Canada CSA 30 CSA 145 CSA 30 CSA 137 CSA 157 CSA 30 CSA 137 CSA 30 CSA 30 CSA 30 CSA 30 CSA 159 CSA 145 CSA 174

Explosionproof other electrical equipment Intrinsic safety (2 fault) Purged/Pressurized (Type X or Y) Division 2 Hermetically sealed Nonincendive circuits, components & equipment Non-Sparking Purged/Pressurized (Type Z) Any Class I, Division 1 method Any Class I, Zone 0, 1 or 2 method

UL 1203 UL 913 NFPA 496 UL 1604

CSA 30 CSA 157 NFPA 496 CSA 213

UL 1604

CSA 213

UL 1604 NFPA 496 ---UL 60079 series

CSA 213 NFPA 496 --CSA E60079 series

Class I, Zone 0, 1 and 2 Protection Methods Applicable Certification Documents Area Protection Methods USA Canada IECEx Scheme IEC 60079-11 Europe EN 50020

Zone 0

Intrinsic safety, 'ia' (2 fault) Class I, Div. 1 intrinsic safety (2 fault) method Special requirements

UL 60079-11

CSA E60079-11

UL 913

CSA 157

---

--EN 50284 EN 50028 EN 50018 EN 50019

--UL 60079-18 UL 60079-1 UL 60079-7

--CSA E79-18 CSA E60079-1 CSA E79-7

--IEC 60079-18 IEC 60079-1 IEC 60079-7

Zone 1

Encapsulation, 'm' Flameproof, 'd' Increased safety, 'e'

Intrinsic safety, 'ib' (1 fault) Oil immersion, 'o' Powder filling, 'q' Pressurization, 'px' or py ('p' for USA & Europe) Any Class I, Zone 0 method Any Class I, Div. 1 method Zone 2 Energy limited, 'nC' ('nL' for Canada & Europe) Hermetically sealed, 'nC' Nonincendive, 'nC' Non-sparking, 'nA' Pressurization, 'nZ ('nP' for Europe) Pressurization, 'pz' ('p' for USA) Restricted breathing, 'nR' Any Class I, Zone 0 or 1 method Any Class I, Div. 1 or 2 method

UL 60079-11 UL 60079-6 UL 60079-5 NFPA 496 -----

CSA E60079-11 CSA E60079-6 CSA E60079-5 CSA E60079-2 -----

IEC 60079-11 IEC 60079-6 IEC 60079-5 IEC 60079-2 -----

EN 50020 EN 50015 EN 50017 EN 50016 -----

UL 60079-15

CSA E60079-15

IEC 60079-15

EN 50021

UL 60079-15 UL 60079-15 UL 60079-15

CSA E60079-15 CSA E60079-15 CSA E60079-15

IEC 60079-15 IEC 60079-15 IEC 60079-15

EN 50021 EN 50021 EN 50021

---

CSA E60079-15

IEC 60079-15

EN 50021

NFPA 496

CSA E60079-2

IEC 60079-2

---

UL 60079-15

CSA E60079-15

IEC 60079-15

EN 50021

---

---

---

---

---

---

---

---

Note: In addition to the IEC 60079 series noted above that address Class I protection methods, there is also a product specific Class I, Zone 1 & 2 certification document for electrical resistance heat tracing, IEC 62086-1. Note: As part of the European ATEX Directive, Category 1 (Zone 0) electrical apparatus shall also comply with EN 50284.

Note: EN 50284 contains special requirements for construction, test and marking of Category 1 (Zone 0) electrical apparatus under the European ATEX Directive. Class I, Division 1 Explosionproof apparatus: "Apparatus enclosed in a case that is capable of withstanding an explosion of a specified gas or vapor that may occur within it and of preventing the ignition of a specified gas or vapor surrounding the enclosure by sparks, flashes, or explosion of the gas or vapor within, and that operates at such an external temperature that a surrounding flammable atmosphere will not be ignited thereby." (See ANSI/UL 1203) Intrinsically safe apparatus: "Apparatus in which all the circuits are intrinsically safe." (See ANSI/UL 913) Intrinsically safe circuit: "A circuit in which any spark or thermal effect is incapable of causing ignition of a mixture of flammable material in air under prescribed test conditions." (See ANSI/UL 913) Intrinsically safe system: An assembly of interconnected intrinsically safe apparatus, associated apparatus, and interconnecting cables in that those parts of the system that may be used in hazardous (classified) locations are intrinsically safe circuits." (See ANSI/UL 913) Purged and Pressurized (Type X or Y): The process of supplying an enclosure with a protective gas at a sufficient flow and positive pressure to reduce the concentration of any flammable gas or vapor initially present to an acceptable level." (See ANSI/NFPA 496) Class I, Division 2 Hermetically sealed equipment: "Equipment sealed against the entrance of an external atmosphere where the seal is made by fusion, for example, soldering, brazing, welding, or the fusion of glass to metal." (See UL 1604) Nonincendive circuit: "A circuit, other than field wiring, in which any arc or thermal effect produced under intended operating conditions of the equipment is not capable, under specified test conditions, of igniting the flammable gasair, or vaporair mixture." (See UL 1604) Nonincendive component: "A component having contacts for making or breaking an incendive circuit and the contacting mechanism is constructed so that the component is incapable of igniting the specified flammable gasair or vaporair mixture. The housing of a nonincendive component is not intended to exclude the flammable atmosphere or contain an explosion." (See UL 1604) Nonincendive equipment: Equipment having electrical/electronic circuitry that is incapable, under normal operating conditions, of causing ignition of a specified flammable gasair, or vaporair mixture due to arcing or thermal means." (See UL 1604) Nonincendive field circuit: "A circuit that enters or leaves the equipment enclosure and that under intended operating conditions is not capable, under the test conditions specified, of igniting the specified flammable gas- or vapor-air mixture." (See UL 1604) Nonincendive field wiring: Wiring that enters or leaves an equipment enclosure and, under normal operating conditions of the equipment, is not capable, due to arcing or thermal effects, of igniting the flammable gasair, or vaporair mixture. Normal operation includes opening, shorting, or grounding the field wiring. (See UL 1604) Nonincendive field wiring apparatus: Apparatus intended to be connected to nonincendive field wiring. (See UL 1604) Non-sparking apparatus: "Apparatus that has no normally arcing parts or thermal effects capable of ignition. Examples of normally arcing parts are relays, circuit breakers, servopotentiometers adjustable resistors, switches, non-latching type connectors and motor brushes. (See UL 1604) Purged and Pressurized (Type Z): The process of supplying an enclosure with a protective gas at a sufficient flow and positive pressure to reduce the concentration of any flammable gas or vapor initially present to an acceptable level." (See ANSI/NFPA 496)

Sealed device: "A device that is constructed so that it cannot be opened, has no external operating mechanisms, and is sealed to restrict entry of an external atmosphere without relying on gaskets. The device may contain arcing parts or internal hot surfaces." (See UL 1604) Class I, Zone 0 Intrinsic safety, ia (2 fault): Type of protection in which any spark or any thermal effect produced under prescribed test conditions, which include normal operation and specified two-fault conditions, is not capable of causing ignition of a given explosive gas atmosphere. (See ANSI/UL 60079-11) Class I, Zone 1 Encapsulation, m: Type of protection where electrical parts that could ignite an explosive atmosphere by either sparking or heating are enclosed in a compound in such a way that this explosive atmosphere cannot be ignited. (See ANSI/UL 60079-18) Flameproof, d: Type of protection where the enclosure will withstand an internal explosion of a flammable mixture that has penetrated into the interior, without suffering damage and without causing ignition, through any joints or structural openings in the enclosure, of an external explosive gas atmosphere consisting of one or more of the gases or vapors for which it is designed. (See ANSI/UL 60079-1) Increased safety, e: Type of protection applied to electrical equipment that does not produce arcs or sparks in normal service and under specified abnormal conditions, in which additional measures are applied so as to give increased security against the possibility of excessive temperatures and of the occurrence of arcs and sparks. (See ANSI/UL 60079-7) Intrinsic safety, ib (1 fault): Type of protection in which any spark or any thermal effect produced under prescribed test conditions, which include normal operation and specified one-fault conditions, is not capable of causing ignition of a given explosive gas atmosphere. (See ANSI/UL 60079-11) Oil immersion, o: Type of protection where electrical equipment is immersed in a protective liquid in such a way that an explosive atmosphere that may be above the liquid or outside the enclosure cannot be ignited. (See ANSI/UL 60079-6) Powder filling, q: Type of protection where electrical parts capable of igniting an explosive atmosphere are fixed in position and completely surrounded by filling material (glass or quartz powder) to prevent the ignition of an external explosive atmosphere. (See ANSI/UL 60079-5) Pressurization, p: Type of protection for electrical equipment that uses the technique of guarding against the ingress of the external atmosphere, which may be explosive, into an enclosure by maintaining a protective gas therein at a pressure above that of the external atmosphere. (See ANSI/NFPA 496) Class I, Zone 2 Type of protection n: Type of protection where electrical equipment, in normal operation, is not capable of igniting a surrounding explosive gas atmosphere and a fault capable of causing ignition is not likely to occur. (See ANSI/UL 60079-15) Hermetically sealed equipment: "Equipment sealed against the entrance of an external atmosphere where the seal is made by fusion, for example, soldering, brazing, welding, or the fusion of glass to metal." (See ANSI/UL 60079-15) Nonincendive circuit, nC: "A circuit, other than field wiring, in which any arc or thermal effect produced under intended operating conditions of the equipment is not capable, under specified test conditions, of igniting the flammable gasair, or vaporair mixture." (See ANSI/UL 60079-15) Nonincendive component, nC: "A component having contacts for making or breaking an incendive circuit and the contacting mechanism is constructed so that the component is incapable of igniting the specified flammable gasair or vaporair mixture. The housing of a

nonincendive component is not intended to exclude the flammable atmosphere or contain an explosion." (See ANSI/UL 60079-15) Nonincendive equipment, nC: Equipment having electrical/electronic circuitry that is incapable, under normal operating conditions, of causing ignition of a specified flammable gasair, vaporair, or dustair mixture due to arcing or thermal means." (See ANSI/UL 60079-15) Nonincendive field circuit, nC: "A circuit that enters or leaves the equipment enclosure and that under intended operating conditions is not capable, under the test conditions specified, of igniting the specified flammable gas- or vapor-air mixture." (See ANSI/UL 6007915) Nonincendive field wiring, nC: Wiring that enters or leaves an equipment enclosure and, under normal operating conditions of the equipment, is not capable, due to arcing or thermal effects, of igniting the flammable gasair, or vaporair. Normal operation includes opening, shorting, or grounding the field wiring. (See ANSI/UL 60079-15) Nonincendive field wiring apparatus, nC: Apparatus intended to be connected to nonincendive field wiring. (See ANSI/UL 60079-15) Non-sparking apparatus, nA: "Apparatus that has no normally arcing parts or thermal effects capable of ignition. Examples of normally arcing parts are relays, circuit breakers, servo-potentiometers adjustable resistors, switches, non-latching type connectors and motor brushes. (See UL 1604) Pressurization, p: Type of protection for electrical equipment that uses the technique of guarding against the ingress of the external atmosphere, which may be explosive, into an enclosure by maintaining a protective gas therein at a pressure above that of the external atmosphere. (See ANSI/NFPA 496) Restricted breathing, nR: "The enclosure relies on tight seals and gaskets to prevent diffusion of the explosive atmosphere into the equipment enclosure. Provision for checking that the restricted breathing properties of the enclosure are maintained is provided." (See ANSI/UL 60079-15) Back to the Technical Summary page For comments or questions on this page, please contact hazloc@ul.com.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 33 KV Transmission Line Design DrawingsДокумент265 страниц33 KV Transmission Line Design DrawingsJuben Bhaukajee89% (9)

- Abs Machinery Feb09Документ798 страницAbs Machinery Feb09xfredx8100% (2)

- Navy FlangesDims MIL F 20042Документ3 страницыNavy FlangesDims MIL F 20042Herbert TuckerОценок пока нет

- DuplexДокумент4 страницыDuplexvivek_recОценок пока нет

- Stainless OverviewДокумент6 страницStainless OverviewClaudia MmsОценок пока нет

- Selecting Process Piping Materials (2007)Документ7 страницSelecting Process Piping Materials (2007)spamfilter02Оценок пока нет

- 4 20ma Loop Design TutorialДокумент4 страницы4 20ma Loop Design TutorialHerbert TuckerОценок пока нет

- Tools Utilities in Free SoftwareДокумент365 страницTools Utilities in Free SoftwareHerbert TuckerОценок пока нет

- Intro TwoWire Transmitters 4 20ma Current LoopДокумент8 страницIntro TwoWire Transmitters 4 20ma Current Loopchandushar1604Оценок пока нет

- Process Flange Dimensions Per The Following Standards: DIN, En, ASME, JIS, GOSTДокумент28 страницProcess Flange Dimensions Per The Following Standards: DIN, En, ASME, JIS, GOSTHerbert Tucker100% (1)

- Stuff Happens Backup and Restore GuideДокумент46 страницStuff Happens Backup and Restore GuideHerbert TuckerОценок пока нет

- Creative An Inclusive ClassroomДокумент3 страницыCreative An Inclusive Classroommuneeba zafarОценок пока нет

- 14DayReset Meals GeneralДокумент40 страниц14DayReset Meals GeneralRiska100% (1)

- Drug Abuse - A Threat To Society, Essay SampleДокумент3 страницыDrug Abuse - A Threat To Society, Essay SampleAnonymous o9FXBtQ6H50% (2)

- Area 1 PROBLEM SET #2Документ10 страницArea 1 PROBLEM SET #2JC YabisОценок пока нет

- LapasiДокумент3 страницыLapasiWenny MellanoОценок пока нет

- Thai Book Lesson From Genius SchoolДокумент85 страницThai Book Lesson From Genius SchoolAlexis L.D (Riker94)Оценок пока нет

- Project Report On MKT Segmentation of Lux SoapДокумент25 страницProject Report On MKT Segmentation of Lux Soapsonu sahОценок пока нет

- Harvard Referencing GuideДокумент6 страницHarvard Referencing GuideKhánh Nguyên VõОценок пока нет

- Physio Essay #4Документ2 страницыPhysio Essay #4Maria Margarita Chon100% (1)

- ARS122 Engine Spare Part Catalogue PDFДокумент134 страницыARS122 Engine Spare Part Catalogue PDFIrul Umam100% (1)

- Responsibility Accounting Practice ProblemДокумент4 страницыResponsibility Accounting Practice ProblemBeomiОценок пока нет

- Air MassesДокумент22 страницыAir MassesPrince MpofuОценок пока нет

- Ctaa040 - Ctaf080 - Test 4 Solution - 2023Документ7 страницCtaa040 - Ctaf080 - Test 4 Solution - 2023Given RefilweОценок пока нет

- Damasco - Cpi - Activity No. 10Документ18 страницDamasco - Cpi - Activity No. 10LDCU - Damasco, Erge Iris M.Оценок пока нет

- 2nd Term Biology Ss3Документ20 страниц2nd Term Biology Ss3Wisdom Lawal (Wizywise)Оценок пока нет

- Mock Test MCQ 2017Документ18 страницMock Test MCQ 2017Alisha ChopraОценок пока нет

- Keandalan Bangunan Rumah SusunДокумент9 страницKeandalan Bangunan Rumah SusunDewi ARimbiОценок пока нет

- Protein Metabolism and Urea Recycling in Rodent HibernatorsДокумент5 страницProtein Metabolism and Urea Recycling in Rodent HibernatorsBud Marvin LeRoy RiedeselОценок пока нет

- Tinh Toan Tang AP Cau Thang - CT Qui LongДокумент20 страницTinh Toan Tang AP Cau Thang - CT Qui Longntt_121987Оценок пока нет

- Bonding and Adhesives in DentistryДокумент39 страницBonding and Adhesives in DentistryZahn ÄrztinОценок пока нет

- June 2019Документ64 страницыJune 2019Eric SantiagoОценок пока нет

- Exterior Wall PrimerДокумент2 страницыExterior Wall PrimerAsian PaintsОценок пока нет

- Week 2 - ValEdДокумент30 страницWeek 2 - ValEdBernadette MacalindongОценок пока нет

- JAR Part 66 Examination Mod 03Документ126 страницJAR Part 66 Examination Mod 03Shreyas PingeОценок пока нет

- 18-MCE-49 Lab Session 01Документ5 страниц18-MCE-49 Lab Session 01Waqar IbrahimОценок пока нет

- Julie Trimarco: A Licensed Speech-Language PathologistДокумент5 страницJulie Trimarco: A Licensed Speech-Language PathologistJulie TrimarcoОценок пока нет

- Red Bank Squadron - 01/22/1942Документ28 страницRed Bank Squadron - 01/22/1942CAP History LibraryОценок пока нет

- Quiz BowlДокумент36 страницQuiz BowlSherry GonzagaОценок пока нет

- Texas Steering and Insurance DirectionДокумент2 страницыTexas Steering and Insurance DirectionDonnie WeltyОценок пока нет