Академический Документы

Профессиональный Документы

Культура Документы

12.5 Site Specific Quality Control Plan Template

Загружено:

loveanbu24Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

12.5 Site Specific Quality Control Plan Template

Загружено:

loveanbu24Авторское право:

Доступные форматы

SITE SPECIFIC QUALITY CONTROL PLAN

- Work Safely - Build it Right - Communicate Clearly - Document Accurately

Contractor:

12.5

Date Prepared: ___/___/___ Revision: 8 Office Phone: LeChase Project #:

Subcontractor Minimum Requirements

Prepared by: Project Name: Location: Scope of Services: Owner Name:

Project Start: ___/___/___, Finish: ___/___/___

LeChase Quality Team

Project Manager: Phone #: Phone #: Email:

Site Quality Representative:

(Responsible for this project's Job Specific Quality Program)

Email:

Subcontractor Quality Team

Project Manager: Phone #: Phone #: Email:

Site Quality Representative:

Email:

(Responsible for this project's Job Specific Quality Control Plan)

Quality Program Objective:

The principle objective of this Quality Control Plan is to provide our customer with the specified materials and high Quality workmanship that meets or exceeds their expectations. To accomplish this, both management and its employees are committed to continuous improvement in the quality of our products and services we provide. This Job Specific Quality Control Plan has been established to ensure that all work performed by employees or tiered subcontractors of ________________________________ meet all contractual and regulatory requirements. Your Quality Team (defined above) takes total responsibility for the implementation of this program and its success for your scope of work on this project.

1 of 3

6/14/2010

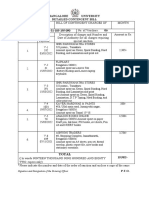

Quality Control Requirements

Topic: Required Actions & Documentation: Initial Keep an organized file of all required documents up to date and on site at all Documentation Control times. Communicate with LeChase when the inspection or test reports will be completed & the frequency of submission. Conform to all contractual requirements and use the LeChase Submittal Cover Page for this project. If the project specifications do not call out what is to be submitted on then the Project Team is to create a list of what the requirements will be. Complete the Material & Equipment Verification List for all materials and equipment. This is an active document that will be updated though the course of construction. LeChase will receive these updates on a weekly basis or on a schedule that is agreed to up front. (See attached "Material & Equipment Verification List" template) Identify any special requirements and documentation specific to your contract. Utilize a Storage and Handling Log to organize this information. (See attached "Material / Equipment Storage & Handling Procedures Log" template) Attendance is mandatory by field supervision and/or Project Manager. No documentation required.

Submittal Process

100% Material & Equipment Verification

Storage & Handling of Materials / Equipment Pre-Installation Meetings

Trade specific Quality Control Checklists will be utilized on an area by area basis. All checklists are to be signed off by your Quality Control Quality Control Checklists Inspector & the LeChase Quality Inspector. Any special & Special Documentation documentation will be completed and turned over to LeChase with your completed checklists as required. All contractual requirements will be listed first and turned in with your plan. Tests & Inspections will be witnessed by your Quality Control Inspector and any documentation or reports will be turned over to the LeChase Quality Supervisor within 72 hours. Participation in weekly field inspections is required. Track all contractual and non-contractual inspections or tests on a Testing & Inspection Log. (See attached "Testing & Inspection Log" template) Full participation from your company is mandatory in documenting and rectifying Non-Conformances. All issues will be remediated per the approved corrective action and completed in an excepted time frame. All issues will be looked at on a week by week basis during inspections. Updated status of each will be required. Take them, take them often, and keep them organized by areas and by date. Submission requirements are on a project by project basis. Ask the LeChase Project Manager what your requirements will be. The master as-built set kept by LeChase in the field office will be updated by your field Supervisor on a weekly basis.

Testing & Inspections

Non-Conformance

Progress Photos

As-built Drawings

2 of 3

6/14/2010

Quality Assurance Contract Requirements

Item # Description Action / Documentation Required

-

Instructions: Please utilize the above spreadsheet to indicate each contractual requirement (test, inspection, certification, mockups, etc) that will be performed for your scope of work. These requirements can be found in the following places but not limited to the specifications, drawings, or the LeChase Master Matrix. Also, indicate in the right hand column what actions or documents are necessary. Note: All attached templates are LeChase documents that the subcontractor is welcome to utilize. If a subcontractor chooses to create their own or already has their own, they must meet or exceed the LeChase minimum requirements. This will be determined by the LeChase Site Quality Representative for this project. The following are the required documents to be a part of every Quality Control Plan: - The "Site Specific Quality Control Plan" (LeChase Document) - "Material & Equipment Verification List" (at initial submission it should have all high risk and long lead items listed) (LeChase or Subcontractor) - "Material / Equipment Storage & Handling Procedure Log" as required (LeChase or Subcontractor) - Trade specific Quality Control checklists and special documents (LeChase or Subcontractor) - "Testing & Inspection Report" as required (LeChase or Subcontractor) - "Testing & inspection Log" mandatory - at a minimum will include all contractually required tests or inspections (LeChase or Subcontractor)

Signature: Subcontractor Site Quality Representative or Project Manager

Date:

Reviewed by: LeChase Site Quality Representative

Date:

3 of 3

6/14/2010

Вам также может понравиться

- Quality Control PlanДокумент13 страницQuality Control PlanMohammad Taqi HamidiОценок пока нет

- Road Construction Essentials QA/QC PlanДокумент10 страницRoad Construction Essentials QA/QC Planrafiullah amireeОценок пока нет

- N-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFДокумент10 страницN-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFRaziKhanОценок пока нет

- ER288-Rebar Test PlanДокумент4 страницыER288-Rebar Test PlanalfieОценок пока нет

- 01 ITP TemplateДокумент6 страниц01 ITP TemplateHelsy FuentesОценок пока нет

- Method Statement For Casting Blinding ConcreteДокумент2 страницыMethod Statement For Casting Blinding ConcreteCrazyBookWorm100% (2)

- QUALITY CONTROL PLAN-Rev-CДокумент10 страницQUALITY CONTROL PLAN-Rev-Csivagnanam s100% (1)

- Project Quality Plan: SSBVPL/GPL/QCДокумент23 страницыProject Quality Plan: SSBVPL/GPL/QCmayank dixitОценок пока нет

- Method Statement of Mass Concrete Block Precast WorksДокумент41 страницаMethod Statement of Mass Concrete Block Precast WorksShams JogОценок пока нет

- Civil Construction ProcedureДокумент6 страницCivil Construction Procedureคุณพ่อน้อง บิ๊กบอสОценок пока нет

- PQP EpldtДокумент8 страницPQP Epldtmartin leeОценок пока нет

- Quality Management Plan-MacksamsДокумент12 страницQuality Management Plan-Macksamssahanun yakubu100% (1)

- 027 ITP For Pre Cast Concrete PDFДокумент27 страниц027 ITP For Pre Cast Concrete PDFlinga2014Оценок пока нет

- DieselStorage Tank Refurbishment - MOSДокумент6 страницDieselStorage Tank Refurbishment - MOSSaran rasayaОценок пока нет

- Method Statement For Cement Board Dry Wall PartitionsДокумент10 страницMethod Statement For Cement Board Dry Wall PartitionsComet GroupОценок пока нет

- ITP For Civil WorksДокумент15 страницITP For Civil WorksNoor A Qasim100% (8)

- Quality Assurance Plan For Building ConstructionДокумент18 страницQuality Assurance Plan For Building ConstructionAmit Kumar Pandey100% (1)

- Inspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CДокумент1 страницаInspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CYash SharmaОценок пока нет

- Method Statement For Installation of Wooden Flooring PDFДокумент18 страницMethod Statement For Installation of Wooden Flooring PDFChris EnyinnayaОценок пока нет

- QAQC GuidelinesДокумент19 страницQAQC GuidelinesBonaventure Nzeyimana100% (1)

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsДокумент7 страниц84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoОценок пока нет

- 17 Kerb MethodologyДокумент2 страницы17 Kerb MethodologyAnish Panchal100% (2)

- Qa QC ChecklistДокумент1 страницаQa QC ChecklistCeedee ValenciaОценок пока нет

- Construction Quality Control PlanДокумент18 страницConstruction Quality Control PlanKhawaja Arslan Ahmed83% (6)

- Acmc-Qaqc-001 - Quality Observation Report Form - QorДокумент12 страницAcmc-Qaqc-001 - Quality Observation Report Form - QorerwinОценок пока нет

- Method Statement For Claustra Block Works.Документ12 страницMethod Statement For Claustra Block Works.sathiyaprasath80% (5)

- Rev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectДокумент11 страницRev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectM Waqas HabibОценок пока нет

- Quality Control Plan SufiДокумент23 страницыQuality Control Plan SufiSufi Shah Hamid JalaliОценок пока нет

- 021-Itp For Site Preparation and Earth Works PDFДокумент6 страниц021-Itp For Site Preparation and Earth Works PDFKöksal Patan100% (2)

- Project Qa/Qc Plan: Wade Adams Contracting LLCДокумент21 страницаProject Qa/Qc Plan: Wade Adams Contracting LLCnice hossainОценок пока нет

- Construction Method StatementДокумент18 страницConstruction Method StatementAziz RahmanОценок пока нет

- Epoxy Painting MethodДокумент3 страницыEpoxy Painting MethodKaram MoatasemОценок пока нет

- PQPДокумент16 страницPQPMuhammad ShazwanuddinОценок пока нет

- Inspection Checklist: Concrete Screed PlacementДокумент2 страницыInspection Checklist: Concrete Screed PlacementZiaul HaqОценок пока нет

- QA-QC PlanДокумент18 страницQA-QC PlanSen IMO67% (3)

- Civil Works Inspection - QA - QC-Construction LTDДокумент1 страницаCivil Works Inspection - QA - QC-Construction LTDNashrul KarimОценок пока нет

- Quality PlanДокумент21 страницаQuality PlanTAHER AMMAR88% (8)

- Project Quality Plan (PQP) Submittal Checklist: Available Y / N Adequate Y / NДокумент3 страницыProject Quality Plan (PQP) Submittal Checklist: Available Y / N Adequate Y / NMylean Monterola100% (3)

- Method Statement For Concrete WorksДокумент12 страницMethod Statement For Concrete WorksRajarajan RajaОценок пока нет

- QC Inspection and Test PlanДокумент9 страницQC Inspection and Test PlanAjaz MalikОценок пока нет

- Method - Statement - For Aluminum Door and Window InstallationДокумент10 страницMethod - Statement - For Aluminum Door and Window Installationirfan khan100% (1)

- Quality ManualДокумент4 страницыQuality ManualAli IrvaliОценок пока нет

- Field Quality Assurance ProgrammeДокумент8 страницField Quality Assurance ProgrammeSiddhardha MsvОценок пока нет

- CRSE-SA-T-775 Monthly Quality Management Report For The Month of July 2020Документ65 страницCRSE-SA-T-775 Monthly Quality Management Report For The Month of July 2020Ahmad Assad mrednОценок пока нет

- Construction MethodologyДокумент15 страницConstruction MethodologyLorens RiezaОценок пока нет

- Piling Project Quality Plan 1 PDFДокумент74 страницыPiling Project Quality Plan 1 PDFNazirul Naim Zamri100% (1)

- MTS-Hard Landscaping & Road WorksДокумент7 страницMTS-Hard Landscaping & Road WorksAshimolowo BabatundeОценок пока нет

- Mobilization Work MSДокумент18 страницMobilization Work MSjones100% (3)

- ITP For Concrete Paving WorkДокумент15 страницITP For Concrete Paving WorkShewale Pravin100% (1)

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Документ3 страницыInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0ResearcherОценок пока нет

- Method Statement: Construction CompanyДокумент8 страницMethod Statement: Construction CompanyDhimas Surya NegaraОценок пока нет

- Project Quality Plan (8.7.2012)Документ27 страницProject Quality Plan (8.7.2012)Vinodh Palanichamy75% (4)

- External QC Inspection Request-Report FormДокумент1 страницаExternal QC Inspection Request-Report FormEdison WalitОценок пока нет

- Quality Plan 2 PDF FreeДокумент21 страницаQuality Plan 2 PDF FreeEng.arifОценок пока нет

- Itp - Building WorksДокумент15 страницItp - Building WorksVasilica BArbarasaОценок пока нет

- Project Quality Plan (PQP) (Project Construction and Management)Документ23 страницыProject Quality Plan (PQP) (Project Construction and Management)Imran ZamanОценок пока нет

- CAS090503QAQCPlan PDFДокумент20 страницCAS090503QAQCPlan PDFvyly1723Оценок пока нет

- Acdi-Claveria, Apc Dairy Farm Milking Parlour - (Project Implementation Plan)Документ11 страницAcdi-Claveria, Apc Dairy Farm Milking Parlour - (Project Implementation Plan)Anna Lorraine AquinoОценок пока нет

- Important Core Knowledge For QA - QC Civil Engineers or InspectorsДокумент7 страницImportant Core Knowledge For QA - QC Civil Engineers or Inspectorsதமிழ் தமிழ்Оценок пока нет

- Construction Quality ControlДокумент57 страницConstruction Quality ControlMark GalleposoОценок пока нет

- Workplace Safety Audit ChecklistДокумент4 страницыWorkplace Safety Audit Checklistloveanbu24Оценок пока нет

- 5S - Sort FormДокумент2 страницы5S - Sort Formloveanbu24Оценок пока нет

- Short Notes On Laser Radiation: Health Sciences AuthorityДокумент11 страницShort Notes On Laser Radiation: Health Sciences Authorityloveanbu24Оценок пока нет

- 2007 Form 5S InstructionsДокумент25 страниц2007 Form 5S Instructionsloveanbu24Оценок пока нет

- Bolt Load Software: ANSI B16.5 Api 6A Api 17Sv Norsok L-005 SPO Compact Flanges Taperlok FlangesДокумент2 страницыBolt Load Software: ANSI B16.5 Api 6A Api 17Sv Norsok L-005 SPO Compact Flanges Taperlok Flangesloveanbu24Оценок пока нет

- Tool Box Talk 2-07 Excavation Egress - OSHAДокумент3 страницыTool Box Talk 2-07 Excavation Egress - OSHAloveanbu24Оценок пока нет

- 1.8 Sample Customer Feedback Form: Home Reference Section 1. NASA Specific Cost Estimating ResourcesДокумент2 страницы1.8 Sample Customer Feedback Form: Home Reference Section 1. NASA Specific Cost Estimating Resourcesloveanbu24Оценок пока нет

- 4 DanaДокумент88 страниц4 Danaloveanbu24Оценок пока нет

- Toolbox Meeting Record FormДокумент1 страницаToolbox Meeting Record Formloveanbu24100% (1)

- Tool Box Talk 8-05 Job Electrical SafetyДокумент2 страницыTool Box Talk 8-05 Job Electrical Safetyloveanbu240% (1)

- 105 - KeroseneДокумент13 страниц105 - Keroseneloveanbu24Оценок пока нет

- Pumps: Suggested Specifications Submersible Sump Pump Type SMДокумент4 страницыPumps: Suggested Specifications Submersible Sump Pump Type SMloveanbu24Оценок пока нет

- Topcable Eng 01 Topflex VK H05VK H07VKДокумент1 страницаTopcable Eng 01 Topflex VK H05VK H07VKloveanbu24Оценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Combined Workforce RIDDOR Accident Frequency Rate - National PerformanceДокумент1 страницаCombined Workforce RIDDOR Accident Frequency Rate - National Performanceloveanbu24Оценок пока нет

- Working Safely at Heights ChecklistsДокумент2 страницыWorking Safely at Heights Checklistsloveanbu24Оценок пока нет

- 4.5.22 Corrective and Preventive Actions Procedure 2011Документ3 страницы4.5.22 Corrective and Preventive Actions Procedure 2011loveanbu24Оценок пока нет

- Govt. College of Nusing C.R.P. Line Indore (M.P.) : Subject-Advanced Nursing PracticeДокумент17 страницGovt. College of Nusing C.R.P. Line Indore (M.P.) : Subject-Advanced Nursing PracticeMamta YadavОценок пока нет

- Fluphenazine Drug Study!Документ3 страницыFluphenazine Drug Study!EmJay Balansag100% (3)

- HA2 Week 9: Lesson 1 Homework: X y X yДокумент9 страницHA2 Week 9: Lesson 1 Homework: X y X ySebastien TaylorОценок пока нет

- Professionalism in The Dental Office, Part One: I Chairside Conscience IДокумент3 страницыProfessionalism in The Dental Office, Part One: I Chairside Conscience IKingjokerОценок пока нет

- Souvenir As Tourism ProductДокумент13 страницSouvenir As Tourism ProductThree Dimensional Product DesignОценок пока нет

- Data Structures - Python 3.9.6 DocumentationДокумент15 страницData Structures - Python 3.9.6 DocumentationShahab-ud-din KhanОценок пока нет

- Truth Beyond Paradox (Final Download)Документ217 страницTruth Beyond Paradox (Final Download)andreas waneyОценок пока нет

- Placer Deposits: Submitted By: Bhaskarjyoti Rajkhowa, 5 Sem, Roll No.-07Документ2 страницыPlacer Deposits: Submitted By: Bhaskarjyoti Rajkhowa, 5 Sem, Roll No.-07Day 2 DayОценок пока нет

- Astm A490M Heavy Hex Structural Bolts (Metric)Документ7 страницAstm A490M Heavy Hex Structural Bolts (Metric)cragmarОценок пока нет

- Discrete Mathematics MATH 006 (TIP Reviewer)Документ12 страницDiscrete Mathematics MATH 006 (TIP Reviewer)James LindoОценок пока нет

- Philippine Urban TreesДокумент83 страницыPhilippine Urban TreesKit LorenzОценок пока нет

- Stainless Tubing in BiotechДокумент14 страницStainless Tubing in BiotechClaudia MmsОценок пока нет

- UA&P-JD Application FormДокумент4 страницыUA&P-JD Application FormuapslgОценок пока нет

- Folio SainsДокумент15 страницFolio SainsMohammad Afifi Rohman80% (5)

- Thermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eДокумент3 страницыThermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eAnas ImdadОценок пока нет

- BIO331 Group Assignment 1Документ3 страницыBIO331 Group Assignment 1andra amartyaОценок пока нет

- À Bout de Souffle (Breathless) : Treatment by François TruffautДокумент10 страницÀ Bout de Souffle (Breathless) : Treatment by François TruffautAlex KahnОценок пока нет

- First ContingencyДокумент2 страницыFirst Contingencymanju bhargavОценок пока нет

- Johnson Power Pumping CatalogДокумент24 страницыJohnson Power Pumping CatalogAlvaro Patricio Etcheverry TroncosoОценок пока нет

- The Atom: Cornell Doodle NotesДокумент22 страницыThe Atom: Cornell Doodle NotesSalina SalujaОценок пока нет

- ISC HydroCom ComparisonДокумент22 страницыISC HydroCom Comparisonrahilshah100Оценок пока нет

- The Sparrow: Srijani Bhowmick Class VДокумент12 страницThe Sparrow: Srijani Bhowmick Class VsgphycoОценок пока нет

- Business Plan PDFДокумент86 страницBusiness Plan PDFNicholas SalisОценок пока нет

- Week Logical FallaciesДокумент79 страницWeek Logical FallaciesSaqib AbbasОценок пока нет

- Clean and GreenДокумент75 страницClean and Greenkevin ray danielОценок пока нет

- MIS Downloads Requirement Specification Document Example 2Документ14 страницMIS Downloads Requirement Specification Document Example 2Rajashree PatilОценок пока нет

- Wap-3101 Um V1.0 PDFДокумент34 страницыWap-3101 Um V1.0 PDFhtweakОценок пока нет

- Mod6 4Документ10 страницMod6 4mn3mОценок пока нет

- AwanishTrivedi PastryChefДокумент3 страницыAwanishTrivedi PastryChefChandra MohanОценок пока нет

- Revenge, Hypnotism, and Oedipus in OldboyДокумент13 страницRevenge, Hypnotism, and Oedipus in OldboyAdrián PiqueroОценок пока нет