Академический Документы

Профессиональный Документы

Культура Документы

Module 7 Assignment Info

Загружено:

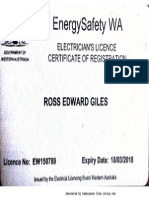

Ross GilesАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Module 7 Assignment Info

Загружено:

Ross GilesАвторское право:

Доступные форматы

Conductor sizing and protection o Conductor sizing: methodology and definition o Overcurrent protection principles o Practical values for

a protective scheme o Location of protective devices o Conductors in parallel Practical method for determining the smallest allowable cross-sectional area of circuit conductors o General method for cable sizing o Recommended simplified approach for cable sizing o Busbar trunking systems Determination of voltage drop o Maximum voltage drop limit o Calculation of voltage drop in steady load conditions Short-circuit current o Short-circuit current at the secondary terminals of a MV/LV distribution transformer o 3-phase short-circuit current (Isc) at any point within a LV installation o Isc at the receiving end of a feeder as a function of the Isc at its sending end Particular cases of short-circuit current o Calculation of minimum levels of short-circuit current o Verification of the withstand capabilities of cables under short-circuit conditions Protective earthing conductor o Connection and choice for protective earthing conductor o Sizing of protective earthing conductor o Protective conductor between MV/LV transformer and the main general distribution board (MGDB) o Equipotential conductor The neutral conductor o Sizing the neutral conductor o Protection of the neutral conductor o Breaking of the neutral conductor o Isolation of the neutral conductor

BY its very nature, electricity is as dangerous a substance as anyone can work with. When adjacent cables carrying threephase power currents suffer a short circuit fault, the induced magnetic fields result in the cables experiencing significant opposing forces. If the cables are incorrectly or poorly restrained, the opposing forces can free them from their restraints, resulting in costly damage to cables and cable management systems; it can also result in expensive production down time and risk to life. A video showing the dramatic, damaging effects of short circuit faults is available from IPD Industrial Products. In addition to the possible risks of short circuit faults, the video also illustrates the extensive testing done by the company to ensure complete protection from faults. Cable cleats are designed to fix, retain and support cables. Correctly selected and applied cleats will contain cables in the event of a fault, and will enable the circuit to be restored once the fault has been repaired. Selection of a correct cleat begins during the design of a project: the force between cables is calculated to determine the cleat type and strength required. A number of other factors then need to be taken into account, including physical performance, mounting surface, installation space and the environment in which the installation will operate. Only when these have all been considered can a project designer be confident in specifying the correct cleats for an installation. The recent introduction of IEC61914:2009 Cable Cleats for Electrical Installations was a huge boost for Ellis Patents, the world-leading manufacturer of cable cleats. The companys products are used extensively in offshore and onshore environments and all are comprehensively tested and certified by third parties.

In Australia and New Zealand, Ellis cable cleats are managed exclusively by IPD. The company can also provide complete technical support and product application engineering solutions. More information can be found on the IPD

Вам также может понравиться

- Arc Flash Application Guide PDFДокумент16 страницArc Flash Application Guide PDFGilberto SanchezОценок пока нет

- NewДокумент4 страницыNewRoss GilesОценок пока нет

- Arc Flash CalculationДокумент8 страницArc Flash CalculationRoss GilesОценок пока нет

- Testing Tagging Work InstructionДокумент3 страницыTesting Tagging Work InstructionRoss GilesОценок пока нет

- NewDoc 11Документ1 страницаNewDoc 11Ross GilesОценок пока нет

- XR Impact On CTДокумент3 страницыXR Impact On CTpulasta109Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Fire Service ManualOS16Документ54 страницыFire Service ManualOS16enviro100% (1)

- Fiitjee Test PaperДокумент23 страницыFiitjee Test PaperNikita GargОценок пока нет

- LVDC Distribution SystemДокумент52 страницыLVDC Distribution SystemAhmad TouqirОценок пока нет

- Air ConditioningДокумент57 страницAir Conditioningnim_gourav1997Оценок пока нет

- Applied Marine Control Systems and AutomationДокумент15 страницApplied Marine Control Systems and AutomationSrinivasan PrakashОценок пока нет

- Review InputsДокумент2 страницыReview InputsSumit SharmaОценок пока нет

- Simple Harmonic MotionДокумент9 страницSimple Harmonic MotionJay JembeОценок пока нет

- Comparison of ExperimentalДокумент19 страницComparison of ExperimentalamourqtriОценок пока нет

- Dataline Surge ProtectionДокумент2 страницыDataline Surge ProtectionMansoor AbbasОценок пока нет

- United States Patent: ShkondinДокумент16 страницUnited States Patent: ShkondinAngel DiosdadoОценок пока нет

- Cja 4Документ24 страницыCja 4pachterОценок пока нет

- Distribution Arrester Ac Rating CalculatorДокумент4 страницыDistribution Arrester Ac Rating CalculatorOoi Ban JuanОценок пока нет

- Working Principle of Earth Leakage Circuit Breaker (ELCB), RCD PDFДокумент6 страницWorking Principle of Earth Leakage Circuit Breaker (ELCB), RCD PDFjobpei250% (4)

- Electrical Machines-II QuestionsДокумент2 страницыElectrical Machines-II QuestionsHari Reddy0% (1)

- Unitops - ch7 ProblemsДокумент5 страницUnitops - ch7 ProblemstasyaОценок пока нет

- M M M M M: HapterДокумент16 страницM M M M M: HapterYabhijit Dutta100% (1)

- List No. 01 Problems Proposed in The Course of Differential EquationsДокумент2 страницыList No. 01 Problems Proposed in The Course of Differential EquationsMiller Ccanccapa MacedoОценок пока нет

- Declination Angle - PVEducationДокумент5 страницDeclination Angle - PVEducationSWATHIОценок пока нет

- SVC and STATCOM Application in Electric Arc Furnace Efficiency ImprovementДокумент7 страницSVC and STATCOM Application in Electric Arc Furnace Efficiency Improvementteektak1Оценок пока нет

- 212 - Problem Set 4Документ1 страница212 - Problem Set 4everyoneMDОценок пока нет

- Slot Line On A Dielectric SubstrateДокумент11 страницSlot Line On A Dielectric SubstrateAsad RahmanОценок пока нет

- Units and Measurements CH2Документ57 страницUnits and Measurements CH2Rishab SharmaОценок пока нет

- Micro Processor Based Neutral Earth Resistor Monitoring RelayДокумент3 страницыMicro Processor Based Neutral Earth Resistor Monitoring RelayPrasenjit MaityОценок пока нет

- Heat Engines 4Документ19 страницHeat Engines 4member1000Оценок пока нет

- Class 11 Alpha Physics - Chapter 04 - Vectors (Lect-04)Документ16 страницClass 11 Alpha Physics - Chapter 04 - Vectors (Lect-04)Samipan Dey100% (1)

- Projectile Motion NotesДокумент6 страницProjectile Motion NotesJoseph MawonikeОценок пока нет

- AC6 Module11Документ22 страницыAC6 Module11Fred BorjaОценок пока нет

- Friction Sample Question AnswersДокумент7 страницFriction Sample Question AnswersIbrahim HossainОценок пока нет

- PM - TB Solutions - C03 PDFДокумент5 страницPM - TB Solutions - C03 PDFVishwajeet Ujhoodha56% (9)

- PM42M048Документ1 страницаPM42M048Lendry NormanОценок пока нет