Академический Документы

Профессиональный Документы

Культура Документы

Materials Science and Engineering by Callister Chapter 1 Reviewer

Загружено:

Ty ztickИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Materials Science and Engineering by Callister Chapter 1 Reviewer

Загружено:

Ty ztickАвторское право:

Доступные форматы

GE304: FUNDAMENTALS OF MATERIALS SCIENCE AND ENGINEERING Chapter 1 | Prepared by: Ariane Joyce Gara Learning Objectives 1.

List six different property classifications of materials that determine their applicability. 2. Cite the four components that are involved in the design, production, and utilization of materials, and briefly describe the interrelationships between these components. 3. Cite three criteria that are important in the materials selection process. 4. a. List the three primary classifications of solid materials, and then cite the distinctive chemical feature of each. b. Note the four types of advanced materials and, for each, its distinctive feature(s). 5. a. Briefly define smart material/system. b. Briefly explain the concept of nanotechnology as it applies to materials 1.1. Historical Perspective Stone Age Bronze Age Iron Age Concrete/Steel Polymer Age Silicon Age Information Age

It was discovered that the properties of a material could be altered by heat treatments and by the addition of other substances.

1.2. Materials Science and Engineering Materials Science Materials Engineering Involves investigating the Designs or engineers the relationships that exist structure of a material to between the structures and produce a predetermined set properties of materials of properties Create new products or systems using existing Develop or synthesize new materials, and/or to develop materials techniques for processing materials Four components that are involved in the design, production, and utilization of materials:

Processing Structure Properties Performance

Thermal property the heat capacity and thermal conductivity of the material Magnetic property the response of a material to the application of a magnetic field Optical property The stimulus is electromagnetic or light radiation Ex. Index of refraction, reflectivity Deteriorative property chemical reactivity of a material

Performance of a Material A materials performance will be a function of its properties Example: All have the same material, aluminum oxide. Processing: Each material was produced using a different processing technique Structure: Different in terms of crystal boundaries and pores, which affect the optical transmittance properties (Optical) Properties: (1) transparent (2) translucent (3) opaque Performance: If optical transmittance is an important parameter relative to the ultimate in-serve application, the performance of each material will be different. 1.3. Why Study Materials Science and Engineering? Three criteria that are important in the materials selection process: The in-service conditions must be characterized, for these will dictate the properties required of the material o Ex. Normally, a material having a high strength will have only a limited ductility The deterioration of material properties that may occur during service operation o Ex. Significant reductions in mechanical strength may result from exposure to elevated temperatures or corrosive environments The cost of a finished piece o Ex. A material may be found that has the ideal set of properties but is prohibitively expensive

Processing of a Material - The structure of a material will depend on how it is processed. Structure of a Material arrangement of its internal components Subatomic structure involves electrons within the individual atoms and interactions with their nuclei Atomic structure encompasses the organization of atoms or molecules relative to one another Microscopic structure contains large groups of atoms that are normally agglomerated together and is subject to direct observation using some type of microscope Macroscopic structure structural elements that may be viewed with the naked eye Property of a Material material trait in terms of the kind of magnitude of response to a specific imposed stimulus Mechanical property - deformation to an applied load or force Ex. Elastic modulus (stiffness), strength, toughness Electrical property the stimulus is an electric field. Ex. Electrical conductivity, dielectric constant

-35,000 Years -1,800 Years -3,300 Years -60 Years -50 Years -35 Years -15 Years

Early civilizations have been designated by the level of their materials development (Stone Age, Bronze Age, Iron Age) The earliest humans had access to those materials that occur naturally only like stone, wood, clay, skins. They discovered techniques for producing materials like pottery and various metals that had properties superior to those of the natural ones.

1.4. Classification of Materials Metals composed of one or more metallic elements (e.g., iron, aluminum, copper, titanium, gold, and nickel), and often also nonmetallic elements (e.g., carbon, nitrogen, and oxygen) in relatively small amounts Metal alloy a metallic substance that is composed of two or more elements Familiar objects that are made of metals and metal alloys: silverware, scissors, coins, a gear, a wedding ring, and a nut and bolt Ceramics compounds between metallic and nonmetallic elements; they are most frequently oxides, nitrides, and carbides Ex. Aluminum oxide (or alumina, Al2O3), silicon dioxide (or silica, SiO2), silicon carbide (SiC), silicon nitride (Si3N4), traditional ceramics (those composed of clay materials (i.e., porcelain)), cement, glass Common objects that are made of ceramic materials, scissors, a china teacup, a building brick, a floor tile, and a glass vase

Properties

Metals

Ceramics - Relatively stiff and strong stiffness and strengths are comparable to those of metals - Typically very hard - Exhibit extreme brittleness - Highly susceptible to fracture - Typically insulative to the passage of electricity - Typically insulative to the passage of heat - More resistant to high temperatures than metals and polymers - May be transparent, translucent, or opaque - Some of the oxide ceramics (e.g., Fe3O4) exhibit magnetic behavior - More resistant to harsh environments than metals and polymers

Mechanical

- Relatively stiff and strong - Ductile - Resistant to fracture

Polymers - Not as stiff nor as strong as metallic and ceramic materials - However, many times their stiffness and strengths on a per-mass basis are comparable to the metals and ceramics - Many of the polymers are extremely ductile and pliable (i.e., plastic) - Low electrical conductivities - Have tendency to soften and/or decompose at modest temperatures

Electrical Polymers include the familiar plastic and rubber materials. Many of them are organic compounds that are chemically based on carbon, hydrogen, and other nonmetallic elements (i.e., O,N, and Si). Ex. Polyethylene (PE), nylon, poly(vinyl chloride) (PVC), polycarbonate (PC), polystyrene (PS), and silicon rubber They have large molecular structures. Several common objects that are made of polymeric materials: plastic tableware, billiard balls, a bicycle helmet, two dice, a lawn mower wheel, plastic milk carton Composites composed of two (or more) individual materials, which come from metals, ceramics, and polymers. Design goal of a composite o to achieve a combination of properties that is not displayed by any single material o to incorporate the best characteristics of each of the component metals Some naturally occurring materials that are composites: wood and bone Most common familiar composites: o Fiberglass/glass fiber-reinforced polymer (GFRP) composite small glass fibers are embedded within a polymetric material (normally an epoxy or polyester) Relatively stiff, strong, and flexible, low density o Carbon fiber-reinforced polymer (CFRP) composite carbon fibers that are embedded within a polymer Stiffer and stronger than glass fiber-reinforced materials, but more expensive Used in some aircraft and aerospace applications, high-tech sporting equipment, automobile bumpers

- Extremely good conductors of electricity - Extremely good conductors of heat - Not transparent to visible light - Has a lustrous appearance - Has desirable magnetic properties

Thermal

Optical

Magnetic

- Nonmagnetic - Relatively inert chemically - Unreactive in a large number of environments

Deteriorative

Notes: Ductile capable of large amounts of deformation without fracture Brittleness lack of ductility Newer ceramics are being engineered to have improved resistance to fracture; these materials are used for cookware, cutlery, and even automobile engine parts Insulative have low electrical conductivities Pliable they are easily formed into complex shapes

1.5. Advanced Materials Semiconductors Have electrical properties that are intermediate between the electrical conductors (i.e., metal and metal alloys) and insulators (i.e., ceramics and polymers) The electrical characteristics of these materials are extremely sensitive to the presence of minute concentrations of impurity atoms these concentrations may be controlled over very small spatial regions Used for integrated circuitry Biomaterials These are employed in components implanted into the human body to replace diseased or damaged body parts They must not produce toxic substances and must be compatible with body tissues They must not cause adverse biological reactions Smart (or intelligent) materials A group of new and state-of-the art materials now being developed that will have a significant influence on many of our technologies The adjective smart implies that these materials are able to sense changes in their environment and then respond to these changes in predetermined manners Components of a smart material (or system) o Some type of sensor detects an input signal Ex. Optical fibers, piezoelectric materials (including some polymers), and microelectromechanical systems o Actuator performs a responsive and adaptive function may called upon to change shape, position, natural frequency, or mechanical characteristics in response to changes in temperature, electric field, and/or magnetic fields.

4 types of materials that are common used for actuators: Shape-memory alloys metals that, after having been deformed, revert back to their original shape when temperature is changed Piezoelectric ceramics expand and contract in response to an applied electric field (or voltage); conversely, they also generate an electric field when their dimensions are altered Magnetostrictive materials Their behavior is analogous to that of piezoelectrics, except that they are responsive to magnetic fields Electrorheotological/ magnetorheological fluids liquids that experience dramatic changes in viscosity upon the application of electric andmagnetic fields, respectively Examples: o Used in helicopters to reduce aerodynamic cockpit noise that is created by the rotating rotor blades o Piezoelectric sensors inserted into the blades to monitor blade stresses and deformations ; feedback signals from those sensors are fed into a computer-controlled adaptive device, which generates noise-canceling antinoise

Rankings: Density: Relatively Densed: 1. Metals 2. Ceramics Relatively not Densed: 3. Polymers 4. Composites Stiffness: Relatively Stiff: 1. Metals 2. Ceramics 3. Composites Relatively not stiff: 4. Polymers Strength: Relatively Strong: 1. Metals 2. Composites 3. Ceramics Relatively not Strong: 4. Polymers Resistance to fracture: Relatively high: 1. Metals 2. Composites Relatively low: 3. Ceramics 4. Polymers Electrical conductivity: Relatively conductive: 1. Metals 2. Semiconductors Relatively insulative: 3. Polymers 4. Ceramics

Nanomaterials May be any one of the four basic types metals, ceramics, polymers, and composites. These materials are distinguished according to size

Вам также может понравиться

- An Introduction To Materials Science For EngineersДокумент38 страницAn Introduction To Materials Science For Engineersy_alinia100% (2)

- Engineering Materials Lec Notes Iprc KigaliДокумент195 страницEngineering Materials Lec Notes Iprc KigaliAlexis MUHIRWAОценок пока нет

- Cyg PRS-7367Документ235 страницCyg PRS-7367MarkusKunОценок пока нет

- Chapter 6 Mechanical Behavior of MaterialsДокумент46 страницChapter 6 Mechanical Behavior of Materialsmuhammad haris100% (1)

- Material Science and EngineeringДокумент1 страницаMaterial Science and EngineeringRap itttt88% (8)

- Materials Science and Engineering - Concept Check SolutionsДокумент112 страницMaterials Science and Engineering - Concept Check SolutionsJuan C Casillas50% (6)

- ME2253 - Engineering Materials and Metallurgy QBДокумент3 страницыME2253 - Engineering Materials and Metallurgy QBVasantha KumarОценок пока нет

- Material Science and Metallurgy: Unit I Structure of MaterialsДокумент127 страницMaterial Science and Metallurgy: Unit I Structure of MaterialsViraj Babar100% (1)

- Materials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985От EverandMaterials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985J. V. BeeОценок пока нет

- Chapter One, Introduction PDFДокумент9 страницChapter One, Introduction PDFOmar Abu MahfouthОценок пока нет

- Introduction of Material Science & Engineering: Processing Structure Properties PerformanceДокумент40 страницIntroduction of Material Science & Engineering: Processing Structure Properties PerformanceGladi RosinОценок пока нет

- Bonga University: Engineering Material (Meng2091)Документ19 страницBonga University: Engineering Material (Meng2091)Mul'isaa JireenyaaОценок пока нет

- Advances in Engineering Plasticity and its ApplicationsОт EverandAdvances in Engineering Plasticity and its ApplicationsW.B. LeeОценок пока нет

- WET PCB Fabrication ProcessДокумент14 страницWET PCB Fabrication Processwebip33713100% (1)

- Materials Science and EngineeringДокумент4 страницыMaterials Science and EngineeringZesi Villamor Delos SantosОценок пока нет

- Introduction To Materials Science and EngineeringДокумент30 страницIntroduction To Materials Science and EngineeringElmerОценок пока нет

- Materials Science and Engineering QuizДокумент3 страницыMaterials Science and Engineering QuizSheba ThomasОценок пока нет

- Chapter 1 Introduction On Material ScienceДокумент33 страницыChapter 1 Introduction On Material ScienceZjian Wai100% (1)

- Assignment 1Документ11 страницAssignment 1राधे कृष्णा वर्ल्डОценок пока нет

- Laser Welder Manual PDFДокумент14 страницLaser Welder Manual PDFMaurizioОценок пока нет

- Materials Science CHAPTER 1Документ5 страницMaterials Science CHAPTER 1KTINE08Оценок пока нет

- Material Science Cht04 and Cht08Документ43 страницыMaterial Science Cht04 and Cht08Arnaldo Bester67% (3)

- Test Exams PDFДокумент7 страницTest Exams PDFShaheer Ahmed KhanОценок пока нет

- MENG - 331 - Spring 2019-2020 - TUTORIAL PROBLEMSДокумент66 страницMENG - 331 - Spring 2019-2020 - TUTORIAL PROBLEMSİREM Taşlı100% (1)

- Adf (Draft)Документ15 страницAdf (Draft)vanmorrison69100% (1)

- Engineering Material AssignmentДокумент3 страницыEngineering Material AssignmentSharjeel Faisal100% (1)

- Mechanical Properties of MaterialsДокумент33 страницыMechanical Properties of MaterialsAaron Dela CruzОценок пока нет

- Material Science QuestionsДокумент40 страницMaterial Science QuestionsLucky KapoorОценок пока нет

- Chapter 1 - Classification of Materials TytДокумент19 страницChapter 1 - Classification of Materials Tytpandimr100% (1)

- Injection Molding Lab ReportДокумент9 страницInjection Molding Lab ReportEdgar ThorpeОценок пока нет

- Kom Unit 2Документ24 страницыKom Unit 2Muthuvel M100% (3)

- 1.classification of Engineering MaterialsДокумент6 страниц1.classification of Engineering MaterialsMuhammad Tanweer100% (2)

- Introduction To Smart MaterialsДокумент47 страницIntroduction To Smart MaterialsRajat AgrawalОценок пока нет

- MFJFJДокумент4 страницыMFJFJShiva Paddam25% (4)

- Microwave Transmission LineДокумент28 страницMicrowave Transmission Lineshagunbhatnagar2Оценок пока нет

- Capdis-S2+: Voltage Detecting System (VDS) For High VoltageДокумент2 страницыCapdis-S2+: Voltage Detecting System (VDS) For High VoltageWhitney HoffmanОценок пока нет

- MM PDF Ia1Документ109 страницMM PDF Ia1M.41Mohd AnasОценок пока нет

- Engineering Materials and Metallurgy 2 Mark With AnswersДокумент31 страницаEngineering Materials and Metallurgy 2 Mark With AnswersbrindharajasekarОценок пока нет

- Chapt 13Документ22 страницыChapt 13Kainy YangОценок пока нет

- QB MAT311 Unit-3Документ6 страницQB MAT311 Unit-3Group 5 Product LaunchОценок пока нет

- ch3 p1Документ42 страницыch3 p1Sary KilanyОценок пока нет

- Mt-I 2 Marks With Answer PDFДокумент15 страницMt-I 2 Marks With Answer PDFSiva RamanОценок пока нет

- Course Content: No. Title Slide NoДокумент54 страницыCourse Content: No. Title Slide NoDilip YadavОценок пока нет

- Classification of Material TypesДокумент6 страницClassification of Material TypesMohamedОценок пока нет

- Engineering Materials Questions and AnswersДокумент4 страницыEngineering Materials Questions and AnswersEmıły WınıfredОценок пока нет

- Assignment No. 1 Materials Science and MetallurgyДокумент2 страницыAssignment No. 1 Materials Science and MetallurgySamruddhi MirganeОценок пока нет

- Structural Materials: Unit 3Документ53 страницыStructural Materials: Unit 3Jayashree MisalОценок пока нет

- Material Science and MetallurgyДокумент43 страницыMaterial Science and MetallurgySanjay Kumar SinghОценок пока нет

- Introduction To Mechanism and KinematicsДокумент17 страницIntroduction To Mechanism and Kinematicsfieramina83% (6)

- Solution Smuth Cap 5Документ32 страницыSolution Smuth Cap 5Joyce Caroline Lima Nunes100% (1)

- F04 3.012 Syllabus - Fundamentals of Materials Science: Structure, Bonding, and ThermodynamicsДокумент5 страницF04 3.012 Syllabus - Fundamentals of Materials Science: Structure, Bonding, and ThermodynamicsSalem GarrabОценок пока нет

- Crystal StructureДокумент30 страницCrystal StructureSujit Singh100% (1)

- Engineering MaterialsДокумент25 страницEngineering MaterialsNichan CanilloОценок пока нет

- Material Science NotesДокумент11 страницMaterial Science NotesRyan Ryan RyanОценок пока нет

- Chapter 3 Engineering MaterialДокумент62 страницыChapter 3 Engineering MaterialSyaa MalyqaОценок пока нет

- Introduction To Electrometallurgy SyllabusДокумент3 страницыIntroduction To Electrometallurgy SyllabusSalem GarrabОценок пока нет

- Assignment 2 Fluctuating LoadДокумент3 страницыAssignment 2 Fluctuating Loadabhishek chaurasiyaОценок пока нет

- Mechanical Engineering Test Assignment: Solution Numerical 1Документ9 страницMechanical Engineering Test Assignment: Solution Numerical 1Raj PatelОценок пока нет

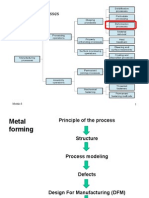

- Handout-8a-Metal Forming BasicДокумент23 страницыHandout-8a-Metal Forming BasicAmardhianaОценок пока нет

- ME6601-Design of Transmission Systems PDFДокумент27 страницME6601-Design of Transmission Systems PDFJeevitha RОценок пока нет

- Material Science Question BankДокумент3 страницыMaterial Science Question BankSirish Chand PutlaОценок пока нет

- Unit 10 Properties and Applications of Engineering MaterialsДокумент12 страницUnit 10 Properties and Applications of Engineering MaterialsRavishanker Baliga0% (1)

- TestДокумент36 страницTestRashedОценок пока нет

- Introduction To Materials Science & EngineeringДокумент30 страницIntroduction To Materials Science & Engineering2zvhqpfxy2Оценок пока нет

- (Stone Age, Bronze Age, and Iron Age) : Design, Production, and Utilization of MaterialsДокумент8 страниц(Stone Age, Bronze Age, and Iron Age) : Design, Production, and Utilization of Materialsرائد عبد العزيز فرحانОценок пока нет

- MCM MaterialДокумент32 страницыMCM MaterialGeleta BekeleОценок пока нет

- Lesson 1 Introduction To Materials Science and EngineeringДокумент33 страницыLesson 1 Introduction To Materials Science and EngineeringJone Zelita Culanculan Orlina100% (1)

- 21 PrimepowerДокумент2 страницы21 PrimepowerfernandoОценок пока нет

- DOD Gonkulator How It Works OriginalДокумент1 страницаDOD Gonkulator How It Works OriginaltttymonОценок пока нет

- Important NumericalsДокумент1 страницаImportant NumericalscheshankarОценок пока нет

- Design & Construction of 220 V Voltage StabilizerДокумент46 страницDesign & Construction of 220 V Voltage StabilizerNitin VermaОценок пока нет

- Samsung 43' AU8000 (EN)Документ2 страницыSamsung 43' AU8000 (EN)Lemoj SerapseОценок пока нет

- LG 42pj350 Training Manual (ET)Документ132 страницыLG 42pj350 Training Manual (ET)RomelyGery Martinez89% (9)

- Ee2304 Power Electronics Lab ManualДокумент49 страницEe2304 Power Electronics Lab ManualSree GaneshОценок пока нет

- Section 68 - Pools, Tubs and Spas: 68-404 Controls and Other Electrical EquipmentДокумент2 страницыSection 68 - Pools, Tubs and Spas: 68-404 Controls and Other Electrical EquipmentmarkfoyОценок пока нет

- MNRE ALMM Dated 18.08.22Документ43 страницыMNRE ALMM Dated 18.08.22Minal MimaniОценок пока нет

- Pope Mac Series AmpilifiersДокумент9 страницPope Mac Series AmpilifiersFikri HidayatОценок пока нет

- CITATION Cov19 /L 1033Документ6 страницCITATION Cov19 /L 1033Ian LlapitanОценок пока нет

- Powerflex 750-Series Ac Drives: Programming ManualДокумент548 страницPowerflex 750-Series Ac Drives: Programming ManualJose GimenezОценок пока нет

- Gejala Kilat: 1. General KarakteristikДокумент4 страницыGejala Kilat: 1. General KarakteristikKhaddavi KhalifОценок пока нет

- FFT Based Differential Protection For Power Transformers: Suribabu & Sanker RamДокумент14 страницFFT Based Differential Protection For Power Transformers: Suribabu & Sanker RamTJPRC PublicationsОценок пока нет

- PomonatestcatalogДокумент100 страницPomonatestcatalogvemuri_sriОценок пока нет

- Part 3 - Technical SpecsДокумент659 страницPart 3 - Technical Specsateef idreesОценок пока нет

- Tba 120 UДокумент9 страницTba 120 UVictor Constantin BadeaОценок пока нет

- EFSPL-1 ManualДокумент7 страницEFSPL-1 ManualALCALAB EL EQUIP TESTINGОценок пока нет

- UGC Autonomous III B.Tech - II Sem - I MID Examinations (2017 Batch) Jan-2020 TSSNДокумент1 страницаUGC Autonomous III B.Tech - II Sem - I MID Examinations (2017 Batch) Jan-2020 TSSNdearprasanta6015Оценок пока нет

- Mason S Flow Graph Formula PDFДокумент21 страницаMason S Flow Graph Formula PDFRUBIOОценок пока нет

- Analysis and Design of A Functional Electric Motorcycle PrototypeДокумент6 страницAnalysis and Design of A Functional Electric Motorcycle PrototypearielguerreroОценок пока нет

- Online Quiz #03 Electrical Engineering 1Документ2 страницыOnline Quiz #03 Electrical Engineering 1Koo Ferdinand AdriantoОценок пока нет

- 50kw To 5000kw Low RPM Three Phase AcДокумент11 страниц50kw To 5000kw Low RPM Three Phase AcashagrieОценок пока нет