Академический Документы

Профессиональный Документы

Культура Документы

An Examination of The Electrochemical Characteristics of Two Stainless Steels (UNS S32654 and UNS S31603) Under Liquid-Solid Impingement

Загружено:

sureshjeevaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

An Examination of The Electrochemical Characteristics of Two Stainless Steels (UNS S32654 and UNS S31603) Under Liquid-Solid Impingement

Загружено:

sureshjeevaАвторское право:

Доступные форматы

Wear 256 (2004) 537544

An examination of the electrochemical characteristics of two stainless steels (UNS S32654 and UNS S31603) under liquidsolid impingement

Xinming Hu, Anne Neville

Corrosion and Surface Engineering Research Group, School of Engineering and Physical Sciences, Heriot-Watt University, Edinburgh, Scotland, UK

Abstract The erosioncorrosion resistance of high alloy stainless steel UNS S32654 and standard stainless steel UNS S31603 has been assessed under liquidsolid impingement conditions. The electrochemical characteristics of the two stainless steels have been examined via free corrosion potential measurements, anodic polarisation, linear polarisation and potentiostatic control in erosioncorrosion. It has been shown in this paper that high alloy stainless steel UNS S32654 exhibits better corrosion and erosioncorrosion performance than lower grade alloy UNS S31603. A general linear relationship between two electrochemical parameters (Ecorr and Rp ) has been shown in this study. A critical solid loading between 60 and 100 mg/l, at which there is a transition from corrosion to erosioncorrosion for the two stainless steels under different conditions, has been determined. 2003 Elsevier B.V. All rights reserved.

Keywords: Stainless steels; Corrosion; Erosion; Electrochemical

1. Introduction It is common for components subjected to liquid ows containing solid particles to experience high degradation rates. In particular, for components where the ow experiences a sudden diversion (e.g. in pumps, valves, tees and elbows in pipework) high rates of material loss can occur as a result of combined mechanical erosion and abrasion and electrochemical corrosion. Flow-induced corrosion describes a process whereby the corrosion rate of a material is increased in a moving uid. It was reviewed by Weber [1] in 1992 who dened the effects of ow velocity to be in three categories. At low ow velocities and in the absence of induced convection, natural convection is responsible for mass transfer and can affect corrosion rates. When induced convection leads to increased mass transfer at moderate ow velocities the corrosion rate can increase but in this regime there are no mechanical effects of ow. At high velocities mechanical ow effects can result and in this case the damage mechanisms become increasingly complex. The phenomenon of erosioncorrosion has received widespread study over the last two decades

Corresponding author. Tel.: +44-131-451-4365; fax: +44-131-451-3129. E-mail address: a.neville@hw.ac.uk (A. Neville). 0043-1648/$ see front matter 2003 Elsevier B.V. All rights reserved. doi:10.1016/S0043-1648(03)00563-5

where the focus has been on assessment of material performance under varying conditions and assessment of how erosion affects corrosion rates and vice versa e.g. [26]. During this time it has become generally appreciated that signicant interactions exist between electrochemical and mechanical effects and these result in sometimes very large synergistic [79] or additive [10] effects where the combined processes result in much greater material loss than the sum of their individual components. In ASTM G119-93 (1998) guidelines are given for the calculation of synergism between wear and corrosion [11]. Erosioncorrosion maps are often used to give a visual representation of these interactions and to isolate regimes, in terms of ow parameters, which are erosion-dominated or corrosion-dominated [12,13]. Electrochemical techniques are often used to assess the effect of tribological processes in tribo-corrosion [1417]. The free corrosion potential was monitored by Huang and Chuang [18] in a rotating arrangement where a load was applied to the surface to form an abrasive contact. Under rotation with no load the free corrosion potential showed a trend of ennoblement and in contrast once a load of 3.92 N was applied a shift in the active direction (signifying loss of passivity) was observed. Oltra et al. [19] coupled electrochemical measurements with acoustic emission measurements to monitor erosioncorrosion in aggressive slurries to capture the mechanical response of the surface and the

538

X. Hu, A. Neville / Wear 256 (2004) 537544

electrochemical response. Acoustic emission in isolation enabled a critical ow velocity on steel in sulphuric acid to be determined [20]. In the case of stainless steels and other similar materials which rely on their passive lm for corrosion protection in static environments, the effect of the ow of a solid-containing stream of liquid can be to cause mechanical removal of the protective layer and charge transfer is temporarily enhanced. As stated by Li et al. [21] in circumstances where the surface material is removed by impingement of a liquidsolid stream the generation rate of fresh oxide and the repassivation ability of the material are two parameters that are of importance. Such depassivation and repassivation effects are known to be of importance also in wear-accelerated corrosion caused by sliding wear in a corrosive media [21]. In this paper the overall erosioncorrosion damage rates of the superaustenitic stainless steel (UNS S32654) and austenitic stainless steel (UNS S31603) are presented but the main focus of the work is to look at the corrosion rates and the detailed electrochemical response of the alloys under impingement conditions. Electrochemical measurements were used to assess the transition for different regimes (ow-induced corrosion to erosioncorrosion). The paper also enables more detailed understanding of the generic differences between a high grade and a standard austenitic stainless steels to be obtained.

2. Materials and experimental methods Two stainless steels are included in this study and their compositions are given in Table 1. The two stainless steels are chosen to represent a super grade (UNS S32654) and a standard austenitic (UNS S31603). The additional alloying of Mo, N and Cr are known to be important for localised corrosion resistance in static saline environments [22] and in this work a comparison is made of their resistance to ow-induced corrosion and erosioncorrosion. Also shown in Table 1 are the average Vickers microhardness values taken from 10 measurements on each surface. The impingement apparatus comprised a submerged liquidsolid jet generated using a recirculating rig and the electrochemical apparatus used for in situ monitoring as described in [23]. The rig comprised a dual nozzle system each nozzle diameter being 4 mm. The exit velocity of the jet for this study was kept constant at 17 m/s which is a relatively high velocity for applications of stainless steels in pump impeller and casing etc. The nozzle-to-specimen distance was kept constant at 5 mm. The area of the specimen

Table 1 Nominal compositions and microhardness of UNS S32654 and UNS S31603 Cr UNS S32654 UNS S31603 24 1618 Ni 22 7 Mo 7.3 3.5 Mn 3.5 0.8 C 0.01 0.03 N 0.5 Hv 337 265

is 4 cm2 . The solid loading of silica sand in the 3.5% NaCl uid was varied between 5 and 6000 mg/l. The solid loading was tested during every test by extracting water samples (three replicates) from the nozzles, ltering and weighing the solids collected. The size distribution of the silica sand is given in Fig. 1. The temperature of the liquid was kept at 18 C by using a cooling system. For all tests the angle of impingement was 90 . Tests were typically conducted for 8 h for three times for each of the solid loading and the specimens were weighed before and after the experiment to determine the total material loss. Errors of results are determined from three replicated experiments in this study. The in situ corrosion rate was measured using a three-electrode electrochemical cell comprising a Ag/AgCl reference electrode connected by means of a salt bridge and a platinum counter electrode. DC anodic polarisation tests involved scanning the potential of the working electrode (the specimen under examination) from the free corrosion potential (Ecorr ) in the more noble (positive) direction at a xed rate of 25 mV/min. The potential was scanned in the positive direction until the current owing in the external circuit between the working and counter electrodes reached a value of 500 A/cm2 . The anodic polarisation tests were started after 30 min exposure to the impinging jet. To measure changes in the corrosion rate as a function of solid loading, linear polarisation tests were conducted. In these tests the potential of the working electrode (the sample under erosioncorrosion) was shifted at a rate of 15 mV/min from 0.02 V negative to the free corrosion potential to 0.02 V positive to the free corrosion potential. The applied potential is then a linear function of the current density in the external cell. Changes in the polarisation resistance (Rp ) can be calculated from the slope E/ i. In this work the assumption is made that the change in the slope and hence the change in Rp is inversely proportional to the change in corrosion rate. The free corrosion potential (Ecorr ) of the two alloys were measured in situ on adding solids into the recirculating system with a range of solid loading between 0 and 3000 mg/l, the sampling rate was 1 Hz. In order to determine the critical solid loading at which there is a transition from ow-induced corrosion to erosioncorrosion and to investigate the anodic current transients in liquidsolid impingement conditions, potentiostatic tests were carried out at an applied (anodic) potential of 0 V (Ag/AgCl) and the solid loading was incrementally increases in the range 06000 mg/l. The current density was monitored for 5 min at each solid loading and the data was recorded at a rate of 1 Hz.

3. Results 3.1. Total weight loss (TWL) In Fig. 2, the TWL measured after exposure to the impinging jet for 8 h at 17 m/s is shown as a function of solid

X. Hu, A. Neville / Wear 256 (2004) 537544

539

Fig. 1. Distribution of sand size for erosioncorrosion tests.

loading for the two stainless steels. For the high alloy stainless steel UNS S32654 the TWL and solid loading exhibit an exponential relationship which has also been conrmed by other high alloy stainless steels [24]. It is clear from the gure that high alloy stainless steel UNS S32654 has shown superior overall erosioncorrosion resistance compared with UNS S31603. This is in accordance to results presented under cavitationerosion and wear-corrosion conditions by other workers [25,26].

3.2. Anodic polarisation In situ electrochemical monitoring using DC anodic polarisation enables the corrosion characteristics under the inuence of liquidsolid impact to be determined. The complex anodic polarisation behaviour of high alloy stainless steels has been reported previously [24]. The in situ corrosion current (icorr ) can be obtained via the Tafel extrapolation technique [27] and this enables the material loss due to pure

Fig. 2. Weight loss tests on materials in erosioncorrosion after 8 h, 17 m/s, 18 C in 3.5% NaCl.

540

X. Hu, A. Neville / Wear 256 (2004) 537544

Fig. 3. icorr determined from AP for UNS S32654 and UNS S31603 at various solid loadings.

electrochemical effects (C) to be determined. The icorr values are shown in Fig. 3 and it is clear that UNS S31603 has much greater anodic current densities at the three solid loadings. 3.3. Linear polarisation Anodic polarisation tests enabled the corrosion current density to be determined. However, this method is generally

destructive given the extent of potential change imposed on the surface during the measurement, and as such only one measurement per experiment can be made. Linear polarisation is an alternative method for measuring the corrosion rate, which permits rapid corrosion rate measurements and can be used to monitor the corrosion rate in various conditions. Using this method, the applied potential is approximately a linear function of current density in the region

Fig. 4. K (Equation 2) determined on UNS S32654 and UNS S31603 in erosioncorrosion at 18 C, 17 m/s in 3.5% NaCl.

X. Hu, A. Neville / Wear 256 (2004) 537544

541

adjacent to Ecorr within which the tested specimens are not suffering serious corrosion attack due to high applied potential as used in Tafel extrapolation method. From measurement of the E/ i relationship over the small potential range from 20 mV more negative to 20 mV more positive than Ecorr the changes in polarisation resistance (Rp ) as a

function of solid loading can be determined from Eq. (1): E a c = = Rp i 2.3icorr (a + c ) (1)

where a and c are the Tafel constants [16] for the anodic and cathodic reactions, respectively (Fig. 4).

Fig. 5. Free corrosion potential at various solid loadings for (a) UNS S31603 and (b) UNS S32654 at 18 C, 17 m/s in 3.5% NaCl.

542

X. Hu, A. Neville / Wear 256 (2004) 537544

In this work it has been shown that there is little change in the absolute value of the grouping K as dened in Eq. (2) as solid loading increases but there is a substantial difference between the two different stainless steels as shown in Fig. 7 a c K= 2.3(a + c ) (2)

gressively adding solids at 10 min intervals to reach a solid loading of 3129 mg/l. The following trends emerge on both materials: The Ecorr shifts in the negative (active) direction on adding solids. Ennoblement is observed at the lowest solid loadings (most evident on UNS S32654 as shown in Fig. 5b) during the 10 min periods but as the solid loading increases the ennoblement effect is no longer evident. The shift in the active direction on adding solids is reduced as the solid loading is increased. The oscillations (noise) in the Ecorr values are enhanced as the solid loading increases. 3.5. Potentiostatic measurements The current density, while the sample is maintained at a potential of 0 V (Ag/AgCl) for a period of 150 min with solids progressively added into the system was monitored. The mean value of the current density is plotted as a function of solid loading for the two stainless steels in Fig. 6. It is clear that there is an increase in current density as solids is increased and UNS S31603 exhibits higher values in all conditions. At lower solid loadings (<200 mg/l), there is a critical point at 60100 mg/l at which the current starts to oscillate at a much greater rate for both alloys as shown in Fig. 7a and b and this physically may be due to the transition to erosioncorrosion occurring from a corrosion regime. It can also be seen that the current transient oscillations are enhanced at higher solid loadings.

As a result the variation in Rp can be used to determine the change in icorr for the two materials. And these results of Rp will be correlated with the free corrosion potential results in the discussion section. In agreement with the measurement of icorr by Tafel extrapolation, the corrosion resistance at all solid loadings is lower on UNS S31603 than on UNS S32654. However, there is a difference between the ratios of corrosion rate determined from linear polarisation and anodic polarisation and this is probably due to the experimental processes. Anodic polarisation tests were conducted on a fresh specimen surface at one constant solid loading, while the linear polarisation measurements were made during a continuous experimental process where the solids are progressively added to the recirculating system. The specimen corrosion rate, determined by linear polarisation is therefore the corrosion rate as a result of the progressive increase in solids. This may therefore vary the specimen surface and implied that some history effect is evident which leads to anomalies in the corrosion rates. 3.4. Free corrosion potential (Ecorr ) measurements Fig. 5a and b shows free corrosion potential measurements made on UNS S31603 and UNS S32654 while pro-

Fig. 6. Mean values of current density as a function of solid loading for UNS S32654 and UNS S31603, at 0 V, 17 m/s, 18 C in 3.5% NaCl.

X. Hu, A. Neville / Wear 256 (2004) 537544

543

Fig. 7. Potentiostatic measurements as a function of solid loading for (a) UNS S31603 and (b) UNS S32654 at 0 V, 17 m/s, 18 C in 3.5% NaCl.

4. Discussion The overall erosioncorrosion resistance of higher alloy stainless steel UNS S31654 is greatly improved over UNS S31603 in both mechanical and electrochemical terms. From Table 1 it is clear that UNS S32654 is a harder material which improves the mechanical erosion resistance of this alloy. In this study UNS S31603 also exhibits a much greater corrosion rate than UNS S32654. Development of high-grade stainless steels has been driven by the need to improve resistance to localised corrosion attack and loss of passivity in the form of pitting and crevice corrosion [22]. This has been achieved through additions of N, Mo and some other elements which have been found to promote passivation. In

erosioncorrosion conditions it has been shown here and elsewhere [25] that even high grade alloys can be in the active corrosion regime, casting doubt on the benets of the additional alloying for resisting degradation. However, it is clear in this study that there is a substantial benet in terms of lowering the electrochemical charge transfer during erosion. Better resistance to corrosion under erosioncorrosion conditions (which shows UNS S32654 better resistant than UNS S31603) correlates to better overall performance measured by TWL for the two alloys. This implies that corrosion and its subsequent effect on erosion is of great importance and it is more signicant for austenitic stainless steel UNS S31603. In terms of electrochemical corrosion the most readily available parameter which can be measured is Ecorr and this

544

X. Hu, A. Neville / Wear 256 (2004) 537544

was done in situ during tests under liquidsolid erosion conditions with various solids. However, generally Ecorr cannot be used as a direct way to quantify the corrosion rate. Ecorr and Rp have been measured at different solid loadings and these data enabled the relationship between the two electrochemical parameters for UNS S32654 and UNS S31603 to be determined under erosioncorrosion conditions. Detailed studied on the Tafel constants have shown that the values of K (Eq. (2)) remain almost constant at different solid loadings as shown in Fig. 4. It is noticed that in this study only solid loading was varied as the erosioncorrosion parameter and other important parameters have not been taken into consideration such as temperature, impinging velocity and impingement angle. The current study is also focused on determining the critical solid loading where the material degradation regime changes from corrosion or ow-induced corrosion to a more severe stage of erosioncorrosion which can result in greater material loss. Flow-induced corrosion has been reported [28,29] to result in an enhancement of corrosion rate due to impingement effect on active alloys. According to the current work carried out on the stainless steels at a velocity of 17 m/s, the two stainless steels exhibit low current densities under potentiostatic control under solid-free and low solid loading (<100 mg/l) impingement conditions. At an apparent control solid loading of 100 mg/l the oscillations significantly increase and depassivationrepassivation processes become the controlling factor. As determined from this study the critical solid loading for the two alloys is between 60 and 100 mg/l suggesting that high grade alloy does not prevent mechanical breakdown of the passive lm, but it exhibits less charge transfer than UNS S31603 under liquidsolid impingement. And this better corrosion resistance benets from the alloy additions on the high alloy stainless steel to reduce the susceptibility to corrosion and to improve the repassivation behaviour. 5. Conclusions Alloying additions on UNS S32654 have improved the corrosion and overall erosioncorrosion resistance. The

corrosion rate is more pronounced on austenitic stainless steel UNS S31603 under liquidsolid impingement conditions. A relationship between Ecorr and Rp in erosion corrosion enables the corrosion rate to be determined by an easily measured electrochemical parameter Ecorr . A critical solid loading has been determined to be 60100 mg/l for the two stainless steels. References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] J. Weber, Brit. Corros. J. 27 (3) (1992) 193199. Y. Li, G.T. Burstein, I.M. Hutchings, Wear 186187 (1995) 515522. J.A. Carew, M. Islam, Mater. Perform. 4 (1995) 5457. H. Abd-El-Kader, S.M. El-Raghy, Corros. Sci. 26 (8) (1986) 647 653. G.R. Hoey, J.S. Bednar, Mater. Perform. 4 (1983) 915. E. Heitz, Corrosion 47 (2) (1991) 135145. A. Neville, T. Hodgkiess, J.T. Dallas, Wear 186187 (1995) 497507. A. Neville, T. Hodgkiess, Brit. Corros. J. 32 (3) (1997) 197205. A. Neville, T. Hodgkiess, Wear 235 (1999) 596607. M.M. Stack, S. Zhou, R.C. Newman, Wear 186187 (1995) 523532. ASTM G119-93, Guide for determining synergism between wear and corrosion, 1998, pp. 522527. M.M. Stack, N. Corlett, S. Zhou, Wear 214 (1998) 175185. M.M. Stack, N. Corlett, S. Zhou, Wear 225229 (1999) 190198. E. Lemaire, M. Le Calvar, Wear 249 (2001) 338344. S. Mischler, A. Spiegel, D. Landolt, Wear 225229 (1999) 1078 1087. D. Landolt, S. Mischler, M. Stemp, Electrochem. Acta 46 (2001) 39133929. G.T. Burstein, K. Sasaki, Electrochim. Acta 46 (2001) 36753683. H.H. Huang, T.H. Chuang, Mater. Sci. Eng. A 292 (2000) 9095. R. Oltra, B. Chapey, L. Renaud, Wear 186187 (1995) 533541. F. Ferrer, T. Faure, J. Goudiakas, E. Andres, Corros. Sci. 44 (2002) 15291540. J. Li, Y.G. Zheng, J.Q. Wang, Z.M. Yao, Z.F. Wang, W. Ke, Wear 186187 (1995) 562567. I. Olefjord, B. Brox, U. Jelvestam, J. Electrochem. Soc. 132 (12) (1985) 28542861. A. Neville, M. Reyes, H. Xu, Tribol. Int. 35 (2002) 643650. A. Neville, X. Hu, Wear 251 (2001) 12841294. C.T. Kwok, F.T. Cheng, H.C. Man, Mater. Sci. Eng. A 290 (2000) 145154. A. Fan, J. Long, Z. Tao, Wear 193 (1996) 7377. M. Stern, A.L. Geary, J. Electrochem. Soc. 104 (1) (1957) 5663. A. Neville, T. Hodgkiess, Corros. Sci. 38 (6) (1996) 927956. P. Andrews, T.F. Illson, S.J. Matthews, Wear 233235 (1999) 568 574.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- S19 Exam 3 Practice Test KEY PDFДокумент10 страницS19 Exam 3 Practice Test KEY PDFsmithОценок пока нет

- Exp5 T10 Group 4Документ9 страницExp5 T10 Group 4NaimzNaimОценок пока нет

- Light Fresh Sun Gel SPF 30 PA+++ (Formulation #UV-DE-14-166-2-4)Документ2 страницыLight Fresh Sun Gel SPF 30 PA+++ (Formulation #UV-DE-14-166-2-4)Anahit AvagyanОценок пока нет

- Oisd STD 189Документ43 страницыOisd STD 189sureshjeeva67% (6)

- Kirloskar Brothers LimitedДокумент2 страницыKirloskar Brothers LimitedsureshjeevaОценок пока нет

- Membership Application FormДокумент2 страницыMembership Application FormsureshjeevaОценок пока нет

- Tamil Panchangam 2016, April 14Документ5 страницTamil Panchangam 2016, April 14sureshjeevaОценок пока нет

- Analysis of Fire Hazard and Safety Requirements of A Sea Vessel Engine RoomsДокумент8 страницAnalysis of Fire Hazard and Safety Requirements of A Sea Vessel Engine RoomssureshjeevaОценок пока нет

- CS 62 (2003) - 59 - NZC, HHS, CGS - Reliability Analysis of A Ship Hull in Commposite MaterialДокумент8 страницCS 62 (2003) - 59 - NZC, HHS, CGS - Reliability Analysis of A Ship Hull in Commposite MaterialsureshjeevaОценок пока нет

- Alagappa University, Karaikudi-630 003: Distance Education Practical Examinations Time Table, December 2014Документ2 страницыAlagappa University, Karaikudi-630 003: Distance Education Practical Examinations Time Table, December 2014sureshjeevaОценок пока нет

- G Day AnnouncementДокумент1 страницаG Day AnnouncementsureshjeevaОценок пока нет

- Jyothis Academy - AMIE BДокумент2 страницыJyothis Academy - AMIE BsureshjeevaОценок пока нет

- How To Care For Red Dragon FlowerhornsДокумент8 страницHow To Care For Red Dragon Flowerhornssureshjeeva100% (1)

- Manganese Removal Physical-Chemical WayДокумент1 страницаManganese Removal Physical-Chemical WaysureshjeevaОценок пока нет

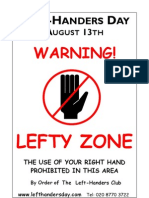

- There's A Bit of Sinistrality in Allofus!!Документ1 страницаThere's A Bit of Sinistrality in Allofus!!sureshjeevaОценок пока нет

- Lefty ZoneДокумент1 страницаLefty ZonesureshjeevaОценок пока нет

- Fish GalleryДокумент3 страницыFish GallerysureshjeevaОценок пока нет

- Important Table Tennis Rules For Ping-Pong BeginnersДокумент5 страницImportant Table Tennis Rules For Ping-Pong BeginnerssureshjeevaОценок пока нет

- Specialists in Left-Handed Items For Over 30 YearsДокумент1 страницаSpecialists in Left-Handed Items For Over 30 YearssureshjeevaОценок пока нет

- Universiti Malaysia Perlis Laboratory Report Metal Extraction Technology PDT 262 SEMESTER 2 (2016/2017)Документ17 страницUniversiti Malaysia Perlis Laboratory Report Metal Extraction Technology PDT 262 SEMESTER 2 (2016/2017)amirolОценок пока нет

- Hyperconjugation - Chemistry LibreTextsДокумент2 страницыHyperconjugation - Chemistry LibreTextsAatmaanandaОценок пока нет

- Review of SmeddДокумент23 страницыReview of Smeddkulbhushan singhОценок пока нет

- Science Class X Sample Paper Test 02 For Board Exam 2024 AnswersДокумент14 страницScience Class X Sample Paper Test 02 For Board Exam 2024 Answerssingh2008adityaОценок пока нет

- CHROMATOGRAPHY - Class #2Документ11 страницCHROMATOGRAPHY - Class #2Brijesh SharmaОценок пока нет

- Brochure KS-SE2Документ6 страницBrochure KS-SE2Mudzakkir AbduhОценок пока нет

- Patente Estearato de CalcioДокумент7 страницPatente Estearato de CalcioKevinVivarezОценок пока нет

- Properties and Transformation of MatterДокумент2 страницыProperties and Transformation of MatterDyan RiojaОценок пока нет

- Topic 2 QuestionsДокумент16 страницTopic 2 QuestionsthasmiaОценок пока нет

- Ex Nitrogen NitrateДокумент2 страницыEx Nitrogen Nitrate9480754788Оценок пока нет

- Week 2Документ15 страницWeek 2ALPHEAUS-MBA AwajibenejiОценок пока нет

- Oxidation Reduction ReactionsДокумент23 страницыOxidation Reduction ReactionsRussОценок пока нет

- Subsea: Fluids Pte LTDДокумент7 страницSubsea: Fluids Pte LTDcacalot93Оценок пока нет

- LAPRAK KafeinДокумент7 страницLAPRAK KafeindikabellОценок пока нет

- Comprehensive Analytical Testing of Cannabis and Hemp: Anthony MacheroneДокумент27 страницComprehensive Analytical Testing of Cannabis and Hemp: Anthony MacheroneyixovОценок пока нет

- Production of High Silicon Alloys: January 1998Документ8 страницProduction of High Silicon Alloys: January 1998aryamesaОценок пока нет

- Fall 2023 Chapter 7, 9 & 10 CHEM 517 Bioreactor Processing & ControlДокумент78 страницFall 2023 Chapter 7, 9 & 10 CHEM 517 Bioreactor Processing & ControlskyliairojoОценок пока нет

- CHM031 Module 3 ReviewerДокумент21 страницаCHM031 Module 3 ReviewerrainОценок пока нет

- The World of Polymers and PlasticsДокумент21 страницаThe World of Polymers and PlasticsNoor Farrah Wahida MuradОценок пока нет

- Jarissa Banner Nitration of Bromobnzene LabДокумент15 страницJarissa Banner Nitration of Bromobnzene LabJuiloОценок пока нет

- 205Документ2 страницы205acarisimovicОценок пока нет

- Quantifying Trimethylamine and Trimethylamine-N-Oxide in Human Plasma: Interference From Endogenous Quaternary Ammonium CompoundsДокумент3 страницыQuantifying Trimethylamine and Trimethylamine-N-Oxide in Human Plasma: Interference From Endogenous Quaternary Ammonium CompoundsVeneta GizdakovaОценок пока нет

- Choosing A Suitable Support For Co3O4 As An NH3 Oxidation CatalystДокумент5 страницChoosing A Suitable Support For Co3O4 As An NH3 Oxidation Catalystjuan davidОценок пока нет

- Functionalization of TextilesДокумент51 страницаFunctionalization of Textilesrana hussainОценок пока нет

- Universitas Ahmad Dahlan - JellyДокумент15 страницUniversitas Ahmad Dahlan - JellyMaqfirotul LailyОценок пока нет

- Battery TechnologyДокумент44 страницыBattery Technologyvishnu100% (1)

- Test 3 Extra Mechanism PracticeДокумент3 страницыTest 3 Extra Mechanism PracticeShlok ParekhОценок пока нет