Академический Документы

Профессиональный Документы

Культура Документы

LED Project Abstact

Загружено:

Arjun SreenivasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LED Project Abstact

Загружено:

Arjun SreenivasАвторское право:

Доступные форматы

design

Edited by Bill Travis

ideas

a two-byte binary integer, which converts to decimal for display. A third byte in the protocol indicates any decimal points or colons. This data format allows the easiest interface from binary measurement or calculation. A second protocol accepts four bytes that directly control the segments and decimal points, allowing the display of a variety of characters and symbols possible on a seven-segment display. You can download the source code and hex object file for the ATtiny12 from the Web version of this Design Idea at www.edn.com. The code provides a two-wire I2C interface for a four-digit Lumex (www.lumex.com) LCD-S401C52TR display.

Seven-segment LCD uses two-wire interface ..........................................89 Open-collector output provides fail-safe operation..........................................90 Low-battery indicator uses fleapower ......90 Indicator has electronic lens ....................92 Thermal switches provide circuit disconnect............................................98

Seven-segment LCD uses two-wire interface

Hans Krobath, EEC, Nesconset, NY

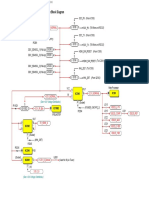

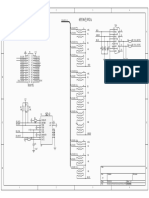

ou can connect seven-segment LCDs using only a two-wire interface (Figure 1). The two-wire interface may be at the field-effect, directdrive LCD or at a serial interface (such as I2C) that uses an eight-pin microcontroller. The design in Figure 1 uses an Atmel (www.atmel.com) ATtiny12 microcontroller, IC1. VCC can range from 2.7 to 5.5V. Each digit receives drive from an 8bit 74HC164 shift register, which provides seven outputs for each of the segments and one output for a decimal point or a colon. The data input to the shift register drives the LCDs common terminal. Software for the eight-pin microcontroller generates the required symmetrical ac square wave between the segments and the common terminal (Listing 1, which you can find at the Web version of this Design Idea at www.edn.com). This generation entails shifting the seven-segment data and decimal points to the appropriate outputs and setting the shiftregister-input/LCD-common-terminal to low at a less-than 1-msec rate. A delay

of 16 msec followed by shifting the same data complemented, as well as the complement of the LCD common terminal with another 16-msec delay, provides the second half of the required ac waveform. Because field-effect LCDs takes tens of milliseconds to respond, the rapid datashifting and display-common changing does not affect the displayed image. You can use the two 16-msec delays per cycle for application processing. Directly driving the segments allows the display of not only the numbers zero to nine, but also any combination of segments and decimal points. You can use the eight-pin ATtiny12 with a built-in, 1MHz clock oscillator to produce the described two-wire signal and to provide a two-wire I2C application interface. The dedicated use of the microcontroller for display control and its I2C interface frees the application hardware and software from timing and resource restrictions. The implemented I2C interface operates at 0 to 40 kbps and is bit-synchronous. One data protocol allows for the input of

VCC C1 0.1 F SRDA SRCL TO INTO

VCC IC1 ATTINY12 8 VCC 7 PB2 6 PB1 5 PB0 1 RST 2 PB3 3 PB4 4 GND R1 10k BACKLIGHT CONTROL SCK

Buck-boost regulator suits battery operation ........................................100

Publish your Design Idea in EDN. See the Whats Up section at www.edn.com.

DSD

VCC IC2 1 2 74HC164 8 A B CLK 9 CLR IC3 1 2 74HC164 8 A B CLK

VCC 9 CLR IC4 1 2 74HC164 8 A B CLK

VCC 9 CLR

VCC IC5 9 1 2 74HC164 8 A B CLR CLK QA QB QC QD QE QF QG QH 3 4 5 6 10 11 12 13

QA QB QC QD QE QF QG QH 3 4 5 6 10 11 12 13

QA QB QC QD QE QF QG QH 3 4 5 6 10 11 12 13

QA QB QC QD QE QF QG QH 3 4 5 6 10 11 12 13

Figure 1

37 36 5 6 7 34 35 8 32 31 9 10 11 29 30 12 2G 2F 2E 2D 2C 2B 2A 2DP 27 26 13 14 15 24 25 16 3G 3F 3E 3D 3C 3B 3A 3DP 23 22 17 18 19 20 21 28 4G 4F 4E 4D 4C 4B 4A COL CM2 CM1 40 1

A minuscule 8-bit microcontroller lets you use a two-wire interface to drive a seven-segment LCD. www.edn.com

1G 1F 1E 1D 1C 1B 1A 1DP

IC6 LCD40

September 4, 2003 | edn 89

design

ideas

Open-collector output provides fail-safe operation

Susanne Nell, Breitenfurt, Austria

24V t is common practice to use digital open-collector outputs for control 2 units in industrial applications. Using J1 OUTPUT 1 these outputs, you can switch loads, such as relays, lamps, solenoids, and heaters. One possible problem inherent to this FROM CONTROL LOGIC OR MICROCONTROLLER R type of output stage is a short circuit 4 2 1.2k from the output to the supply voltage (of1 Q1 3 IC1 D2 ten, 24V). This condition can destroy the BD139 1N4004 R3 output transistor if it lacks protection. 100 D1 R2 The simplest approach to solving this BAT85 10k problem is to use a fuse. This method has Q2 a disadvantage, however: You have to reBC548 place the fuse after it blows. A Figure 1 C1 R1 PTC (resettable) fuse is often too 47 F 2.2k slow to protect the transistor under the short-circuit condition. Another possibility is to use a current source as the This circuit provides fail-safe protection of an open-collector output stage. switching element. This approach is safe and simple, but it produces heat during ground. If a short circuit exists on the the Schottky diode, D1, is forward-biased the error condition. If the power rating output J1 or if the impedance of the load and thus discharges C1 and switches off and the cooling of the transistor are in- is lower than specified, the voltage on the Q2. If the steering output from the conadequate, the transistor fails because of collector of Q1 rises because too little trol logic again switches to the high state, thermal overload. The circuit in Figure base-current feed comes from the control Q2 stays in the switched-off condition 1 shows another simple approach to the logic (via R4) to saturate Q1. If the collec- during the charging of C1. If the output fail-safe protection of such switching de- tor voltage of Q1 reaches the switching of Q1 is not overloaded, Q1 saturates voltage on the base of Q2, Q2 turns on, again and stays switched on. If the output vices. The principal function of the circuit is and Q1 switches off. You can adjust this has a short circuit to the supply or it is to switch off the transistor if the voltage switching point with the R1-R2 voltage di- overloaded, then Q1 switches on only on the collector is higher than a prede- vider. Now, the voltage on the collector of during the charging of C1; after this time, termined value. Under normal switching Q1 rises to 24V, and the output stays in Q2 switches off Q1. The maximum load conditions, transistor Q1 should saturate the switched-off condition. To reset the current depends on the value of R4, the when it turns on with a voltage lower circuit, you must switch the steering out- output voltage from the control logic, than 0.2V between the collector of Q1 and put from the control logic to low. Now, and the current gain of Q1.

Low-battery indicator uses fleapower

Yongping Xia, Navcom Technology, Redondo Beach, CA

t is always desirable to use a lowbattery indicator that consumes as little power as possible. For a 9V, 450mAhr alkaline battery, a 50-A lowbattery indicator can by itself run the battery down in a little more than a year. Battery-powered devices that need to run continuously for a long time require battery indicators that consume minimal power. The circuit in Figure 1, designed for a 9V battery, uses extra-low power. When the battery is at full charge (9V),

the circuit draws 1.4-A current. At the indication-threshold voltage, 6.5V, the circuit draws 1 A. Assume that the average operating current is 1.2 A. The circuit uses 42 mAhr in a four-year period, less than 10% of the batterys rated energy. A red LED, D2, flashes periodically when the battery voltage drops below 6.5V. IC1, an LTC1540, is a nanopower comparator with a built-in 1.18V reference. A battery-voltage divider comprising R1and R2, and a positive-feedback

network, R3, feed the positive input of the comparator. The positive feedback generates hysteresis in the comparator. The negative input of the comparator receives bias from the reference voltage, through the R4-C1 delay circuit. During normal operation, the voltage at the positive input is approximately 1.62V when the battery is at 9V. The output of the comparator is at a high state, such that no current flows through D1 and D2. When the battery voltage drops

www.edn.com

90 edn | September 4, 2003

design

ideas

R5

2.2k below 6.5V, the voltage at the positive input drops below the reference voltage at D1 R6 1N4148 20k the negative input. The output of IC1 switches from high to low, thereby lightR3 20M ing the LED, D2. The switching R1 D2 Figure 1 changes the voltage at the positive 20M LED 7 input to 0.58V and causes C1 to discharge V+ through D1 and R6. Because the value of 3 + R6 is much smaller than that of R4, the IC1 8 LTC1540 voltage at the negative input drops 4 _ 9V quickly, according to the time constant R4 5 HYST that C1 and R6 set. Once the voltage at the 10M 6 REF negative input falls below 0.58V, the R2 comparator switches back to a high state. 2.2M GND C1 This change sets the voltage at the posi2 1 0.33 F tive input to 1.18V, turns off the LED, and reverse-biases D1, so the reference charges C1 through R4. When the voltage at the negative input again reaches This fleapower low-battery indicator draws just 1.2-A operating current. 1.18V, the cycle repeats. The LEDs ontime is a function of C1 and R6, and the times are 20 msec and 10 sec, respective- 1.8V)/2.2 k2.1 mA. The average LED off-time is a function of C1 and R4. With ly, at 6.5V threshold voltage. At this point, current is (20 msec2.1 mA)/10 sec4.2 the values in Figure 1, the on- and off- the LEDs on-state current is (6.5V A.

Indicator has electronic lens

Abel Raynus, Armatron International Inc, Melrose, MA

he method for implementing an extended-scale meter described in an PW earlier Design Idea had a conceptual IOIP PERIOD error: The meter impedance must change R 5 MC68HRC908JK1 continuously, not discretely as expressed 3 IP OSC (Reference 1). You could achieve the deC IQ sired result by using a digital potenTIME tiometer controlled by an input voltage PW PWM RV ADC via an appropriate interface. But this apPB7 PD4 PERIOD 19 6 proach is probably too sophisticated. Fig2 ure 1 shows an alternative approach that VIN A needs only a small and inexpensive microcontroller. The method exploits the fact that a dc meter measures Figure 1 the average value of a PWM signal: IAVGIPEAK(TPULSEWIDTH)/(TPERIOD). An inexpensive microcontroller allows you to expand any portion of the scale of a linear meter. Therefore, you can control the current through the meter by changing the pulse and d denotes the expansion of the upper 8-bit hex equivalent. The microcontroller width of the PWM signal. The PWM- end of the scale. The curves with high program (Listing 1 at the Web version of generating software determines the law slopes in the graph of Figure 2 corre- this Design Idea at www.edn.com) reads that governs the change in current in the spond to expanded scales. You can create the hex value and finds a corresponding meter. In the process of creating this soft- the scale patterns by choosing the thresh- pulse width from a table in its memory. ware, you can choose expansion of any old voltages (breakpoints) and slopes. Finally, the routine generates the PWM The circuit resembles an electronic lens signal with the given pulse width. Figure part of the scale (Figure 2). The transfer function, a, represents a attached to the meter, which magnifies 3 shows the software flow chart for the linear meter response; b denotes expan- any chosen part of the scale. The ADC in process. sion of the beginning of the scale; c indi- the microcontroller of Figure 1 transAs an example of the method, calculate cates expansion of the middle of the scale; forms the measured input voltage into its the scale expansion of a 100-A dc me-

92 edn | September 4, 2003

www.edn.com

design

ideas

A

ter with a measured-voltage range of 0 to 50 40 60 30 70 5V. You need to magnify the portion of 20 80 100 2 VOLTS 3 10 90 the input from 2 to 3V, from 20 to 70%, 1 4 a 100 90 0 leaving 10% at the beginning and 20% at A 0 5 80 50 the end of the scale (Figure 2, character40 60 30 70 a 70 20 80 istic c). Table 1 shows the steps of the calc VOLTS 10 90 b 1 60 b 2 culations, which you execute as follows: 0 3 100 CURRENT 45 1. Choose a number (N) and the val50 0 (A) A . ues of the measured input voltages, VIN 50 40 d 40 60 30 70 These parameters depend on the desired 20 80 30 VOLTS 10 90 3 accuracy of the meter scale. As an examc 0 100 20 4 2 1 5 ple, assume voltages with increments of A 0 10 50 40 60 0.5V for the low slope (Figure 2) and 30 70 20 80 0 0.1V for the high slope (Table 1, column VOLTS 10 90 0 1 2 3 4 5 d 0 100 2). Therefore, N19. VIN 34 2 5 01 2. Calculate the 8-bit ADCs Figure 2 digital output, NIN, for the seBy selecting slopes and breakpoints, you can expand the bottom (b), the middle (c), or the top (d) lected input voltages (column 3): NIN portions of a linear meters response. (256/5)VIN51.2VIN. 3. Transform NIN from decimal to microcontrollers time intervals is a func- ponents R20 k and C10 pF should hexadecimal format (column 4). The er- tion of the accuracy of its oscillator fre- yield a frequency of approximately 4.5 rors arising from the 8-bit quantization quency, which for the MC68HRC908K1 MHz. The measured frequency is 5.75 are insignificant for an analog indicator. depends on the external RC circuit. The MHz. With the timer/counter prescaler 4. Choose the PWM period, T. This data sheet for the IC recommends a tol- set at 64, the timer-clock period is 44.5 value depends on the rapidity of the in- erance of 1% or less for these components sec. Hence, you can calculate the numput-voltage change and should be rela- to obtain a clock tolerance of 10% or bet- ber of timer cycles for any time interval as tively short to prevent needle chatter. As- ter. But it is difficult to find a 10-pF1% Nt(t in milliseconds)/(44.5103) sume T10 msec for easy Table 1 capacitor, so this design uses a less ex- 22.5(t in milliseconds). Thus, for T10 calculations. pensive 5% capacitor and measures the msec, N10225 or NHEX$E1. 6. Determine the duty cycle () of the 5. Calculate the number of timer cycles oscillation frequency. According to the for the PWM period. The accuracy of any microcontroller manual, the timing com- PWM signal for each chosen input voltage, VIN, as well as the scale-expansion pattern (column 5); (IV/IMAX)100%. RESET You could either read the current value directly from the diagram in Figure 2 (charINITIALIZATION acteristic c) or calculate it for three linear parts of the scale with the following equaMAIN tion: IVITiSi(VINVTi), where IV is the current for the given input voltage VIN, ITi CLEAR X-REGISTER is the current for the threshold voltage VTi CONVERT VIN TO (i{1,2,3}), and Si is the slope of each linHEX FORMAT BY ADC ear portion of the scale in Figure 2 (characteristic c). The expressions for the three START piecewise-linear segments are as follows: COMPARE VIN WITH VX 10 VT1 = 0; IT1 = 0; S1 = = 5 A / V. FROM THE C MEMORY 2

DOES IT MATCH? ARE ALL VX CHECKED? COMPARE VIN WITH THE NEXT VX YES

YES

YES VINV0? SET PWX FROM MEMORY GENERATE PWM SIGNAL STOP GENERATING PWM

Figure 3

This flow chart shows the steps in the scale-expansion process.

VT 2 = 2 V ; IT 2 = 10 A; 80 10 S2 = = 70 A / V. 32 VT 3 = 3V ; IT 3 = 80 A; 100 80 S3 = = 10 A / V. 53 7. Determine the pulse width of the PWM signal: PWT (column 6). 8. Calculate the number of timer cycles, NOUT, for this pulse width by using

www.edn.com

96 edn | September 4, 2003

design

ideas

TABLE 1EXAMPLE OF MIDSCALE EXPANSION

1 x 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 2 VIN (V) 0.04 0.5 1 1.5 2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3 3.5 4 4.5 5 3 NIN 2 25.6 51.2 76.8 102.4 107.5 112.6 117.8 122.9 128 133.1 138.2 143.3 148.5 153.6 179.2 204.8 230.4 250.9 4 NIN (hexadecimal) $2 $1A $33 $4D $66 $6C $71 $76 $7B $80 $85 $8A $8F $94 $9A $B3 $CD $E6 $FB 5 (%) 0 2.5 5 7.5 10 17 24 31 38 45 52 59 66 73 80 85 90 95 99 6 Pulse width (msec) 0 0.25 0.5 0.75 1 1.7 2.4 3.1 3.8 4.5 5.2 5.9 6.6 7.3 8 8.5 9 9.5 9.9 7 NOUT 0 5.6 11.2 16.87 22.5 38.25 54 69.75 85.5 101.25 117 132.75 148.5 164.25 180 191.25 202.5 213.75 222.75 8 NOUT (hexadecimal) $0 $6 $0b $11 $16 $26 $36 $46 $55 $65 $75 $85 $95 $A4 $B4 $BF $CB $D6 $DF

the equation for Nt and transform the number into hexadecimal format (columns 7 and 8). 9. Enter NIN and NOUT Listing 1. You can use any microcontroller with a PWM function and built-in ADC. The one in Figure 1 has a 12-channel, 8-bit ADC and the capability to generate a PWM signal. This microcontroller has 15 I/O pins, which are necessary for executing other functions. If your application needs only to effect the meter-scale expansion, then the eight-pin 68HC908QT2 is probably a better choice. This microcontroller has a built-in oscillator and costs less than $1.You can download Listing 1 from the Web version of this Design Idea at www.edn.com. Reference 1. Raynus, Abel,Expanded-scale indicator revisited, EDN, Aug 8, 2002, pg 112.T

Thermal switches provide circuit disconnect

Mark Cherry, Maxim Integrated Products, Sunnyvale, CA

single temperature sensor can blow the fuse. You must take precau- cause the SCR to turn on. Once trigprovide an interrupt to a micro- tions to ensure that the SCR does not gered, the SCR cannot turn off, and the controller when the measured tem- trigger on a false gate pulse. Power-sup- fuse blows. A small RC filter, R3 and C3, perature goes out of range. You need ply transients can cause a false high sig- suppresses any gate transients that multiple temperature sensors when you nal at the output of the OR gate and would otherwise turn on the SCR. have to monitor more than one hot TO CIRCUIT spot. A microcontroller implements the proper protective action when one of 6 5 the temperature monitors detects an C1 0.1 F VCC OUTSET overtemperature condition. It is some3 OUT times easier and more cost-effective to IC1 simply disconnect the offending circuit MAX6510 5V SET 1 from the power supply without involvPOWER R1 D1 SUPPLY HYST GND 13.7k ing a microcontroller. A simple therEC103A 4 2 R mal-protection circuit (Figure 1) in3 10k cludes two temperature switches, IC1 and IC2, with active-high outputs. TemIC3 C3 perature thresholds for these switches 74HC32 0.033 F 6 5 C 2 depend on resistors R1 and R2, and the VCC OUTSET 0.1 F 3 switch outputs connect to the inputs of OUT IC2 a dual-input OR gate, IC3. OR gates MAX6510 with more than two inputs are available SET 1 R2 if you need more than two temHYST GND 13.7k Figure 1 perature switches. When excessive 4 2 temperature drives either input high, the OR gates output switches high, causing an SCR (silicon-controlled rectifier) to crowbar the power supply and This thermal-protection circuit includes a crowbar device, D1, driven by thermal switches IC1 and IC2.

98 edn | September 4, 2003

www.edn.com

design

ideas

Buck-boost regulator suits battery operation

Kahou Wong, On Semiconductor, Phoenix, AZ

buck/boost converter can 32.1V to an output of 14.1V. INPUT OUTPUT step a voltage up or down. Such The MC33166/7 has a 40V maxMC33166/7 a converter is appropriate for imum switch rating, and it can acCOMP V battery-powered applications. One commodate 95% duty cycle, so its IN GROUND application derives a regulated adequate for the application. To SWITCH 14.1V at 1A from 12V solar panels implement synchronous rectificaFB with 9 to 18V variation. In this type tion for better efficiency, the design of battery application, efficiency is uses an additional transformer 5V an important factor; hence, this dewinding and a MOSFET. The auxsign uses an inexpensive synchroiliary winding provides bias voltnous-rectifier-based MC33166/7 age to turn on the MOSFET when circuit. It is difficult to find a the switching-node polarity turns Figure 1 buck-boost controller in the negative. Note that the synchromarket. It is even more difficult to nous rectifier is an important facfind an inexpensive one with an in- This inexpensive buck-boost controller uses synchronous recti- tor in the efficiency of this circuit, tegrated high-current switch. One fication for high efficiency. because the input-to-output ratio way to build a buck-boost convertis approximately 1-to-1. So, the er is to use a buck regulator with an in- and a resistor pair divides the 14.1V out- duty cycle is approximately 50%, which ternal switch, such as the MC33166/7 put voltage to 5V for connection to the FB means that the MOSFET conducts for (Figure 1). The negative-polarity output pin of the IC. So, the IC effectively regu- half the switching-frequency period. voltage connects to the ICs ground pin, lates an input of VINVOUT1814.1

100 edn | September 4, 2003

www.edn.com

Вам также может понравиться

- Sony KDL-60W610B - RB2G 9-888-602-01 PDFДокумент27 страницSony KDL-60W610B - RB2G 9-888-602-01 PDFIDGG2011Оценок пока нет

- Control IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 AДокумент17 страницControl IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ASledge HammerОценок пока нет

- Sony Vaio VGN-AW Series MBX-194 M780 SD FOXCONN M780 CantigaP WPCE775LДокумент77 страницSony Vaio VGN-AW Series MBX-194 M780 SD FOXCONN M780 CantigaP WPCE775LChetin TekinОценок пока нет

- PIC PWM ControllerДокумент10 страницPIC PWM Controllerkeitabando100% (2)

- Vinafix - VN - Asus 1015cx Cedar Trail Training MaterialsДокумент67 страницVinafix - VN - Asus 1015cx Cedar Trail Training Materialsrasrozi51700% (1)

- Schematic Diagram: 1. ScalerДокумент7 страницSchematic Diagram: 1. ScalerMilan HouskaОценок пока нет

- KDL 40 BX 450Документ37 страницKDL 40 BX 450Jose GonzalesОценок пока нет

- Bridgeless Buck PFC Rectifier With Voltage Doubler OutputДокумент24 страницыBridgeless Buck PFC Rectifier With Voltage Doubler Outputakshaya5293Оценок пока нет

- Wistron Jm31 CPДокумент62 страницыWistron Jm31 CPVadim ShapovalovОценок пока нет

- TPM17.1E EuДокумент112 страницTPM17.1E EuViktor SteinþórssonОценок пока нет

- Plasma TV SMPS TroubleshoutingДокумент5 страницPlasma TV SMPS TroubleshoutingmindjokerОценок пока нет

- SP 360 CmanualДокумент35 страницSP 360 CmanualencontreelrepuestoОценок пока нет

- UOC III 21 G-III Chassis Service ManualДокумент33 страницыUOC III 21 G-III Chassis Service ManualAlexandra BarzaianuОценок пока нет

- Sony+KDL 32EX521 1 PDFДокумент43 страницыSony+KDL 32EX521 1 PDFpolloОценок пока нет

- Repair Guide For PhillipstvДокумент25 страницRepair Guide For PhillipstvRobert BellОценок пока нет

- Ebook LCD Best OneДокумент125 страницEbook LCD Best Oneananad addictОценок пока нет

- LCD TV: Service ManualДокумент43 страницыLCD TV: Service Manualmariana acostaОценок пока нет

- Panel Volts LCD Led PDFДокумент3 страницыPanel Volts LCD Led PDFRaj ChoudharyОценок пока нет

- Manual de Service para TV LED PhilipsДокумент108 страницManual de Service para TV LED Philipstavillo1980Оценок пока нет

- Wistron LA710 - 17513 PDFДокумент107 страницWistron LA710 - 17513 PDFArny Mayedo CastilloОценок пока нет

- Basic Connecting Microcontroller Power Clock ResetДокумент6 страницBasic Connecting Microcontroller Power Clock ResetJuan CarlOs Culqui Melendez100% (1)

- Samsung Ue60h7000 Chassis U8dc PDFДокумент67 страницSamsung Ue60h7000 Chassis U8dc PDFDa El80% (5)

- KDL-22 - 32 - 40 - 46CX520 - 32 - 40 - 46CX523 CH - AZ2G (sm-9-888-127-01)Документ98 страницKDL-22 - 32 - 40 - 46CX520 - 32 - 40 - 46CX523 CH - AZ2G (sm-9-888-127-01)Jory2005100% (1)

- LCD Panel Repairing Book - Parte5Документ40 страницLCD Panel Repairing Book - Parte5Ricardo Nicolau WerlangОценок пока нет

- SONY - KDL-32-37-40-46-55EX505 Chassis - AZ1-L - SM PDFДокумент64 страницыSONY - KDL-32-37-40-46-55EX505 Chassis - AZ1-L - SM PDFAnselmo Baturite100% (1)

- Introduction To Laptop Fix and DiagnosesДокумент51 страницаIntroduction To Laptop Fix and Diagnosesablacon64Оценок пока нет

- Another 6 Pin SMD IC in LED & LCD TV/Monitor: Home Articles Download Page Recommend Contact UsДокумент10 страницAnother 6 Pin SMD IC in LED & LCD TV/Monitor: Home Articles Download Page Recommend Contact UsyudelbysОценок пока нет

- 26LX1D Service Manual, LG LCD TVДокумент48 страниц26LX1D Service Manual, LG LCD TVaoc2000Оценок пока нет

- Tecnica Guia Panasonic TH-42PZ700UДокумент77 страницTecnica Guia Panasonic TH-42PZ700UAlberto Pernia100% (1)

- การติดตั้งแผงโซล่าเซลล์ในบ้านรุปแบบวิธีการและเอกสารДокумент39 страницการติดตั้งแผงโซล่าเซลล์ในบ้านรุปแบบวิธีการและเอกสารChanade WichasilpОценок пока нет

- Msi b85m Pro-Vd (Ms-7a01) Rev 1.1Документ34 страницыMsi b85m Pro-Vd (Ms-7a01) Rev 1.1Angel RuizОценок пока нет

- Sanyo Avm2751s Service ManualДокумент26 страницSanyo Avm2751s Service ManualKastaliaОценок пока нет

- LC470WX1-SLA_6870C-0143B PCB Schematic SectionsДокумент35 страницLC470WX1-SLA_6870C-0143B PCB Schematic SectionsEveraldoОценок пока нет

- Sony TV Bravia KLV-32S550A ManualДокумент28 страницSony TV Bravia KLV-32S550A Manualmilind1983Оценок пока нет

- TFT-LCD Modules " Improving Video Performance/ Reducing CostДокумент7 страницTFT-LCD Modules " Improving Video Performance/ Reducing CostAnonymous O5WK6kiLiV100% (1)

- LCD TV General Troubleshooting and Tips To RCA L32WD22 FixДокумент6 страницLCD TV General Troubleshooting and Tips To RCA L32WD22 Fixdfenncatman20% (1)

- Sony PDP-01 Plasma TrainingДокумент91 страницаSony PDP-01 Plasma Trainingdann222Оценок пока нет

- 1 SamsungДокумент106 страниц1 SamsungBeni GiurgiuОценок пока нет

- Service Manual: ChassisДокумент43 страницыService Manual: ChassisSokol Kadare50% (2)

- 2010 Plasma TV Troubleshooting HandbookДокумент62 страницы2010 Plasma TV Troubleshooting Handbookjay1988j50% (2)

- 42PQ30 Manual de EntrenamientoДокумент124 страницы42PQ30 Manual de Entrenamientoparis68Оценок пока нет

- CV801LE-A-15: System BlockДокумент18 страницCV801LE-A-15: System BlockJibon DasОценок пока нет

- Idoc - Pub - LCD Monitor Repair PDFДокумент26 страницIdoc - Pub - LCD Monitor Repair PDFElektroNiОценок пока нет

- DSUB-25P Male Pinout DiagramДокумент1 страницаDSUB-25P Male Pinout DiagramabnomaloОценок пока нет

- LVDSДокумент2 страницыLVDSmarco giustiОценок пока нет

- Reference Design-6 STR-W6756 Universal-Input 140 W Power SupplyДокумент2 страницыReference Design-6 STR-W6756 Universal-Input 140 W Power SupplyShamol KormokerОценок пока нет

- CCFL Tester For LCD Screens PDFДокумент1 страницаCCFL Tester For LCD Screens PDFShrivlsi RamОценок пока нет

- VGA SchematicДокумент1 страницаVGA SchematicalexanderОценок пока нет

- EDN Design Ideas 2007Документ146 страницEDN Design Ideas 2007chag1956100% (2)

- DiДокумент6 страницDipani256Оценок пока нет

- 93004diДокумент8 страниц93004dirogererfredererОценок пока нет

- Two diodes change demagnetization-signal polarity for flyback convertersДокумент7 страницTwo diodes change demagnetization-signal polarity for flyback convertersBruceОценок пока нет

- Best of Design Ideas - Volume 2Документ18 страницBest of Design Ideas - Volume 2ableseaman100% (3)

- DiДокумент5 страницDiByron DamaniaОценок пока нет

- EDN Design Ideas 2002Документ198 страницEDN Design Ideas 2002chag1956100% (1)

- 40104diДокумент6 страниц40104dimariastalinОценок пока нет