Академический Документы

Профессиональный Документы

Культура Документы

Novel Design For The Nozzle of A Laminar Jet Absorber

Загружено:

my_khan20027195Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Novel Design For The Nozzle of A Laminar Jet Absorber

Загружено:

my_khan20027195Авторское право:

Доступные форматы

2568

Ind. Eng. Chem. Res. 2004, 43, 2568-2574

Novel Design for the Nozzle of a Laminar Jet Absorber

Ahmed Aboudheir, Paitoon Tontiwachwuthikul,*, Amit Chakma, and Raphael Idem

International Test Centre for Carbon Dioxide Capture (ITC), Faculty of Engineering, University of Regina, Regina, Saskatchewan, Canada, and Chemical Engineering Department, University of Waterloo, Waterloo, Ontario, Canada

A novel design for the nozzle of a laminar jet absorber has been produced and used to obtain high-quality absorption-kinetics data devoid of interfacial resistance and interfacial turbulence. The nozzle design consists of a circular hole in a 0.07 ( 0.005 mm thick stainless steel sheet having an inside diameter of between 0.50 and 0.65 mm. The hydrodynamics of the various jets produced from this nozzle were checked by studying the physical absorption of carbon dioxide into water and nitrous oxide into monoethanolamine. Wetting of the orifice face, oscillations in the jet, and interfacial resistance were completely absent. In addition, the new nozzle design was tested by comparing the measured kinetics data with published data for carbon dioxide reactive absorption in monoethanolamine solutions. The measured kinetic data were in excellent agreement with literature data obtained over a period of four decades. This shows that the nozzle design produces high-quality absorption data, and that the kinetic data obtained were accurate and not subject to any interfacial turbulence.

Introduction The kinetics of the reactive absorption of a gas into liquids are usually obtained in a laminar jet absorber, wetted wall column, one-sphere unit, or stirred cell unit. The use of each apparatus depends mainly on the physical and chemical properties of the absorption system. For fast chemical reactions between absorbed gases and reactive liquids such as carbon dioxide (CO2) in monoethanolamine (MEA) solutions, the laminar jet absorber has proven to be the best apparatus that can be used to generate reliable absorption data. This is because the contact time between gas and liquid is short, the interfacial area is known accurately, and the physical absorption rates have been shown to agree with penetration theory predictions.1,2 The most important and critical part of the laminar jet absorber is the nozzle that produces the liquid jet. This is because the extent of departure of the behavior of the jet from an ideal rodlike flow depends on the shape of the nozzle or orifice at which the liquid-jet is formed.1 Basically, the liquid jet can be formed with a bell-shaped nozzle3-7 or an orifice-plate nozzle.6,8-12 Raimondi and Toor8 and Clarke6 tested both design types and concluded that jets produced by orifice-plate nozzles have a flat velocity distribution, whereas the bell-shaped nozzles produce a surface retardation which shows the absorption rate to be lower than theoretical predictions. On this basis, it was decided to base the nozzle design in this work on the orifice-plate nozzle type. Raimondi and Toor8 used a square-edged orifice in a plate of 0.1 mm thickness, where the diameter of the orifice was in the range from 0.571 to 0.851 mm. The authors claimed that measurements of the absorption rate of CO2 into water at 295 K, with contact time

* To whom correspondence should be addressed. E-mail: paitoon@uregina.ca. Fax: (306) 585-4855. University of Regina. University of Waterloo.

between 1 and 20 ms, agreed closely with those predicted theoretically even though they were 1-4% lower than the theoretical. Al-Ghawas et al.9 also used a square-edged orifice, 0.51 mm in diameter, drilled in a 0.08-mm thick stainless steel sheet. Using this nozzle design, the diffusion coefficient of CO2 into water at 298 K was reported as 1.95 10-5 cm2/s, which was within the range of values available in the literature13 (from 1.75 10-5 to 2.05 10-5 cm2/s). A similar design for the nozzle was used by Ashour et al.10 and Rinker et al.,11 except that the diameter in this case was 0.533 mm instead of 0.51 mm. The measured diffusion coefficients of CO2 into water at 293 and 313 K were reported11 as 1.74 10-5 and 2.67 10-5 cm2/s, respectively, which are in close agreement with those correlated by the expression of Versteeg and van Swaaij.13 Good absorption data can be obtained with a square-edged orifice as illustrated above. However, because most theoretical models are predicated on a rodlike jet, it is essential to produce a rodlike jet in the laminar jet absorber as this is key to obtaining good agreement between theoretical and experimental values. It is predicted that a circular-hole orifice might be better at producing a rodlike liquid jet on which the theoretical expressions are based. Consequently, not only are we using the nozzle design in this work, but we are also evaluating the circular-hole orifice in producing a rodlike jet. In some experiments, unusual operating conditions have been imposed, or modified chemical solvents have been used, to obtain accurate experimental absorption rates relative to theoretical predictions. For example, Clarke6 conducted the experiments at a reduced pressure to avoid the suspected depletion of unreacted MEA at the interface. Hikita et al.5 and Hagewiesche et al.14 added a small amount of surface-active agent to reduce the values of the experimental absorption rates. They indicated that the higher absorption rates observed in the case of the solution without surface active agent could be attributed to interfacial turbulence, presumably

10.1021/ie0341606 CCC: $27.50 2004 American Chemical Society Published on Web 04/07/2004

Ind. Eng. Chem. Res., Vol. 43, No. 10, 2004 2569

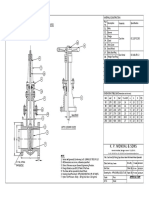

Figure 1. Schematic drawing of the laminar jet apparatus.

produced by a surface tension gradient during the chemical absorption process, as observed by Brian et al.15 and also reported by Sada et al.16 The higher absorption rates obtained in these cases could be attributed to the design of the nozzle in addition to both the suspected depletion of unreacted MEA at the interface and interfacial turbulence. In this work, a new nozzle design is proposed and then used to show that it can eliminate the contributions of these parameters (i.e., the depletion of unreacted MEA at the interface and the interfacial turbulence) to the observed absorption rates. It was also used to show that with the new nozzle design it was not necessary to modify the experimental conditions or modify the properties of the liquid to obtain accurate kinetics data. Experimental Section The purpose of the laminar jet experiments was to test the reliability of the new nozzle design under several operating conditions. It was also to show that with the new nozzle design there was no need to modify the experimental conditions or modify the properties of the liquid to obtain accurate kinetic data. The main materials used in measuring the rate of gas absorption in the laminar jet absorber are carbon dioxide (CO2), nitrous oxide (N2O), and monoethanolamine (MEA). CO2 with a purity of 99.9% and N2O with a purity of 99.5% were purchased from PRAXAIR (Regina, SK). The MEA with a purity of 99.0% was purchased from Fisher Scientific (Nepean, ON) and used without any further purification. The experimental kinetic data were obtained by absorption of CO2 into aqueous MEA solutions. The free MEA concentrations were in the range from 0.193 to 3.158 mol/L with an average CO2 loading of 1.81 mol/L. All the kinetics experiments were conducted at atmospheric pressure at temperatures in the range of 293-313 K. Apparatus. The main parts of the laminar liquid jet apparatus used for the measurements reported in this work are schematically presented in Figure 1. The absorbing liquid from a constant-head system was fed by gravity through a temperature-controlled bath to a jet chamber. The constant-head system was used to

maintain a constant liquid flow rate. A jet of the liquid issued from a circular nozzle, flowed intact downward through an atmosphere of the absorbed gas, and was collected in a capillary receiver. The absorbed gas was supplied from a pressure cylinder and was saturated with water vapor at the experimental temperature before entering the absorber chamber. In addition to the new nozzle and new receiver design, the apparatus combined various features of the designs of Danckwerts,1 Astarita et al.,2 and Al-Ghawas et al.,9 such as the jet chamber design, the degassing process of the liquid, and the gas flow rate measurement process. Jet Chamber Assembly. The jet chamber, which is similar to the design of Al-Ghawas et al.,9 was a 250mm long and 50-mm i.d. acrylic cylinder enclosed in a constant-temperature jacket constructed from a 250-mm long and 150-mm i.d. acrylic cylinder. Both cylinders were held between two aluminum flanges, and the ends were sealed with rubber gaskets. The nozzle was mounted on the end of a 6.4-mm i.d. acrylic delivery tube, which passed through a Swagelok nut in the aluminum cover flange. The delivery tube could slide vertically to change the jet length, and could also be locked into position by the Swagelok nut. The jet chamber was provided with a gas entry near the bottom, a gas outlet near the top, a manometer port, and a 6.4-mm i.d. receiver tube fitted into a funnelshaped base. A hole in the base allowed draining of any liquid overflow through the overflow port. To avoid vibration, the jet absorber was placed on an antivibration pad and all the lines leading to the jet absorber were made from flexible tubes. Nozzle. It is our hypothesis that a circular-hole orifice on a very thin sheet should be better at producing a rodlike liquid jet than a square-edged orifice design, which previous literature has recommended.8-11 In this work, several nozzles were designed as circular holes in 0.07 ( 0.005 mm-thick stainless steel sheets and used to evaluate their ability to produce a smooth-surfaced uniform rod-like flow. Very thin sheets were used to minimize boundary-layer effects and to approach a flat velocity distribution at the charge point. The circular holes had diameters ranging from 0.50 to 0.65 mm. These nozzles were used without any further treatments such as the paraffin-wax coating employed by Scriven and Pigford3 to prevent wetting. With our design, no wetting of the orifice faces and no oscillations in the jets were observed. Photographs of typical jet nozzle components and dimensions are shown in Figure 2. The hydrodynamics of the various jets were checked by studying the physical absorption of CO2 into water within the temperature range of 288-333 K. Testing the apparatus within this temperature range is required to ensure that the behavior of the laminar jet as a function of temperature is correct. Receiver. Usually the receiver is made from a glass capillary tube having an internal diameter 20-40% greater than the jet diameter.3,6,9 This capillary tube is capped by a Teflon plug into which a hole is drilled according to the capillary tube diameter. This design is complex, difficult to produce, and thus expensive to obtain. To overcome these shortcomings, the receiver in this work was designed as a capillary hole drilled into an acrylic rod as shown in Figure 3. The length and diameter of the hole were 20.0 mm and 1.0 mm, respectively. This design is simpler, cheaper, and much easier to produce than the ones reported in the litera-

2570 Ind. Eng. Chem. Res., Vol. 43, No. 10, 2004

Figure 2. Jet nozzle components and dimensions.

Figure 3. Receiver of the liquid jet.

ture.3,6,9 The receiver assembly was fitted onto the end of the receiver tube by two O-rings. The downstream end of the receiver was connected to a constant-level device, which was mounted on a vertical slide rod and provided with a fine-adjustment leveling screw (see Figure 1). This receiver design assisted in the collection of the liquid jet without any liquid spillover or gas entrainment inside the receiver for several hours of continuous operation. Operating Procedures. The absorbing liquid was degassed by spraying it into a vacuum, similar to the Danckwerts1 procedures, and kept under a nitrogen blanket. This degassing process was found to be more effective, easier, and safer than the degassing process by heating while the solution was under vacuum as implemented by other workers,9,11 especially when hazardous chemical solutions are used. The degassed solution was fed by gravity to the jet chamber from a constant-head system, located about 3.0 m above the absorption chamber (see Figure 1). This was to provide sufficient head for the required rate of flow. The constant-head system is a 200-cm3 capacity cup provided with a liquid-inlet port and a liquid-outlet port on its bottom. During the liquid feed operation, the inlet flow rate was kept higher than the outlet flow rate and the overflow from the cup was returned to the feed tank. The liquid in both the constant-head system and the

feed tank was kept under a blanket of nitrogen during the operation. The N2 supply to replace the used liquid was stored in a balloon connected to both the feed tank and the constant-head system. The flow rate of the liquid was controlled with a rotameter. This technique did prove to give a stable and constant flow rate for several hours of operation and was found to be better than the surge-tank technique applied in the liquid line between the pump and the rotameter to eliminate the pump pulses, as implemented by other workers.9,11 The actual flow rate of liquid was determined by weighing the liquid discharged in a timed interval during each experiment. A 1-L volumetric flask was used to collect the discharged liquid. The constant-level device was used to adjust the liquid level in the receiver. When the level was slightly too high, not all the liquid-jet was collected in the receiver; some of the jet spilled over. When the level was too low, the free jet continued several mm down into the receiver and small gas bubbles were entrained in the rapidly moving liquid inside the receiver. The level was adjusted to give the condition in which there was neither spillover of liquid nor entrainment of gas. A two-dimensional traveling microscope was used to measure the jet-length to within 0.01 mm and the jet-diameter to within 0.001 mm. The gas from a pressure cylinder was saturated with water vapor at the experimental temperature before entering the jet chamber as practiced by many researchers.9,11 Temperatures of the liquid entering and leaving the jetchamber, the gas entering the jet-chamber, and the gas entering the gas-flow meter were measured. The temperatures of the liquid and the gas entering the jet chamber were controlled to within (0.3 C. This was achieved by having two separate heating/cooling circulator units, one for controlling the gas-stream temperature and the other for controlling the liquid-stream temperature. The best method for measuring the mass transfer rate in terms of the absorption rate is the volumetric technique, as reported by other authors.9,11,17 As shown in Figure 1, after obtaining a stable jet-flow, a gaseous stream consisting of only the gas to be absorbed was forced to flow through the absorption chamber of the laminar jet and purged through a digital flow meter (soap-film meter). The used flow meter was designed to measure flows from 0.1 to 50 cm3/minute with an accuracy of (3% of readings. After sufficient time had elapsed to make sure that the jet chamber, the soap meter, and the long-purge tube had been filled with the gas, the gas-feed valve was closed. At this point, the flow rate of gas that was indicated by the soap-film meter was equal to the volumetric rate of absorption. Experiments were repeated several times and an average was taken. In all cases, the purge gas was vented into a fume hood. The choice of the operating conditions of the laminar jet is based on a number of design constraints (mainly the design of the nozzle and the receiver). First, the length of the jet cannot be varied over a wide range. If the jet is too short, end effect becomes too important; if it is too long, operation of the receiver becomes difficult. Second, the liquid flow rate can be changed only over a limited range: a lower limit is imposed by the requirement of avoiding dripping and an upper limit is imposed by the need to avoid turbulence. This behavior has been reported by Astarita et al.,2 and has been observed and confirmed in this experimental work. As a result, the

Ind. Eng. Chem. Res., Vol. 43, No. 10, 2004 2571

first constraint restricts the range of the interfacial area and the latter constraint limits the range of the masstransfer coefficient.2 Results and Discussion The experimental data generated in this work were obtained by a dynamic method in which a jet of liquid moves continuously through the gas for a known contact time. The absorption rate was measured volumetrically with a digital soap-film meter. The absorption rates were utilized to determine molecular diffusivity and kinetics of reaction. The physical absorption data, from the CO2-water and N2O-MEA systems, were used to test the apparatus and to calculate the molecular diffusivities. The chemical absorption data, from the CO2-MEA system, were used to calculate the kinetics. These results were compared with the published data to confirm the reliability of the nozzle and the receiver design in this work. CO2-Water Absorption. The laminar jet absorber designed in this work was first tested by absorbing CO2 into water, which is a standard method for testing this type of apparatus because the solubility and the diffusivity of CO2 in water are well known.1,2 In the absence of reaction, the total rate of absorption into the jet can be calculated theoretically from eq 1, which was based on a rodlike jet.1,18

Figure 4. Physical absorption rates of CO2 into water and N2O into 1 M MEA solution at 298 K and atmospheric pressure in laminar jet absorber: experimental (points), and theoretical (line). Table 1. Diffusivity of CO2 in Water at 298 K and Atmospheric Pressure D, cm2/s 1.75 1.90 10-5 1.87 10-5 1.94 10-5 2.00 10-5 1.85 10-5 2.05 10-5 1.95 10-5 1.87 10-5 1.98 10-5 1.93 10-5 1.98 10-5 1.95 10-5 1.94 10-5 1.96 10-5 1.96 10-5

a

reference Tamann and Jessen, 1929a Taniguchi and Sakurada, 1955a Scriven, 1956a Davidson and Cullen, 1957a Vivian and King, 1964a Unver and Himmelbau, 1964a Clarke, 1964a Thomas and Adams, 1965a Tang and Himmelbau, 1965a Duda and Vrentas, 1968a Haimour and Sandall, 198428 Tang and Sandall, 198529 Al-Ghawas et al., 19899 Tamimi et al., 199430 Perry and Green, 199727 this work

10-5

RA ) 4Ce*(DLh)1/2

(1)

where RA is the total rate of absorption of gas, Ce* is the equilibrium concentration of gas at the interface, D is the diffusivity of gas in liquid, L is the liquid flow rate, and h is the jet length. A plot of RA against (Lh)1/2 at various flow rates and jet lengths, should give a straight line through the origin with a slope equal to 4Ce*D1/2. The raw experimental data for the absorption rate of CO2 into water are documented elsewhere.19 The absorption experiments were carried out over the temperature range of 288-333 K using seven different nozzle diameters ranging from 0.50 to 0.65 mm. All experiments were done under atmospheric pressure. The proper partial pressure of carbon dioxide that was used in calculating the absorption rate was taken to be equal to the total pressure less the vapor pressure of water at the temperature of the experiment. The water vapor pressure was calculated from the Antoine equation at the experimental temperature. The experimental data as well as the theoretical predictions of the absorption rate of CO2 into water are shown in Figure 4. The points are the experimental data and the line in this figure is calculated from eq 1. The diffusivity and solubility of carbon dioxide in water used in this equation at 298 K and atmospheric pressure were taken as 1.96 10-5 cm2/s and 3.29 10-5 mol/cm3, respectively.27 The agreement between the measured and calculated absorption rates is excellent over various flow rates and jet lengths with an average absolute deviation of 0.8% from the calculated rates. This excellent agreement shows the reliability of the experimental apparatus design and arrangement to produce a rodlike jet, as well as indicates the absence of any interfacial resistance. In addition, the average experimental value found for the diffusion coefficient of CO2 in water at 298 K and atmospheric pressure was 1.96 10-5 cm2/s. This value

Data reported in Versteeg and van Swaaij, 198813.

is calculated by using the slope of the experimental data, which is 5.83 10-7, and the solubility of CO2 into water. The experimental diffusivity that was obtained in this work shows good agreement with that available in the literature, as shown in Table 1. It should be mentioned that the data presented in Figure 4 were produced by using the 0.63-mm diameter nozzle. The other six nozzles designed in this work gave similar satisfactory results. The measured absorption rates at 298 K from all nozzles and the predicted absorption rates calculated from eq 1 were compared in the parity plot shown in Figure 5. This shows excellent agreement between the measured rates of CO2 absorption into water using the seven different nozzle diameters and the rates of CO2 absorption predicted from the theoretical model. The average absolute deviation of the measured rates from the predicted rates is 1.7%. On the basis of this result, any nozzle diameter within the range of 0.5-0.65 mm will give satisfactory absorption rates if it is as well-designed as the nozzle in this work. In addition, these excellent agreements again show that the experimental apparatus, especially the nozzle design, is excellent. It also shows the absence of any interfacial resistance. To test the behavior of the laminar jet absorber as a function of temperature, the temperature effect on the diffusivity of CO2 in water was determined experimen-

2572 Ind. Eng. Chem. Res., Vol. 43, No. 10, 2004

Figure 7. Water-jet diameter for a 0.630-mm i.d. nozzle in a stainless steel plate 0.07 mm thick. Figure 5. Comparison of measured and predicted CO2 absorption rate into water at 298 K in the laminar liquid jet absorber.

Figure 6. Diffusivity of CO2 in water as a function of temperature.

tally within the temperature range from 288 to 333 K, the typical temperature range found in gas absorbers. Figure 6 shows this experimental diffusivity as well as the diffusivity from eq 2 based on the correlation developed by Versteeg and van Swaaij13 (diffusivity is in cm2/s and temperature is in Kelvin).

D ) 2.35 10-2 exp(-2119/T)

(2)

Excellent agreement between the measured and predicted diffusivity was obtained. The average absolute deviation of the measured diffusivity from the predicted diffusivity was 1.7%. This indicates that the behavior of the laminar jet is excellent within the temperature range of 288-333 K. It is well-known that there could be a small departure from the assumption of idealized rodlike jet. The departure from ideal behavior is caused by several factors: first, an entrance effect caused by the nonflattened velocity profile at the nozzle; second, a gravity effect caused by the acceleration and shrinkage under the influence of gravity; and third, an exit effect caused mainly by rippling and surface stagnation induced by the jet receiver.2 The results obtained from our nozzle

design illustrate very clearly that the departure from the assumption of idealized rodlike cylindrical jet can be kept to a minimum by using a well-designed nozzle. Regarding the measurements of the jet diameter, it is found that the measurements taken at the middle of the jet length were sufficient for the mass transfer calculation. Diameter measurements for a 0.630-mm i.d. nozzle in a stainless steel plate of 0.07-mm thick are shown in Figure 7. It can be seen that the diameter of the water jet is reduced from 0.630 to 0.506 mm within the first 2.0 mm of the downstream flow mainly because of the influences of viscous drag in the nozzle and gravitational acceleration. At a distance downstream of the nozzle of more than 2.0 mm, the change in diameter with length is somewhat negligible. This was achieved by using a very thin stainless steel plate for manufacturing the nozzle. It can also be seen from the figure that the diameter is a function of temperature and the liquid flow rate. Thus, it is recommended to take new measurements for the diameter whenever there are extreme changes in these operating conditions. From this it can be concluded that any absorption calculation should be based on the measured diameter of the liquid jet and not on the nozzle diameter. Basing calculations on nozzle diameter instead of the actual measured diameter may explain the high experimental absorption rates reported by Hagewiesche et al.14 N2O-MEA Absorption. An additional test for the laminar jet apparatus was performed by the physical absorption of N2O into MEA solution, from which the diffusivity (D) of N2O in 1 M MEA solution at 298 K was measured. The absorption rates (RA) of N2O shown in Figure 4 were measured at different gas-liquid contact times ranging from 1.3 to 6.0 ms by varying both the jet length and liquid flow rate. Each absorption rate value reported in this figure was an average of 5-7 measurements. In the absence of reaction, the total rate of absorption into the jet can be represented theoretically by eq 1. In this case, Ce* is the interfacialequilibrium concentration of the N2O gas in the liquid phase, which is known as the solubility of N2O in MEA solution. This solubility was calculated from the semiempirical model of Wang et al.20 The enhanced parameters for this model by Tsai et al.21 were adapted in this solubility calculation. As shown in Figure 4, a plot of the experimental data of RA against (Lh)1/2, at various flow rates and jet lengths, should give a straight line through the origin with a slope equal to 4Ce*D1/2. From this figure, the value of the slope of the experimental

Ind. Eng. Chem. Res., Vol. 43, No. 10, 2004 2573

data was found to be 3.844 10-7. This slope and the solubility of N2O in 1 M MEA solution at 298 K, which is 2.33 10-5 mol/cm3, were used to determine the experimental diffusivity. The average experimental value found from this work for the diffusion coefficient of N2O in 1 M MEA solution at 298 K was 1.70 10-5 cm2/s. This is in excellent agreement with the value of 1.69 10-5 cm2/s reported under the same conditions by Sada et al.22 In conclusion, the preceding critical analysis of all the physical experimental results, and the absorption rates observed, show that the jets were evidently similar to an ideal rodlike cylindrical jet thereby yielding accurate results from the laminar jet absorber designed in this work. On the basis of the range of dimensions used in our work, it is recommended that the nozzle be a circular hole in a 0.07 ( 0.005-mm thick stainless steel sheet and that the inside diameter of this nozzle should be between 0.50 and 0.65 mm. We have confirmed that with this design, no wetting of the orifice face, no oscillations in the jets, and no interfacial resistance are observed. It is also recommended to feed the liquid by gravity to the jet chamber using a constant-head system with a blanket of inert gas. This technique gives a stable and constant liquid flow rate for several hours of continuous operation. CO2-MEA Absorption. The reaction between CO2 and MEA solutions was investigated in the laminar jet absorber to further test the reliability of the new nozzle design and receiver of this work. The absorption experiments were carried out within the temperature range of 293-313 K because the CO2-MEA kinetics is well defined within this temperature range in the literature where a second-order kinetics (eq 3) for CO2 reaction with MEA solution has been reported.23

Figure 8. Experimental results of the apparent reaction-rate constants for CO2 reaction with aqueous MEA solutions.

r ) - k2[MEA][CO2] ) kapp[CO2]

(3)

Figure 9. Arrhenius plot for the reaction between CO2 and aqueous MEA solutions. Table 2. Apparent Reaction Order and Second-Order Rate Constant for CO2 Absorption into MEA Solutions, When Assuming R ) kapp[CO2] and kapp ) k2[MEA]n [MEA] (mol/L) PCO2 (kPa) av. n [CO2]tot (reaction k2 (mol/L) order) (L/mols) 1.81 1.81 1.83 1.04 1.08 1.16 4615 6674 10119

It is well-known that the accuracy of the deduced kinetic data decreases with increasing depletion of free amine toward the gas-liquid interface because the absorption flux is increasingly determined by diffusion.24 Therefore, to minimize the effect of the diffusion limitation, we used loaded MEA solutions in our work to generate experimental kinetics data. This resulted in the difference between bulk and interfacial concentrations of free amine being kept as low as possible during the experiment. In addition, all the experimental data were interpreted with the aid of a developed numerically solved absorption-rate/kinetics model reported elsewhere25 to obtain reliable kinetics or reaction-rate data.11,23,24 This absorption-rate/kinetics model takes into account the coupling between chemical equilibrium, mass transfer, and chemical kinetics of all possible chemical reactions. The mathematical model is capable of predicting gas absorption rates and enhancement factors from the system hydrodynamics and the physicochemical properties, as well as predicting the kinetics of reaction from experimental absorption data.25 Details of the kinetics calculation from absorption data are documented elsewhere.25,26 In brief, for each absorption rate obtained experimentally, the calculated enhancement factor by the absorption-rate/kinetics model was fitted to the experimentally observed enhancement factor with the apparent reaction-rate constant, kapp, as an adjustable parameter. The experimental results of these apparent reaction-rate constants are presented in Figure 8. A definite temperature depen-

T (K) 293 303 313

0.193-2.016 91.59-92.97 0.223-2.021 89.84-91.08 0.254-3.158 86.97-88.54

dence of the overall reaction rate can be observed for the three temperatures studied (293, 303, and 313 K). The data presented in Figure 8 were regressed to obtain the orders of reaction and the reaction rate constant at each temperature as presented in Table 2. From this table it can be seen that the obtained order of reaction is approximately one with respect to MEA within this temperature range and MEA concentrations. This is in agreement with the data reported in the literature.23 An Arrhenius plot was obtained using the secondorder rate constants, k2, presented in Table 2. The results are shown in Figure 9 as solid points. Also included in this figure are the literature kinetic data reported over a period of four decades (1960-2002) as reported elsewhere.26 This figure shows that the reaction rate constants obtained in this work are in agreement with the kinetic data reported in the literature. Thus, the overall results confirm that the absorption

2574 Ind. Eng. Chem. Res., Vol. 43, No. 10, 2004

rates and the kinetic data obtained in the laminar jet apparatus are accurate. Again, this indicates the absence of any interfacial turbulence during the experimental work. Conclusions A novel design for the nozzle of a laminar jet absorber has been introduced. The nozzle is a circular hole in a 0.07 ( 0.005-mm thick stainless steel sheet, and the inside diameter of this nozzle is between 0.50 and 0.65 mm. A very thin sheet is used to minimize boundarylayer effects and to approach a flat velocity distribution at the charge point. In addition, a new design for the receiver of the liquid jet has been introduced. The receiver is a capillary-hole, 20.0 mm long with 1.0 mm diameter, drilled in an acrylic rod. This receiver design assisted in the collection of the liquid jet without any liquid spillover or gas entrainment inside the receiver for several hours of continuous operation. The nozzle and receiver designs gave high-quality absorption data obtained without interfacial resistance and without interfacial turbulence. The test results show that the agreement between the measured and calculated absorption rates is excellent over various liquid flow rates and jet lengths for two physical absorption systems, CO2-water and N2O-MEA. In addition, the diffusivities of CO2 into water and N2O into MEA solution, as well as the kinetics of the CO2-MEA system at low concentrations and temperatures, were found to be in agreement with published data. These agreements indicate the reliability of the experimental apparatus design and configuration. Acknowledgment Financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC) and from the consortium members of the International Test Centre for Carbon Dioxide Capture (ITC) are gratefully acknowledged. Literature Cited

(1) Danckwerts, P. V. Gas Liquid Reactions; McGraw-Hill: New York, 1970. (2) Astarita, G.; Savage, D. W.; Bisio, A. Gas Treating with Chemical Solvents; John Wiley & Sons: New York, 1983. (3) Scriven, L. E.; Pigford, R. L. On Phase Equilibrium at the Gas-Liquid Interface During Absorption. AIChE J. 1958, 4 (4), 439-444. (4) Nijsing, R. O.; Hendriksz, R. H.; Kramers, H. Absorption of CO2 in Jets and Falling Films of Electrolyte Solutions, with and without Chemical Reaction. Chem. Eng. Sci. 1959, 10, 88-104. (5) Hikita, H.; Asai, S.; Katsu, Y.; Ikuno, S. Absorption of Carbon Dioxide into Aqueous Monoethanolamine Solutions. AIChE J. 1979, 25 (5), 793-800. (6) Clarke, J. K. A. Kinetic of Absorption of Carbon Dioxide in Monoethanolamine Solutions at Short Contact Times. Ind. Eng. Chem. Fundam. 1964, 3 (3), 239-245. (7) Hikita, H.; Asai, S.; Yano, A.; Nose, H. Kinetic of Absorption of Carbon Dioxide into Aqueous Sodium Sulfite Solutions. AIChE J. 1982, 28 (6), 1009-1015. (8) Raimondi, P.; Toor, H. L. Interfacial Resistance in Gas Absorption. AIChE J. 1959, 5 (1), 86-92. (9) Al-Ghawas, H.; Hagewiesche, D.; Ruiz-Ibanez, G.; Sandall, O. Physicochemical Properties Important for Carbon Dioxide

Absorption in Aqueous Methyldiethanolamine. J. Chem. Eng. Data 1989, 34, 385-391. (10) Ashour, S. S.; Rinker, E. B.; Sandall, O. C. Absorption of Chlorine into Aqueous Bicarbonate Solution and Aqueous Hydroxide Solutions. AIChE J. 1996, 42 (3), 671-682. (11) Rinker, E. B.; Ashour, S. S.; Sandall, O. C. Kinetics and Modeling of Carbon Dioxide Absorption into Aqueous Solutions of Diethanolamine. Ind. Eng. Chem. Res. 1996, 35, 1107-1114. (12) Rinker, E. B.; Ashour, S. S.; Sandall, O. C. Absorption of Carbon Dioxide into Aqueous Blends of Diethanolamine and Methyldiethanolamine. Ind. Eng. Chem. Res. 2000, 39, 43464356. (13) Versteeg, G. F.; van Swaaij, W. P. M. Solubility and Diffusivity of Acid Gases (CO2, N2O) in Aqueous Alkanolamine Solutions. J. Chem. Eng. Data 1988, 33, 29-34. (14) Hagewiesche, D. P.; Ashour, S. S.; Al-Ghawas, H. A.; Sandall, O. C. Absorption of Carbon Dioxide into Aqueous Blends of Monoethanolamine and N-Methyldiethanolamine. Chem. Eng. Sci. 1995, 50 (7), 1071-1079. (15) Brian, P. L. T.; Vivian, J. E.; Matiatos, D. C. Interfacial Turbulence During the Absorption of Carbon Dioxide into Monoethanolamine. AIChE J. 1967, 13 (1), 28-36. (16) Sada, E.; Kumazawa, H.; Butt, M., Lozano, J. Interfacial Turbulence Accompanying Chemical Reaction. Can. J. Chem. Eng. 1977, 55, 293-296. (17) Astarita, G. Carbon Dioxide Absorption in Aqueous Monoethanolamine Solutions. Chem. Eng. Sci. 1961, 16, 202-207. (18) Astarita, G. Mass Transfer with Chemical Reaction; Elsevier: New York, 1967. (19) Aboudheir, A. Kinetics, Modeling, and Simulation of Carbon Dioxide Absorption into Highly Concentrated and Loaded Monoethanolamine Solutions; Ph.D. Thesis; University of Regina: Regina, SK, 2002. (20) Wang, Y. W.; Xu, S.; Otto, F. D.; Mather, A. E. Solubility of N2O in Alkanolamines and Mixed Solvents. Chem. Eng. J. 1992, 48, 31-40. (21) Tsai, T.; Ko, J.; Wang, H.; Lin, C.; Li, M. Solubility of Nitrous Oxide in Alkanolamine Aqueous Solutions. J. Chem. Eng. Data. 2000, 45, 341-347. (22) Sada, E.; Kumazawa, H.; Butt, M. Solubility and Diffusivity of Gases in Aqueous Solutions of Amines. J. Chem. Eng. Data 1978, 23 (2), 161-164. (23) Versteeg, G. F.; van Dijck, L. A.; van Swaaij, W. P. M. On the kinetics between CO2 and Alkanolamines both in Aqueous and Nonaqueous Solutions: An Overview. Chem. Eng. Commun. 1996, 144, 113-158. (24) Littel, R. J.; Versteeg, G. F.; Swaaij, W. P. M. Kinetics of CO2 with Primary and Secondary Amines in Aqueous SolutionsII. Influence of temperature on Zwitterion Formation and Deprotonation Rates. Chem. Eng. Sci. 1992, 47 (8), 2037-2045. (25) Aboudheir, A.; Tontiwachwuthikul, P.; Chakma, A.; Idem, R. On the numerical Modeling of Gas Absorption into Reactive Liquids in a Laminar Jet Absorber. Can. J. Chem. Eng. 2003, 81 (3), 604-612. (26) Aboudheir, A.; Tontiwachwuthikul, P.; Chakma, A.; Idem, R. Kinetics of Reactive Absorption of Carbon Dioxide in High CO2Loaded, Concentrated Aqueous Monoethanolamine Solutions. Chem. Eng. Sci. 2003, 58 (23), 5195-5210. (27) Perry, R. H.; Green, D. W. Perrys Chemical Engineers Handbook, 7th ed.; McGraw-Hill: New York, 1997. (28) Haimour, N.; Sandall, O. C. Absorption of Carbon Dioxide into Aqueous Methyldiethanolamine. Chem. Eng. Sci. 1984, 39 (12), 1791-1796. (29) Tang, A.; Sandall, O. C. Diffusion Coefficient of Chlorine in Water at 25-60. J. Chem. Eng. Data. 1985, 30 (2), 189-191. (30) Tamimi, A.; Rinker, E. B.; Sandall, O. C. Diffusion Coefficients for Hydrogen Sulfide, Carbon Dioxide, and Nitrous Oxide in Water over the Temperature Range 293-368 K. J. Chem. Eng. Data. 1994, 39 (2), 330-332.

Received for review October 1, 2003 Revised manuscript received January 5, 2004 Accepted January 9, 2004 IE0341606

Вам также может понравиться

- Venturi Scrubber Theory & ExperimentДокумент6 страницVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- Investigation of Flooding Re-Entrainment and Grade Efficiency in Axial FloДокумент11 страницInvestigation of Flooding Re-Entrainment and Grade Efficiency in Axial FlorezОценок пока нет

- Technical Paper Glass Bubbles Insulation For Liquid Hydrogen Storage TanksДокумент8 страницTechnical Paper Glass Bubbles Insulation For Liquid Hydrogen Storage Tankshuangyixuan0306Оценок пока нет

- Inert Purge VentingДокумент14 страницInert Purge VentingNurulОценок пока нет

- HPC - P-Alegre Gas Permeability in High Performance ConcreteДокумент19 страницHPC - P-Alegre Gas Permeability in High Performance Concretegonzalez_m_aОценок пока нет

- Comparison of Gas Hold-Up Distribution Measurement in A Otation Cell Using Capturing and Conductivity TechniquesДокумент11 страницComparison of Gas Hold-Up Distribution Measurement in A Otation Cell Using Capturing and Conductivity TechniquesRita Olmedo MoralesОценок пока нет

- Permeabilidad en Celda TriaxialДокумент7 страницPermeabilidad en Celda TriaxialLuis Lemus MondacaОценок пока нет

- Aeration System in WWTPДокумент10 страницAeration System in WWTPashokОценок пока нет

- Mobilisation of Trapped Gas From Below The Gas-Water ContactДокумент13 страницMobilisation of Trapped Gas From Below The Gas-Water ContactJavier E. Guerrero ArrietaОценок пока нет

- Cyclone hấp thụ SO2Документ10 страницCyclone hấp thụ SO2Black AutumnОценок пока нет

- Assessment of Aeration Capacity of Stepped Cascade System For Selected GeometryДокумент9 страницAssessment of Aeration Capacity of Stepped Cascade System For Selected GeometrySong Nguyen NguyenОценок пока нет

- Sca2005 13Документ15 страницSca2005 13Rosa K Chang HОценок пока нет

- SCR Oddie ShiДокумент32 страницыSCR Oddie ShiFrancisco OppsОценок пока нет

- Effects of Superficial Gas Velocity and Fluid Property On The Hydrodynamic Performance of An Airlift Column With Alcohol SolutionДокумент9 страницEffects of Superficial Gas Velocity and Fluid Property On The Hydrodynamic Performance of An Airlift Column With Alcohol SolutionhypermekoolОценок пока нет

- Velocity String Helps To Revive A Standing Gas Well in Saudi ArabiaДокумент14 страницVelocity String Helps To Revive A Standing Gas Well in Saudi Arabiaerdal aydin100% (1)

- Study and Analysis On Boiler Tubes For Performance Enhancement With Varying Corrugated Tube ShapesДокумент6 страницStudy and Analysis On Boiler Tubes For Performance Enhancement With Varying Corrugated Tube ShapesukachukwuОценок пока нет

- WST 2010 240Документ10 страницWST 2010 240Marc NguyenОценок пока нет

- GwaderaM AdsorptionWaterДокумент11 страницGwaderaM AdsorptionWaterhortalemosОценок пока нет

- The Ow Pattern and Entropy Generation in An Axial Inlet Cyclone With Re Ux Cone and Gaps in The Vortex FinderДокумент12 страницThe Ow Pattern and Entropy Generation in An Axial Inlet Cyclone With Re Ux Cone and Gaps in The Vortex FinderdadОценок пока нет

- Spe 126Документ13 страницSpe 126advantage025Оценок пока нет

- Inlet Diameter and Flow Volume Effects On Separation and Energy Efficiency of HydrocyclonesДокумент11 страницInlet Diameter and Flow Volume Effects On Separation and Energy Efficiency of HydrocyclonesAdrian SetyadharmaОценок пока нет

- Airlift PumpДокумент18 страницAirlift Pumptushar patelОценок пока нет

- 11evaluation of Oxygen Transfer Efficiency Via Off-Gas Testing at FullДокумент8 страниц11evaluation of Oxygen Transfer Efficiency Via Off-Gas Testing at FullIrving VazquezОценок пока нет

- A Simple Model For Falling Film Absorption On (Bagus)Документ9 страницA Simple Model For Falling Film Absorption On (Bagus)Fadli Ryan ArikundoОценок пока нет

- ARCHIVE Proceedings of the Institution of Mechanical Engineers Conference Proceedings 1964-1970 (Vols 178-184) Various Titles Labelled Volumes a to S Volume 180 Issue 310 1965 [Doi 10.1243_PIME_CONFДокумент13 страницARCHIVE Proceedings of the Institution of Mechanical Engineers Conference Proceedings 1964-1970 (Vols 178-184) Various Titles Labelled Volumes a to S Volume 180 Issue 310 1965 [Doi 10.1243_PIME_CONFSree288Оценок пока нет

- 04 - SPE 63197 - Shallow Gas KickДокумент10 страниц04 - SPE 63197 - Shallow Gas KickRachid Touati100% (1)

- Gas Holdup in A Gasliquid Up Flow Bubble Column in The Presence of Double Cone Promoter PDFДокумент8 страницGas Holdup in A Gasliquid Up Flow Bubble Column in The Presence of Double Cone Promoter PDFCastañeda ValeriaОценок пока нет

- A Modified Triaxial Apparatus For Measuring The Stress Path Dependent Water Retention-A PDFДокумент6 страницA Modified Triaxial Apparatus For Measuring The Stress Path Dependent Water Retention-A PDFAnonymous D5s00DdUОценок пока нет

- Collect Accurate HP/HT Reservoir Samples: Production OptimizationДокумент2 страницыCollect Accurate HP/HT Reservoir Samples: Production OptimizationAngel GuamánОценок пока нет

- Low-Speed Wind TunnelДокумент32 страницыLow-Speed Wind TunnellucioctsicilОценок пока нет

- Study and Theoretical Calculation On New Type of Adsorption ChillerДокумент9 страницStudy and Theoretical Calculation On New Type of Adsorption ChillerUmut Sinan ÇetinbaşОценок пока нет

- Membrane Reactor Configuration For Separation of H2S CO2 and H2Документ56 страницMembrane Reactor Configuration For Separation of H2S CO2 and H2AbdelSamed MohamedОценок пока нет

- A Baffled Apron As A Spillway Energy Dissipator - T. J. RhoneДокумент32 страницыA Baffled Apron As A Spillway Energy Dissipator - T. J. RhoneSantiago MuñozОценок пока нет

- Comparison of Hydraulic Conductivity Test Methods For Landfill Clay Liners 5084Документ10 страницComparison of Hydraulic Conductivity Test Methods For Landfill Clay Liners 5084Geovanny HerediaОценок пока нет

- SPE-190936-MS Solving Gas Interference Issues With Sucker Rod Pumps in The Permian BasinДокумент15 страницSPE-190936-MS Solving Gas Interference Issues With Sucker Rod Pumps in The Permian Basinjulio valenciaОценок пока нет

- Development of A New Large Calibration Chamber For Testing Thickened Tailings With The Cone Penetration TestДокумент9 страницDevelopment of A New Large Calibration Chamber For Testing Thickened Tailings With The Cone Penetration TestHuang BenОценок пока нет

- Watted Wall TowerДокумент13 страницWatted Wall TowerRajdeep MallickОценок пока нет

- Lab 5 Thermo FluidsДокумент13 страницLab 5 Thermo FluidsAimiWaniОценок пока нет

- CFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientДокумент9 страницCFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientCharan RavulaОценок пока нет

- The Influence of The Equivalent Hydraulic Diameter On The Pressure Drop Prediction of Annular Test SectionДокумент9 страницThe Influence of The Equivalent Hydraulic Diameter On The Pressure Drop Prediction of Annular Test SectionFernandoОценок пока нет

- Spe 127981 MSДокумент9 страницSpe 127981 MSLeopold Roj DomОценок пока нет

- D.D.S., M.S.D.": University of Manitoba, Faculty of Dentistry, Winnzpeg, ManДокумент4 страницыD.D.S., M.S.D.": University of Manitoba, Faculty of Dentistry, Winnzpeg, ManAmar BhochhibhoyaОценок пока нет

- Velocity Measurements in The Near Field of A Radial SwirlerДокумент8 страницVelocity Measurements in The Near Field of A Radial SwirlerVignesh PanneerselvamОценок пока нет

- CHL 103 TermpaperДокумент8 страницCHL 103 TermpaperAnanth S PemmarajuОценок пока нет

- A Numerical Investigation of The Incompressible Flow Through A Butterfly Valve Using CFDДокумент7 страницA Numerical Investigation of The Incompressible Flow Through A Butterfly Valve Using CFDAhmed El-dawy100% (1)

- Astm E96 1995Документ10 страницAstm E96 1995Kasra GolbanОценок пока нет

- Corrosion in High Pressure CO2-Equipment For Water Solubility MeasurementsДокумент4 страницыCorrosion in High Pressure CO2-Equipment For Water Solubility MeasurementstheijesОценок пока нет

- SPE 15950 Analysis of Air Drilling Circulating Systems With Application To Air Volume Requirement EstimationДокумент10 страницSPE 15950 Analysis of Air Drilling Circulating Systems With Application To Air Volume Requirement EstimationJessica KingОценок пока нет

- Processes 10 00429 v2Документ15 страницProcesses 10 00429 v2souliesОценок пока нет

- Smoothing of Slug Tests For Laboratory Scale Aquifer Assessment-A Comparison Among Different Porous MediaДокумент18 страницSmoothing of Slug Tests For Laboratory Scale Aquifer Assessment-A Comparison Among Different Porous MediaMaria Fernanda Rivera VelasquezОценок пока нет

- 1995 - Removal of SiO2 Particles With An Ejector Venturi ScrubberДокумент5 страниц1995 - Removal of SiO2 Particles With An Ejector Venturi Scrubberamin342100% (1)

- Design of An Intake StructureДокумент6 страницDesign of An Intake StructureBhaskar Reddy100% (2)

- Astm D 3178 - 89 R02Документ5 страницAstm D 3178 - 89 R02phaindikaОценок пока нет

- Study On Bubble Formation at A Submerged Micro-HolДокумент11 страницStudy On Bubble Formation at A Submerged Micro-HolMarc LarreОценок пока нет

- Effect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration SystemДокумент11 страницEffect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration Systemmailmaverick8167Оценок пока нет

- Spe 147765 Advanced Chemical Water-Shutoff Treatments in Multilayer Gas Reservoirs: A Case Study Frompeciko Field, East Kalimantan, IndonesiaДокумент12 страницSpe 147765 Advanced Chemical Water-Shutoff Treatments in Multilayer Gas Reservoirs: A Case Study Frompeciko Field, East Kalimantan, Indonesiahade wantoОценок пока нет

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984От EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984Оценок пока нет

- Dynamic Well Testing in Petroleum Exploration and DevelopmentОт EverandDynamic Well Testing in Petroleum Exploration and DevelopmentОценок пока нет

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManОт EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManОценок пока нет

- Grid Standards RegДокумент19 страницGrid Standards RegEzhil Vendhan PalanisamyОценок пока нет

- Variation of Funding Agreement: PO Box Telephone: Facsimile: Email: Website: TtyДокумент7 страницVariation of Funding Agreement: PO Box Telephone: Facsimile: Email: Website: Ttymy_khan20027195Оценок пока нет

- Transformer Short Circuit Current Calculation and SolutionsДокумент37 страницTransformer Short Circuit Current Calculation and Solutionsmano_bacsi100% (1)

- Cable Design QuestionsДокумент2 страницыCable Design Questionsmy_khan20027195Оценок пока нет

- Short CircuitДокумент0 страницShort CircuitMuruganantham ChandrappanОценок пока нет

- GeneratorsДокумент27 страницGeneratorsthecodekingОценок пока нет

- IEEECSStyleGuide2013 PDFДокумент109 страницIEEECSStyleGuide2013 PDFmy_khan20027195Оценок пока нет

- FiatДокумент19 страницFiatHdxChdОценок пока нет

- 14C PM SN 050101 & Up PDFДокумент604 страницы14C PM SN 050101 & Up PDFManuais De Catálogos Jose Carlos100% (3)

- Heart BookДокумент96 страницHeart BookskilmagОценок пока нет

- Icd BluebookДокумент267 страницIcd BluebookBharath HollaОценок пока нет

- Convective Solar DryerДокумент28 страницConvective Solar Dryermy_khan20027195100% (1)

- Cable Design QuestionsДокумент2 страницыCable Design Questionsmy_khan20027195Оценок пока нет

- 2 OPRD JulyДокумент213 страниц2 OPRD Julymy_khan20027195Оценок пока нет

- Electric Motors Whitepaper PDFДокумент8 страницElectric Motors Whitepaper PDFCesario GillasОценок пока нет

- 978 3 86922 146 5 - DatenblattДокумент1 страница978 3 86922 146 5 - Datenblattmy_khan20027195Оценок пока нет

- ADP 2014-15 HealthДокумент29 страницADP 2014-15 Healthmy_khan20027195Оценок пока нет

- Feed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang MachineryshopsДокумент14 страницFeed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang Machineryshopsmy_khan20027195Оценок пока нет

- AJTips No8 Solarnet v7n1 2005Документ5 страницAJTips No8 Solarnet v7n1 2005my_khan20027195Оценок пока нет

- Building Faster Rapport With Coaching Clients 140828155405 Phpapp01Документ18 страницBuilding Faster Rapport With Coaching Clients 140828155405 Phpapp01my_khan20027195Оценок пока нет

- Cas Sample Application FormДокумент2 страницыCas Sample Application Formmy_khan20027195Оценок пока нет

- How Boilers WorkДокумент18 страницHow Boilers Workhozipek5599100% (1)

- Performance Evaluation of Biomass Fired Dryer For Copra Drying A Comparison With Traditional Drying in Subtropical Climate 2157 7110.1000294Документ5 страницPerformance Evaluation of Biomass Fired Dryer For Copra Drying A Comparison With Traditional Drying in Subtropical Climate 2157 7110.1000294my_khan20027195Оценок пока нет

- An Open Letter To Any Service Provider Who Works With ClientsДокумент3 страницыAn Open Letter To Any Service Provider Who Works With Clientsmy_khan20027195Оценок пока нет

- Feed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang MachineryshopsДокумент14 страницFeed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang Machineryshopsmy_khan20027195Оценок пока нет

- Hany Et AlДокумент13 страницHany Et AlprevrtljivacОценок пока нет

- Cec 500 2010 043Документ172 страницыCec 500 2010 043my_khan20027195Оценок пока нет

- Grid Standards RegДокумент19 страницGrid Standards RegEzhil Vendhan PalanisamyОценок пока нет

- AG Potato-BrochureДокумент4 страницыAG Potato-Brochuremy_khan20027195Оценок пока нет

- Convective Solar DryerДокумент28 страницConvective Solar Dryermy_khan20027195100% (1)

- Mechanics of Composite Materials PDFДокумент2 страницыMechanics of Composite Materials PDFAhmad BurhanudinОценок пока нет

- Revised Guidelines For Bio-Medical Waste IncineratorДокумент34 страницыRevised Guidelines For Bio-Medical Waste Incineratorandik_yОценок пока нет

- Laboratory Manual For HardnesstestДокумент12 страницLaboratory Manual For Hardnesstest15 Saad HassanОценок пока нет

- Eco Friendly Building MaterialsДокумент40 страницEco Friendly Building MaterialsHuy Tập CấnОценок пока нет

- Rising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeДокумент1 страницаRising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeTanmoy DuttaОценок пока нет

- Background Report AP-42 SECTION 8.6: Hydrochloric Acid ProductionДокумент26 страницBackground Report AP-42 SECTION 8.6: Hydrochloric Acid ProductionQuang ThanhОценок пока нет

- Ford New Holland 8160 8260 8360 8560 Repair ManualДокумент6 страницFord New Holland 8160 8260 8360 8560 Repair Manualebookpdfman18% (11)

- PanX Installguide RevaДокумент67 страницPanX Installguide Revaalpharepair0% (1)

- 2nd YearДокумент24 страницы2nd YearAlxalx Alex50% (2)

- INTERFLEX Catalogue (Conduits and Fittings)Документ8 страницINTERFLEX Catalogue (Conduits and Fittings)cherif yahyaouiОценок пока нет

- Method Statement Sipchem-2201 B PDFДокумент10 страницMethod Statement Sipchem-2201 B PDFCharlie TacanОценок пока нет

- PCI Chapter 14Документ20 страницPCI Chapter 14Sergio Adolfo ParedesОценок пока нет

- DSMTS-0095.3 NiCrAlMo CompositeДокумент3 страницыDSMTS-0095.3 NiCrAlMo Compositeivanis_davorОценок пока нет

- Sensors Pt100 TF Datasheet e ZIEHL-1Документ4 страницыSensors Pt100 TF Datasheet e ZIEHL-1Anom HarimurtiОценок пока нет

- Agvs: Bridging The Gap in Automation: Brian Keiger, CsoДокумент36 страницAgvs: Bridging The Gap in Automation: Brian Keiger, Csobodeks dexОценок пока нет

- Combustion CalculationsДокумент6 страницCombustion CalculationsknsaravanaОценок пока нет

- Flat Rack Loading Guidelines 5-28 (NCB Revised Mod 2)Документ25 страницFlat Rack Loading Guidelines 5-28 (NCB Revised Mod 2)Shane Anderson100% (1)

- Electrical BOQ FinalДокумент45 страницElectrical BOQ FinalmahasubbuОценок пока нет

- Calefactor TG8HДокумент6 страницCalefactor TG8HIng. José Antonio GuerreroОценок пока нет

- Samsung DVM Chiller InstallationManualДокумент56 страницSamsung DVM Chiller InstallationManualjlmoleroОценок пока нет

- Chemistry Presentation (Viva)Документ41 страницаChemistry Presentation (Viva)ZiHong100% (1)

- 1 s2.0 S0017931021011261 MainДокумент27 страниц1 s2.0 S0017931021011261 MainKuwar Ranvijay Singh (B19ME040)Оценок пока нет

- Design Criteria For Concrete Foundations & Structures 2Документ24 страницыDesign Criteria For Concrete Foundations & Structures 2Chetan ToliaОценок пока нет

- Mit 185UD5Документ2 страницыMit 185UD5Pakito ChocolateroОценок пока нет

- Engineering Failure Analysis: S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. GijbelsДокумент8 страницEngineering Failure Analysis: S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. GijbelsGholamreza MahmoodiОценок пока нет

- AFT Trolley 50-02Документ2 страницыAFT Trolley 50-02Forum PompieriiОценок пока нет

- Wiring DevicesДокумент6 страницWiring DevicesMohammed Hussain OMОценок пока нет

- PDFДокумент3 страницыPDFJoaquin UreñaОценок пока нет

- Sizing Vacuum Pump or Ejector For Chemical ProcessДокумент4 страницыSizing Vacuum Pump or Ejector For Chemical ProcessscranderiОценок пока нет

- Inspection and Test Plan (Towers & Fasteners) : DescriptionДокумент84 страницыInspection and Test Plan (Towers & Fasteners) : DescriptionPinku MaitiОценок пока нет