Академический Документы

Профессиональный Документы

Культура Документы

ES Specification

Загружено:

irfanbaig36Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ES Specification

Загружено:

irfanbaig36Авторское право:

Доступные форматы

PURE Humidifier Company

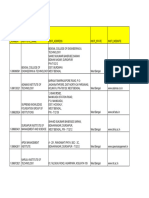

Sample Specification ES Series Humidifier The humidifier shall be an electrically heated immersion heater type as manufactured by PURE Humidifier Company of Chaska, Minnesota. The humidifier shall be tested and approved by ETL/ETL-C Testing Laboratories, Inc. (ETL #472940). The humidifier shall have an evaporating reservoir with a gasket sealed cover which is capable of operating at pressures of at least 19-48 cm (W.C.) without steam or water leaks. The reservoir shall be made of type 304 stainless steel with welded joints. The humidifier shall be designed to facilitate easy removal of the heater assembly for periodic scale removal and inspection. The cover and heater assembly shall be secured to the unit by the use of quick release clamps. The heater assembly shall be removable from the side of the humidifier without disturbing the cover or injection tube systems steam supply piping. Humidifier shall be field convertible from an electric immersion heater style "ES" humidifier to a steam heat exchanger style "SX" humidifier with a simple change of the side entry assembly. An adjustable surface water flusher shall be included to drain away a portion of the water upon each refill cycle. This is to allow mineral deposits produced by earlier evaporation cycles to be removed. Flusher height should be adjustable for minimal water waste and efficient flushing. The immersion heater(s) shall be incoloy clad and designed for 80 watts per sq. inch. Expansion and contraction of the heater(s) sheath allows mineral build-up to flake off. A brass body, solenoid operated water fill valve shall be factory mounted on the top near the front of the humidifier reservoir. A bottom fill system shall be utilized to prevent any collapse of the steam head during the fill process. The fill valve shall be located to allow a minimum water gap of 1 (3.81 cm). An inline strainer shall be factory mounted upstream of the fill valve to remove any water born particulate matter before the humidifier fill valve. The water strainer shall have a removable screen to permit periodic inspection and cleaning. The humidifier shall have a manual reset over-temperature switch factory installed on the humidifier reservoir. The temperature switch shall provide humidifier over-temperature protection. An INTAC programmable microprocessor control module shall be factory mounted on the cover of the control panel and shall electronically control the automatic refilling, low water cut-off, high water cutoff, manual surface water flushing and safety switch interlock functions. When in the flush mode the water fill valve shall stay open for 5 minutes, then close. The control module shall control all water level control functions through a Tri-Probe sensor with stainless steel shield mounted on the top front of the humidifier reservoir. The Tri-Probe sensor shall electrically sense the water level within the reservoir.

A motor operated drain valve with a brass body, and a cumulative timer will be incorporated into the INTAC microprocessor controller. When the timer is activated the heater(s) will be de-energized and the drain valve will open. The drain period will be field adjustable in 1-hour increments between 1 and 500 hours with the drain duration adjustable in 1-minute increments between 1 and 120 minutes. During the drain period, the humidifying chamber will drain completely and the fill valve will be energized to provide thorough rinsing action. After the drain period is completed, the drain valve will close and the humidifier will refill and provide humidity on demand. A seasonal drain system shall automatically drain the humidifier after a selected "NON-USE" period. The controller shall automatically reset the humidifier on a call for humidity. The humidifier shall be provided with an ETL listed JIC NEMA 12 control cabinet, shipped loose (reference factory mounting option). The control cabinet shall be made of 14-gauge steel with ANSI 61 gray polyester powder coating, continuous hinge and oil-resistant gasket. The panel shall include a factory wired sub-panel with magnetic contactor(s), Tri-Probe water level control module, fused control circuit transformer, numbered terminal block and heater fuse(s).

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Miniature Daisy: Crochet Pattern & InstructionsДокумент8 страницMiniature Daisy: Crochet Pattern & Instructionscaitlyn g100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Character Analysis EssayДокумент5 страницCharacter Analysis Essayirfanbaig36100% (1)

- Hans Belting - The End of The History of Art (1982)Документ126 страницHans Belting - The End of The History of Art (1982)Ross Wolfe100% (7)

- Leadership Styles-Mckinsey EdДокумент14 страницLeadership Styles-Mckinsey EdcrimsengreenОценок пока нет

- Machine Room Ventilation - International Code: InputДокумент15 страницMachine Room Ventilation - International Code: Inputirfanbaig36Оценок пока нет

- (1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsДокумент102 страницы(1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsHerbert Hillary Booker 2nd100% (1)

- Lieh TzuДокумент203 страницыLieh TzuBrent Cullen100% (2)

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionДокумент10 страницMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyОценок пока нет

- Invoice: PTCL STN: PTCL NTNДокумент1 страницаInvoice: PTCL STN: PTCL NTNirfanbaig36Оценок пока нет

- Revit Tutorial PDFДокумент326 страницRevit Tutorial PDFCaleb KreegerОценок пока нет

- Evolution Army 3 R DadДокумент341 страницаEvolution Army 3 R DadStanisław DisęОценок пока нет

- Challan #: Challan #: Challan #:: Total Total TotalДокумент1 страницаChallan #: Challan #: Challan #:: Total Total Totalirfanbaig36Оценок пока нет

- Life Life Cost Cost OF OF IN IN Buildings in Buildings In: AIR Air - Conditioning ConditioningДокумент15 страницLife Life Cost Cost OF OF IN IN Buildings in Buildings In: AIR Air - Conditioning Conditioningirfanbaig36Оценок пока нет

- HVAC For Doc StoreДокумент27 страницHVAC For Doc Storeirfanbaig36Оценок пока нет

- Centralized Vs Decentralized System PDFДокумент49 страницCentralized Vs Decentralized System PDFRendani VeleОценок пока нет

- Challan #: Challan #: Challan #:: Total Total TotalДокумент1 страницаChallan #: Challan #: Challan #:: Total Total Totalirfanbaig36Оценок пока нет

- Cost AE CalcsДокумент18 страницCost AE Calcsirfanbaig36Оценок пока нет

- Air Water System Design Using Revit Mep For A Residential BuildingДокумент5 страницAir Water System Design Using Revit Mep For A Residential BuildingEditor IJTSRDОценок пока нет

- Heat Pipe MITДокумент221 страницаHeat Pipe MITirfanbaig36Оценок пока нет

- 30% Glycol AHU: Friday, February 01, 2008 9:41 AMДокумент3 страницы30% Glycol AHU: Friday, February 01, 2008 9:41 AMirfanbaig36Оценок пока нет

- Hvac Works - NPT Labs: 2 Make (For Reference Only) Aerotech Aerotech AerotechДокумент1 страницаHvac Works - NPT Labs: 2 Make (For Reference Only) Aerotech Aerotech Aerotechirfanbaig36Оценок пока нет

- Black DeckerДокумент1 страницаBlack Deckerirfanbaig36Оценок пока нет

- The Q-Sort Method in Personality Assessment and Psychiatric ResearchДокумент107 страницThe Q-Sort Method in Personality Assessment and Psychiatric ResearchSandeep Prabhu100% (2)

- Character Analysis Paper AssignmentДокумент3 страницыCharacter Analysis Paper Assignmentirfanbaig36Оценок пока нет

- 30% Glycol AHU: Friday, February 01, 2008 9:41 AMДокумент6 страниц30% Glycol AHU: Friday, February 01, 2008 9:41 AMirfanbaig36Оценок пока нет

- QD Volume 22 October 2006Документ128 страницQD Volume 22 October 2006irfanbaig36Оценок пока нет

- Hosts UmbrellaДокумент1 страницаHosts UmbrellaFabsor SoralОценок пока нет

- Pak-USAID Merit and Needs Based Scholarship Program: Brief HistoryДокумент2 страницыPak-USAID Merit and Needs Based Scholarship Program: Brief HistoryArslan ShaukatОценок пока нет

- Genetics Pharma Dehumidifying Load Input Sheet: 1 BlisteringДокумент1 страницаGenetics Pharma Dehumidifying Load Input Sheet: 1 Blisteringirfanbaig36Оценок пока нет

- Mixed Air CalculatorДокумент4 страницыMixed Air Calculatorirfanbaig36Оценок пока нет

- TaxДокумент3 страницыTaxirfanbaig36Оценок пока нет

- Income Tax Return E-Filing Guide (Salaried) - 2009Документ16 страницIncome Tax Return E-Filing Guide (Salaried) - 2009Zohaib HussainОценок пока нет

- Irfan Baig Account Number: 300200139510001 Product: Currency: From Date: Fri 14-Sep-2012 To Date: Thu 20-Sep-2012Документ1 страницаIrfan Baig Account Number: 300200139510001 Product: Currency: From Date: Fri 14-Sep-2012 To Date: Thu 20-Sep-2012irfanbaig36Оценок пока нет

- Air Density CorrectionДокумент5 страницAir Density Correctionirfanbaig36Оценок пока нет

- 7535 7500 1750 1060 13 14 5.4 Inches 8.9 Inches 38 Inches 0.875 7.77 InchesДокумент2 страницы7535 7500 1750 1060 13 14 5.4 Inches 8.9 Inches 38 Inches 0.875 7.77 Inchesirfanbaig36Оценок пока нет

- Mixed Air CalculatorДокумент4 страницыMixed Air Calculatorirfanbaig36Оценок пока нет

- Mixed Air CalculatorДокумент4 страницыMixed Air Calculatorirfanbaig36Оценок пока нет

- Anemia in PregnancyДокумент5 страницAnemia in PregnancycfgrtwifhОценок пока нет

- Cloud Comp PPT 1Документ12 страницCloud Comp PPT 1Kanishk MehtaОценок пока нет

- WBДокумент59 страницWBsahil.singhОценок пока нет

- 8051 NotesДокумент61 страница8051 Notessubramanyam62Оценок пока нет

- Systems Analysis and Design in A Changing World, Fourth EditionДокумент41 страницаSystems Analysis and Design in A Changing World, Fourth EditionKoko Dwika PutraОценок пока нет

- Canoe Matlab 001Документ58 страницCanoe Matlab 001Coolboy RoadsterОценок пока нет

- Wner'S Anual: Led TVДокумент32 страницыWner'S Anual: Led TVErmand WindОценок пока нет

- Chapter 2Документ13 страницChapter 2Kumkumo Kussia KossaОценок пока нет

- Topic 3Документ21 страницаTopic 3Ivan SimonОценок пока нет

- A Survey On Security and Privacy Issues of Bitcoin-1Документ39 страницA Survey On Security and Privacy Issues of Bitcoin-1Ramineni HarshaОценок пока нет

- Algoritm BackTracking EnglezaДокумент6 страницAlgoritm BackTracking Englezaionutz_67Оценок пока нет

- Standard Answers For The MSC ProgrammeДокумент17 страницStandard Answers For The MSC ProgrammeTiwiОценок пока нет

- John L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiДокумент12 страницJohn L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDivya AggarwalОценок пока нет

- Heimbach - Keeping Formingfabrics CleanДокумент4 страницыHeimbach - Keeping Formingfabrics CleanTunç TürkОценок пока нет

- PC Model Answer Paper Winter 2016Документ27 страницPC Model Answer Paper Winter 2016Deepak VermaОценок пока нет

- Sample Resume For Supply Chain Logistics PersonДокумент2 страницыSample Resume For Supply Chain Logistics PersonAmmar AbbasОценок пока нет

- Winter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportДокумент6 страницWinter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportColette AdamsОценок пока нет

- Implementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorДокумент11 страницImplementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorChristie YohanaОценок пока нет

- SweetenersДокумент23 страницыSweetenersNur AfifahОценок пока нет

- Physics Education Thesis TopicsДокумент4 страницыPhysics Education Thesis TopicsPaperWriterServicesCanada100% (2)

- Latched, Flip-Flops, and TimersДокумент36 страницLatched, Flip-Flops, and TimersMuhammad Umair AslamОценок пока нет

- Student Exploration: Inclined Plane - Simple MachineДокумент9 страницStudent Exploration: Inclined Plane - Simple MachineLuka MkrtichyanОценок пока нет

- B I o G R A P H yДокумент17 страницB I o G R A P H yRizqia FitriОценок пока нет