Академический Документы

Профессиональный Документы

Культура Документы

Acronal Pro 80

Загружено:

chayanunИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Acronal Pro 80

Загружено:

chayanunАвторское право:

Доступные форматы

Acronal PRO 80

PROtective (high performance anti-corrosion) or PROfessional (Industrial environment friendly)

preliminary datasheet

Key features and benefits

enhanced corrosion protection exellent barrier and inhibiting properties APEO- and zinc-free good adhesion good early rain resistance high PVC low odor

a next generation polymer emulsion for medium-duty anti-corrosion primers, fillers or topcoats for industrial metal coatings

General information

Typical physical characteristics (not to be considered specifications) appearance white emulsion solids by weight ~ 50 % viscosity at 23 C (73 F) (DIN EN ISO 3219) ~190 mPa.s pH ~ 8.5 specific mass as supplied 1,090 kg/m minimum film-forming temperature ~ 22 C (72 F) freeze/thaw stable no

registered trademark of BASF Group

page 1 of 2

C APRO80e/12-2008

C APRO80e/12-2008

page 2 of 4

Acronal PRO 80

Applications

Acronal PRO 80 is a unique barrier and inhibiting polymer emulsion for medium-duty anti-corrosion primers, fillers or topcoats (ISO 12944-2:C2-C3 or C3-C4).

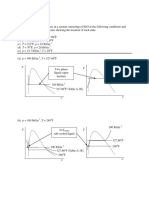

Performance

Acronal PRO 80 offers exceptionally high salt-spray resistance (ca. > 700 hours) with dry film thickness of 80 microns. This new barrier and inhibiting product offers an active corrosion protection barrier against oxygen water and other ions that cause surface erosion as well as good early rain resistance and excellent adhesion.

C APRO80e/12-2008

page 3 of 4

Acronal PRO 80

Formulation Guidelines

Acronal PRO 80 is compatible with a variety of anti-corrosion additives. The product provides the possibility to formulate with a range of reactive anti-corrosion pigments, especially those based on zinc phosphates. The minimum film-forming temperature of Acronal PRO 80 is approximately 22 C. Suitable film-forming agents should generally be added to achieve homogeneous films at lower temperatures. The recommended addition is 2-4 % of a blend of white spirit and 2-butoxyl ethanol and/or 2-(2-butoxyethoxy) ethanol or phenoxy propanol). Viscosity and flow can be adjusted by adding thickeners, preferably in the final stage of production. In particular from the corrosion-protection aspect, associative thickeners such as Collacral PU 85 are timetested. Good leveling and Newtonian flow can be achieved with water-miscible solvents present. In aqueous anticorrosion formulations, the proportion of thickener should not exceed 1 %, calculated as solids on solid binder.

C APRO80e/12-2008

page 4 of 4

Acronal PRO 80

Safety

When handling these products, advice and information given in the safety data sheet must be complied with. Further, protective and workplace hygiene measures adequate for handling chemicals must be observed.

Note

The data contained in this publication are based on our current knowledge and experience. In view of the many factors that may affect processing and application of our product, these data do not relieve processors from carrying out their own investigations and tests; neither do these data imply any guarantee of certain properties, nor the suitability of the product for a specific purpose. Any descriptions, drawings, photographs, data, proportions, weights, etc. given herein may change without prior information and do not constitute the agreed contractual quality of the product. It is the responsibility of the recipient of our products to ensure that any proprietary rights and existing laws and legislation are observed.

Acronal PRO 80 (12-2008 )

BASF Nederland B.V. Performance Chemicals P. O. Box 390 8440 AJ Heerenveen, The Netherlands Phone +31 513 619 619 Fax +31 513 619 600 resins@basf.com www.basf.com/resins

Вам также может понравиться

- PEI-QHSE-002-Hazards Identification and Risk Management ProcedureДокумент16 страницPEI-QHSE-002-Hazards Identification and Risk Management ProcedureJacob Keemink100% (1)

- Commissioning ProceduresДокумент152 страницыCommissioning Proceduresmabrarahmed100% (1)

- Bottles, Preforms and Closures: A Design Guide for PET PackagingОт EverandBottles, Preforms and Closures: A Design Guide for PET PackagingРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Adhesive Theory N TypesДокумент11 страницAdhesive Theory N TypesgautamahujaОценок пока нет

- PlurafacДокумент13 страницPlurafacchayanunОценок пока нет

- Chemicals Zetag DATA Powder Magnafloc 155 - 0410Документ2 страницыChemicals Zetag DATA Powder Magnafloc 155 - 0410PromagEnviro.comОценок пока нет

- Phase Change Materials PCM For Cooling ApplicationsДокумент80 страницPhase Change Materials PCM For Cooling ApplicationsGerit LinggarОценок пока нет

- Dpta v18 3 PDFДокумент24 страницыDpta v18 3 PDFchayanunОценок пока нет

- ACS800 GeneralДокумент14 страницACS800 GeneralAnonymous AMQMyB2EbОценок пока нет

- 303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFДокумент1 страница303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFJkkhyhОценок пока нет

- Automotive After Market Information MEA PDFДокумент60 страницAutomotive After Market Information MEA PDFjose03Оценок пока нет

- Chemicals Zetag DATA Powder Magnafloc 5250 - 0410Документ2 страницыChemicals Zetag DATA Powder Magnafloc 5250 - 0410PromagEnviro.comОценок пока нет

- Alcohol EthoxylatesДокумент16 страницAlcohol EthoxylatesJose CencičОценок пока нет

- Chemicals Zetag DATA Beads Zetag 7587 - 0410Документ2 страницыChemicals Zetag DATA Beads Zetag 7587 - 0410PromagEnviro.comОценок пока нет

- Modeling, Control, and Optimization of Natural Gas Processing PlantsОт EverandModeling, Control, and Optimization of Natural Gas Processing PlantsРейтинг: 5 из 5 звезд5/5 (1)

- Ecolab Permaclean PC 33 LДокумент3 страницыEcolab Permaclean PC 33 LKumbang KambingОценок пока нет

- Aerial AdssДокумент2 страницыAerial AdssMd Irshad AlamОценок пока нет

- Metalworking BrochureДокумент6 страницMetalworking BrochurechayanunОценок пока нет

- Chemicals Zetag DATA Powder Zetag 8185 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 8185 - 0410PromagEnviro.comОценок пока нет

- Jotun Resist 86Документ5 страницJotun Resist 86Ansar AliОценок пока нет

- JOTUN Jotamastic 80Документ5 страницJOTUN Jotamastic 80Hafiz KamalОценок пока нет

- Chemicals Zetag DATA Beads Zetag 7583 - 0410Документ2 страницыChemicals Zetag DATA Beads Zetag 7583 - 0410PromagEnviro.comОценок пока нет

- Parker O RingДокумент0 страницParker O RingRazvan C GoranОценок пока нет

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlОт EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlОценок пока нет

- Chemicals Zetag DATA Beads Magnafloc 156 - 0410Документ2 страницыChemicals Zetag DATA Beads Magnafloc 156 - 0410PromagEnviro.comОценок пока нет

- Astm D473. SedimentosДокумент6 страницAstm D473. SedimentosgeralОценок пока нет

- Chemicals Zetag DATA Beads Zetag 7553 - 0410Документ2 страницыChemicals Zetag DATA Beads Zetag 7553 - 0410PromagEnviro.comОценок пока нет

- Chemicals Zetag DATA Powder Zetag 8190 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 8190 - 0410PromagEnviro.comОценок пока нет

- Chemicals Zetag DATA Powder Zetag 8180 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 8180 - 0410PromagEnviro.comОценок пока нет

- Chemicals Zetag DATA Powder Zetag 7650 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 7650 - 0410PromagEnviro.comОценок пока нет

- Chemicals Zetag DATA Powder Magnafloc 336 - 0410Документ2 страницыChemicals Zetag DATA Powder Magnafloc 336 - 0410PromagEnviro.comОценок пока нет

- Flare SystemДокумент29 страницFlare SystemLuis EnriqueОценок пока нет

- Chemicals Zetag DATA Powder Magnafloc 1011 - 0410Документ2 страницыChemicals Zetag DATA Powder Magnafloc 1011 - 0410PromagEnviro.com100% (1)

- Chemicals Zetag DATA Powder Zetag 7645 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 7645 - 0410PromagEnviro.comОценок пока нет

- Chemicals Zetag DATA Powder Magnafloc 919 - 0410Документ2 страницыChemicals Zetag DATA Powder Magnafloc 919 - 0410PromagEnviro.comОценок пока нет

- Chemicals Zetag DATA Beads Zetag 7593 - 0410Документ2 страницыChemicals Zetag DATA Beads Zetag 7593 - 0410PromagEnviro.comОценок пока нет

- Loxanol CA 5120Документ2 страницыLoxanol CA 5120Victor LopezОценок пока нет

- Stabaxol LДокумент3 страницыStabaxol LnazarienОценок пока нет

- Baltoflake: Technical Data SheetДокумент6 страницBaltoflake: Technical Data SheetSaul AntayhuaОценок пока нет

- Polyflex UltrachemДокумент2 страницыPolyflex UltrachemBraulio Candela NoriegaОценок пока нет

- ELASTOSIL R 40170 S en 2021.07.01 v6Документ3 страницыELASTOSIL R 40170 S en 2021.07.01 v6M J VoraОценок пока нет

- DOW Propylene OxideДокумент2 страницыDOW Propylene OxideA MahmoodОценок пока нет

- Chemflake SpecialДокумент5 страницChemflake Specialmajmor-1Оценок пока нет

- TDS 2280 Penguard+FC Euk GB PDFДокумент5 страницTDS 2280 Penguard+FC Euk GB PDFRyukiОценок пока нет

- Aircol PG 185Документ2 страницыAircol PG 185nauta007Оценок пока нет

- Purell ACP 6031 D Technical Data SheetДокумент3 страницыPurell ACP 6031 D Technical Data SheetPiyush A JoshiОценок пока нет

- Chem FlakeДокумент5 страницChem Flakejay2kay5793Оценок пока нет

- HEMPADUR 47140: DescriptionДокумент2 страницыHEMPADUR 47140: DescriptionMashudi FikriОценок пока нет

- Chemflake Special - English (Uk) - Issued.08.01.2010Документ5 страницChemflake Special - English (Uk) - Issued.08.01.2010Mohamed FaragОценок пока нет

- Galata CFA Properties GuideДокумент12 страницGalata CFA Properties GuideToniHospitalerОценок пока нет

- GPCDOC Local TDS United States Shell Naturelle HF-E 46 (en-US) TDS v1Документ3 страницыGPCDOC Local TDS United States Shell Naturelle HF-E 46 (en-US) TDS v1angel de mi guardaОценок пока нет

- Hetron CR 197Документ3 страницыHetron CR 197Faidhi SobriОценок пока нет

- F013Документ2 страницыF013Sai PrasathОценок пока нет

- AOC Corrosion GuideДокумент36 страницAOC Corrosion GuidebiondimiОценок пока нет

- (Painting) Jotamastic 87Документ5 страниц(Painting) Jotamastic 87Mohd FadliОценок пока нет

- Aircol PG 185Документ2 страницыAircol PG 185carmaОценок пока нет

- Chemicals Zetag DATA Powder Magnafloc 10 - 0410Документ2 страницыChemicals Zetag DATA Powder Magnafloc 10 - 0410PromagEnviro.comОценок пока нет

- Stepanpol PS 2352Документ2 страницыStepanpol PS 2352A MahmoodОценок пока нет

- Chemicals Zetag DATA Beads Zetag 7563 - 0410Документ2 страницыChemicals Zetag DATA Beads Zetag 7563 - 0410PromagEnviro.comОценок пока нет

- Pds Hempadur Mastic 45881Документ3 страницыPds Hempadur Mastic 45881kasosei0% (1)

- Chemicals Zetag DATA Powder Zetag 7652 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 7652 - 0410PromagEnviro.comОценок пока нет

- PDS 52140Документ2 страницыPDS 52140ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Pet Resin: Technical Data SheetДокумент6 страницPet Resin: Technical Data Sheetemad03Оценок пока нет

- Acronal 7095Документ3 страницыAcronal 7095kishanptlОценок пока нет

- BASF Acronal S 400Документ1 страницаBASF Acronal S 400Victor LopezОценок пока нет

- TDS Chemflake Glass Flake SuggestedДокумент5 страницTDS Chemflake Glass Flake SuggestedShankar Pl GowdaОценок пока нет

- Valve Lubricants, Sealants, Cleaners and Packings CatalogДокумент12 страницValve Lubricants, Sealants, Cleaners and Packings CatalogJohn NelsonОценок пока нет

- Chemicals Zetag DATA Powder Zetag 8110 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 8110 - 0410PromagEnviro.comОценок пока нет

- Technical Data Sheet Baltoflake EcolifeДокумент5 страницTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadОценок пока нет

- 1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Документ5 страниц1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Akram AlhaddadОценок пока нет

- Filmtec™ Membranes: Product Data SheetДокумент3 страницыFilmtec™ Membranes: Product Data Sheetcello loОценок пока нет

- Jotafix Pu Topcoat PDFДокумент2 страницыJotafix Pu Topcoat PDFcahyo hutomoОценок пока нет

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsОт EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsОценок пока нет

- Flooring and Textile 4-28-2016Документ8 страницFlooring and Textile 4-28-2016chayanunОценок пока нет

- Adhesive PlasticДокумент13 страницAdhesive PlasticchayanunОценок пока нет

- Comparative Enactment of Formaldehyde-Free and Formaldehyde-Based Cross-Linkers On Cotton Woven FabricsДокумент9 страницComparative Enactment of Formaldehyde-Free and Formaldehyde-Based Cross-Linkers On Cotton Woven FabricschayanunОценок пока нет

- Linered Electroplating/ Anodizing Tape: Technical Data August, 1995Документ2 страницыLinered Electroplating/ Anodizing Tape: Technical Data August, 1995chayanunОценок пока нет

- Product List: Preventol® P 91Документ3 страницыProduct List: Preventol® P 91chayanunОценок пока нет

- Silicone Fluids Stable Inert MediaДокумент32 страницыSilicone Fluids Stable Inert MediachayanunОценок пока нет

- Bio Treatment Water PDFДокумент11 страницBio Treatment Water PDFchayanunОценок пока нет

- Thermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002Документ5 страницThermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002chayanunОценок пока нет

- Unit Conversion Table - NewДокумент1 страницаUnit Conversion Table - NewShankar PranavОценок пока нет

- Insulations and JacketsДокумент1 страницаInsulations and JacketschayanunОценок пока нет

- Linered Electroplating/ Anodizing Tape: Technical Data August, 1995Документ2 страницыLinered Electroplating/ Anodizing Tape: Technical Data August, 1995chayanunОценок пока нет

- MSDS Citric Acid MonohydrateДокумент6 страницMSDS Citric Acid MonohydratechayanunОценок пока нет

- Da 108HДокумент1 страницаDa 108HchayanunОценок пока нет

- Eastman Chemical Company's Certification of Kosher ProductsДокумент4 страницыEastman Chemical Company's Certification of Kosher ProductschayanunОценок пока нет

- 2283Документ4 страницы2283chayanunОценок пока нет

- High Mole LinearДокумент1 страницаHigh Mole LinearchayanunОценок пока нет

- Stepan Tex VT 90Документ2 страницыStepan Tex VT 90chayanunОценок пока нет

- Da 128Документ1 страницаDa 128chayanunОценок пока нет

- Da 128Документ1 страницаDa 128chayanunОценок пока нет

- 591152Документ7 страниц591152chayanunОценок пока нет

- Air ProductsДокумент2 страницыAir ProductschayanunОценок пока нет

- Clarity Synthetic Hydraulic Oil AWДокумент5 страницClarity Synthetic Hydraulic Oil AWchayanunОценок пока нет

- INCITermsДокумент11 страницINCITermschayanunОценок пока нет

- PlurafacДокумент1 страницаPlurafacchayanunОценок пока нет

- Final GreenBuildingWhitePaperДокумент10 страницFinal GreenBuildingWhitePaperchayanunОценок пока нет

- Di - Octyl Phthalate (Dop) y y Primar Plasticizer For PVC and PVC Copol MersДокумент2 страницыDi - Octyl Phthalate (Dop) y y Primar Plasticizer For PVC and PVC Copol MersalguzduxtanОценок пока нет

- S2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationДокумент7 страницS2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationvivekpecОценок пока нет

- Croz - Beckert PDFДокумент16 страницCroz - Beckert PDFNeelakandan DОценок пока нет

- 4 Cs of Dust Control InformationalДокумент5 страниц4 Cs of Dust Control Informationalabu_shofiaОценок пока нет

- A Total Look at Oil Burner Nozzles: Iso 9001 CertifiedДокумент36 страницA Total Look at Oil Burner Nozzles: Iso 9001 Certifiedhoody_leeОценок пока нет

- Containers and Closures of Parenteral ProductДокумент2 страницыContainers and Closures of Parenteral ProductCarlos Alberto Bayona LópezОценок пока нет

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Документ1 страницаHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleОценок пока нет

- Amercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsДокумент4 страницыAmercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsTony KhouryОценок пока нет

- ME 231 Montazami Whharris 9-10-18 SOLUTIONДокумент4 страницыME 231 Montazami Whharris 9-10-18 SOLUTIONEduardo Perez UriegasОценок пока нет

- Guelph PrmeДокумент3 страницыGuelph PrmeRK MEHTAОценок пока нет

- Rev C - MS.50015 - ENДокумент4 страницыRev C - MS.50015 - ENBonifácio Pacheco AmaralОценок пока нет

- MEGO AFEK Technical Manual 2013Документ46 страницMEGO AFEK Technical Manual 2013odraci2Оценок пока нет

- Ion Exchangein Hydrometallurgical Processing An Overviewand Selected ApplicationsДокумент22 страницыIon Exchangein Hydrometallurgical Processing An Overviewand Selected ApplicationsShikoyeniОценок пока нет

- Fan Coil Unit: TCR TCRQ TFM TC TKM TFRДокумент20 страницFan Coil Unit: TCR TCRQ TFM TC TKM TFRydsОценок пока нет

- Reported by ACI/TMS Committee 216Документ26 страницReported by ACI/TMS Committee 216DIDIER ANGEL LOPEZ RINCONОценок пока нет

- DielectricResonatortype A4Документ2 страницыDielectricResonatortype A4denivaldo2009Оценок пока нет

- Study of Prefabrication in IndiaДокумент6 страницStudy of Prefabrication in IndiaSayed WafiОценок пока нет

- CoatingДокумент8 страницCoatingMuhammad Rizki Ash-ShidiqОценок пока нет

- Lenovo t400 Service Manual PDFДокумент386 страницLenovo t400 Service Manual PDFJosé Fabio Lou100% (1)

- Normex Valves Pricelist PDFДокумент2 страницыNormex Valves Pricelist PDFjhony MudОценок пока нет

- Unbrick Seagate HDDДокумент58 страницUnbrick Seagate HDDFly KuОценок пока нет