Академический Документы

Профессиональный Документы

Культура Документы

EP0215351B1 Acyl Fluorides

Загружено:

techkasambaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EP0215351B1 Acyl Fluorides

Загружено:

techkasambaАвторское право:

Доступные форматы

111! II II !l II I II II t li I II i l l l !

II J ) European Patent Office Dffice europeen des brevets EUROPEAN Oy Publication number: n K O C 1 B D1 I U 0 1 13 J3I

PATENT

SPECIFICATION

Date of publication of patent specification: 10.04.91 Application number: 86111905.5 % Date of filing: 28.08.86

@ Int. CI.5: C07C 45/46, C07C 4 9 / 7 6 , C07C 49/788, C07C 4 9 / 8 2 5 , C07C 49/83, C07C 4 9 / 8 4

Process for producing acetyl-substituted aromatic compound.

g) Priority: 31.08.85 JP 191521/85 @ Date of publication of application: 25.03.87 Bulletin 87/13 Publication of the grant of the patent: 10.04.91 Bulletin 91/15 Designated Contracting States: DEFRGBITNL (56) References cited: EP-A- 0 069 597 EP-A- 0 196 805 FR-A-2 348181 EP-A- 0 170 483 EP-A- 0 203 276 US-A- 3 234 286

@ Proprietor: MITSUBISHI GAS CHEMICAL COMPANY, INC. 5-2, Marunouchi 2-chome Chiyoda-Ku Tokyo, 100(JP) @ Inventor: Fujiyama, Susumu 522-65, Kamitomii Kurashiki-shi(JP) Inventor: Matsumoto, Shunichi 1168-3, Tanoue Kurashiki-shi(JP) Inventor, Yanagawa, Tatsuhiko 1987, Nakashima Kurashiki-shi(JP) Representative: Patentanwalte Grunecker, Kinkeldey, Stockmair & Partner Maximilianstrasse 58 W-8000 Munchen 22(DE)

CHEMICAL ABSTRACTS, vol. 104, no. 13, March 1986, Columbus, OH (US); p. 685, no. 109223s & JP-A-60 188343 CQ in CO in rC M O Q_ LU J.A.C.S., vol. 61, July 1939, pages 1795-1796; J.H. SIMONS et al.: "Hydrogen fluoride as a condensing agent. VII. The acylation of aromatic compounds"

Note: Within nine months from the publication of the mention of the grant of the turopean patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid (Art. 99(1) European patent convention). Rank Xerox (UK) Business services

EP 0 215 351 B1 Description This invention relates to a continuous process for producing an acetyl-substitued aromatic compound which comprises: obtaining an acetyl fluoride by the reaction of acetic anhydride with a substantially anhydrous hydrogen fluoride and separating formed acetyl fluoride by distillation, making an aromatic compound selected from alkylbenzenes, alkyl-naphtalenes, phenols, naphtols or aromatic ethers react with the separated acetyl fluoride in the presence of substantially anhydrous hydrogen fluoride as a catalyst at a temperature of from 0 - 70 C, thermally decomposing the resulting complex compound between the acetyl-substituted aromatic compound and hydrogen fluoride at a temperature of 40 C or higher. It is disclosed in Japanese Patent Application Kokai (Laid-open) No. 135756/79 to produce a 2-alkyl-6acylnaphthalene by acylating a 2-alkynaphthalene with an acid fluoride in the presence of boron fluoride as a catalyst. It is described in the above-mentioned invention that the presence of boron fluoride as a catalyst component is essential and the absence of boron fluoride results in low yield of the acylation product. However, according to the experiment of the present inventors, it has been found that when boron fluoride is used as a catalyst component in the reaction of aromatic compound with acetyl fluoride, it is difficult to decompose the resulting complex compound on accound of the instability of aromatic keton of the reaction product. EP-A-196 805 discloses acylation of a naphthalene compound in a batch or semi-continuous manner by using hydrogen fluoride and an acylating agent. EP-A-203 276 discloses a process for selectively acylating of aromatic compounds wherein an alkyl or aryl substituted aromatic compound is dissolved in hydrogen fluoride and reacted with an acylating agent. EP-A-69 597 discloses the preparation of p-phenoxybenzoyle ketone in a batch manner by reacting diphenyl ether and an acylating agent and converting the resulting p-phenoxybenzoyl ketone into pphenoxybenzoic acid. EP-A-170 483 discloses to produce 4-hydroxy-acetophenone in a batch wise manner by Friedel-Crafts acetylation of phenol, using hydrogen fluoride as catalyst and acetic acid as acylating agent. The object of the present invention is to conduct a process for producing an acetyl substituted aromatic compound continuously. Accordingly, the present inventors have made extensive studies to attain a process for producing an acetyl-substituted aromatic compound with higher efficiency including the steps of the decomposition of the complex compound and the recovery of the catalyst component. The object of the present invention has been achieved in obtaining acetyl fluoride by making the molar ratio of acetyle fluoride to starting aromatic compound 1 or below, and making an excess of acetic anhydride of 5 mol % or below react with hydrogen fluoride. It has been found that, in the reaction of an aromatic compound with acetyl fluoride, even when hydrogen fluoride is used as a catalyst they intended acetyl-substituted aromatic compound can be obtained in excellent yield and further the complex compound form can be readily decomposed and the hydrogen fluoride catalyst can be easily recovered. This invention has been accomplished on the basis of the above findings. Thus, this invention provides a continuous process for producing an acetyl-substituted aromatic compound which comprises making an aromatic compound including an 2-alkylnaphthaiene react with acetyl fluoride in the presence of substantially anhydrous hydrogen fluoride as a catalyst. The aromatic compounds used as the starting material in this invention include alkylbenzenes such as toluene, xylene, trimethylbenzene, ethylbenzene, cumene, and butylbenzene; naphthalene and alkylanphthalenes such as methylnaphthalene; phenols and naphthols; and further aromatic ethers such as anisoie and phenyl ether. Particularly preferred are compounds in which the para position to the substituent in the aromatic ring is vacant and naphthalenes having a substituent in the 2-position. Acetyl fluoride as the other starting material, can be obtained by mixing acetic anhydride with hydrogen fluoride to produce acetyl fluoride according to the following equation (1) and separating the free acid simultaneously formed. (CH3CO)20 + HF CH3COF + CH3COOH (1) It is essential here that the reaction (1 ) mentioned above should be carried out at a slight excess of acetic anhydride. Thus, when hydrogen fluoride is in excess of the equivalent, the maximum azeotropic mixture combined hydrogen fluoride with the acid, which leads to the loss of hydrogen fluoride, is formed to become inseparable and further the acid formed is contaminated with fluorine, so that special treatments 2

15

20

25

30

35

40

45

so

55

=P 0 215 351 B1 are required to remove it. when acetic anhydride is in excess, such difficulties do not occur and hydrogen fluoride can be quantitatively recovered as acetyl fluoride. However, there is no need of large excess and the ratio of excess acetic anhydride to hydrogen fluoride may be 5 mol% or below. The apparatus used for generating acetyl fluoride may be a conventional distillation column having a number of plates necessary for fractionating acetyl fluoride and the free acid. Acetic anhydride and 5 hydrogen fluoride are fed to the appropriate plate of the distillation column as a mixture or separately, the column bottom is heated up to the boiling point of the acid and the column top is given an appropriate reflux. Such a conventional distillation operation makes it possible to recover pure acetyl fluoride from the column top and an acid containing no fluorine from the column bottom. Since the reaction proceeds at a high rate, virtually no residence time is necessary. The reaction can 70 be conducted under an ordinary or an applied pressure, for example 1 kg/cm2Q, and either flow operation or batchwise operation may be used. The difference of boiling point between acetyl fluoride and the acid formed is so large that the two can be easily separated. The acetyl fluoride thus formed is used for acetylation as the acetylating agent. The molar ratio of 75 acetyl fluoride to the starting aromatic compound is 1 or below, 0.9 to 0.5 being particularly preferable. The presence of excess acetyl fluoride decreases the overall reaction rate (i.e. the space time yield of the acetylation product). As the catalyst, a substantially anhydrous hydrogen fluoride is used. Its water content is preferably 5% or below because the presence of water in hydrogen fluoride causes the rapid decrease of catalytic activity. 20 In order to obtain a sufficient reaction rate, the molar ratio of hydrogen fluoride to be used relative to the acetylating agent is 5 or above, preferably in the range of 10 to 20. Hydrogen fluoride used in a molar ratio of 20 or above gives little additional effect and hence is not advantageous from the economical viewpoint of the process. The reaction temperature of acetylation is 0 to 70C, preferably 10 to 50C. Since the reaction rate 25 increases as the temperature is increased but also the side reaction increases, an optimum temperature is selected from the above-mentioned range depending upon the starting material used. When the starting compound has a high melting point and further is insoluble in hydrogen fluoride as in the case of aromatic hydrocarbons, it is effective to use a suitable solvent in order to make the reaction proceed smoothly. Preferable solvents are those which can dissolve the starting compound well, are chemically inert under 30 reaction conditions, and have a good compatibility also with the reaction liquid formed. They include, for example, benzene or halogenated hydrocarbons such as chlorobenzene, dichloromethane, dichloroethane and freon. Particularly, benzene is the most suitable solvent in the present process because it is not only substantially inert under the present reaction conditions but also favorable as the solvent in the step of recovering the catalyst from the reaction mixture. The amount of the solvent to be used in the reaction is not specifically limited. The amount of 0.5 mole 35 or below per mole of the starting compound is usually sufficient. Although the reaction pressure is varied depending on the reaction temperature, usually it ranges from an ordinary pressure to a slightly elevated pressure of up to 2 kg/cm2G. The reaction proceeds in a homogeneous liquid phase or, according to circumstances, in two-liquid consisting of a starting aromatic compound phase and a catalyst phase, so that there is no need of phases 40 vigorous stirring. Since the reaction is slightly exothermic, a reactor provided with heat removal equipment is used as required. The acetylation reaction liquid thus obtained is a solution of an aromatic ketone, the acetylation product, in hydrogen fluoride. On heating the reaction liquid, the affinity between the reaction product and hydrogen 45 fluoride is broken and hydrogen fluoride can be easily vaporized and separated. It is necessary to conduct the above-mentioned catalyst recovery operation as rapidly as possible in order to avoid the thermal degradation of the reaction product. For this purpose, the catalyst recovery operation is preferably conducted in a flow operation using a multistage gas-liquid contact apparatus (i.e. a distillation column). For catalyst recovery, heating at a temperature of 40C or higher, particularly 40 to so 100 C, is necessary. The decomposition column is preferably fed with an amount of heat which is in excess of that necessary for vaporizing hydrogen fluoride fed to the column. It is advantageous in the process to conduct the catalyst recovery operation under atmospheric pressure or a slightly increased pressure of 2 kg/cm2G or below. In order to make the thermal decomposition of the complex compound between the acetyl-substituted aromatic compound and hydrogen fluoride proceed smoothly, the de55 composition is preferably conducted by heating the complex compound under reflux using as a diluent a substance which has a boiling point such that it is easily separable from hydrogen fluoride, has a good compatibility with the reaction product, namely the acetyl-substituted aromatic compound, and with hydrogen fluoride, and is inert to hydrogen fluoride. Examples of such diluent used include aromatic 3

EP 0 215 351 B1 compounds such as benzene and chlorobenzene. Particularly, benzene is the most preferable. According to this invention, aromatic compounds can be acetylated in a simple operation under low reaction pressure, and hydrogen fluoride used as the catalyst can be completely recovered and recycled. So this invention is of great industrial advantage. The accompanying drawing is a flow diagram showing the acetylation process of this invention. 5 The process for acetylating an aromatic compound according to this invention is illustrated below with reference to Fig. 1. In Fig. 1, acetic anhydride is fed to the middle plate of an acetyl fluoride generating apparatus 2 through pipe 1 and contacted there with heating with hydrogen fluoride introduced through a pipe 3. The w acetyl fluoride formed is distilled out through an outlet pipe 4 and acetic acid is withdrawn through a pipe 5. The acetyl fluoride is fed to an acetylation reactor 6 equipped with a stirrer 19 and is contacted there with stirring with the starting aromatic compound fed through a pipe 7 and with hydrogen fluoride fed through a pipe 8. The reaction begins in two liquid phases of the hydrogen fluoride phase and the starting material oil phase, which then change into a homogeneous liquid phase as the reaction proceeds. The reaction liquid is drawn out through a pipe 9, led to a hydrogen fluoride recovery column 10, and contacted there with a 15 diluent such as benzene which is being refluxed and recycled. Hydrogen fluoride is separated by vaporization and drawn out through a pipe 11. The column top vapor is condensed by cooling and separated into layers. The benzene phase is refluxed from a pipe 12 to the recovery column 10; hydrogen fluoride is recycled to the acetyl fluoride generating apparatus and the acetylation reactor (not shown in the 20 Figure). From the bottom of the hydrogen fluoride recovery column is withdrawn through a pipe 13 the acetylation product, a crude product, whicn is then freed from trace amount of residual acid in a neutralization and washing equipment 14 and distilled in a distillation apparatus 15, whereby the byproduct is removed through a pipe 16, the unreacted raw material is removed through a pipe 17 to be recycled to the reaction step, and the final product is obtained through a pipe 18. A suitable solvent is used to make the reaction proceed smoothly as required. This is added to the 25 starting material in a pipe 7. Fig. 1 shows a case where the solvent and the diluent for decomposition are the same. But, in the case where both are different, further a process for recovering the solvent is added to it. This invention will be further explained in detail below with reference to Examples, but it is not limited 30 thereto. Example 1 35 Synthesis of acetyl fluoride

A stainless steel packed column having a diameter of 50 mm and a height of 1000 mm provided with a top reflux apparatus and a bottom reboiler was used as the acetyl fluoride synthesizer. Acetic anhydride 40 (22.0 moles per hour) and hydrogen fluoride (21 .0 moles per hour) were mixed and fed continuously to the middle plate of the packed column, and heat was supplied to the reboiler with an electric heater at a rate of 260 Kcal per hour. The synthesizer was operated under a pressure of 1.0 kg/cm2G. While reflux was applied so as to keep the temperature of the column top at about 35C, acetyl fluoride was distilled out of the column top at a rate of 21 moles per hour, and a liquid mixture comprising 21 moles of acetic acid and 45 1 mole of acetic anhydride was withdrawn every hour from the bottom. The yield of acetyl fluoride relative to supplied hydrogen fluoride was quantitative. Acetylation of 2-methylnaphthalene Two stainless steel vessels each equipped with a stirrer, the first reactor having an inner liquid volume of Ql and the second reactor having an inner liquid volume of 41 , were connected in series to be used as the acetylation reactor. A solution comprising 1.5kg of 2-methylnaphthalene and 0.3kg of benzene was fed every hour to the first reactor. Simultaneously, 0.5kg per hour of acetyl fluoride synthesized above and 2.5kg per hour of hydrogen fluoride were also fed to the first reactor. The reaction temperature was adjusted to 25 C by passing cooling water through the jacket of the reactor. The pressure in the reaction was 1 kg/cm2G. The reaction mixture was continuously withdrawn from the second reactor to be fed to the subsequent hydrogen fluoride recovery column. 4

55

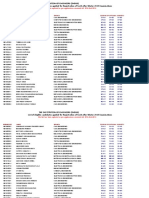

=P 0 215 351 B1 Recovery of hydrogen fluoride The packed column used in acetyl fluoride synthesis was employed as the hydrogen fluoride recovery column. The hydrogen fluoride recovery column was charged with benzene, and heat was supplied at a rate of 300 Kcal per hour to the reboiler under a pressure of 1 kg/cm2G to keep the benzene refluxing. Then the above-mentioned reaction mixture was continuously fed to the upper part of the column at a rate of 1kg per hour, and the hydrogen fluoride recovery column was continuously operated while being replenished with benzene. From the column top were distilled out hydrogen fluoride and unreacted acetyl fluoride, while from the column bottom were recovered every hour 243g of acetylated methylnaphthalene, 109g of unreacted methylnaphthalene, and 20g of a high boiling point product as the crude acetylation product. The acetylation product contained 75% of 2-acetyl-6-methylnaphthalene. Example 2 Acetylation of toluene 20 Toluene was acetylated by using the same apparatus and the same operation as in Example 1. To the first reactor were fed every hour 0.9kg of toluene, 0.4kg of acetyl fluoride, and 2.0kg of hydrogen fluoride, and the reaction was conducted at a reaction temperature of 40 C and under a reaction pressure of 1.5 kg/cm2G. The reaction mixture was continuously withdrawn from the second reactor and hydrogen fluoride was recovered in the same manner as in Example 1. The crude product obtained from the bottom 25 of the hydrogen fluoride recovery column had the following composition: unreacted toluene 55%, methylacetophenone 41%, high boiling point product 4%. The methylacetophenone contained 97.5% of 4methylacetophenone. 30 Example 3 Acetylation of m-xylene 35 A stainless steel autoclave of 500ml volume equipped with a jacket and a stirrer was used as the acetylation reactor. A solution of 56g (0.9 mole) of acetyl fluoride in 103.1g (1 mole) of m-xylene was placed in the autoclave, and then, with cooling, 300g (15 moles) of hydrogen fluoride was introduced thereinto. The mixture was allowed to react at a reaction temperature of 40 C under a reaction pressure of 1.5 kg/cm2G for 1.5 hours. Thereafter, the reaction mixture was withdrawn into ice water. The resulting oil layer was washed with alkaline water and distilled to determine the amount of high boiling point byproducts and analyzed by gas chromatograph to determine the yield of the acetylated product. Examples of acetylations conducted in the same manner as mentioned above using various aromatic compounds as the starting material are summarized in Table 1.

io

is

40

45

50

55

I C -rl 0 +> *^ J H R dP PHrtJ 3(DwrH H ^ 0 >i o s +) 4J w < D rH <3 "H >i

1 13 d) p c h -P c 0 O < D .Q 0 +>

o c o n < x >

c r

N O co

M tji

n oo

H co

r-

6 3 HO E-i J3 (0 C 1 0 H H + > 0) H H 'Ug-P C ( U 0 Eh O 0 *H +> rrj rH >i + C D 0 <

<n

m < H

in . r r n c N c v j rH

1 Si (d H

0) U 3 U o ' f0

in cn

in cn

in <n

in cn

0 -H + > (0 u u rd 0

fa u < \ a -~ ' O <

o m i n H r H r - f r -

o i n o o o ! H < N C V J C N

in O

in O O O O O O

in O

C-H C H +J 3 +> ( T j O . m g cu*a Id O E +> M O C03O

< u C J < u rH irj 43 43 di (0 0)0 c c rH < D 0) >1 f3 rH < D j 3 C ( U > 1 + > a ) r H + < U 3 > i - H S H X W O < 1 O 1 0)

( U C N a

jq H >, (J) P r H H r H J s o o > i X l C t Q C D - H < U 43 S W X!

M < u +> 0J

EP 0 215 351 B1

1 U

d.\J

W H cn >i H 4J rrj o a M t 3 rd 0 0 U Gh-H 0 QtXi HOj +1 C ! (d H O H w -h cn O-PO C U rd -P EH id 0 >iS O-PO C UU 0 Xi J 0 W rd o

i n f> cn

o o O H

o o O rH

u 5 < T t

r (T\

c C T \

Cn

< 0 -P U -P 3 O T3 3 O ao o >i+) u 04 Si C D C r >> G G -H O H -P -H rH (d -P i H H rd 0 C DrH U >i -P 1 43 C D C n 0 h (d

< U C C D c u G h o rd ( D C J3 G C D +) J3 C D 0 ,G G G C D Oi C D C D & C D C D O O G G G f C G X i - P G O O O G O & c D C D G G G H G O 0 .G C D C U C D > i C D - P r d a . . G , G r C ,G C D H Q * C U 0 Q * +) a o -P 0 >i 0 O C D O . G C D - P - P - P P -p g rH 0 < D C D C D 1 C D >i C D rd O O 0 < > 0 , G g H r d r d r d -P 1 < d >i -H >i >i >i H H C D H 4 J X X X > i > i g E - i 3 0 0 0 - P X l - H I X S V i ^ G < D - P Q < x > O r d - P C D o a ) i ^ w > t c u I G 1 1 1 1 I * C N rr C N C N & pj C u Q,

T5 -P G O U JO

rH Si

< * > -P S ^

C O

"5"

4S

Claims I. A continuous process for producing an acetyl-substituted aromatic compound which comprise: obtaining an acetyl fluoride by the reaction of acetic anhydride with a substantially anhydrous hydrogen fluoride and separating formed acetyl fluoride by distillation, making an aromatic compound selected from alkylbenzenes, alkyl-naphtalenes, phenols, naphtols ethers react with the separated acetyl fluoride in the presence of substantially anhydrous aromatic or hydrogen fluoride as a catalyst at a temperature of from 0 C - 70 C, thermally decomposing the resulting complex compound between the acetyl-substituted aromatic 7

EP 0 215 351 B1 compound and hydrogen fluoride at a temperature of 40 C or higher characterized in that acetyl fluoride is obtained by making the molar ratio of acetyl fluoride to starting aromatic compound 1 or below, and making an excess of acetic anhydride of 5 mol % or below react with hydrogen fluoride. 2. 3. A process for according to claim 1, characterized in that the reaction pressure in the acetylation is from atmospheric pressure to 2 kg/cm2 (20265 Pa)G. A process according to claim 1, characterized in that the thermal decomposition of the complex compound between the acetyl-substituted aromatic compound and hydrogen fluoride is performed in the presence of an inert solvent.

Revendications 1. Un precede continu pour la preparation d'un compose aromatique acetyl-substitue, qui comprend: I'obtention d'un fluorure d'acetyle par la reaction de I'anhydride acetique avec un fluorure d'hydrogene sensiblement anhydre, et la separation par distillation du fluorure d'acetyle forme, la mise en reaction d'un compose aromatique choisi parmi les alcoylbenzenes, les alcoylnaphtalenes, les phenols, les naphtols ou les ethers aromatiques avec le fluorure d'acetyle separe en presence de fluorure d'hydrogene sensiblement anhydre comme catalyseur a une temperature de 0C a 70 C, la decomposition thermique du compose complexe forme entre le compose aromatique acetylsubstitue et le fluorure d'hydrogene a une temperature de 40 C ou plus, caracterise en ce que le fluorure d'acetyle est obtenu par fixation du rapport molaire du fluorure d'acetyle au compose aromatique de depart a 1 ou moins et mise en reaction d'un exces d'anhydride acetique de 5% molaires ou moins avec du fluorure d'hydrogene. Un procede selon la revendication 1, caracterise en ce que la pression de reaction dans I'acetylation est comprise entre la pression atmospherique et 2 kg/cm2 (20 265 Pa) manometriques. Un procede selon la revendication 1, caracterise en ce que la decomposition thermique du compose complexe forme entre le compose aromatique acetyl-substitue et le fluorure d'hydrogene est effectuee en presence d'un solvant inerte.

2. 3.

Anspriiche 1. Kontinuierliches Verfahren zur Herstellung einer acetylsubstituierten aromatischen Verbindung, umfassend: Erzielung eines Acetylfluorids durch die Umsetzung von Essigsaureanhydrid mit einem im wesentlichen wasserfreien Wasserstoffluorid und Abtrennen des gebildeten Acetylfluorids durch Destination, Umsetzen einer aromatischen Verbindung, gewahlt aus Alkylbenzolen, Alkylnaphthalinen, Phenolen, Naphtholen oder aromatischen Ethern mit dem abgetrennten Acetylfluorid in Gegenwart von im wesentlichen wasserfreiem Wasserstoffluorid als Katalysator bei einer Temperatur von 0 C - 70 C, thermisches "Zersetzen der resultierenden Komplex-Verbindung zwischen der acetylsubstituierten aromatischen Verbindung und Wasserstoffluorid bei einer Temperatur von 40 C oder daruber, dadurch gekennzeichnet, da/3 Acetylfluorid dadurch erzielt wird, da/3 das molare Verhaltnis von Acetylfluorid zu der aromatischen Ausgangsverbindung auf 1 oder darunter eingestellt wird, und da/3 ein Uberschu/3 an Essigsaureanhydrid von 5 Mol % oder darunter mit dem Wasserstoffluorid umgesetzt wird. Verfahren nach spruch 1, dadurch gekennzeichnet, da/3 der Reaktionsdruck bei der Acetylierung im Bereich von atmospharischem Druck bis 2 kg/cm2 (20265 Pa)G liegt. Verfahren nach Anspruch 1, dadurch gekennzeichnet, da/3 die thermische Zersetzung der KomplexVerbindung zwischen der acetylsubstituierten aromatischen Verbindung und Wasserstoffluorid in Gegenwart eines inerten Losungsmittels durchgefuhrt wird.

2. 3.

EP 0 215 351 B1

F I G .

Вам также может понравиться

- Triazoles ChemistryДокумент4 страницыTriazoles ChemistrytechkasambaОценок пока нет

- Benzoylation of AcetophenoneДокумент3 страницыBenzoylation of AcetophenonetechkasambaОценок пока нет

- Sheet1 F2:F51 Contains 1 Sheet1 G2:G51 Contains 2 Sheet1 F2:F51 Contains 1 Sheet1 G2:G51 Contains 2Документ9 страницSheet1 F2:F51 Contains 1 Sheet1 G2:G51 Contains 2 Sheet1 F2:F51 Contains 1 Sheet1 G2:G51 Contains 2techkasambaОценок пока нет

- Biological Wastewater Treatment: Aerobic & AnaerobicДокумент8 страницBiological Wastewater Treatment: Aerobic & Anaerobic007_pppqqqОценок пока нет

- Weird World PDFДокумент67 страницWeird World PDFAllanki Sanyasi Rao67% (6)

- DWNДокумент28 страницDWNtechkasambaОценок пока нет

- The Decomposition of Aqueous Sodium Bromite: Department of Chemistry, University of Toronto, Toronto OntarioДокумент6 страницThe Decomposition of Aqueous Sodium Bromite: Department of Chemistry, University of Toronto, Toronto OntariotechkasambaОценок пока нет

- S.No Company Name Price On 7 April 201 Buy Amount Quantity Current Priceprofit/LossДокумент3 страницыS.No Company Name Price On 7 April 201 Buy Amount Quantity Current Priceprofit/LosstechkasambaОценок пока нет

- Chaos TheoryДокумент77 страницChaos TheoryshhtiklaОценок пока нет

- Ues845 PDFДокумент11 страницUes845 PDFMaheswarReddy SathelaОценок пока нет

- 2018 IciciДокумент32 страницы2018 IcicitechkasambaОценок пока нет

- Wa0042Документ1 страницаWa0042techkasambaОценок пока нет

- Beauty of India PDFДокумент73 страницыBeauty of India PDFtechkasambaОценок пока нет

- The Truth About Fibonacci TradingДокумент22 страницыThe Truth About Fibonacci TradingrsvelforexОценок пока нет

- Save Water, Save Life PDFДокумент30 страницSave Water, Save Life PDFtechkasambaОценок пока нет

- Short PDFДокумент3 страницыShort PDFtechkasambaОценок пока нет

- Options OracleДокумент45 страницOptions OraclenetygenОценок пока нет

- Multi BaggerДокумент1 страницаMulti BaggertechkasambaОценок пока нет

- Horiba P e Final Flyer NewДокумент2 страницыHoriba P e Final Flyer NewtechkasambaОценок пока нет

- Assessing The Profitability of Intraday Opening Range Breakout StrategiesДокумент11 страницAssessing The Profitability of Intraday Opening Range Breakout StrategiestechkasambaОценок пока нет

- Selective Synthesis of 2-Picoline from AcetoneДокумент8 страницSelective Synthesis of 2-Picoline from AcetonetechkasambaОценок пока нет

- Hse PlanДокумент3 страницыHse Planresure100% (5)

- Waste Water Treatment MethodДокумент8 страницWaste Water Treatment MethodtechkasambaОценок пока нет

- Good KPДокумент16 страницGood KPtechkasambaОценок пока нет

- Green Life - What We DoДокумент11 страницGreen Life - What We DotechkasambaОценок пока нет

- Experienced Based Rules of Chemical EngineeringДокумент33 страницыExperienced Based Rules of Chemical Engineeringintania66Оценок пока нет

- IPTFAДокумент9 страницIPTFAtechkasambaОценок пока нет

- Ages For Signs - 19th VerseДокумент7 страницAges For Signs - 19th VerseKhoo Hock Leong KhooОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Lumion PRO 5Документ6 страницLumion PRO 5paparock34Оценок пока нет

- Trafo 40 Mva PDFДокумент719 страницTrafo 40 Mva PDFeug_manu8Оценок пока нет

- Deep Glow v1.4.6 ManualДокумент6 страницDeep Glow v1.4.6 ManualWARRIOR FF100% (1)

- Dokumen - Tips - Simple Stresses From MathalinoДокумент58 страницDokumen - Tips - Simple Stresses From MathalinoMidas Troy VictorОценок пока нет

- More About Generating FunctionДокумент11 страницMore About Generating FunctionThiên LamОценок пока нет

- CB Climbing Bracket PERIДокумент52 страницыCB Climbing Bracket PERINathan FryerОценок пока нет

- Frege: Sense and Reference One Hundred Years LaterДокумент215 страницFrege: Sense and Reference One Hundred Years LaterfabioingenuoОценок пока нет

- SCADAДокумент14 страницSCADANunna BaskarОценок пока нет

- Data Communication & Computer NetworksДокумент32 страницыData Communication & Computer NetworksMuhammad NadeemОценок пока нет

- Electrical Plant Load AnalysisДокумент36 страницElectrical Plant Load AnalysisJesus EspinozaОценок пока нет

- Development and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormsДокумент6 страницDevelopment and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormswiracanaОценок пока нет

- Chemistry Investigatory File Handmade NewДокумент17 страницChemistry Investigatory File Handmade NewMadhusudan PeriwalОценок пока нет

- Maquina de Anestesia - ADSIIДокумент2 страницыMaquina de Anestesia - ADSIIalexanderОценок пока нет

- 03a IGCSE Maths 4MB1 Paper 2R - January 2020 Examination PaperДокумент32 страницы03a IGCSE Maths 4MB1 Paper 2R - January 2020 Examination PaperMehwish ArifОценок пока нет

- An Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringДокумент15 страницAn Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringKrinta AlisaОценок пока нет

- Answer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large OutliersДокумент2 страницыAnswer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large Outliersroshia maeОценок пока нет

- 25 Most Frequently Asked DSA Questions in MAANGДокумент17 страниц25 Most Frequently Asked DSA Questions in MAANGPranjalОценок пока нет

- List of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Документ9 страницList of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Sateesh NayaniОценок пока нет

- Manual EAP1.5-2kg 040Документ21 страницаManual EAP1.5-2kg 040mykeenzo5658Оценок пока нет

- Modeling Confined Masonry Walls with OpeningsДокумент11 страницModeling Confined Masonry Walls with OpeningsMangisi Haryanto ParapatОценок пока нет

- MC Maths - Lesson Plans - Stage 6 - C05Документ9 страницMC Maths - Lesson Plans - Stage 6 - C05syasmiitaОценок пока нет

- Aircraft Engine InstrumentsДокумент11 страницAircraft Engine Instrumentssamuelkasoka641Оценок пока нет

- The Role of Pets in PreadolescentДокумент17 страницThe Role of Pets in PreadolescentshimmyОценок пока нет

- Standard Rotary Pulse Encoder Operation Replacement SettingДокумент8 страницStandard Rotary Pulse Encoder Operation Replacement SettingGuesh Gebrekidan50% (2)

- Irfp4768Pbf: Application V 250V R 14.5M 17.5M I 93AДокумент9 страницIrfp4768Pbf: Application V 250V R 14.5M 17.5M I 93AKrishna InamdarОценок пока нет

- CO Limba Engleza, Anul 2Документ56 страницCO Limba Engleza, Anul 2Bocaneala Gianina100% (1)

- 01 New StaffДокумент9 страниц01 New StaffCIS AdminОценок пока нет

- NX Advanced Simulation坐标系Документ12 страницNX Advanced Simulation坐标系jingyong123Оценок пока нет

- English ThesisДокумент112 страницEnglish ThesisMaria Teresa OndoyОценок пока нет

- Aditya Rahul Final Report PDFДокумент110 страницAditya Rahul Final Report PDFarchitectfemil6663Оценок пока нет