Академический Документы

Профессиональный Документы

Культура Документы

Magnetocaloric Effect in Melt-Spun MnCoGe Ribbons

Загружено:

Sumith SaleheenИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Magnetocaloric Effect in Melt-Spun MnCoGe Ribbons

Загружено:

Sumith SaleheenАвторское право:

Доступные форматы

Available online at www.sciencedirect.

com

Scripta Materialia 69 (2013) 211214 www.elsevier.com/locate/scriptamat

Magnetocaloric eect in melt-spun MnCoGe ribbons

nchez-Valde s,a J.L. Sa nchez Llamazares,b, H. Flores-Zu os-Jara,b n C.F. Sa iga,b D. R c d P. Alvarez-Alonso and Pedro Gorria

Institut de Ciencia de Materials de Barcelona (C.S.I.C.), Campus U.A.B., 08193 Bellaterra, Spain n de Materiales Avanzados, Instituto Potosino de Investigacion Cientca y Tecnologica A.C., Divisio 2055, CP 78216, San Luis Potos , Mexico Camino a la presa San Jose c nica, Universidad del Pa s Vasco (UPV/EHU), 48940 Leioa, Spain Departamento de Electricidad y Electro d sica, EPI, Universidad de Oviedo, Gijon, Spain Departamento de F

b a

Received 25 February 2013; revised 21 March 2013; accepted 21 March 2013 Available online 28 March 2013

Single-phase MnCoGe ribbons with an NiIn2-type structure were produced by using the melt-spinning technique. We reduced the annealing time for stabilizing the lower-symmetry orthorhombic TiNiSi-type crystal structure by two orders of magnitude compared 1 with that of the parent bulk alloy. Both phases exhibit a second-order magnetocaloric eect, with DS peak K 1 M % 2:84:0J kg 1 and RC % 238 (281) J kg for the maximum isothermal magnetic entropy change and refrigerant capacity, respectively, for a magnetic eld change of 5 T. 2013 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Keywords: MnCoGe melt-spun ribbon; Magnetocaloric eect; Magnetic entropy change; Refrigerant capacity

The stoichiometric MnCoGe compound exhibits polymorphism and can adopt either the hexagonal Ni2In-type (space group P63/mmc) or the orthorhombic TiNiSi-type (space group Pnma) crystal structure at room temperature [1]. Both phases are ferromagnetically ordered, although the values for the Curie temperature, TC, and saturation magnetic moment, mS, dier: TC % 275 and 355 K and mS % 2.8 and 4.1 lB f.u.1 for the hexagonal and orthorhombic phases, respectively [2,3]. Both Mn and Co have magnetic moments, although the main contribution comes from the Mn atoms [2,4]. The orthorhombic variant, usually referred to as the low-temperature phase, is obtained after homogenization is achieved by thermal annealing at temperatures in the range of 7731123 K [59], followed by slow or fast cooling to room temperature. However, a serious practical drawback in the homogenization process is the annealing time, which typically requires several days. On heating, this phase undergoes a rst-order diusionless structural phase transformation to the hexagonal phase (i.e. a martensitic-type transformation) with a

Corresponding author. Tel.: +52 4448342000; fax: +52 4448342010;

e-mail: jose.sanchez@ipicyt.edu.mx

large thermal hysteresis of $DT = 40 K [3,10]. The temperature for the beginning of the structural transition Tstr varies between 420 K [5] and 650 K [3,10]. Although the high-temperature stable phase is hexagonal (for T > Tstr), it has also been reported that, when the alloy is annealed at a high temperature and rapidly quenched in water, this hexagonal phase can be obtained at room temperature in a metastable state [2,11]. An interesting feature of MnCoGe-based alloys is the strong interplay between structure and magnetism. Several factors, such as Co vacancies [8,12,13], Mn deciency [14], the application of hydrostatic pressure [10,11,15], substitution of a small amount of Mn or Co by a fourth element [3,5,8,9,11,16,17] and the introduction of interstitial elements [1820], may aect the intrinsic magnetic properties of both structural variants, as well as the value of Tstr, considerably. The magnetocaloric (MC) response of MnCoGebased alloys has drawn considerable attention in the last few years. Large, and even giant, peak values of the isohave been rethermal magnetic entropy change DS peak M ported in pure [6,13] or doped alloys [8,9,1520] with an orthorhombic crystal structure. In MnCo0.95Ge1.14 alloys a sizable DS peak of 6.4 Jkg1 K1 is induced by M a rather low magnetic eld change of loDH = 1 T [6]. The eect has been explained by the large, sharp drop

1359-6462/$ - see front matter 2013 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.scriptamat.2013.03.022

212

nchez-Valde s et al. / Scripta Materialia 69 (2013) 211214 C. F. Sa

in magnetization close to the ferromagnetic (FM) to paramagnetic (PM) transition as a consequence of the negative exchange striction of the lattice around TC (i.e. due to the strong magneto-elastic coupling nature of the magnetic transition). More recently, a giant magnetic entropy change has been found in interstitially modied MnCoGeBx [16,19] and MnCoGeCx [19] alloys, or by partial replacement of Mn by Cr in Mn1 xCrxCoGe [15,16,19], by reducing the Tstr to below the Curie point of the orthorhombic phase. Until now, MnCoGe alloys have been produced as bulk samples by means of conventional melting techniques followed by lengthy thermal annealing. In view of the current interest and great potential of these compounds as MC materials near room temperature, here we report the synthesis of the equiatomic MnCoGe compound by rapid solidication using the melt-spinning technique, as well as characterizations of the crystal structure, the magnetic properties and the MC eect to a maximum magnetic eld change up to loDHmax = 5 T. To our knowledge, neither the synthesis of MnCoGe melt-spun ribbons nor their MC properties have been reported yet. Signicantly, the use of rapid solidication to produce the orthorhombic variant of this compound results in a substantial reduction in the annealing time. Rapidly solidied ribbons (with thicknesses % 30 35 lm) were produced by melt spinning in an Ar atmosphere at a wheel linear speed of 20 ms1 from as-cast pellets of nominal composition of MnCoGe previously obtained by arc melting from highly pure elements (>99.9%), also under an Ar atmosphere. Any Mn losses during arc melting were carefully compensated for by adding the appropriate excess of this element. Samples were annealed at 923 K for 1 h to stabilize the orthorhombic structure. Annealing was followed by water quenching. X-ray powder diraction (XRD) patterns were obtained with a Bruker AXS model D8 Advance diractometer using Cu Ka radiation. Microstructure and elemental composition were determined using a FEI/Philips XL30 eld emission gun SEM equipped with an energy-dispersive analysis system (EDS). Magnetization measurements were performed using a PPMS platform equipped with a vibrating sample magnetometer module. The magnetic eld loH was applied along the major length of the ribbon samples (typically, $4 mm) to minimize the demagnetizing eld eect. Magnetization vs. temperature (M(T)) curves were recorded under a low applied magnetic eld of 5 mT with the aim of accurately determining the value of TC. The magnetic entropy change as a function of the temperature curves, DSM(T), was obtained by numerical integraR lo H max tion @ M of the Maxwell relation DS M T lo o dH from a set of isothermal magnetization curves @ T lo H M(loH) measured up to loHmax = 5 T. The refrigerant capacity RC, which measures the thermal eciency of the material on the energy transfer from cold to hot reservoirs for an ideal thermodynamic cycle, was estimated using the following three well-established R T cold methods: RC -1 DS peak M dT FWHM [20], RC -2 T hot DS M T DB dT [21] and RC-3 by maximizing the product jDS M j DT below the DSM(T) curve (referred to as the

Figure 1. Experimental (red dots) and calculated (violet line) XRD patterns using the Rietveld method for (a) as-quenched and (b) annealed MnCoGe alloy ribbons. Vertical lines indicate the positions of the Bragg reections for the hexagonal and orthorhombic phases. Insets: typical microstructure observed at the free ribbon surface. (c) M(T) and dM/dT vs. T curves (inset) at 5 mT for aq (open squares) and annealed (full circles) MnCoGe ribbons. The horizontal arrows indicate the heating/cooling regime. (For interpretation of the references to color in this gure legend, the reader is referred to the web version of this article.)

Wood and Potter method) [22,23]. In the case of RC-1 and RC-2, Thot and Tcold are the temperatures that dene the temperature interval of the full width at half maximum of the DSM(T) curve (i.e. dTFWHM = Thot Tcold). Figure 1(a and b) shows the room-temperature XRD patterns obtained for the as-quenched (aq) and annealed samples, respectively. Both patterns were rened using the FullProf analytical package based on the Rietveld method [24], with good reliability factors from the renements (aq sample: RB = 9.3%, Rf = 9.3% and v2 = 2.2; annealed sample: RB = 3.6%, Rf = 3.3%, and v2 = 2.0). As-quenched ribbons crystallize as a single-phase hexagonal NiIn2-type structure with lattice parameters and c = 5.313(1) A , which roughly agree a = 4.083(1) A with those reported for bulk alloys [3]. The homogeneous distribution of chemical elements and the singlephase character of the ribbons were also conrmed by SEM examinations in the backscattered electron emission mode (i.e. no minor or secondary phases were detected). Numerous EDS analyses performed on both cross-section and ribbon surfaces for dierent ribbon akes conrmed that the average chemical composition of the samples is close to the nominal one (i.e. 1:1:1) within experimental error ($0.1% wt.). The XRD pattern corresponding to the annealed sample (Fig. 1b) reveals the formation of an orthorhombic TiNiSi-type structure as the major phase (98% wt.), with lattice , parameters a = 5.958(2) A b = 3.822(1) A and (in agreement with Refs. [3,4]). A residc = 7.059(2) A ual amount of the hexagonal phase ($2% wt.; ; c = 5.344(1) A ) is also present in the a = 4.060(1) A sample.

nchez-Valde s et al. / Scripta Materialia 69 (2013) 211214 C. F. Sa

213

Figure 2. M(loH) Isothermal magnetization curves for (a) aq and (b) annealed MnCoGe ribbons together with the corresponding Arrott plots (c and d), respectively.

The typical microstructures of aq and annealed samples are shown in the inset of Figure 1(a and b), respectively. The aq ribbons are fully crystalline, indicating that the alloy exhibits fast nucleation and growth kinetics. In both samples, polyhedral micronic grains with an average grain size of %5 lm are observed. Due to the low annealing temperature needed to form the orthorhombic phase, the microstructure does not show any substantial change. Both samples were found to be quite fragile, with numerous intergranular cracks (that are more clearly observed in the annealed ribbons). The low-eld M(T) curves measured for the hexagonal, and orthorhombic phases, together with the respective dM/dT vs. T curves (inset), are shown in Figure 1(c). The TC values inferred from the minima in the dM/dT(T) curves, of 273 K (hexagonal) and 355 K (orthorhombic), are in good agreement with previously reported data for the bulk MnCoGe compound [1,2,14]. The small knee at around 275 K in the M(T) curve (indicated in the gure by a vertical arrow) is attributed to an impurity from the residual hexagonal phase detected by XRD. Moreover, no noticeable thermal hysteresis is observed between the heating and cooling pathways of the curve (62 K). Figure 2(a and b) shows the M(loH) curves and Figure 2(c and d) the resultant Arrott plots, respectively, for aq and annealed ribbons. The Arrott plots were used to check the nature of the FM to PM transition of both samples. The Arrott plots for the hexagonal phase exhibit positive slopes across the whole temperature range, with changes in curvature around TC (from negative to positive), thus conrming the second-order character of the transition. Those of the annealed ribbons show a slightly dierent behaviour (Figure 2(d)): between 355 and 380 K the Arrott plots display a smooth inection, thus suggesting that in the 1:1:1 phase the coupling between structural changes around TC that results from the lattice distortion of the orthorhombic phase and the magnetic structure is weak. A very dierent situation is found in Mn- or Co-decient MnCoGe alloys, in which

Figure 3. (a) DSM(T) curves at loDHmax = 2 and 5 T for the hexagonal (open and full squares) and orthorhombic (open and full circles) variants in MnCoGe alloy ribbons. Inset: DS peak as a function of M (loH)2/3. (b) Field dependence of the refrigerant capacity RC-2 for the hexagonal and orthorhombic MnCoGe phase. Inset: eld dependence of the temperatures Thot and Tcold that dene the FWHM of the DSM(T) curve. (c) M(loH) measured in increasing and decreasing magnetic elds for annealed MnCoGe ribbons in the temperature interval close to the magnetic phase transition of the MnCoGe orthorhombic phase.

strong magneto-elastic coupling leads to a sharp fall in the magnetization at TC, giving rise to a giant MCE [6,13]. Figure 3(a) shows the DSM(T) curves at 2 and 5 T, 2/3 curves (inset). At along with the jDS peak M j vs. (loH) 5 T, the aq sample shows a moderate absolute peak value of the magnetic entropy change of 2.8 J kg1 K1, along with a working temperature span dTFMHW of 85 K. The left inset shows that jDS peak M j depends linearly on (loH)2/3, as expected for materials with second-order FM transitions [20,25]. At 5 T (2 T), the annealed sam1 K1 and a ple shows a jDS peak M j of 4.0 (2.0) J kg dTFMHW value of 68 K (50 K). In agreement with the 2/3 , Arrott plots, jDS peak M j is nearly proportional to (loH) which, again, is a consequence of the second-order-like nature of the magnetic transition [20,25]. Also, the set of eld-up and eld-down magnetization isotherms around TC measured up to loHmax = 3 T shown in Figure 3(c) exhibit fully reversible behaviour. Figure 3(b) compares the eld dependence of both the refrigerant capacity RC-2 and the characteristic temperatures, Thot and Tcold, that dene the full width at half maximum of the DSM(T) curve for both phases. The increase in RC for the orthorhombic phase is mainly due to the higher entropy change since both compounds have similar values of dTFWHM. Moreover, the RC-1 value of the samples produced (99 and 281 J kg1 for a eld change of 2 and 5 T, respectively) may be similar to the one deduced from the DSM(T) curve for chemically modied MnCoGe alloys with a giant MCE [6,8,9,13,1520]. For all of them, the DSM(T) is quite sharp and narrow, leading to dTFWHM values of typically 57 K, which limits the practical use of the material as a magnetic refrigerant. An outline of the

214 DS peak M ,

nchez-Valde s et al. / Scripta Materialia 69 (2013) 211214 C. F. Sa

Table 1. Tcold, Thot, dTFWHM, dTRC-3 and refrigerant capacity values RC-1, RC-2, and RC-3 for eld change values of loDHmax = 2 T and 5 T. Material As-quenched loDHmax (T) 2T

1 K1) jDS peak M j (Jkg Tcold (K) Thot (K) dTFWHM (K) RC-1 RC-2 RC-3 Tcold (K)* Tcold(K)* dTRC-3 (K) *

Annealed loDHmax (T) 2T 2.0 322 373 50 99 76 50 318 374 56 5T 4.0 317 385 68 281 218 143 305 391 86

5T 2.8 225 310 85 238 176 135 180 326 146

1.5 241 295 54 79 60 49 179 311 132

Associated with RC-3.

MC properties at 2 and 5 T for the samples is given in Table 1 (i.e. the absolute value of DS peak M , RC-1, RC-2 and RC-3 and the related temperature parameters are listed). In summary, the hexagonal and orthorhombic variants of the stoichiometric MnCoGe compound were produced in rapidly solidied polycrystalline alloy ribbons and their MC properties studied. The use of the melt-spinning technique allows a signicant reduction in the annealing time (at 923 K) to produce the orthorhombic phase compared to the time required for bulk alloys; this represents an important advantage regarding the synthesis of these materials that exhibit giant MCE near room temperature for appropriate chemical compositions. Both the hexagonal and orthorhombic structures of the 1:1:1 alloy exhibit a reversible MC eect around their respective second-order FM transition (i.e. at 273 and 355 K, respectively). In agreement, moderate peak values of the magnetic entropy change were measured. The estimated refrigerant capacity (RC1 = 238 and 281 J kg1 for the hexagonal and orthorhombic variants, respectively, for a magnetic eld change of 5 T) is near that of modied MnCoGe giant MCE alloys, owing to the larger dTFWHM values and negligible magnetic hysteresis of MnCoGe ribbons. The authors acknowledge the support from CONACYT, Mexico (project No. 156932) LINAN (IPICyT) and Spanish CICyT (projects number MAT2011-27573-C04-02 and 03). The technical support received from M.Sc. G.J. Labrada-Delgado, B.A. Riveguez (IIM-UNAM, ra-Escoto and A.G. Lara-Rodr Mexico DF) is recognized. C.F.S.V. thanks Spanish CSIC for the PhD Grant received (JAEPRE-08-00508).

[1] O. Beckman, L. Lundgren, in: K.H.J. Buschow (Ed.), Handbook of Magnetic Materials, New York, Elsevier, 1991, vol. 6, (Chapter 3).

[2] S. Kaprzyk, S. Niziol, J. Magn. Magn. Mater. 87 (1990) 267. _ ela, A. Szytula, D. Fruchart, [3] S. Niziol, A. Bombik, W. Baz J. Magn. Magn. Mater. 27 (1982) 281. [4] V. Johnson, Inorg. Chem. 14 (1975) 1117. [5] S. Niziol, A. Weselucha, W. Bazela, A. Szytula, Solid State Commun. 39 (1981) 1081. [6] Y.K. Fang, C.C. Yeh, C.W. Chang, W.C. Chang, M.G. Zhu, W. Li, Scripta Mater. 57 (2007) 453. [7] Weiguang Zhang, O. Tegus, Yongli Wu, Yirgeltu, Huanying Yan, Song Lin, J. Mater. Sci. Technol. 25 (2009) 781. [8] S. Lin, O. Tegus, E. Bruck, W. Dagula, T.J. Gortenmulder, K.H.J. Buschow, IEEE Trans. Magn. 42 (2006) 3776. [9] Tapas Samanta, Igor Dubenko, Abdiel Quetz, Shane Stadler, Naushad Ali, Appl. Phys. Lett. 101 (2012) 242405. [10] T. Kanomata, H. Ishigaki, T. Suzuki, H. Yoshida, S. Abe, T. Kaneko, J. Magn. Magn. Mater. 140144 (1995) 131. [11] S. Niziol, A. Zieba, R. Zach, M. Baj, L. Dmowski, J. Magn. Magn. Mater. 38 (1983) 205. [12] J.T. Wang, D.S. Wang, C. Chen, O. Nashima, T. Kanomata, H. Mizuseki, Y. Kawazoe, Appl. Phys. Lett. 89 (2006) 262504. [13] Yi-Kun Fang, Jia-Chun Yeh, Wen-Cheng Chang, XiuMei Li, Wei Li, J. Magn. Magn. Mater. 321 (2009) 3053. [14] E.K. Liu, W. Zhu, L. Feng, J.L. Chen, W.H. Wang, G.H. Wu, H.Y. Liu, F.B. Meng, H.Z. Luo, Y.X. Li, Eur. Phys. Lett. 91 (2010) 17003. [15] L. Caron, N.T. Trung, E. Bru ck, Phys. Rev. B 84 (2011) 020414. [16] N.T. Trung, V. Biharie, L. Zhang, L. Caron, K.H.J. Buschow, E. Bru ck, Appl. Phys. Lett. 96 (2010) 162507. [17] S.C. Ma, Y.X. Zheng, H.C. Xuan, L.J. Shen, Q.Q. Cao, D.H. Wang, Z.C. Zhong, Y.W. Du, J. Magn. Magn. Mater. 324 (2012) 135. [18] N.T. Trung, L. Zhang, L. Caron, K.H.J. Buschow, E. Bru ck, Appl. Phys. Lett. 96 (2010) 172504. [19] N.T. Trung, Ph.D. thesis, Technische Universiteit Delft, http://dx.doi.org/10.1063/1.3399773. [20] A.M. Tishin, Y.I. Spichkin, The Magnetocaloric Eect and its Applications, IOP, Bristol, 2003. [21] K.A. Gschneidner Jr, V.K. Pecharsky, A.O. Pecharsky, C.B. Zimm, Mater. Sci. Forum 315317 (1999) 69. [22] M.E. Wood, W.H. Potter, Cryogenics 25 (1985) 667. [23] P. Gorria, J.L. Sanchez Llamazares, P. Alvarez, M.J. Perez, J. Sanchez Marcos, J.A. Blanco, J. Phys. D Appl. Phys. 41 (2008) 192003. guez-Carvajal, Phys. B 192 (1992) 55. [24] J. Rodr [25] Julia Lyubina, Michael D. Kuzmin, Konstantin Nenkov, Oliver Guteisch, Manuel Richter, Devo L. Schlagel, Thomas A. Lograsso, Karl A. Gschneidner Jr, Phys. Rev. B 83 (2011) 012403.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Koel Colours FINALДокумент20 страницKoel Colours FINALShruti Lovekar100% (1)

- Sodium Hexameta Phosphate e CHB 038Документ1 страницаSodium Hexameta Phosphate e CHB 038Wasif KarimОценок пока нет

- Responsible Conduct of ResearchДокумент1 страницаResponsible Conduct of ResearchSumith SaleheenОценок пока нет

- ECM 21 Workshop PDFДокумент62 страницыECM 21 Workshop PDFSumith SaleheenОценок пока нет

- XRD Overview Theory and PractiseДокумент48 страницXRD Overview Theory and PractiseSumith SaleheenОценок пока нет

- Pulsed NMR Grad LabДокумент3 страницыPulsed NMR Grad LabSumith SaleheenОценок пока нет

- AUtomotive Heat ExchangerДокумент28 страницAUtomotive Heat ExchangersantoshkumarvenuОценок пока нет

- CHEM 221/PHY 335 - Molecular Symmetry IДокумент34 страницыCHEM 221/PHY 335 - Molecular Symmetry Ipaul javed0% (1)

- Acumer4300technotes PDFДокумент4 страницыAcumer4300technotes PDFdalton2003Оценок пока нет

- Chemistry Sba LabДокумент5 страницChemistry Sba LabTawayna HemmingsОценок пока нет

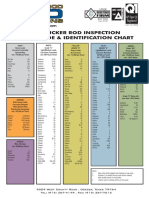

- Permian Rod Operations - Sucker Rod Identification Chart PDFДокумент1 страницаPermian Rod Operations - Sucker Rod Identification Chart PDFMinimaxou78Оценок пока нет

- Sheet Metal Worker Level 2: Rev. September 2009Документ16 страницSheet Metal Worker Level 2: Rev. September 2009Brennen WilsonОценок пока нет

- STAT152 Test Prep 1Документ6 страницSTAT152 Test Prep 1Hilmi HusinОценок пока нет

- ASTM A385-Providing High-Quality Zinc Coatings (Hot-Dip)Документ8 страницASTM A385-Providing High-Quality Zinc Coatings (Hot-Dip)trjithinraj100% (2)

- ME Vol 2 FMДокумент364 страницыME Vol 2 FMDeepak Gupta100% (4)

- HeatДокумент75 страницHeatVanessaYanjanHarryОценок пока нет

- Data Sheet Acss TW Dove (Ma3)Документ1 страницаData Sheet Acss TW Dove (Ma3)kjkljkljlkjljlkОценок пока нет

- Supernova Simulation LabДокумент3 страницыSupernova Simulation LabAlli AОценок пока нет

- Valve de FlujoДокумент22 страницыValve de FlujoimpwrcОценок пока нет

- Dawlance Report1Документ17 страницDawlance Report1engr_dkОценок пока нет

- Hempel Protective Infrastructure Corrosion Protection For Cargo Handling Equipment Low ResДокумент12 страницHempel Protective Infrastructure Corrosion Protection For Cargo Handling Equipment Low Reskamardheen majithОценок пока нет

- Wiper Seal Data Sheet A02 B 11782 1 enДокумент2 страницыWiper Seal Data Sheet A02 B 11782 1 enghanОценок пока нет

- HIRAYAMA, HIRAYAMA AUTOCLAVE HVE-50, 50L HICLAVE WITH 3PCS SS WIRE BASKETS - Alat Lab, Water Analysis, Microbiology - PT. Sumber Aneka Karya Abadi PDFДокумент2 страницыHIRAYAMA, HIRAYAMA AUTOCLAVE HVE-50, 50L HICLAVE WITH 3PCS SS WIRE BASKETS - Alat Lab, Water Analysis, Microbiology - PT. Sumber Aneka Karya Abadi PDFuptdlabОценок пока нет

- Uni of Frankfurt - Thermodynamic PotentialsДокумент15 страницUni of Frankfurt - Thermodynamic PotentialstaboogaОценок пока нет

- Steel Pipes and Tubes For Pressure Purposes: Carbon and Carbon Manganese Steel With Specified Elevated Temperature PropertiesДокумент24 страницыSteel Pipes and Tubes For Pressure Purposes: Carbon and Carbon Manganese Steel With Specified Elevated Temperature PropertiessyakirohОценок пока нет

- 76 202Документ8 страниц76 202wawanОценок пока нет

- Microwave Level SwitchДокумент3 страницыMicrowave Level SwitchDidinAndresIIОценок пока нет

- AD-761 644 Structural and Force Diagrams of The Landing Gear V. L. Belskii, Et AlДокумент42 страницыAD-761 644 Structural and Force Diagrams of The Landing Gear V. L. Belskii, Et Alebooks list1Оценок пока нет

- Shear Strengthening of RC Beams With NSM FRP Strips Concept and Behaviour of Novel FRP AnchorsДокумент7 страницShear Strengthening of RC Beams With NSM FRP Strips Concept and Behaviour of Novel FRP AnchorsEngr. RaihanОценок пока нет

- Lysol Brand III Disinfectant All Purpose Cleaner 4 in 1 US EnglishДокумент7 страницLysol Brand III Disinfectant All Purpose Cleaner 4 in 1 US EnglishpatelpiyushbОценок пока нет

- Environment VocabularyДокумент5 страницEnvironment VocabularyJ Adrian HidrovoОценок пока нет

- Alpha s708 - TdsДокумент2 страницыAlpha s708 - TdsMahmoud Moustafa ElnegihiОценок пока нет

- Concrete TestingДокумент32 страницыConcrete TestingAveesh singh100% (1)

- Chem Record AnalysisДокумент7 страницChem Record AnalysisKasi Bala Guru VОценок пока нет