Академический Документы

Профессиональный Документы

Культура Документы

Tolerance Stack Up

Загружено:

avisid9150Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tolerance Stack Up

Загружено:

avisid9150Авторское право:

Доступные форматы

Center for Continuing Engineering Education

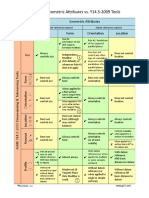

Tolerance Stack-up Analysis

About This Course

Through This Course, Participants Will Be Able To:

o Calculate minimum and maximum wall thicknesses, air spaces and

interferences for assemblies.

o Create loop analysis/circuit diagrams for tolerance stack-up analysis for

both plus and minus toleranced dimensions and geometric tolerances.

o Create both simple and complex number charts for stack-up analysis using

a variety of geometric tolerances, basic dimensions, resultant conditions,

virtual conditions and plus and minus toleranced dimensions.

o Do tolerance stack-up analysis for floating fastener situations for clearance

holes, screws and shafts.

o Do tolerance stack-up analysis for fixed fastener situations using, screws,

clearance holes, slots, tabs, overall dimensions and projected tolerance

zones for threaded holes.

o Calculate minimum and maximum gaps for assemblies that use a variety

of datum structures.

o Learn a system of logic and mathematics to analyze tolerances.

Topics

Course participants will be trained to apply tolerance stack-up analysis techniques

to a wide variety of assemblies, from the very simple to the more complex

situations commonly faced in industry today. Both plus and minus and

geometrically toleranced assemblies will be examined and stack-up analysis

taught and practiced on each. Many different datum structures will be discussed

and analyzed. The concepts taught in this course are: loop analysis (also known as

circuit diagrams), number charting, virtual condition, resultant condition, inner

and outer boundaries, minimum airspace, maximum wall thickness, maximum

interference, minimum and maximum overall dimensions, fixed and floating

fastener assembly conditions, projected tolerance zones, the logic of stackup

analysis, and much more.

Who Should Attend

This course is directed to anyone with the professional responsibility of analyzing

or applying tolerances to assemblies, or anyone seeking a more thorough

understanding of tolerance analysis. Attendees should have a basic working

knowledge of ASME Y 14.5M1994 (the current American standard on

dimensioning and tolerancing). However, the basics of all principles used in this

course are either thoroughly covered or (in the case of the refresher section)

explained to a level that will allow all participants to be successful in learning the

techniques of tolerance stack-up analysis.

Course Instructor

James D. Meadows is president of James D. Meadows and Associates, Inc., a

seminar and consulting corporation specializing in geometric dimensioning and

tolerancing (GD&T). He has been a full time consultant, lecturer and author of the

application, usage and measurement of GD&T since 1983. Mr. Meadows is a

member of eight American National Standards Institute (ANSI) and International

Organization for Standardization (ISO) committees. He serves as chairman for

ASME Y14.43, the committee on Dimensioning and Tolerancing of Functional

Gages. He is the author of four books currently available on Geometric

Dimensioning and Tolerancing, Measurement of Geometric Tolerances in

Manufacturing, and Tolerance Stack-Up Analysis.

Program Schedule

Day 1

7:30 am Registration/Cheek-In

See facility lobby

8:00 am Lecture/Discussion

4:30 pm Adjourn

Day 2

8:00 am Lecture/Discussion

4:30 pm Adjourn

Day 3

8:00 am Lecture/Discussion

1:00 pm Adjourn (without lunch)

Frequent breaks with coffee and soft drinks are planned.

Group luncheons are included except for Day 3

Note adjournment at 1:00 pm on Day 3.

Course Outline

Class exercises with answers follow each section to augment and illustrate the

key concepts of each section.

1.The Basics of Tolerance Stack Up Analysis

Where to begin a stack

Designating positive and negative routes

What are you calculating, what dimensions are factors

How to push the parts to create the worst case

Which geometric tolerances are factors?

Finding the mean

Calculating boundaries for GD&T, MMC, LMC and RFS material

condition modifiers

Mean boundaries with equal bilateral tolerances

2.Analysis of an eleven part assembly using plus and minus tolerancing

The calculations

The loop analysis chart

The numbers analysis chart

Finding MIN and MAX gaps

3.Vertical vs. horizontal analyses for features of size

Where to start and end

Graphing the loop

Minimum and maximum gap analysis

4.Assemblies with plus and minus tolerances

Multiple dimension loops

Positive and negative values

Airspace vs. interferences

5.Floating fastener five part assembly analysis

Resultant and virtual conditions

Inner, outer, and mean boundaries

Converting to radii

Mixing widths and diameters

Complex loop analyses with geometric dimensioning and

tolerancing

6.Fixed fastener assemblies

Calculating overall minimum and maximum assembly dimensions

Mixing holes, slots, tabs and shafts

Calculating minimum and maximum gaps within the assembly

Projected tolerance zones for total runout as a factor

Determining if geometric tolerances are a factor

Ruling out features and patterns as factors

7.A rail assembly

Threaded features

Multiple geometric controls

Projected tolerance zones

Gaps with and without perpendicularity as a factor

Calculating interference

Theoretically vs. physically worst case possibilities

When logic becomes an integral step

Factoring in assembly conditions

Maximum wall thickness vs. minimum airspace for assemblies

8.Single part analysis

Two-single segment positional controls

Switching datum reference frames and accumulating geometric

tolerances

Datum features a MMC (pattern shift)

Profile tolerances, flatness

Envelopes of perfect form at MMC

Creating envelopes of perfect orientation at MMC

MIN and MAX axial separation

Datum planes vs. datum features

Separate requirements and accumulating tolerance

Tolerances in degrees; trig functions introduction

Composite positional tolerancing

9.Five part rotating assembly analysis

Position, perpendicularity, parallelism, profile, flatness

Threaded holes with projected tolerance zones

Mounted screws

Part to part analysis (from two parts to an infinite number)

Runout, total runout, concentricity, positional coaxiality

Simplifying a complex assembly

Determining assembly housing requirements

Radial clearance MIN and MAX calculations

Interference calculations

10.Trigonometry and Proportions in Tolerance Stack-Up Analysis

Rocking datum features

Constructing a valid datum

Consideration of differing orientations from measurement to

assembly

An in-depth assembly analysis using trigonometric functions

Computer programs versus personal analysis

Vertical stacking as it effects horizontal housing requirements

When stacked parts are not flat or parallel

Formulae to calculate worst case fit conditions when trig is a factor

Using proportions and trigonometry to calculate fit conditions

beyond the GD&T formulae

11.The Theory of Statistical Probability

Review of statistical concepts

Gaussian frequency curve, standard deviations, plus or

minus 3 sigma, root sum square formula

Steps to calculate and apply statistical tolerances

Statistical tolerancing applied

to plus and minus toleranced assemblies

to geometric toleranced assemblies

When best to allow statistical tolerances and when it should not be

The logic of statistical tolerancing

Modifying the root sum square formula with a safety/correction

factor

Reintegrating the statistical tolerance into the assembly

Bookmark This Page

Email This Page

Format for Printing

Attach Document

Tolerance Stack-Up Analysis Show Entire ThreadBeta

Posted by: Gabriel Search The Forum

Posted on: Monday, 9th December 2002, 11:41 AM. By Individual Post

By Thread

Past 1 Day of Posts

Assumptions: Both components have the same symetrical Past 2 Days of Posts

tolerance arround their nominal value, and both nominal values Past Week of Posts

sum 40. The manufacturing process of both components have the By Keyword or

Phrase

same variation and meet the capability requirement of Cpk not

lower than 1.33. The assembly process adds no extra variation on

the toal length (i.e L=L1+L2)

Because Cp=2 and tolerance range=2mm, then S=1/6mm for the assembly. Also, because

Cpk>1.5 the average must be at least 4.5 S = 0.75mm away from the closest limit, so the

maximum shif of the average from the target value (40) is 0.25mm.

To assure that the assembly average will not be more than 0.25mm away from the target, the

average of the components must not be more than 0.125mm away from the target.

S^2 = S1^2 + S2^2= 2 x S1^2 ==> S1 = S/sqrt(2) = 0.11785mm (this is the standard deviation of

the manufacturing process of the components). The average of the manufacturing process of the

components shall be at least 4 x S1 = 0.47140mm away from the specification limit to assure a

Cpk>1.33.

If we take "Distance form the specification limit to the average" = 0.47140mm and "Distance form

the average to the target" = 0.125mm; then "Distance from the specification limit to the target" =

0.125mm + 0.47140mm = 0.59640mm (let's say 0.6mm?)

So a tolerance of +/-0.6 for the components will assure a Cp=2 and Cpk>1.5 for the assembly, if

the components are manufctured with a Cpk>1.33.

Note however that you said Cp=2, and not Cp>2, that means that S1=0.11785mm and not

smaller. If S1 was improved (reduced), you could offset more and more the average of the

components mantaining a Cpk>1.33, In the limit, with a very low variation in the components (S1)

you could keep a Cpk>1.33 withh all the distribution very close to the specification limit (let's say

+0.6mm) and the sum of components will be arround 40 +1.2mm (i.e. out of tolerance)

Вам также может понравиться

- GDTДокумент38 страницGDTAntonio CervantesОценок пока нет

- Agi Zeiss Day 2016 Gdandt Presentation HandoutsДокумент20 страницAgi Zeiss Day 2016 Gdandt Presentation HandoutsJuan Posada G100% (1)

- Composite Positional TolerancingДокумент5 страницComposite Positional TolerancingCarlos García Hernández100% (1)

- Guide to Load Analysis for Durability in Vehicle EngineeringОт EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonРейтинг: 4 из 5 звезд4/5 (1)

- GD&T CylindricityДокумент15 страницGD&T CylindricityjaithilagarajОценок пока нет

- Geometric Dimensioning And Tolerancing A Complete Guide - 2020 EditionОт EverandGeometric Dimensioning And Tolerancing A Complete Guide - 2020 EditionОценок пока нет

- GD&T Form MeasurementДокумент19 страницGD&T Form MeasurementBobby McfaddenОценок пока нет

- (A) "Basics of GD&T + Advanced GD&T" SyllabusДокумент4 страницы(A) "Basics of GD&T + Advanced GD&T" SyllabusSwapnil GujarathiОценок пока нет

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainОт EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainОценок пока нет

- Geometric Dimensioning & Tolerancing (GD&T)Документ43 страницыGeometric Dimensioning & Tolerancing (GD&T)Victor Manuel Estrada0% (1)

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysОт EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysРейтинг: 1 из 5 звезд1/5 (1)

- GD&TДокумент6 страницGD&TRavindra ErabattiОценок пока нет

- GD T Q BankДокумент9 страницGD T Q Banknewchap chapОценок пока нет

- 05 - True Position TheoryДокумент36 страниц05 - True Position TheoryPeelamedu Shiyam100% (6)

- GD&T QuestionsДокумент12 страницGD&T Questionsநளின் கான்100% (1)

- Mu Ltiview and Sectional: DrawingsДокумент54 страницыMu Ltiview and Sectional: Drawingschaitanya kulkarniОценок пока нет

- Geometric Dimensioning & TolerancingДокумент47 страницGeometric Dimensioning & TolerancingVinoth BalasubramaniyanОценок пока нет

- Introduction To Geometric Dimensioning and TolerancingДокумент3 страницыIntroduction To Geometric Dimensioning and TolerancinganandparasuОценок пока нет

- Functional Gage Design PDFДокумент32 страницыFunctional Gage Design PDFmartinОценок пока нет

- GD&T PDFДокумент49 страницGD&T PDFnupurvinodОценок пока нет

- The New Y14.5: We've Improved The Gold StandardДокумент9 страницThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamОценок пока нет

- Tolerance Analysis ManualДокумент262 страницыTolerance Analysis ManualelfrascosОценок пока нет

- F 5 Geo TolerancesДокумент23 страницыF 5 Geo TolerancesRodrigo RomeroОценок пока нет

- Tolerance Stack Up StatisticsДокумент92 страницыTolerance Stack Up StatisticsAmolPagdal100% (5)

- ASME Y1441powerpointДокумент45 страницASME Y1441powerpointAgus GerezОценок пока нет

- GD&T Training BrochureДокумент5 страницGD&T Training BrochurePritam PolekarОценок пока нет

- Relationships Between Material Modifiers and FitsДокумент3 страницыRelationships Between Material Modifiers and FitsDo The CuongОценок пока нет

- Approximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingДокумент11 страницApproximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingCan CemreОценок пока нет

- (BS EN ISO 17450-3) - Geometrical Product Specifications (GPS) - General Concepts. Part 3. Toleranced FeaturesДокумент28 страниц(BS EN ISO 17450-3) - Geometrical Product Specifications (GPS) - General Concepts. Part 3. Toleranced Featuresaditya sasmalОценок пока нет

- 2limits Fits WebinarДокумент122 страницы2limits Fits WebinarPbОценок пока нет

- Maximum Material Condition (GD&T)Документ15 страницMaximum Material Condition (GD&T)Kishor kumar Bhatia67% (3)

- DimXpert and TolAnalyst Made Easy-021808Документ105 страницDimXpert and TolAnalyst Made Easy-021808Gurpreet Singh100% (2)

- GDT TutorialДокумент76 страницGDT TutorialSivananthaa MurtheeОценок пока нет

- Finite Element Analysis of Spur Gear Set PDFДокумент85 страницFinite Element Analysis of Spur Gear Set PDFCan CemreОценок пока нет

- Advanced Concepts of GD&T PDFДокумент1 страницаAdvanced Concepts of GD&T PDFPritam PolekarОценок пока нет

- Comparison Between GD&T and Coordinate TolerancingДокумент5 страницComparison Between GD&T and Coordinate TolerancingHarish Neware50% (2)

- GD and T Basic Level March 2014Документ206 страницGD and T Basic Level March 2014jealousyОценок пока нет

- (Gene Cogorno) Geometric Dimensioning and Toleranc (B-Ok - Xyz) PDFДокумент105 страниц(Gene Cogorno) Geometric Dimensioning and Toleranc (B-Ok - Xyz) PDFamasiddayОценок пока нет

- GD&T TutorialДокумент76 страницGD&T TutorialAnish PaiОценок пока нет

- Tolerance Analysis of 2-D and 3-D AssembliesДокумент30 страницTolerance Analysis of 2-D and 3-D AssembliesKvs PhaniОценок пока нет

- Calculating Bonus TollДокумент4 страницыCalculating Bonus TollkarthiblackОценок пока нет

- SFOL Matrix GD&TДокумент1 страницаSFOL Matrix GD&TJesus GallardoОценок пока нет

- Mechanical Tolerance Stackup and Analysis - MuyaДокумент230 страницMechanical Tolerance Stackup and Analysis - MuyaME195850% (2)

- Y14 43Документ1 страницаY14 43Adrian JoelОценок пока нет

- Gear ShavingДокумент6 страницGear ShavingRuchira Chanda InduОценок пока нет

- Radial Stackups - Concentric Components ExampleДокумент5 страницRadial Stackups - Concentric Components ExampleGeorge HerreraОценок пока нет

- GD&T Advanced Manual - 3 DayДокумент74 страницыGD&T Advanced Manual - 3 Dayimtiyaz100% (2)

- Geometric Dimension and Tolerancing For Body in White Sheet MetalДокумент115 страницGeometric Dimension and Tolerancing For Body in White Sheet Metaltoyota952100% (1)

- GD&TДокумент70 страницGD&TKarthi KeyanОценок пока нет

- Latest Report 2Документ13 страницLatest Report 2Piyush BariОценок пока нет

- Distribucion Log NormalДокумент52 страницыDistribucion Log NormalmtorrejonОценок пока нет

- 14-2 Effects of Electron-Electron Repulsion: 14-3 Exclusion Principle and Exchange InteractionДокумент4 страницы14-2 Effects of Electron-Electron Repulsion: 14-3 Exclusion Principle and Exchange InteractionFina Aulia RitongaОценок пока нет

- Bourbaki - Lie Groups and Lie Algebras (Chapters 4-6)Документ314 страницBourbaki - Lie Groups and Lie Algebras (Chapters 4-6)Zoe RossiОценок пока нет

- Lesson Plan MathДокумент7 страницLesson Plan MathSERAD, WILMA LOUISEОценок пока нет

- Exercise For StatisticДокумент2 страницыExercise For StatisticCarinaOngОценок пока нет

- Leibniz and Clarck CorrespondenceДокумент29 страницLeibniz and Clarck CorrespondenceFrank CamposОценок пока нет

- Istat10w - ch04 Edited Ver 2Документ107 страницIstat10w - ch04 Edited Ver 2Zaisy RayyanОценок пока нет

- Multi Step Questions - PowerPointДокумент9 страницMulti Step Questions - PowerPointbrhОценок пока нет

- Quantitative - Methods Course TextДокумент608 страницQuantitative - Methods Course TextJermaine RОценок пока нет

- 1974 Fast Convolution Using Fermat Number Transforms With Applications To Digital FilteringДокумент11 страниц1974 Fast Convolution Using Fermat Number Transforms With Applications To Digital FilteringRajesh BathijaОценок пока нет

- Bhakta Kavi Narsinh Mehta University JunagadhДокумент16 страницBhakta Kavi Narsinh Mehta University JunagadhacmvdrteachingОценок пока нет

- Domino Effect AnalysisДокумент16 страницDomino Effect Analysisapi-270822363Оценок пока нет

- 4pm1 02r Que 20230121Документ36 страниц4pm1 02r Que 20230121M.A. HassanОценок пока нет

- Problem 5-3 Red Reservoir Material BalanceДокумент2 страницыProblem 5-3 Red Reservoir Material BalanceCharles PabaneОценок пока нет

- NormalizationДокумент45 страницNormalizationWasim Hyder ChitraliОценок пока нет

- Extended State Observer For Nonlinear Systems With UncertaintyДокумент6 страницExtended State Observer For Nonlinear Systems With UncertaintysheelakhanОценок пока нет

- Analysis Methods ReflectometryДокумент8 страницAnalysis Methods ReflectometrymilitiamonОценок пока нет

- Interaction of Local, Distortional, and Global Buckling - Anil Kumar, Kalyanaraman 2018Документ9 страницInteraction of Local, Distortional, and Global Buckling - Anil Kumar, Kalyanaraman 2018amokeОценок пока нет

- Instruction Set 1 Rev.Документ54 страницыInstruction Set 1 Rev.msantoshkkdОценок пока нет

- Conic SectionsДокумент10 страницConic Sectionsmatyie77Оценок пока нет

- Design of Experiments: Lecture 1: Introduction (CH 1 DAE) Nitin Padhiyar IIT - GandhinagarДокумент9 страницDesign of Experiments: Lecture 1: Introduction (CH 1 DAE) Nitin Padhiyar IIT - GandhinagarShouharda GhoshОценок пока нет

- Motion 1 TheoryДокумент13 страницMotion 1 TheoryAyaan KachwalaОценок пока нет

- Semantic Data ControlДокумент12 страницSemantic Data Controlfatima_akramОценок пока нет

- 0607 - 63 Cambridge International Mathematics Paper 6 Investigation and Modelling (Extended) IGCSEДокумент5 страниц0607 - 63 Cambridge International Mathematics Paper 6 Investigation and Modelling (Extended) IGCSEHitha ReddyОценок пока нет

- Class-8 Mathematics (Annual Exam) 2021-22 SET-AДокумент2 страницыClass-8 Mathematics (Annual Exam) 2021-22 SET-AAnjali SharmaОценок пока нет

- Stuff You MUST KNOW COLDДокумент2 страницыStuff You MUST KNOW COLDNikki Nguyen NguyenОценок пока нет

- 1st Quarter Exam 2022Документ4 страницы1st Quarter Exam 2022Angela RuleteОценок пока нет

- PLC GuideДокумент59 страницPLC Guidev2304451Оценок пока нет

- Noise Attenuation TechniquesДокумент2 страницыNoise Attenuation TechniquesadobiОценок пока нет

- BJT and JFET Frequency ResponseДокумент16 страницBJT and JFET Frequency ResponseVert WheelerОценок пока нет

- Secrets of the Millionaire Mind: Mastering the Inner Game of WealthОт EverandSecrets of the Millionaire Mind: Mastering the Inner Game of WealthРейтинг: 4.5 из 5 звезд4.5/5 (197)

- Certified Solidworks Professional Advanced Weldments Exam PreparationОт EverandCertified Solidworks Professional Advanced Weldments Exam PreparationРейтинг: 5 из 5 звезд5/5 (1)

- Proof of Heaven: A Neurosurgeon's Journey into the AfterlifeОт EverandProof of Heaven: A Neurosurgeon's Journey into the AfterlifeРейтинг: 3.5 из 5 звезд3.5/5 (165)

- The Game: Penetrating the Secret Society of Pickup ArtistsОт EverandThe Game: Penetrating the Secret Society of Pickup ArtistsРейтинг: 4 из 5 звезд4/5 (131)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)