Академический Документы

Профессиональный Документы

Культура Документы

Daily Checklist For Electric Overhead Travelling Cranes

Загружено:

tatonyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Daily Checklist For Electric Overhead Travelling Cranes

Загружено:

tatonyАвторское право:

Доступные форматы

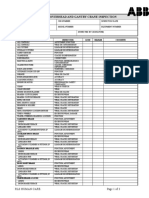

DAILY CHECKLIST FOR ELECTRIC OVERHEAD TRAVELLING CRANES

Owners Name: Location of Crane/s: Date & Time of Inspection:

Notes: Inspect all control mechanisms for proper function. At the beginning of each shift, test upper limit switch by inching into the limit under no load. Inspect all air and hydraulic systems for leaks. Visual inspection of hooks, load chains, magnet chains and slings before start or works

Types of Crane

LM No.

Brand / Model

Manufacturer Year

Crane Capacity (SWL)

Serial No./ Distinctive No.

Date Inspection by A.E | P.E

Date Inspection by Operator

S/N .

1 2 3 4 5

CRANE HOOK (or Clevis):Cracked worn or spread more than 15%Twisted more than 10.REPLACE. DO NOT WELD OR REPAIR LOAD CHAINS, MAGNET CHAINS: Excess wear, twisted, distorted or stretched links beyond manufactures recommended limits? Worn shackles, pins or end connections etc WIRE ROPE SLINGS: Broken wires, stretched, kinked or twisted? CABLE CLAMPS: Proper spacing and number of clips? Are they tight and have the U Bolts on the dead end? RUNNING ROPES: Are they reeved to manufactures recommendations or guidelines on conditions indicating rope replacement: (1) Wear of 1/3 the original diameter of outside individual wires. (b) Rope diameter reduced by stretching or loss of core support 1/64" for ropes up to 5/16" diameter, 1/32 up to 1/2" diameter , 3/64" up to 1/4" diameter, 1/16" up to 1 1/18" diameter and 3/32" up to 1 1/2 " diameter. (c) Kinking, crushing or bird caging. (d) 12 broken wires in one rope lay or 4 broken wires in one strand. Deformed, cracked or corroded structures and runway? Loose bolts or rivets? Cracked or worn sheaves and drums? Worn, cracked or distorted parts, such as pins, bearings, shafts, gears, rollers, locking and clamping devices? Excess wear on brakes systems parts, linings, pawls and ratchets? Load, wind and other indicators any significant inaccuracies? Improper power plant performances? (Genset etc) Excessive wear of chain drive sprocket and excessive chain stretch? Electric contacts, controls, limit switches-any signs of pitting or deterioration? Ladders, walkways, cab-any unsafe conditions?

Yes

No

N.A

Remarks

6 7 8 9 10 11 12 13 14 15 16

Bolted connections in particular high-tensile bolts on end carriage (high-tensile washers checked for correct fit: bevel facing bolt head/ nut)

1|3

DAILY CHECKLIST FOR ELECTRIC OVERHEAD TRAVELLING CRANES

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44

Guide roller spacing adjusted, screwed connection (torque) checked Crane, crab and runway end buffers installed and correctly positioned Crane and crab end approach dimensions checked (according to layout drawing) Gearbox checked for leaks, air vent screws fitted Chain rope reeving, rope mounting checked (rope wedge, rope clamp) Chain/ rope lightly oiled Chain/ rope and cable deflectors mounted (if part of crane equipment) Emergency and operating limit switches in operational condition Long and cross travel limit switches in operational condition Optical crane distancing adjusted (if applicable) Control pendant height and remote control strain relief (if applicable) checked Control panel symbols match actual crane travel movements Accessibility, marking and availability of "mains connection switches" and "emergency-off switches" Check protective earth conductor along entire length for correct marking and connection checked Cable entry glands in terminal boxes correctly wired Control and regulating devices (if applicable) Overload cut-off devices (load measuring devices if applicable) Check terminals for sign of cracks / burn marks Safety distances to other parts of the building and machinery are maintained Smooth running over splices in the runway and of power supply lines Brake check carried out: lifting and lowering Brake check carried out: long and cross travel Speed checks: lifting, lowering, long and cross travel Paint coat checked and touched up where required Operation of wind drift safety device (for cranes operating outdoors) tested Cable drum (for cranes with load handling attachments) checked Warning devices (if available) Valid Lifting Machine (LM) certificate Manufacturer Operating & Maintenance Manual

Inspectorate

Crane Operator Name: Lifting Supervisor Name: Rigger/Signalmen Name: Site Engineer (Sub-con) Name:

2|3

DAILY CHECKLIST FOR ELECTRIC OVERHEAD TRAVELLING CRANES

Sign: Sign: Sign: Sign:

3|3

Вам также может понравиться

- CICB Monthly Crane ChecklistДокумент3 страницыCICB Monthly Crane ChecklistMeritorious Khan100% (3)

- Mobile Crane ChecklistДокумент2 страницыMobile Crane Checklistabe_sein100% (1)

- Horizontal Life Line Inspection FormДокумент1 страницаHorizontal Life Line Inspection FormSelva GanapathiОценок пока нет

- F0556 Crane Weekly Check (Offshore)Документ2 страницыF0556 Crane Weekly Check (Offshore)Vimal Singh0% (1)

- Eot Crane ChecklistДокумент1 страницаEot Crane ChecklistMohammad Abubakar Siddiq75% (8)

- Crane Maintenance and Check PointДокумент12 страницCrane Maintenance and Check Pointspsl5100% (4)

- N405 Crane - Lift Supervisor 20141Документ9 страницN405 Crane - Lift Supervisor 20141dsn_sarmaОценок пока нет

- Mobile CraneДокумент2 страницыMobile CraneRashidi Rahman50% (2)

- Crane Hoist and Rigging SafetyДокумент36 страницCrane Hoist and Rigging SafetySalim Mohd RazОценок пока нет

- Tower Crane Inspection ChecklistДокумент4 страницыTower Crane Inspection Checklistmailme_viju100% (1)

- Lifting EquipmentsДокумент31 страницаLifting Equipmentsjrpatel18853Оценок пока нет

- Examination Procedure For Lifting Beam InspectionДокумент5 страницExamination Procedure For Lifting Beam InspectionTrust Emma50% (2)

- Rp-205 Crane Operation, Maintenance and TestingДокумент30 страницRp-205 Crane Operation, Maintenance and TestingWilman Barrera Grados100% (1)

- Multiple Crane LiftingДокумент11 страницMultiple Crane LiftingAbdul Majid ZulkarnainОценок пока нет

- LEEA-039a Accreditation Scheme Appendix 1Документ25 страницLEEA-039a Accreditation Scheme Appendix 1Deepu Ravikumar50% (2)

- Testing ProcedureДокумент6 страницTesting Procedure810806100% (1)

- Standard Tower Crane Start of Shift ChecklistДокумент1 страницаStandard Tower Crane Start of Shift ChecklistderwaishjeeОценок пока нет

- LEEA Standards 2 2Документ3 страницыLEEA Standards 2 2Steve MorrisonОценок пока нет

- Daily crane checklistДокумент3 страницыDaily crane checklistNurma Rifah100% (4)

- EotДокумент16 страницEotMayuresh GoregaonkarОценок пока нет

- Crane ChecklistДокумент3 страницыCrane ChecklistAbdul Rehman SheikhОценок пока нет

- Tower Crane ComplianceДокумент51 страницаTower Crane ComplianceAnonymous ePcnZoBE100% (1)

- Safe Operating Procedures for Overhead CranesДокумент18 страницSafe Operating Procedures for Overhead Cranesdnageshm4n244100% (1)

- No. 8 - Chain & Chain SlingsДокумент11 страницNo. 8 - Chain & Chain SlingsAhmed AtefОценок пока нет

- Lorry Loader Crane ChecklistДокумент1 страницаLorry Loader Crane ChecklistSameer ParambathОценок пока нет

- Crane InspectionДокумент1 страницаCrane InspectionMKhairulMD100% (1)

- Vertical Lifeline Inspection FormДокумент1 страницаVertical Lifeline Inspection FormSelva GanapathiОценок пока нет

- Spreader Bar to Wire Rope ReportsДокумент10 страницSpreader Bar to Wire Rope ReportsDefid Harfiedz Doank100% (1)

- Safe Work Procedure: Overhead CraneДокумент2 страницыSafe Work Procedure: Overhead CraneNos GoteОценок пока нет

- Safe Work Method Statement - Part 1: Company DetailsДокумент16 страницSafe Work Method Statement - Part 1: Company DetailsNithun Deenadayalan100% (1)

- Safe Use of CranesДокумент33 страницыSafe Use of Craneswasim Akram100% (1)

- New Eot Crane TrainingДокумент11 страницNew Eot Crane Trainingsurnaik100% (5)

- Fall ArrestersДокумент1 страницаFall ArrestersTrust EmmaОценок пока нет

- Inspection Checklist Electric Chain Hoist PDFДокумент2 страницыInspection Checklist Electric Chain Hoist PDFSajeewa Lakmal67% (3)

- Construction Hoists Maintenance and InspectionДокумент38 страницConstruction Hoists Maintenance and Inspectionacward57% (7)

- Crane Checklist PDFДокумент2 страницыCrane Checklist PDFWaqar IftikharОценок пока нет

- Wire Rope Slings Wire Rope SlingsДокумент6 страницWire Rope Slings Wire Rope SlingsegyinspectoryahooОценок пока нет

- OverheadДокумент58 страницOverheaddaveОценок пока нет

- Crane Load Test ProcedureДокумент3 страницыCrane Load Test ProcedureBadeng LawotОценок пока нет

- 7.7 Sf-003 (Mewp Inspection Check List) Manlift, BoomliftДокумент1 страница7.7 Sf-003 (Mewp Inspection Check List) Manlift, Boomliftfadhil AbdullahОценок пока нет

- Crane Proof Testing & LAG Revisions 2020 PDFДокумент26 страницCrane Proof Testing & LAG Revisions 2020 PDF朱峰Оценок пока нет

- Lifting Plan: Section A - Work RequestДокумент3 страницыLifting Plan: Section A - Work RequestDilip PaliwalОценок пока нет

- Managing Crane Safety: © 2000 Cia, IncДокумент180 страницManaging Crane Safety: © 2000 Cia, IncAmeerUlHaqОценок пока нет

- Guidelines For Marine Crane LiftsДокумент25 страницGuidelines For Marine Crane LiftsPaulson JosephОценок пока нет

- Crane Lifting SafetyДокумент12 страницCrane Lifting SafetyAbinesh AB100% (1)

- Lifting & HoistingДокумент70 страницLifting & HoistingOws Anish100% (1)

- New Mobile Crawler Crane ChecklistДокумент2 страницыNew Mobile Crawler Crane ChecklistsunilОценок пока нет

- Monthly Forklift Inspection Checklist OHS PR 009 FM 01 0412Документ1 страницаMonthly Forklift Inspection Checklist OHS PR 009 FM 01 0412cmrig74100% (2)

- SAFETY TRAINING CRANES AND HOISTS (38Документ89 страницSAFETY TRAINING CRANES AND HOISTS (38Jose Antonio García Ruíz100% (3)

- Mobile Crane Load TestДокумент4 страницыMobile Crane Load TestMeritorious KhanОценок пока нет

- EOT Crane ChecklistДокумент3 страницыEOT Crane Checklistankit100% (1)

- Full - Retrofit and Reconditioning of 40T & 60T EOT CRANEДокумент40 страницFull - Retrofit and Reconditioning of 40T & 60T EOT CRANEKhalid Mustafa100% (1)

- Construction Cranes PPT v.05.18.15Документ32 страницыConstruction Cranes PPT v.05.18.15yazardОценок пока нет

- Web Slings-Cintas CERTEXДокумент34 страницыWeb Slings-Cintas CERTEXleonardo_barros_48Оценок пока нет

- Crane & Hoist Inspection ProgramДокумент12 страницCrane & Hoist Inspection ProgramAltayeb Yassin0% (2)

- Angle Grinder ChecklistДокумент4 страницыAngle Grinder Checklistshakti123456789Оценок пока нет

- Checklist For Electrical or Air Powered Hoists: Pre-Use InspectionДокумент1 страницаChecklist For Electrical or Air Powered Hoists: Pre-Use Inspectionben_aizziОценок пока нет

- Preventive Maintenance ChecklistДокумент5 страницPreventive Maintenance ChecklistshabkhaizОценок пока нет

- Article Should Crane InspДокумент2 страницыArticle Should Crane Inspsenioor2004Оценок пока нет

- SUBARUДокумент308 страницSUBARUtatonyОценок пока нет

- Risk Management: A Guide To Workplace Safety and Health RegulationsДокумент10 страницRisk Management: A Guide To Workplace Safety and Health RegulationsGerald100% (2)

- Risk Management: A Guide To Workplace Safety and Health RegulationsДокумент10 страницRisk Management: A Guide To Workplace Safety and Health RegulationsGerald100% (2)

- Fatigue ManagementДокумент21 страницаFatigue ManagementShi Hui Tan100% (2)

- PPE Gloves Approved TypeДокумент1 страницаPPE Gloves Approved TypetatonyОценок пока нет

- Investigations Findings ON Errant Atps: Sam Lim Senior Manager Compliance & Investigation WSH CouncilДокумент17 страницInvestigations Findings ON Errant Atps: Sam Lim Senior Manager Compliance & Investigation WSH CounciltatonyОценок пока нет

- Risk Management: A Guide To Workplace Safety and Health RegulationsДокумент10 страницRisk Management: A Guide To Workplace Safety and Health RegulationsGerald100% (2)

- Hotspots in Singapore 2017Документ4 страницыHotspots in Singapore 2017tatonyОценок пока нет

- Risk Management: A Guide To Workplace Safety and Health RegulationsДокумент10 страницRisk Management: A Guide To Workplace Safety and Health RegulationsGerald100% (2)

- Heat Cold StressДокумент34 страницыHeat Cold StresstatonyОценок пока нет

- At Professional Paris Keratin ProteinДокумент4 страницыAt Professional Paris Keratin ProteintatonyОценок пока нет

- Leading and Lagging Indicators PDFДокумент35 страницLeading and Lagging Indicators PDFtatony100% (1)

- The Mathematics of Lottery (C. Barboianu)Документ72 страницыThe Mathematics of Lottery (C. Barboianu)ochaerry0% (1)

- Hand Gloves PUB RequirementДокумент1 страницаHand Gloves PUB RequirementtatonyОценок пока нет

- Assessing PTW ApplicationДокумент1 страницаAssessing PTW ApplicationtatonyОценок пока нет

- A1 SafetyMetricsEURДокумент12 страницA1 SafetyMetricsEURtatonyОценок пока нет

- PPE PUB RequirementДокумент1 страницаPPE PUB RequirementtatonyОценок пока нет

- SISO Mag - Issue3 - 2014 - v17 - LR PDFДокумент32 страницыSISO Mag - Issue3 - 2014 - v17 - LR PDFtatonyОценок пока нет

- Immigration & Checkpoints Authority - APPLESДокумент2 страницыImmigration & Checkpoints Authority - APPLEStatonyОценок пока нет

- 4D Game RulesДокумент14 страниц4D Game RulestatonyОценок пока нет

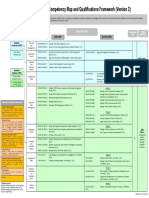

- WSHP Competency MapДокумент4 страницыWSHP Competency MaptatonyОценок пока нет

- WSH Manual Marine IndustriesДокумент360 страницWSH Manual Marine IndustriesluiscremaschiОценок пока нет

- 226 EHS Inspection ReportДокумент5 страниц226 EHS Inspection ReporttatonyОценок пока нет

- Immigration & Checkpoints Authority - APPLESДокумент2 страницыImmigration & Checkpoints Authority - APPLEStatonyОценок пока нет

- Mass Talk On Chemical AwarenessДокумент8 страницMass Talk On Chemical AwarenesstatonyОценок пока нет

- Scaffolds Scaffolding Work General Guide 1Документ16 страницScaffolds Scaffolding Work General Guide 1Mohamad SafwanОценок пока нет

- Devil's Advocate PDFДокумент146 страницDevil's Advocate PDFv642336Оценок пока нет

- Process Safety Performance IndicatorsДокумент35 страницProcess Safety Performance Indicatorstatony100% (4)

- Course Application Form CompanyДокумент3 страницыCourse Application Form CompanytatonyОценок пока нет

- DraftSCAL-PUBGuidebook FinalVersionДокумент37 страницDraftSCAL-PUBGuidebook FinalVersionatac5922Оценок пока нет

- Mushoku Tensei - Volume 21 - Young Man Period - Cliff Chapter (Baka-Tsuki) (Autogenerated)Документ764 страницыMushoku Tensei - Volume 21 - Young Man Period - Cliff Chapter (Baka-Tsuki) (Autogenerated)glen biazonОценок пока нет

- The 30 Gata Defense: Personnel, Fronts and CoveragesДокумент114 страницThe 30 Gata Defense: Personnel, Fronts and Coverageschrisengstrand100% (1)

- Đề cuối kì 2 tiếng anh Smart start 3 có file nghe, ma trận, đáp án ĐỀ 3Документ7 страницĐề cuối kì 2 tiếng anh Smart start 3 có file nghe, ma trận, đáp án ĐỀ 3Hồng Hạnh 100Оценок пока нет

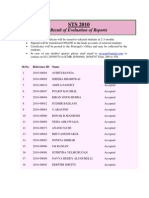

- ICMR STS 2010 Report Submission ResultsДокумент27 страницICMR STS 2010 Report Submission ResultsManish Chandra PrabhakarОценок пока нет

- The Dragon v2Документ2 страницыThe Dragon v2NihilisticWhimОценок пока нет

- Abi SaraДокумент6 страницAbi Sarakeglon002Оценок пока нет

- Games World of Puzzles - February 2017 PDFДокумент85 страницGames World of Puzzles - February 2017 PDFEduardoОценок пока нет

- The Pianist (2002)Документ8 страницThe Pianist (2002)আলটাফ হুছেইনОценок пока нет

- Gmail - Pay Faster Next Time at NOVA SOUTHEASTERN UNIVERSITY INC Using LinkДокумент2 страницыGmail - Pay Faster Next Time at NOVA SOUTHEASTERN UNIVERSITY INC Using LinkAlex TejsheraОценок пока нет

- ESL Brains Fancy A Game TV 2475Документ6 страницESL Brains Fancy A Game TV 2475Yamila FranicevichОценок пока нет

- 2 Microphone 2020Документ15 страниц2 Microphone 2020yap yi anОценок пока нет

- Food and Exercise LogДокумент24 страницыFood and Exercise LogmhetfieldОценок пока нет

- PracticeДокумент4 страницыPracticeAnoop ChauhanОценок пока нет

- One Direction: Background Information Origin Years Active Associated Acts Website MembersДокумент12 страницOne Direction: Background Information Origin Years Active Associated Acts Website MembersOlivia Linseman100% (1)

- User Manual: Ingest SchedulerДокумент80 страницUser Manual: Ingest SchedulerTenОценок пока нет

- New VAS 6154A Aftersales Support ProcessДокумент6 страницNew VAS 6154A Aftersales Support Processvalentin750Оценок пока нет

- Hard JamsДокумент36 страницHard Jamsanon-876493Оценок пока нет

- Overcurrent ProtectionДокумент8 страницOvercurrent ProtectionAdhyartha KerafОценок пока нет

- Benzi Bar & Grill Menu Features Drinks, Appetizers, Entrees & Group PackagesДокумент2 страницыBenzi Bar & Grill Menu Features Drinks, Appetizers, Entrees & Group PackagesRaven AlfareroОценок пока нет

- Funeral Program Design For Oscar CrowderДокумент4 страницыFuneral Program Design For Oscar CrowderPink E. LoveОценок пока нет

- 150 MinoriesДокумент2 страницы150 MinoriesBE OfficesОценок пока нет

- Rapsodia BohemiaДокумент19 страницRapsodia BohemiaHilcA MusicОценок пока нет

- Faking It With My Best FriendДокумент275 страницFaking It With My Best FriendAnika LeistraОценок пока нет

- Helping Your Clavicle To Recover After A Fracture: Physiotherapy DepartmentДокумент4 страницыHelping Your Clavicle To Recover After A Fracture: Physiotherapy Departmentnmmathew mathewОценок пока нет

- Day 1 - PoetryДокумент30 страницDay 1 - PoetryPloribiОценок пока нет

- Social Media AnalysisДокумент2 страницыSocial Media AnalysisVickieОценок пока нет

- Satire TechniquesДокумент3 страницыSatire TechniquesSarahОценок пока нет

- Yoma Strategic Holdings LTDДокумент4 страницыYoma Strategic Holdings LTDHJTANОценок пока нет

- Encyclopedia Needlework 0Документ8 страницEncyclopedia Needlework 0joanae_borgesОценок пока нет

- Corcovada - Hermeto Arr (With Elis Regina) Montreux 1979 & Articles and Interviews About Their Performance TogetherДокумент37 страницCorcovada - Hermeto Arr (With Elis Regina) Montreux 1979 & Articles and Interviews About Their Performance Togetherzimby12Оценок пока нет