Академический Документы

Профессиональный Документы

Культура Документы

An Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice Maker

Загружено:

Ajith KrishnanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

An Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice Maker

Загружено:

Ajith KrishnanАвторское право:

Доступные форматы

Pergamon

www.elsevier.com / locate / solener

PII:

Solar Energy Vol. 68, No. 2, pp. 189195, 2000 2000 Elsevier Science Ltd S 0 0 3 8 0 9 2 X ( 9 9 ) 0 0 0 6 2 6 All rights reserved. Printed in Great Britain 0038-092X / 00 / $ - see front matter

AN ENERGY EFFICIENT HYBRID SYSTEM OF SOLAR POWERED WATER HEATER AND ADSORPTION ICE MAKER

R. Z. WANG, M. LI, Y. X. XU and J. Y. WU

Institute of Refrigeration and Cryogenics, Shanghai Jiao Tong University, Shanghai 200030, Peoples Republic of China Received 12 March 1999; revised version accepted 12 August 1999 Communicated by VOLKER WITTWER

AbstractA new hybrid system of solar powered water heater and adsorption ice maker has been proposed. The working principle of the combined cycles of solar refrigeration and heating is described, theoretical simulation to the thermodynamic processes has been made. Experiments have been performed in a developed prototype hybrid system; it is veried that the hybrid system is capable of heating 60 kg water to about 908C as well as producing ice at 10 kg per day with a 2-m 2 solar collector. 2000 Elsevier Science Ltd. All rights reserved.

1. INTRODUCTION

The ecological problems and energy crisis in the world have induced scientists to develop sustainable energy utilization systems, in which solar energy is attractive. Various solar water heaters, such as plate type, vacuum tube type, heat pipe vacuum tube type etc., have been commercialized with the expanding market. In China, solar water heater has been marketed for about 1 billion Yuan per year, and it is still being developed. Solar powered ice-makers or refrigerators have been reported by a lot of researchers, in which both absorption or adsorption systems have been demonstrated (Iloeje, 1985; Pons and Guilleminot, 1986; Pons, 1987; Hajji et al., 1991), however a potential market seems to be necessary for further research and development. In recent years, we have paid a lot of attention to adsorption refrigeration systems (both for icemaking and heat pump), and good experimental results have been obtained with activated carbon methanol working pairs. With a heat source of about 901008C, we have achieved a specic cooling power of 2.6 kg ice / day per kg-adsorbent for ice-making (Wang et al., 1998a), and 150 W/ kg-adsorbent for air-conditioning (Wang et al., 1998b). More work regarding activated carbon bermethanol pairs for ice-making is on the way, in which 5 kg-ice / day per kg adsorbent will

Author to whom correspondence should be addressed. Tel. / fax: 1 86-21-6293-3250; e-mail: rzwang@mail.sjtu.edu.cn 189

be expected (Wang et al., 1997). Solar ice making is attractive by an adsorption system, however it needs both good heat collecting and heat release for the adsorber, which seems to be a contradiction. By the way, heat release means energy losses. A hybrid system of solar powered water heater and ice maker has been suggested and developed by the authors, the idea is simple but effective! The adsorber of the adsorption ice-maker is put into a water bath which is powered directly by vacuum solar collector. No thermal insulation or enhanced convection are needed for the adsorber, it is just immersed into the water bath of a solar powered water heater, which guarantees both good heating or cooling of the adsorber. With a solar collector of a group of heat pipe vacuum tubes, and proper design of the system, it is possible to reach a bath temperature of up to 80908C after 1 day solar collecting, which is suitable as a heat source for the activated carbon methanol adsorption refrigerator. The hot water will be taken away in the evening (be drained to another insulated water tank or used for taking showers for the whole family), and cold water will be lled in. This cools the adsorption bed and induces adsorption, and the refrigeration process happens almost the whole night. A similar hybrid system for heating and cooling has been developed by Zeo-Tech (Schwarz et al., 1997) in Munich, they used zeolite as adsorbent and water as refrigerant, the sensible heat of the adsorbent bed and the heat of adsorption were used to heat

190

R. Z. Wang et al.

water, while cooling by adsorptionevaporation was used to keep cold in a cold box. This solar energy system is a good combination of solar heating and solar cooling, it is estimated that with a 2-m 2 solar collector, 50 kg 841008C hot water can be made during a sunshine day, meanwhile 3.08.7 kg ice will be also produced in the night. The system will yield a solar refrigeration COP of about 0.04 and heating efciency h of about 0.350.38. The above hybrid combined cycle has been well veried by experiment in a prototype system.

2. WORKING PRINCIPLE

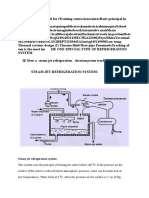

The schematic design of a hybrid solar powered water heater and refrigerator is shown in Fig. 1. The system consists of a solar collector, water tank, adsorber / generator, condenser, evaporator, receiver and ice box and so on. Fig. 2 shows the congured system. The working principle is just a combination of a solar water heater and adsorption refrigeration. Heating of the water tank is started in the morning through vacuum tube type solar collector. With the increase of the water temperature, the temperature in the adsorbent bed rises. In an ideal process, the adsorbent temperature could be very close to the water temperature in the tank. When the temperature in the adsorbent rises up to a temperature (T g1 ) which causes the vapor pressure of the desorbed refrigerant up to the condensing pressure (Pc ), desorption at constant pressure is initiated, the desorbed vapor is condensed in the condenser and collected in the receiver. This liquid ows to the evaporator via a ow rate regulating valve. The temperature of the water

Fig. 2. The congured hybrid system of solar powered water heater and adsorption ice-maker.

Fig. 1. Schematic of the solar water heater and refrigerator. (1) Solar collector; (2) water pipe; (3) adsorber; (4) valve; (5) condensor; (6) evaporator; (7) refrigerator (with cold storage); (8) receiver; (9) hot water container.

and the adsorbent bed continues rising due to solar heating, a maximum temperature (T g2 ) for 801008C could be achieved at the end of the process. The high temperature water is used in the evening for the family, also the hot water in the tank could be drained out and moved into another tank at home, thus hot water can be used very exibly. With the relling of the water tank with cold water, the temperature of the adsorbent bed is reduced rapidly (T g2 T a1 ), and the pressure in the adsorber drops to a value below evaporation pressure (Pe ). Evaporation could happen if the connecting valve is open, and ice will be made in the refrigeration box. The cooling of the adsorber and the rejection of adsorption heat may cause the temperature of cold water in the tank to rise several degrees (T 0 T a2 ), however this energy is not wasted. Several degrees higher than cold water temperature (T 0 ) will not inuence the adsorption refrigeration much, this might be even better than normal cooling to the adsorption bed by natural convection. Refrigeration will continue for the whole night until the next morning. The thermodynamic cycle for adsorption refrigeration can be demonstrated in a PTX diagram shown as Fig. 3. The features of the hybrid system include (1) it has two purposes: water heating and refrigeration with one solar collector, which is suitable for household applications; (2) adsorber / generator is separated from collector, thus a high efciency vacuum collector can be used for water heating, thereby heating the adsorber at the same time. The high efciency heating does not mean a bad

An energy efcient hybrid system of solar powered water heater and adsorption ice maker

191

collector, T a is the environmental temperature, Ut is the heat loss coefcient of the collector face, Ub is the heat loss coefcient of the collector bottom. Of the heat losses, Q b is usually less than 10%.

3.2. Energy analysis of the adsorber in the water tank

The useful heat from the collector, Q u , will contribute both to the heating of the water in the tank and to the heating of the adsorber which will cause the desorption of refrigerant from the adsorbent bed. The energy equation can be written as

T g2

Fig. 3. Adsorption refrigeration cycle.

cooling of the adsorber through the night, as by draining the hot water from the tank, cold water is relled to the tank, thus the adsorber is cooled and refrigeration will take place; (3) energy efciency is high for the use of the total solar energy collected; (4) there is no danger of methanol disintegration as the maximum temperature of the adsorbent bed cannot exceed 1008C, due to the water tank.

3. PERFORMANCE SIMULATION: MODEL

Qu 5

EM

T g1 T a2 T g2

T g2

water

Cwater dT 1

E (M C

m T g2 d T g1

pm

1 Ma Cpa )dT

T a2

T a2

Ex

conc

Ma Cpl dT 1

E h M dx

a

E x(T, p )M C dT

c a pl

(4)

T g1

3.1. Energy analysis of solar heating

Solar heating absorbed by the collector will be used in three ways: (1) Q u , energy to heat the water tank and adsorbent bed, (2) Q s , energy storage in the collector; (3) Q l , energy lost due to various losses. The energy conservation equation is A e G(ta ) 5 Q u 1 Q l 1 Q s (1)

where G is the solar ux density to the adsorber, t is the transmittance of solar radiation through the cover of the collector, a is the absorptance of the collector, A e is the area of the collector. For a plate type or evacuated tube type solar collector, the heat quantity Q u is used to heat the water and adsorber in the water tank, which is mainly determined by the efciency of the collector; the heat quantity Q s is dependent on the solar collector material; Q l is the heat losses composed of the face loss Q t , the bottom loss Q b , and the four sides loss Q e . Usually Q e is relatively smaller than Q t and Q b , in which Q t and Q b can be calculated by Qt 5

in which the rst term represents the heat added to the water bath in the tank, the second term is the sensible heat of the metallic tank and adsorbent mass. Item 3 is the sensible heat of refrigerant liquid in the adsorbent before desorption, item 4 is the heat of desorption, item 5 is the sensible heat of refrigerant remaining in the adsorbent bed. In Eq. (4), Mwater mass of water, Cwater specic heat of water, Mm mass of adsorber, Cpm specic heat of adsorber, Ma mass of adsorbent, Cpa specic heat of adsorbent, Cpl specic heat of refrigerant in the adsorbed state. Heat of desorption can be described by

T g2

Hd 5

dx E h M dx 5 E h M ] dT dT

d a d a T g1

T g2

(5)

T g1

E U A (T 2 T )dt Q 5 E U A (T 2 T )dt.

t e p a b b e p a

(2) (3)

here h d is the heat of adsorption, which is a function of x. In our research, activated carbonmethanol is used as the working pair. The adsorption equation of activated carbonmethanol can be described by the following equation (Wang et al., 1997): T x 5 x 0 exp 2 k ] 2 1 Ts

F S

DG

n

(6)

Here T p is the average temperature of the solar

where x is the adsorption capacity, k and n are the characteristic parameters of adsorption refrigera-

192

R. Z. Wang et al.

tion pair, x 0 is the adsorption capacity at T 5 T s and P 5 Ps (where T s is the saturation temperature at pressure Ps ), T is the adsorption temperature. Typical parameter values for the activated carbonmethanol pair are (Wang et al., 1997): x 0 5 0.284, k 5 10.21, n 5 1.39, T s 5 288.3 K, where Shanghai YK (coconut shell type activated carbon) is used. h d can be calculated from the Clausius-Clapeyron equation, where T s 5 T c (condensing temperature): T h d 5 RA ] Tc (7)

Qc T a2 5 T 0 1 ]]]]] Mwater 3 Cpwater

(10)

which is also the adsorption temperature for the refrigerator.

3.4. Refrigeration capacity

The desorbed refrigerant is condensed in the condenser and ows into the evaporator. When the adsorbent bed pressure is lower than evaporation pressure, the refrigerant liquid in the evaporator will evaporate which causes the refrigeration effect. The refrigeration quantity is Q ref 5 DxMa Le Dx 5 x conc 2 x dil (11) (12)

where R is the gas constant and A is the constant of the Clausius-Clapeyron equation.

3.3. Energy balance between lled water and adsorber

In the evening, the hot water in the tank is drained into another storage tank or is used directly. Cold water is then lled into the tank to cool the adsorber. The sensible heat of adsorber and the heat of adsorption will cause the lled water to rise its temperature for several degrees, thus this energy will not be lost. The adsorption temperature T a2 is determined by the energy balance between the lled cold water and the adsorber to be cooled. The sensible heat for cooling the adsorber bed from T g2 to T a2 is

T g2

where Le is the latent heat of vaporization, x conc is the adsorbent capacity before desorption and x dil is the adsorption capacity after desorption. Some of the cooling quantity will be consumed to cool the refrigerant liquid from condensing temperature T c to evaporation temperature T e Q cc 5 Ma DxCpl (T c 2 T e ). (13)

3.5. Refrigeration COPcycle and system COPsolar

Refrigeration cycle COP can be written as Q ref 2 Q cc COPcycle 5 ]]] Qg (14)

Qc 5

T g2

E (M C

m

where Q g is the heat for the regeneration of the adsorption bed, which is shown as

pm

1 Ma Cpa )dT 1

T a1

T a2

Q g 5 Q u 2 Q water (8)

a pl T g2

Ex

dil

Ma Cpl dT 1

E h M dx 1 E xM C dT

a a T a2

T a1

E (M C

m T g2 d T g1

T g1

pm

1 Ma Cpa )dT 1

T g2

Ex

conc

Ma Cpl dT

T a1

T a2

T a2

T a2

where item 1 is the sensible heat of adsorber mass and adsorbent, item 2 is the sensible heat of refrigerant in adsorbent bed, item 3 is the heat of adsorption, which can be calculated as

T a1

E h M dx 1 E xM C dT

a a pl T g1

(15)

Ha 5

dx E h M dx 5 E h M ] dT, dT

a a a a T a2

T a1

(9)

T a2

and item 4 is the sensible heat of adsorbent during adsorption process. The sensible heat for cooling is transferred to the lled cold water in the tank. This may cause the temperature to increase several degrees for the water in the tank. If water has a temperature T 0 before adsorption, then the water temperature after adsorption is

Tg2 Q water 5 eT Mwater Cwater dT is the sensible heat a2 to heat the water in the tank, here the sensible heat to heat the tank is neglected. In a normal solar powered ice-maker, the collector is in the same unit of adsorber, Q water is zero, Q u is the whole contribution of heating to the adsorber. In this case the energy Q c must be taken away in the evening and the whole night to furnish the refrigeration effect. Cooling by normal convection is difcult to release Q c . The hybrid system has two useful outputs, one is refrigeration, its solar efciency is

An energy efcient hybrid system of solar powered water heater and adsorption ice maker

193

Q ref 2 Q cc COPsolar 5 ]]] G(t )dt

(16)

Table 2. Simulated results of the hybrid system for the whole year Seasons Filled water temp. T 0 ( 8C) Condensing temp. T c ( 8C) Evaporation temp. T e ( 8C) Adsorption temp. T a2 ( 8C) Generation temp. T g2 ( 8C) COPcycle COPsolar hsolar Ice made per day (kg) Jan March 10 20 2 10 19.6 86.6 0.48 0.042 0.372 7.9 April June 15 25 2 10 23.7 93.1 0.44 0.044 0.361 6.3 July Sept 25 35 2 10 31 100 0.32 0.038 0.341 3.05 Oct Dec 10 15 2 10 19.5 84.9 0.51 0.046 0.370 8.7

another is heating the water in the tank, its solar efciency is Q water hsolar 5 ]]] G(t )dt

(17)

where G(t ) is the solar ux density, e G(t )dt is the total solar energy during the whole day.

4. PERFORMANCE SIMULATION

by condensing temperature; it would be suggested to put the condenser partly or fully in a water bath to decrease the condensing temperature especially in summer time.

5. EXPERIMENTS

A hybrid system of solar water heater and refrigerator has been imaged. The system parameters and the parameters for simulation are listed in Table 1. In the concept design, a stainless steel tube type adsorber with a diameter of 230 mm had been tried, and activated carbon was lled, the mass of adsorber and activated carbon are 5 kg and 28 kg, respectively. The conguration of the system is shown in Fig. 2. The solar heat ux density is taken from the solar source in Shanghai, and the total radiant energy to the collector is assumed to be e G(t )dt 5 20 MJ / m 2 per day, the efciency of solar collector is 46% (depending on the product). A solar collector of vacuum tube heat pipe type is selected (efcient area for about 2 m 2 ), its performance parameters are based on the product performances. Table 2 shows the simulated results for the typical climate of four seasons in Shanghai in a year. In the simulation, a xed solar heat ux density of 20 MJ / m 2 per day has been assumed, this value will be changed for the real four seasons. However the simulation results show that about 6108C temperature increase in the water bath will be generated by the sensible heat and adsorption heat in the adsorbent bed, which will spare the energy for solar heating. It is also found that the refrigeration effect is strongly inuenced

Table 1. Simulation parameters of the hybrid solar water heater and ice maker Materials Adsorbent carbon Adsorber stainless steel Water in the tank Mass (kg) Ma 5 28 Mm 5 5 Mwater 5 50 Specic heat (J / kg K) Cpa 5 900 Cpm 5 902 Cpwater 5 4180

Methanol: Cpl 5 750 (J / kg K), x 0 5 0.284 kg / kg, k 5 10.21, n 5 1.39, T s 5 288.3 K, A 5 4413, Le 5 1102 (kJ / kg).

The concept design of the hybrid system shown as Fig. 2 did not prove successful, the reason is that the heat transfer in the activated carbon bed is very bad, which causes heating and cooling of the adsorbent to be a big problem. There are two solutions to solve this problem, one is to have a compressed adsorbent bed with heat transfer enhancement, another is to have an adsorber in which the adsorbent bed is much thinner, thus good heat transfer can still be guaranteed. A modied prototype hybrid system for water heating and ice-making has been developed, the adsorber consisted of 28 f 50 3 1 3 750 mm stainless steel tubes, in which 22 kg activated carbon was lled, the adsorber mass is about 25 kg. The water tank is lled with 120150 kg water. A 1500 W electric heater is used to simulate a 3 m 2 vacuum heat pipe type solar collector. Fig. 4 shows the simulation hybrid system. A typical experiment is demonstrated, the initial water temperature in the water tank is 188C, and the initial adsorbent temperature is 208C. After 6 h heating, the 150 kg water bath temperature reaches 818C, and the adsorbent temperature reaches 728C. The desorption process starts, in a 4-h desorption process heating of the water bath continues. The stop point of heating is 988C for the water bath, the corresponding desorption temperature is 898C. The desorbed methanol is 4.1 l, about 3.3 kg. About 54 MJ heat is added in the 10-h heatingdesorption process. The hot water was taken away in the evening at 20:00 h, then the city water with a temperature of 108C was lled into the tank, the adsorbent bed temperature was thereby reduced to 27.48C. Meanwhile about 15 kg water with a temperature

194

R. Z. Wang et al.

Q water hheating 5 ]] QT

(19)

Fig. 4. The prototype of hybrid water heating and adsorption ice maker.

of 158C was lled into the ice box. Adsorption refrigeration was then initiated, which lasted until the second morning at 08:00 h. We measured the water bath temperature raised up to 17.48C, the adsorbent temperature decreased to 228C. It was found that 10.5 kg ice with a temperature of 2 2.58C had been made. Here the denition of COP and h corresponding to Eqs. (16) and (17) are Q ref 2 Q cc COPheating 5 ]]] QT (18)

where Q T is the total heat added from the heater to the water bath. It was evaluated that the adsorption refrigeration COP driven by heating is COPheating 5 0.067, and the heating efciency is hheating 5 0.906. The adsorption refrigeration cycle COP has been calculated as COPcycle 5 0.386. Table 3 shows the two experimental results of hot water and ice output in two typical seasons: winter and spring. The water bath is relatively big, in which 150 kg water and 112 kg water were lled for testing. In order to get the design value in which hot water output is about 60 kg with a 2-m 2 solar collector heat input, we have made a calculation based upon the above tests shown in Table 3; Table 4 shows the results. Here 60 kg water is assumed in the water bath, the energy accepted is about 2224 MJ per day, which is a simulation to a 2-m 2 solar collector. The calculated results show that a 2-m 2 solar collector is capable of heating 60 kg water to about 908C and producing ice for about 10 kg. Attention should be drawn to the fact that the simulation prototype system of water heating is in an open tank, in which the cover of the tank is not sealed, which caused several percent heat dissipation by evaporation of water. The value of hsystem is thus smaller than the ideal system, so is the COPsystem .

6. CONCLUSION

A hybrid system of solar powered water heater and refrigerator has been described, which is capable of both heating and cooling effects. With

Table 3. The experimental results of the hybrid system Experimental date Dec. 910, 1998 March 1011, 1999 Energy accepted (MJ) 54 49 Hot water output 8C 98 91.3 kg 150 112 Ice output 8C 2 2.5 2 1.8 kg 10.5 10 0.067 0.064 0.386 0.431 0.906 0.758 COPsystem COPcycle

hsystem

Table 4. Calculated performance of the hybrid system based upon experimental results Experimental date Dec. 910, 1998 March 1011, 1999 Energy accepted (MJ) 24.6 22 Hot water output 8C 98 91.3 kg 60 60 Ice output 8C 2 2.5 2 1.8 kg 10.5 10 0.143 0.144 0.386 0.431 0.795 0.797 COPsystem COPcycle

hsystem

An energy efcient hybrid system of solar powered water heater and adsorption ice maker

195

a 2-m 2 solar collector, it is capable of making 60 kg 908C hot water and producing 10 kg ice per day. A prototype simulation system has been constructed, which has proven the suggested idea of combined heating and cooling cycle. The hybrid system is capable of reaching a specic refrigeration density of about 0.5 kg ice / kg-adsorbent per day. The successful design of good adsorbent bed will accelerate practical application of solid adsorption refrigeration driven by solar energy. Although this device is designed just for solar energy utilization, it can be applied to many energy saving elds such as waste heat recovery in industry, the utilization of air conditioning driven by exhaust gas of automobiles. This novel concept of energy utilization provides an efcient way for sustainable development. It is seen that this very attractive idea is reasonable.

NOMENCLATURE

A Ae Cpa Cpl Cpm Cpwater COP COPcycle COPheating COPsolar G(t ) ha Ha hd Hd k Le Ma Mm Mwater n Qc Q cc constant of the Clausius-Clapeyron equation area of the solar collector (m 2 ) specic heat of adsorbent (kJ / kg K) specic heat of refrigerant liquid (kJ / kg K) specic heat of metallic adsorber (kJ / kg K) specic heat of water (kJ / kg K) refrigeration COP refrigeration cycle COP refrigeration cycle COP driven by heating solar power refrigeration COP solar heat ux density (W/ m 2 ) heat of adsorption (kJ / kg) integrated heat of adsorption (kJ) heat of desorption (kJ / kg) integrated heat of desorption (kJ) characteristic parameter of adsorption pair latent heat of evaporation of refrigerant (kJ / kg) mass of adsorbent (kg) mass of metallic adsorber (kg) mass of water in the tank (kg) characteristic parameter of adsorption pair heat to cool down the adsorber and adsorbent bed (kJ) cooling consumed to cool down refrigerant from condensing temperature to evaporation temperature (kJ) heat losses (kJ) refrigeration effect (kJ)

Qs QT Qt Qu T Ta T a1 T a2 Tc Te T g1 T g2 Tp Ts T0 Ub Ut x x dil x conc x0

a t hsolar Dx

heat stored in the collector (kJ) total heat load (kJ) face heat losses (kJ) heat transferred to the water tank (kJ) temperature ( 8C) environmental temperature ( 8C) temperature to start adsorption ( 8C) adsorption temperature ( 8C) condensing temperature ( 8C) evaporation temperature ( 8C) temperature to start desorption ( 8C) desorption temperature ( 8C) average temperature of solar collector ( 8C) saturated temperature ( 8C) lled water temperature ( 8C) bottom heat transfer coefcient (W/ m 2 K) face heat transfer coefcient (W/ m 2 K) adsorption capacity (kg-refrigerant / kg-adsorbent) adsorption capacity at desorbed state (kg / kg) adsorption capacity at adsorbed state (kg / kg) adsorption capacity at a saturated pressure ps corresponding to T s (kg / kg) absorptance transmittance solar heating efciency adsorption capacity difference between adsorption phase and desorption phase Dx 5 x conc 2 x dil (kg / kg)

REFERENCES

Hajji A., Worek W. M. and Lavan Z. (1991) Dynamic analysis of a closed-cycle solar adsorption refrigerator using two adsorbentadsorbate pairs. ASME J. Solar Energy Eng. 113, 73. Iloeje O. C. (1985) Design construction and test run of a solar powered solid absorption refrigerator. Solar Energy 35, 447. Pons M. (1987) Experimental data on a solar-powered ice maker using activated carbon and methanol adsorption pair. ASME J. Solar Energy Eng. 109, 303. Pons M. and Guilleminot J. J. (1986) Design of an experimental solar-powered solid-adsorption ice maker. ASME J. Solar Energy Eng. 108, 332. Schwarz J., Maier-Laxhuber P. and Mayer H. (1997) Gemeinsame Bereitstellung durch ein Zentrales Adsorption-system. Luft Kaltetechnik 7, 305. Wang R. Z., Jia J. P., Zhu Y. H., Teng Y., Wu J. Y., Cheng J. and Wang Q. B. (1997) Study on a new solid adsorption refrigeration pair: active carbon ber-methanol. ASME J. Solar Energy Eng. 119, 214. Wang R. Z., Wu J. Y., Xu Y. X., Teng Y. and Shi W. (1998a) Experiment on a continuous heat regenerative adsorption refrigerator using spiral plate heat exchanger as adsorbers. Appl. Thermal Eng. 18, 13. Wang R. Z., Xu Y. X., Wu J. Y. and Wang W. (1998b) Experiments on heat regenerative adsorption refrigerator and heat pump. Int. J. Energy Research 22, 935.

Ql Q ref

Вам также может понравиться

- Original Gasket Technology GuideДокумент40 страницOriginal Gasket Technology GuideAtty AttyОценок пока нет

- Ansys Transient Thermal ExampleДокумент5 страницAnsys Transient Thermal ExampleMaciejBlokОценок пока нет

- Solar Energy StorageДокумент13 страницSolar Energy StorageNandakumarОценок пока нет

- Adsorption RefrigerationДокумент22 страницыAdsorption RefrigerationVijay Krishnan100% (1)

- Ocean Thermal Energy ConversionДокумент43 страницыOcean Thermal Energy ConversionMaitry DaveОценок пока нет

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningОт EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningРейтинг: 5 из 5 звезд5/5 (2)

- Experimental Investigation of A Two-Phase Closed Thermosyphon Solar Water HeaterДокумент10 страницExperimental Investigation of A Two-Phase Closed Thermosyphon Solar Water HeaterWail SarsamОценок пока нет

- Two Bed Adsorption Chiller With RegenerationДокумент10 страницTwo Bed Adsorption Chiller With RegenerationParimal BhambareОценок пока нет

- Review of Solid Adsorption Refrigerator I An Overview of The Refrigeration CycleДокумент12 страницReview of Solid Adsorption Refrigerator I An Overview of The Refrigeration CycleHamza MoussaОценок пока нет

- 26 Siegfried Kreussler Experiments On Solar Adsorption RefrigДокумент8 страниц26 Siegfried Kreussler Experiments On Solar Adsorption RefrigParimal BhambareОценок пока нет

- Wei 2013Документ7 страницWei 2013PRADEEP SОценок пока нет

- 68-Solar Waste Heat Driven Two-Stage AdsorptionДокумент9 страниц68-Solar Waste Heat Driven Two-Stage Adsorptionali105Оценок пока нет

- Solar RefrigerationДокумент5 страницSolar RefrigerationspectabearОценок пока нет

- Solar Gas Solid Sorption Heat Pump: L.L. Vasiliev, D.A. Mishkinis, A.A. Antukh, L.L. Vasiliev JRДокумент11 страницSolar Gas Solid Sorption Heat Pump: L.L. Vasiliev, D.A. Mishkinis, A.A. Antukh, L.L. Vasiliev JRحسن عرقسوسيОценок пока нет

- Termosifón Tubo de CalorДокумент6 страницTermosifón Tubo de CalorLuis Enrique GonzálezОценок пока нет

- Steam Jet Refrigeration SystemДокумент7 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- Trigeneration System Based On A Solar Energy Input Rankine CycleДокумент3 страницыTrigeneration System Based On A Solar Energy Input Rankine CycletfemilianОценок пока нет

- Steam Jet Refrigeration SystemДокумент7 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- Steam Jet Refrigeration SystemДокумент7 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- Unit 4 Solar CoolingДокумент12 страницUnit 4 Solar CoolingSubhaОценок пока нет

- Shopmillingmsme: Steam Jet Refrigeration SystemДокумент7 страницShopmillingmsme: Steam Jet Refrigeration SystembbaytlОценок пока нет

- Solar Water HeatingДокумент7 страницSolar Water HeatingDener StefanОценок пока нет

- Steam Jet Refrigeration SystemДокумент7 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- Steam Jet RefrigerationДокумент6 страницSteam Jet RefrigerationbbaytlОценок пока нет

- Calentadores SolaresДокумент12 страницCalentadores SolaresAngel M. AlfaroОценок пока нет

- Applied Energy: C. Garnier, J. Currie, T. MuneerДокумент5 страницApplied Energy: C. Garnier, J. Currie, T. MuneerResearcherzОценок пока нет

- Flat Plate Heat Pipe 2Документ5 страницFlat Plate Heat Pipe 2सचिन उरुणकरОценок пока нет

- 10 1016@j Renene 2019 01 114Документ26 страниц10 1016@j Renene 2019 01 114martha veraОценок пока нет

- Steam Jet Refrigeration SystemДокумент6 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- Solar Desiccant CoolingДокумент12 страницSolar Desiccant Coolingdanijelkr88Оценок пока нет

- Ijet V2i6p2Документ6 страницIjet V2i6p2International Journal of Engineering and TechniquesОценок пока нет

- Modeling and Simulation of A Solar Powered Two Bed Adsorption Air Conditioning SystemДокумент15 страницModeling and Simulation of A Solar Powered Two Bed Adsorption Air Conditioning SystemsisayОценок пока нет

- Shopmillingmsme: Steam Jet Refrigeration SystemДокумент7 страницShopmillingmsme: Steam Jet Refrigeration SystembbaytlОценок пока нет

- 2009 10 Otti Solarcooling PalermoДокумент6 страниц2009 10 Otti Solarcooling PalermoKelvinVelasquezPascualОценок пока нет

- Shopmillingmsme: Steam Jet Refrigeration SystemДокумент7 страницShopmillingmsme: Steam Jet Refrigeration SystembbaytlОценок пока нет

- Shopmillingmsme: Steam Jet Refrigeration SystemДокумент7 страницShopmillingmsme: Steam Jet Refrigeration SystembbaytlОценок пока нет

- Solar Water Heater With Shell and Helical Coiled Tube Heat Exchanger As A Storage TankДокумент11 страницSolar Water Heater With Shell and Helical Coiled Tube Heat Exchanger As A Storage TankKarimaОценок пока нет

- Absorption Cooling System by Using Solar EnergyДокумент16 страницAbsorption Cooling System by Using Solar Energyعراقي iraqiОценок пока нет

- CH 9 OTECДокумент6 страницCH 9 OTECscharichОценок пока нет

- Nagaraj 123Документ14 страницNagaraj 123Ganesh harikantraОценок пока нет

- Energies: Thermal Analysis of A Solar Powered Absorption Cooling System With Fully Mixed Thermal Storage at StartupДокумент19 страницEnergies: Thermal Analysis of A Solar Powered Absorption Cooling System With Fully Mixed Thermal Storage at StartupPedro HenriqueОценок пока нет

- Geothermal Heat PumpДокумент22 страницыGeothermal Heat PumpAbhijan ChakrabortyОценок пока нет

- A Case Study On Solar Vapour Absorption Refrigeration SystemДокумент7 страницA Case Study On Solar Vapour Absorption Refrigeration SystemShivam MaheraОценок пока нет

- Classification of Solar Collectors: Žanis JeskoДокумент6 страницClassification of Solar Collectors: Žanis Jesko06l01a0224Оценок пока нет

- The Study of Solar Absorption Air-Conditioning SystemsДокумент8 страницThe Study of Solar Absorption Air-Conditioning SystemsJaime Haro EstropОценок пока нет

- 48 Ragab 1-s2.0-S2352152X23004528-main - CompressedДокумент14 страниц48 Ragab 1-s2.0-S2352152X23004528-main - CompressedAbo AmroОценок пока нет

- Closed Cycle Solar RefrigerationДокумент13 страницClosed Cycle Solar RefrigerationLaura FrancoОценок пока нет

- Steam Jet Refrigeration SystemДокумент6 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- 2.1 Demands For CoolingДокумент25 страниц2.1 Demands For CoolingVivek LokhandeОценок пока нет

- Steam Jet Refrigeration SystemДокумент6 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- The Geothermal Concept: A Homeowner'S Guide To Geothermal Heating and Cooling Comfort SystemsДокумент16 страницThe Geothermal Concept: A Homeowner'S Guide To Geothermal Heating and Cooling Comfort SystemsNouman YasarОценок пока нет

- Paper 17 DesignДокумент7 страницPaper 17 DesignJohannes Angga PanjaitanОценок пока нет

- Thermal ChangeДокумент10 страницThermal Changeakashraj1055Оценок пока нет

- Steam Jet Refrigeration SystemДокумент6 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- New Solar Powered Adsorption Refrigerator With High PerformanceДокумент9 страницNew Solar Powered Adsorption Refrigerator With High PerformanceBudiman Immanuel NainggolanОценок пока нет

- Carbon AmmoniaДокумент9 страницCarbon AmmoniaFeyi AsgillОценок пока нет

- Steam Jet Refrigeration SystemДокумент6 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- Solar Water Heating Detailed ReportДокумент4 страницыSolar Water Heating Detailed ReportRahul RajpalОценок пока нет

- Refrigeration Sysy TypeДокумент6 страницRefrigeration Sysy TypebbaytlОценок пока нет

- Steam Jet Refrigeration SystemДокумент6 страницSteam Jet Refrigeration Systembbaytl100% (1)

- PDFДокумент141 страницаPDFAjith KrishnanОценок пока нет

- Energy Paper Published PDFДокумент19 страницEnergy Paper Published PDFAjith KrishnanОценок пока нет

- MACHIENDRAWINGUnit 1Документ18 страницMACHIENDRAWINGUnit 1Pusker BeralОценок пока нет

- Exergo Economics & E I TL Li Exergoenvironmental Analysis: June 12, 10:45 P.M. - 12:15 P.MДокумент12 страницExergo Economics & E I TL Li Exergoenvironmental Analysis: June 12, 10:45 P.M. - 12:15 P.MAjith KrishnanОценок пока нет

- Latex Figtab HandoutsДокумент9 страницLatex Figtab HandoutsganimedesfqОценок пока нет

- Korea Research Fellowship (KRFДокумент21 страницаKorea Research Fellowship (KRFAjith KrishnanОценок пока нет

- CFD Review - Flow Simulation Improves Photovoltaic Solar Panel PerformanceДокумент4 страницыCFD Review - Flow Simulation Improves Photovoltaic Solar Panel PerformanceAjith KrishnanОценок пока нет

- Stepwise Varying Width Microchannel Cooling Device For Uniform Wall Temperature Experimental and Numerical StudyДокумент9 страницStepwise Varying Width Microchannel Cooling Device For Uniform Wall Temperature Experimental and Numerical StudyAjith KrishnanОценок пока нет

- Introduction To Beamer: Beamer Is A Latex Class For Creating Slides For PresentationsДокумент64 страницыIntroduction To Beamer: Beamer Is A Latex Class For Creating Slides For PresentationsbyrucОценок пока нет

- All About KSRTCДокумент5 страницAll About KSRTCAjith KrishnanОценок пока нет

- IBPS Bank CWE PO Clerical Placement Paper Aptitude Numerical 20640Документ7 страницIBPS Bank CWE PO Clerical Placement Paper Aptitude Numerical 20640Ajith KrishnanОценок пока нет

- Measurement of Thermal Conductivity of Liquids and GasesДокумент10 страницMeasurement of Thermal Conductivity of Liquids and GasesAjith KrishnanОценок пока нет

- Chap01 IntroductionДокумент7 страницChap01 IntroductionMarthEnd PaloboranОценок пока нет

- Adsorption, Absorption and Desorption - What's The Difference - Aug 24 2014 10 - 32 AM - Breaking News - Chromatography TodayДокумент8 страницAdsorption, Absorption and Desorption - What's The Difference - Aug 24 2014 10 - 32 AM - Breaking News - Chromatography TodayAjith KrishnanОценок пока нет

- Navier Stokes EqДокумент5 страницNavier Stokes EqAjith KrishnanОценок пока нет

- Physical Properties AcrylicДокумент5 страницPhysical Properties AcrylicleynatmarОценок пока нет

- Thermo Acoustic RefrigirationДокумент10 страницThermo Acoustic RefrigirationAjith KrishnanОценок пока нет

- Introduction To Wind Energy - E.H.lysenДокумент309 страницIntroduction To Wind Energy - E.H.lysenAjith KrishnanОценок пока нет

- Models - Ssf.phase ChangeДокумент18 страницModels - Ssf.phase ChangeAjith KrishnanОценок пока нет

- Flow Boiling in MicrochannelДокумент32 страницыFlow Boiling in MicrochannelAjith KrishnanОценок пока нет

- Viscometer - Wikipedia, The Free EncyclopediaДокумент8 страницViscometer - Wikipedia, The Free EncyclopediaAjith KrishnanОценок пока нет

- PSG Teflon PtfeДокумент1 страницаPSG Teflon PtfeKanagala Raj ChowdaryОценок пока нет

- MTech Thesis FormatДокумент9 страницMTech Thesis Formatleo de capriОценок пока нет

- Course 9Документ2 страницыCourse 9Rahul TripathiОценок пока нет

- BoilersДокумент20 страницBoilersAjith KrishnanОценок пока нет

- A Review On Direct Two-Phase Phase Change Flow Simulation MethodДокумент10 страницA Review On Direct Two-Phase Phase Change Flow Simulation MethodAjith KrishnanОценок пока нет

- Fli L: CanadaДокумент18 страницFli L: CanadaAjith KrishnanОценок пока нет

- Ijftr 33 (4) 419-425Документ0 страницIjftr 33 (4) 419-425Ajith KrishnanОценок пока нет