Академический Документы

Профессиональный Документы

Культура Документы

API 650 Storage Tank Specification and Design Calculations

Загружено:

samy7354Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

API 650 Storage Tank Specification and Design Calculations

Загружено:

samy7354Авторское право:

Доступные форматы

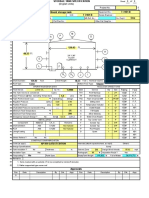

Nass Mechanical

1 Service : 2 Location : 3 Manufacturer : 4 P&ID No. 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Shell Diameter : 25 Roof Type : 26 27 Fluid Stored :

STORAGE TANK SPECIFICATION (English Units)

Project No.

Sheet

1 of 1

R e v .N o .

J543 11-T-503

Seth A. Duazo No. Req'd :

USED LUBE OIL Unit : Al Kharj, Saudi Arabia Model : NMC

Plot Plan No. :

Equipment No. :

11T-503

Mfr Ref. No. :

Design Engineer : Other Ref. Dwg No. :

Two

M G

125.30 Ft 46.00 Ft E L F N1

125.30 Cone

Feet Shell Height :

H

24" X 36" FLUSH CLEANOUT

E D

N2

J

46.00 Feet

I

Nominal Volume :

101,026

Barrels

Bottom Floor Type: Sp. Gr. : Cyclic

Sloped

NOZZLES/CONNECTIONS Qty 1 2 1 1 0 1 1 0 1 1 2 1 1 1 Size 24" 24" 24"x36" 8" 0 12" 8" 0 4" 4" 3/4" 3/4" 4" 3/4"

OPERATING/DESIGN DATA LUBE OIL

0.9000 5.5

psia Design 0.50 2.00

Mark TH1 TH TH2 G H B A K D M F F P D

Service Roof Manway Shell Manway Flush Cleanout MW Stilling Vent Temperature Indicator Outlet Nozzle Fill Nozzle Mixer Manway Water Draw Nozzle Top Center Vent Sample Tap Sample Tap Roof Nozzle Spare

28 This Tank Service is considered: 30 Flash Point (Closed Cup) : 31 Negative Pressure 32 Positive Pressure 33 (Hydro)test Pressure expressed in Psig 34 Minimum Fluid Temperature 35 Maximum Fluid Temperature 36 Emergency Vacuum Design ? 37 38 40 Roof 41 Lining/Coating 42 43 Stress Relieve ? 44 45 Code (as appl.): 46 Design Specifications: 47 Tank Insulation ? 48 Insulation Type: 49 Fireproofing ? 50 Remarks 51 52 No Hot No for: Component 39 Shell & Bottom Material A36 A36 No F F F

29 Vapor Pressure @ Max. Operating Temperature oz/in.2 psig 0.00 1.00

Operating

----25 200

Set @ CA, in. 0.0625 0.0313 0.0.3 oz/in.2

METALLURGY Remarks Normalized Normalized

Rating 150# 125# 125# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150#

Others: 120 Yes

Face F. F. R. F. R. F. F. F. L. J. API L. J. F. F. R. F. API R. F. F. F. L. J. API API API

CONSTRUCTION/FABRICATION

API 650 LATEST EDITION

Thickness : Paint Spec. in.

Internals (attach separate sheet, as req'd): Sump Seismic Zone Radiograph 85 EmptyTank Weight

Design Wind Velocity % Inspection Req'd ? lb Full of Water

mph lb

No

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator. 2. Rafter supported type cone roof

Approvals

Rev 0 Date Description J543 By Chk. Appr. Rev Date Description By Chk. Appr.

API 650 Storage Tank

08/20/2010 Rev: 0

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet 125.30 46.00

38.2 meters 14.0 meters

Shell Plate Design : FROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE SG = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance For First Course (Bottom) A36 Plate Provided ; thickness:

As per API 5.6.3.2 In US Customary units;

0.9 23,200 1.00 24,900 0.1180 20mm 0.569

160 Mpa 171 Mpa 3.00 mm

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St =

14.45 mm 14.95 mm 17.952 mm

0.589 td = Minimum shell course thickness plus C.A, in inches = 0.707 D = Normal tank diameter , in feet = 125.30 H = depth of tank , in feet = 46.00 SG = design Specific gravity of liquid = 1.00 Sd = allowable Stress for Design condition 23,200 E = joint efficiency 1.00 St = allowable stress A36 Hydro Test 24,900 CA = Corrosion Allowance 0.1180 For Second Course A36 Plate Provided thickness: 18.000 0.632

As per API 5.6.3.2 In US Customary units;

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St =

16.05 mm 14.95 mm 16.54 mm

0.589 td = Minimum shell course thickness plus C.A, in inches = 0.651 D = Normal tank diameter , in feet 125.30 H = depth of tank , in feet 39.45 SG = design Specific gravity of liquid = 1.00 Sd = allowable Stress for Design condition 23,200 E = joint efficiency 1.00 St = allowable stress A36 Hydro Test 24,900 CA = Corrosion Allowance 0.0625 For Third Course A36 Plate Provided thickness: 16.000 0.540

As per API 5.6.3.2 In US Customary units;

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St =

13.72 mm 12.78 mm 14.37 mm

0.503 td = Minimum shell course thickness plus C.A, in inches = 0.566 D = Normal tank diameter , in feet 125.30 H = depth of tank , in feet 32.91 SG = design Specific gravity of liquid = 1.00 Sd = allowable Stress for Design condition 23,200 E = joint efficiency 1.00 St = allowable stress A36 Hydro Test 24,900 CA = Corrosion Allowance 0.0625

Seth A. Duazo Nass Mechanical

Page 2 of 5

FileName: 38735700.xls WorkSheet: 11T-503A

API 650 Storage Tank

08/20/2010 Rev: 0

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet For Fourth Course A36 Plate Provided thickness:

As per API 5.6.3.2 In US Customary units;

125.30 46.00 12.000 0.488

38.2 meters 14.0 meters

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St =

12.40 mm 10.60 mm 12.19 mm

0.417 td = Minimum shell course thickness plus C.A, in inches = 0.480 D = Normal tank diameter , in feet 125.30 H = depth of tank , in feet 26.36 SG = design Specific gravity of liquid = 1.00 Sd = allowable Stress for Design condition 21,300 E = joint efficiency 1.00 St = allowable stress A36 Hydro Test 24,900 CA = Corrosion Allowance 0.0625 For Fifth Course A36 Plate Provided thickness: 10mm 0.388

As per API 5.6.3.2 In US Customary units;

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St =

9.85 mm 8.43 mm 10.02 mm

0.332 td = Minimum shell course thickness plus C.A, in inches = 0.394 D = Normal tank diameter , in feet 125.30 H = depth of tank , in feet 19.75 SG = design Specific gravity of liquid = 1.00 Sd = allowable Stress for Design condition 21,300 E = joint efficiency 1.00 St = allowable stress A36 Hydro Test 24,900 CA = Corrosion Allowance 0.0625 For Sixth Course A36 Plate Provided thickness: 8mm 0.258

As per API 5.6.3.2 In US Customary units;

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St =

6.56 mm 6.23 mm 7.82 mm

0.245 td = Minimum shell course thickness plus C.A, in inches = 0.308 D = Normal tank diameter , in feet 125.30 H = depth of tank , in feet 13.19 SG = design Specific gravity of liquid = 0.9 Sd = allowable Stress for Design condition 21,300 E = joint efficiency 1.00 St = allowable stress A36 Hydro Test 24,900 CA = Corrosion Allowance 0.0625 For Seventh Course A36 Plate Provided thickness: 8mm 0.187

As per API 5.6.3.2 In US Customary units;

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St =

4.74 mm 4.05 mm 5.64 mm

0.160 td = Minimum shell course thickness plus C.A, in inches = 0.222 D = Normal tank diameter , in feet 125.30 H = depth of tank , in feet 6.63 SG = design Specific gravity of liquid = 1 Sd = allowable Stress for Design condition 21,300 E = joint efficiency 1.00 St = allowable stress A36 Hydro Test 24,900 CA = Corrosion Allowance 0.0625 Seth A. Duazo Nass Mechanical Page 3 of 5

FileName: 38735700.xls WorkSheet: 11T-503A

API 650 Storage Tank

08/20/2010 Rev: 0

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet BOTTOM PLATE DESIGN:

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.4.1;

125.30 46.00

38.2 meters 14.0 meters

0.25 Minimum Nominal Thickness excluding corrosion allowance, Inch 0.13 Corrosion Allowance for Bottom Plate 0.25 Required Thickness of Bottom Plate 0.38 Used bottom plate thickness 70.87 Minimum Nominal Width, Inch 78.74 Used bottom plate Width,in ANNULAR BOTTOM PLATE DESIGN:

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.5.2;

6.35 mm 3.18 mm 6.35 mm 10 mm 1800.0 mm 2000.0 mm

tb Minimum Annular plate Width shall 215 be = ( GH )0.5 or a Minimum of Annular Plate width provided; in

28.62 23.62

727 mm 600 mm

29.92 760 mm Where: tb = Annular plate thickness, mm H = maximum Design Liquid level, Meter G = liquid Specific gravity

HENCE, OK.

ROOF PLATE DESIGN: ( Non Frangible roof Tank)

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.10.2.2,

Minimum Nominal Thickness excluding corrosion allowance = 0.19 0 Corrosion Allowance for Roof Plate, = 0.19 Required Thickness of Roof Plate = 0.19 Used roof plate thickness = SHELL STABILITY CHECK;

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.9.7.1

5 mm 0 mm 5 mm 5 mm

The Maximum height for the unstiffined shell shall be calculated as follows: H1 = 600,000*(t)*(((t/D)^3)^0.5)*(120 /V)^2 23.82

7.26 Meters Where; H1 = Vertical Distance in ft, betwwen the intermediate wind girder and the top angle of the shell or the top wi t = as built thickness, unless otherwise specified of the thinnest shell course (in Inches) D = Nominal Tank height, Ft V = Designed wind speed (3 sec gust)mph

Seth A. Duazo Nass Mechanical

Page 4 of 5

FileName: 38735700.xls WorkSheet: 11T-503A

API 650 Storage Tank

08/20/2010 Rev: 0

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet Equivalent stable height of shell at ' t ' min. HE = sum He He = W( ' t 'min / ' t 'actual)^2.5 As per API 650 11th Ed. 2009 Add. 2 Sect. V.8.1.4 (b) Course Width (M) t' min (mm) Wtr (Meter) 1 2 20.00 0.202 2 2 16.00 0.353 3 2 15.00 0.414 4 2.0 12.00 0.726 5 2.0 10.00 1.145 6 2.0 8.00 2.000 7 2.0 8.00 2.000 Minimum Shell Thickness = 8mm Transformed shell height, W' tr Maximum height of unstiffined shell= 125.30 46.00

38.2 meters 14.0 meters

6.840

Meters

7.26 Meters

H1 > Wtr, hence intermediate wind girder is not required

Seth A. Duazo Nass Mechanical

Page 5 of 5

FileName: 38735700.xls WorkSheet: 11T-503A

Вам также может понравиться

- Terrorist Explosives HandbooksДокумент35 страницTerrorist Explosives Handbooksdownload1414100% (3)

- API 650 Tank Design 5Документ31 страницаAPI 650 Tank Design 5gon972001Оценок пока нет

- A11Документ1 страницаA11liviu_dovaОценок пока нет

- Data Sheet For Silencer PDFДокумент3 страницыData Sheet For Silencer PDFAlvin Smith0% (1)

- 202517C-0000-JSD-1300-008-B - Piping Stres CalculationДокумент32 страницы202517C-0000-JSD-1300-008-B - Piping Stres CalculationHasan arif KısaalioğluОценок пока нет

- Storage Tank CALC Api 650Документ10 страницStorage Tank CALC Api 650kuselanml100% (3)

- API 650 Tank Design 1foot MethodДокумент4 страницыAPI 650 Tank Design 1foot Methodjakjak67% (3)

- API 650 Storage Tank DesignДокумент8 страницAPI 650 Storage Tank DesignCarey Rich67% (3)

- API 650 Crude Oil Storage Tank DesignДокумент8 страницAPI 650 Crude Oil Storage Tank Designlecongdinh100% (1)

- Weld DefectsДокумент78 страницWeld DefectsKevin CheungОценок пока нет

- Module 2 in Forensic BallisticsДокумент9 страницModule 2 in Forensic Ballisticscriminologyalliance100% (2)

- Step-by-step guide to WRC 107 and 297 nozzle stress checks in Caesar IIДокумент7 страницStep-by-step guide to WRC 107 and 297 nozzle stress checks in Caesar IIaap1Оценок пока нет

- Subcourse Edition FA 3117 B Us Army Field Artillery School Field Artillery Cannon AmmunitionДокумент153 страницыSubcourse Edition FA 3117 B Us Army Field Artillery School Field Artillery Cannon AmmunitionVicente VelezОценок пока нет

- ISRI Metal CodesДокумент56 страницISRI Metal CodesRusman Run100% (1)

- API 650 Tank Design 1Документ5 страницAPI 650 Tank Design 1Jose Ortiz100% (1)

- Storage Tank Design Calculations for Hydrogen PeroxideДокумент12 страницStorage Tank Design Calculations for Hydrogen Peroxidechompink6900Оценок пока нет

- Diesel Tank TaluksangayДокумент70 страницDiesel Tank TaluksangayBert EngОценок пока нет

- API 650 Tank Design CalculationДокумент8 страницAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- Premium TankДокумент26 страницPremium TankAnonymous p0iwBoОценок пока нет

- API Standard 650 Storage Tank Data SheetДокумент3 страницыAPI Standard 650 Storage Tank Data SheetLuis JaraОценок пока нет

- Tank Stability 10.0: Shell Dimension, NewДокумент4 страницыTank Stability 10.0: Shell Dimension, NewjonedОценок пока нет

- Etank Full ReportДокумент108 страницEtank Full ReportFaizal SattuОценок пока нет

- 20100419043934!el Chaguite Tank DesignДокумент37 страниц20100419043934!el Chaguite Tank DesignSana UllahОценок пока нет

- Storage Tank Alumnuim Roof - LatestДокумент22 страницыStorage Tank Alumnuim Roof - LatesthgagОценок пока нет

- API 650-Water SS Tank-060914Документ84 страницыAPI 650-Water SS Tank-060914A.K.M Shafiq MondolОценок пока нет

- 650-1001 Rev 0 - Shell Manhole Cover Flange ThicknessДокумент3 страницы650-1001 Rev 0 - Shell Manhole Cover Flange ThicknessShayan Hasan KhanОценок пока нет

- Compress EvaluateДокумент23 страницыCompress EvaluateVishalDhiman100% (1)

- New Storage Tanks Design GuidelinesДокумент6 страницNew Storage Tanks Design GuidelineschrisevabОценок пока нет

- API 650 Storage Tank TCA PreparationДокумент86 страницAPI 650 Storage Tank TCA PreparationBimal DeyОценок пока нет

- 7-12-0024 Rev 7Документ1 страница7-12-0024 Rev 7cynideОценок пока нет

- Piping Material Tracking (12-April-15)Документ22 страницыPiping Material Tracking (12-April-15)vishal bailurОценок пока нет

- Asme Sec. Viii Div-1) : THK - Calc. (Документ35 страницAsme Sec. Viii Div-1) : THK - Calc. (hardik5818Оценок пока нет

- Drawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013Документ4 страницыDrawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013chompink6900Оценок пока нет

- Preva: Pressure Vessels and Heat ExchangersДокумент6 страницPreva: Pressure Vessels and Heat ExchangersTrishul Nath PallayОценок пока нет

- AWS A5.12: Material Safety Data Sheet (MSDS)Документ3 страницыAWS A5.12: Material Safety Data Sheet (MSDS)Mani VannanОценок пока нет

- PTS Storge Tanks DesignДокумент1 страницаPTS Storge Tanks DesignFaiz AbdullahОценок пока нет

- 302 - Nozzle Design Tool Ver E4.01Документ2 страницы302 - Nozzle Design Tool Ver E4.01Honey TiwariОценок пока нет

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Документ1 страницаShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanОценок пока нет

- Technical Part 1 2 PDFДокумент301 страницаTechnical Part 1 2 PDFKumar Kousik Mondal50% (2)

- 7-12-0006 Rev6 (Angle Leg Support)Документ2 страницы7-12-0006 Rev6 (Angle Leg Support)sumit kumarОценок пока нет

- Design partition plate for refinery distillation columnДокумент5 страницDesign partition plate for refinery distillation columnpippo2378793Оценок пока нет

- Skills: Civil Engineer July 2012-PresentДокумент2 страницыSkills: Civil Engineer July 2012-Presentnirankush rathoreОценок пока нет

- Internal Floating Roof DesignДокумент38 страницInternal Floating Roof DesigncrnewsomОценок пока нет

- L&T GateGlobe&CheckValves-API 600Документ31 страницаL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- Sif B31 3Документ24 страницыSif B31 3vuqar0979100% (1)

- Asme Pipe Wall ThicknessДокумент3 страницыAsme Pipe Wall ThicknessYoke ShuОценок пока нет

- Sample Calculation For Ammonia Tank - API 620 11th EdДокумент43 страницыSample Calculation For Ammonia Tank - API 620 11th EdAde FaruroziОценок пока нет

- API 650 Baseplate DesignДокумент3 страницыAPI 650 Baseplate DesignmjlazoОценок пока нет

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetДокумент1 страницаPY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Оценок пока нет

- BS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, CladДокумент301 страницаBS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, CladPradip ShindeОценок пока нет

- WRC Check List CriteriaДокумент1 страницаWRC Check List CriteriaAlvin Smith100% (1)

- Pipe Span For PVC Pipe Span For CPVCДокумент1 страницаPipe Span For PVC Pipe Span For CPVCNag RajОценок пока нет

- New PA Column - THK CalcДокумент8 страницNew PA Column - THK CalcSabariMechyОценок пока нет

- Output Summary: SI UnitsДокумент42 страницыOutput Summary: SI UnitsAkhil JoseОценок пока нет

- Wind GrideДокумент18 страницWind GridehgagОценок пока нет

- DGS-2010-001 Design BasisДокумент19 страницDGS-2010-001 Design BasisJose ManjooranОценок пока нет

- Pipe Support Details SheetДокумент2 страницыPipe Support Details SheetSeungmin PaekОценок пока нет

- Sphere Design and Thickness Calculation (Div 2)Документ6 страницSphere Design and Thickness Calculation (Div 2)Asad KhanОценок пока нет

- API 650 Datasheet 1Документ16 страницAPI 650 Datasheet 1alwacsОценок пока нет

- Vessel Data SheetДокумент1 страницаVessel Data SheetMichael HaiseОценок пока нет

- API 650 Storage Tank Design CalculationsДокумент5 страницAPI 650 Storage Tank Design CalculationsFabian Nuñez Diaz100% (1)

- API 650 Tank Design 1Документ5 страницAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- API 650 Tank Design CalculationsДокумент8 страницAPI 650 Tank Design Calculationsツ ツОценок пока нет

- Hfo Service Tank - ht003 Data Sheet r1 PDFДокумент4 страницыHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013Оценок пока нет

- API 650 Tank Design CalculationsДокумент8 страницAPI 650 Tank Design CalculationsMohammed EljammalОценок пока нет

- API 650 Tank Design CalculationДокумент9 страницAPI 650 Tank Design CalculationSunday PaulОценок пока нет

- Static Cal 8m Dia CR Tank r2Документ22 страницыStatic Cal 8m Dia CR Tank r2samy7354Оценок пока нет

- Corrective Action ProgramДокумент42 страницыCorrective Action Programbc2255Оценок пока нет

- API Tank DesignДокумент189 страницAPI Tank DesignDD3NZ91% (11)

- Sample1 APVДокумент15 страницSample1 APVevrim77Оценок пока нет

- 3 Phase Test Separator 1 Compress)Документ161 страница3 Phase Test Separator 1 Compress)Indra JumenaОценок пока нет

- API Tank DesignДокумент189 страницAPI Tank DesignDD3NZ91% (11)

- ReadmeДокумент1 страницаReadmeMaheer JoefrieОценок пока нет

- Orifice Plate DrawingsДокумент11 страницOrifice Plate Drawingssamy7354Оценок пока нет

- At&v ProposalДокумент1 страницаAt&v Proposalsamy7354Оценок пока нет

- Root Cause Analysis PDFДокумент52 страницыRoot Cause Analysis PDFtkdrt2166Оценок пока нет

- 80% of Quranic Words (Classified Word Lists For Easy Memorization)Документ12 страниц80% of Quranic Words (Classified Word Lists For Easy Memorization)Reader100% (2)

- Query and manipulate AutoCAD drawingsДокумент107 страницQuery and manipulate AutoCAD drawingssamy7354Оценок пока нет

- H 29 03Документ33 страницыH 29 03samy7354Оценок пока нет

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Документ58 страницFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000Оценок пока нет

- Welding SymbolsДокумент26 страницWelding Symbolssamy7354Оценок пока нет

- Bottom Program OutlineДокумент2 страницыBottom Program Outlinesamy7354Оценок пока нет

- Afua Kwatemaa Obeng 11-26-07Документ1 страницаAfua Kwatemaa Obeng 11-26-07samy7354Оценок пока нет

- Prop Siemens Rev1 Piping Spools 070612Документ6 страницProp Siemens Rev1 Piping Spools 070612samy7354Оценок пока нет

- A511A511MДокумент9 страницA511A511Msamy7354Оценок пока нет

- A522A522MДокумент4 страницыA522A522Msamy7354Оценок пока нет

- ALCONДокумент5 страницALCONsamy7354Оценок пока нет

- A135A135MДокумент9 страницA135A135Msamy7354Оценок пока нет

- A210A210MДокумент3 страницыA210A210Msamy7354Оценок пока нет

- Addo-Yobo 7-16-07Документ2 страницыAddo-Yobo 7-16-07samy7354Оценок пока нет

- A209A209MДокумент3 страницыA209A209Msamy7354Оценок пока нет

- Tam Anulus Casing PackersДокумент20 страницTam Anulus Casing Packersallan_lennoxОценок пока нет

- Mark McCaslin Foam Bladder Tank 8-26-09Документ1 страницаMark McCaslin Foam Bladder Tank 8-26-09samy7354Оценок пока нет

- All Other CountriesДокумент10 страницAll Other Countriessamy7354Оценок пока нет

- Navy Field Manual Provides Tips for MMO Naval Battle GameДокумент61 страницаNavy Field Manual Provides Tips for MMO Naval Battle GameRobby HenrichsОценок пока нет

- Diagnostics For Dec 2022Документ3 страницыDiagnostics For Dec 2022RODOLFO JR. CASTILLOОценок пока нет

- Andrea Doria EnglishДокумент20 страницAndrea Doria Englishnex71Оценок пока нет

- World of Tanks Game Manual Com PDFДокумент74 страницыWorld of Tanks Game Manual Com PDFTrung ĐinhОценок пока нет

- 30mm X 173mm Ammunition: Superior Lethality For Ground and Sea PlatformsДокумент2 страницы30mm X 173mm Ammunition: Superior Lethality For Ground and Sea PlatformsDusmanul0% (1)

- Modelling Soft Body Impact On Composite Structures - (A. Johnson, M. Holzapfel)Документ11 страницModelling Soft Body Impact On Composite Structures - (A. Johnson, M. Holzapfel)pezz07Оценок пока нет

- Ammunition German Flak DetailsДокумент8 страницAmmunition German Flak DetailsenricoОценок пока нет

- RWBY - AlternateДокумент59 страницRWBY - AlternateManuela BuzovОценок пока нет

- Dwnload Full Food and Culture 7th Edition Sucher Test Bank PDFДокумент35 страницDwnload Full Food and Culture 7th Edition Sucher Test Bank PDFjulianpetershg58100% (14)

- Infernal MachinesДокумент247 страницInfernal MachinesChris100% (1)

- Wot Tact ItsДокумент15 страницWot Tact ItsDusan KekicОценок пока нет

- Ammunition Russia 37-40mmДокумент5 страницAmmunition Russia 37-40mmenrico100% (1)

- Achilles Alpha PDFДокумент1 страницаAchilles Alpha PDFDios DimoniОценок пока нет

- Defence Unexploded Ordnance Website Ordnance Information SheetДокумент2 страницыDefence Unexploded Ordnance Website Ordnance Information Sheetghoster33Оценок пока нет

- British 3.7inch Mountain HowitzerДокумент6 страницBritish 3.7inch Mountain HowitzerFrancescoОценок пока нет

- GunneryДокумент31 страницаGunneryStukaОценок пока нет

- The Dictionary of Military AbreviationsДокумент14 страницThe Dictionary of Military AbreviationsKhaledMadridiОценок пока нет

- Possible Causes of The Destruction of Ukrainian TanksДокумент39 страницPossible Causes of The Destruction of Ukrainian TanksdavidpradagarciaОценок пока нет

- 3P PDFДокумент33 страницы3P PDFTrilochan SahooОценок пока нет

- Everything You Need to Know About Ball MillsДокумент14 страницEverything You Need to Know About Ball MillsLaxman Kumar100% (1)

- Recommended Procedures for Mechanical Analysis of Rotary KilnsДокумент27 страницRecommended Procedures for Mechanical Analysis of Rotary KilnsMKPashaPasha100% (5)

- Intelligence Bulletin Jan 1945Документ93 страницыIntelligence Bulletin Jan 1945CAP History Library100% (1)

- Arcane Artillery - Firearms PDFДокумент9 страницArcane Artillery - Firearms PDFPaulo Arámburo100% (1)

- US Army WWII Tank Gunnery Field Manual 17-12-1943Документ109 страницUS Army WWII Tank Gunnery Field Manual 17-12-1943Jiří Adámek100% (1)

- 105MM Howitzer Motor Carriages M37. 187Документ124 страницы105MM Howitzer Motor Carriages M37. 187Dongelx0% (1)