Академический Документы

Профессиональный Документы

Культура Документы

Nitoflor ET Slurry

Загружено:

Venkata Raju KalidindiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Nitoflor ET Slurry

Загружено:

Venkata Raju KalidindiАвторское право:

Доступные форматы

Nitoflor ET Slurry

Heavy duty, flow applied, lightweight anti-skid surface dressing

Uses Nitoflor ET Slurry system provides a lightweight, yet extremely hardwearing anti-skid surface to a variety of substrates including steel, concrete, and timber. Ideally suited for foot and road bridges, RO linkspans, helicopter decks, work platforms, ships decks, car parks, walkways, wet work industrial areas etc. Special non-spark formulations and low flame spread make Nitoflor ET Slurry system especially suitable for offshore oil platforms. Advantages Lightweight - important in design consideration of bridges and while overlaying on old structures. Hard-wearing - proven ability to withstand the heaviest wear in locations around the world. Durable - excellent tensile, flexural strengths and good impact resistance. Properties Pot life at 300C Density Curing time at 300C Technical support 3.0 - 3.5mm Traffic density Light

constructive solutions

Medium 3.5 - 4.0mm

Heavy 4.0 - 5.0mm

Specially selected, hardwearing aggregates are broadcast onto this slurry whilst it is still wet to provide a lightweight, durable, anti-skid dressing. Choice of dressing aggregates is determined by the type and density of traffic expected. The thickness of the finished surface with dressing will be between 5- 8mm, depending upon the exact system chosen to meet the expected end use.

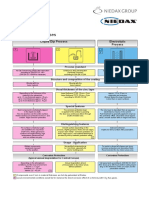

Fosroc is represented worldwide by technically trained personnel providing help and advice on material selection and application.

Excellent adhesion - to prepared steel surfaces and primed concrete substrates Resilient - reduces wear and tear to vehicle tyres and enhances riding comfort Non-slip - Excellent grip even when wet. Non reactive - Chemically resistant to oils, greases, hydraulic fluids and many other chemicals. Waterproof - Excellent corrosion protection to steel and concrete substrates Spark resistant - Zero spread of flame Description Nitoflor ET Slurry, a three component system is based on coal tar modified epoxy resins, amine curing agents and chemically inert, graded silica fillers which when mixed forms a fluid, homogenous slurry. The components of Nitoflor ET Slurry system are supplied in preweighed quantities ready to use on site. The thickness of the Nitoflor ET Slurry system is varied to suit traffic conditions :

Nitoflor ET Slurry

30 min. 1.78 - 1.85 g/cc Foot traffic after 24 hours, vehicular traffic after 48 hours. Fully cured Nitoflor ET Slurry system has been shown to be resistant to the following chemicals after continuous immersion for 3 months at 300C.

Chemical resistance

Petrol Kerosene Diesel Hydraulic fluids Dilute mineral acids and alkalis De-icing salts Aircraft fuel 10% urea in water Mechanical properties Compressive strength (N/mm 2) (BS 6319 Part 2 ) Tensile strength ( N/mm 2) (BS 6319 Part 7) Flexural strength (N/mm 2) (BS 6319 Part 3) 15 8 35

page 1 of 4

Nitoflor ET Slurry

Specification clauses

High performance topping All surfaces as detailed shall be treated to provide a hardwearing, waterproof, light weight, anti-skid surface suitable for the intended end use at a thickness of 3 mm for light duty traffic, 4mm for medium duty traffic and 5mm for heavy duty traffic at a coverage rate of 3.5 -3m2/pack, 3.0 2.5m2/pack, 2.5 - 2.0m2/pack respectively. It shall give a minimum compressive strength of 35N/mm 2 when tested as per BS 6319 part 2, a minimum tensile strength of 8N/mm2 when tested as per BS 6319 part 7, and a minimum flexural strength of 15N/mm2 when tested as per BS 6319 part 3. Nitoflor ET Slurry system is resistant to spread of flame when tested as per BS 476 part 7, clause 2, 1971. It shall be resistant to spillage of kerosene, petrol, diesel, hydraulic fluids, dil. mineral acids and alkalis, aircraft fuels and 10% urea in water. Application instructions Surface preparation Nitoflor ET Slurry system can be applied to a variety of substrates. As with all flooring materials or protective coatings, correct surface preparation is essential. Steel substrate : Nitoflor ET Slurry system is specially formulated to exhibit tenacious adhesion to unprimed steel. However, all steel substrates should be blast cleaned to a minimum SA 2 standard of cleanliness. An angular profile amplitude of atleast 75 microns is recommended. The slurry should be applied as quickly as possible to the blasted steel surface. If the standard of the surface falls below SA 2 then the steel must be reblasted. Concrete substrates : Nitoflor ETSlurry system is applied to clean, sound, dry concrete substrates which are free of any laitance, or loose particles. Mechanical scarifying or blasting methods are strongly recommended. Prepared concrete substrates should be primed with Nitoprime 25. The primer is applied by brush or lambswool roller to provide a thin even coverage. Avoid over application and puddles. Nitoflor ET Slurry system is applied onto the primer whilst it is still tacky.

Mixing Two liquid components shall be mixed thoroughly using a paddle attached to a heavy duty, slow speed drilling machine. The mineral fillers shall be added and mixed until a homogenous slurry consistency is formed. The total mixing operation should take about 3 minutes. The Nitoflor ET Slurry system is now ready for use. Thinners or solvent should not be added. Laying Once mixed the Nitoflor ET Slurry system must be used within the specified pot life. The slurry shall be poured onto the prepared surface. Work in lanes of 2-3m width, masking off edges with tape. The slurry shall be spread using a steel trowel or squeegee taking particular care when joining up to previous day's work. Use of a wet film gauge is recommended to ensure the correct thickness and material usage. The chosen surface dressing aggregate must be applied immediately after laying Nitoflor ET Slurry system. The slurry coating is blinded to saturation by allowing the aggregate to fall vertically until no slurry is visible. Throwing aggregates at an angle over the slurry may cause ridges. Masking tape must be removed before the coating has cured. The Nitoflor ET Slurry system must be allowed to cure for 24 hours at 300C before being subject to traffic. At lower temperatures this period will be increased. Once it is clean and dry, excess dressing aggregate can be removed with a broom and reused after the initial curing period. Cleaning All tolls can be cleaned immediately after use with Nitoflor Sol, solvent. Limitations Temperature limitations Recommended application range is 150C to 350C. Fosroc shall be contacted, if application or service temperatures are outside this range.

constructive solutions

page 2 of 4

Nitoflor ET Slurry

Application limitations Minimum ambient temperature : 15 C Maximum humidity : 75% at 25 C ( Moisture content 5%) Substrate temperature Estimating Supply Nitoflor ET Slurry system Nitoprime 25 Nitoflor Sol Coverage Nitoflor ET Slurry Thickness mm 3.0 4.0 5.0 5.5 - 6.5 m2/ltr Coverage m2/litre 0.33 0.25 0.20 : : : 11 Litres 1&4 Litre 20 Litre : 15 0C minimum

0 0

Precautions

Health & Safety instructions Since some people are sensitive to epoxy resins and cleaning solvents, the use of protective clothing, gloves, proprietary barrier creams and eye goggles is recommended. If contact with resins or solvents occur, the affected area shall be cleaned with resin removing creams followed by washing with soap and water. Washing the resin with solvent is not suggested. In the case of eye contact, it shall be washed thoroughly with clean water and medical advice shall be sought immediately. Fire Nitoflor Sol, solvent is flammable. Ensure adequate

ventilation. Use near naked flame is not suggested. Smoking is prohibited during application/ handling of the product. Flash points (Abel closed cup) Nitoflor Sol, solvent Nitoflor ET Slurry base : : 33 0C above 500C above 400C 25 0C

Light traffic Medium traffic Heavy traffic Nitoprime 25

Nitoflor ET Slurry hardener: Nitoprime 25, primer :

The above coverages are for indication purpose only and vary depending on the nature and texture of surface of application.

Additional information In addition, the Nitoflor range of industrial flooring products include concrete hardeners, resin floor coatings, toppings and screeds designed to meet most requirements of modern industrial environments. For further information contact the local Fosroc office.

Storage

Shelf life Nitoflor ET Slurry system and Nitoprime 25 primer have a shelf life of 12 months when stored in warehouse conditions below 350C.

constructive solutions

page 3 of 4

Nitoflor ET Slurry

Fosroc Chemicals (India) Pvt. Ltd.

Head Office Sapthagiri Palace, No.38, II & III Floor, 12th Cross, CBI Road, Ganganagar North, Bangalore 560 032

Important note : Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice, recommendation specification or information it may give is accurate and correct, it cannot, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products whether or not in accordance with any advice, specification, recommendation or information given by it.

telephone ++91 80-23551500 fax ++91 80-23551510 e-mail enquiryindia@fosroc.com

Regional Offices

Bangalore

Sapthagiri Palace, No. 38 II & III Floor, 12th Cross, CBI Road, Ganganagar North, Bangalore 560 032. Ph:080-23551500 Fax : 080-23551510

Mumbai

1401/1402, 14 Floor, A-WingThe Great Eastern Summit Sector-15, CBD, Belapur Navi Mumbai 400 614 Ph: 022 -43406800-04

Noida

D-166 Sector 10 Noida, UP 201 301 Ph:0120-4270620

Kolkata

304, Jodhpur Park Kolkata 700 068 Ph:033-65343188 Fax: 033-2499-0280

www.fosroc.com

page 4 of 4

INDIA/2011/0614/D

Вам также может понравиться

- Nitoflor ET Slurry PDFДокумент4 страницыNitoflor ET Slurry PDFriverwilliamsОценок пока нет

- Nitoflor EPU1000Документ4 страницыNitoflor EPU1000Venkata Raju KalidindiОценок пока нет

- Conbextra EP75Документ4 страницыConbextra EP75Venkata Raju KalidindiОценок пока нет

- Cicol EtslurryДокумент4 страницыCicol EtslurryVenkata RaoОценок пока нет

- Nitoseal® 200Документ4 страницыNitoseal® 200Venkata Raju KalidindiОценок пока нет

- Nitoseal 290Документ4 страницыNitoseal 290shanon33Оценок пока нет

- Cicol Et SlurryДокумент3 страницыCicol Et SlurryBalasubramanian Ananth100% (1)

- Thioflex 600Документ4 страницыThioflex 600Conifer YuОценок пока нет

- Conbextra EP10Документ4 страницыConbextra EP10Venkata Raju KalidindiОценок пока нет

- Nitoseal 280: Heavy Duty Epoxy Urethane Joint SealantДокумент2 страницыNitoseal 280: Heavy Duty Epoxy Urethane Joint SealantVenkata Raju KalidindiОценок пока нет

- Conbextra EP300Документ4 страницыConbextra EP300Venkata Raju KalidindiОценок пока нет

- Nitomortar S: High Strength, Abrasion - Resistance Epoxy Reinstatement MortarДокумент4 страницыNitomortar S: High Strength, Abrasion - Resistance Epoxy Reinstatement MortarVenkata Raju KalidindiОценок пока нет

- Nitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningДокумент4 страницыNitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningkalidindivenkatarajuОценок пока нет

- Nitoseal 280Документ2 страницыNitoseal 280shanon33Оценок пока нет

- Cicol Et SlurryДокумент3 страницыCicol Et Slurrypravi3434Оценок пока нет

- Nitoflor SL Cond-DissДокумент4 страницыNitoflor SL Cond-DissVenkata Raju KalidindiОценок пока нет

- Nitoflor EU5Документ4 страницыNitoflor EU5Venkata Raju KalidindiОценок пока нет

- Conbextra EP10Документ4 страницыConbextra EP10Binoy Sankar SarkerОценок пока нет

- Nitoseal PU 280 PDFДокумент2 страницыNitoseal PU 280 PDFhelloitskalaiОценок пока нет

- Nitozinc Primer: Two Component Epoxy Zincrich PrimerДокумент4 страницыNitozinc Primer: Two Component Epoxy Zincrich PrimerVenkata Raju KalidindiОценок пока нет

- Conbextra Ep75Документ4 страницыConbextra Ep75Sathiya SeelanОценок пока нет

- Thioflex 600: Multi-Component, Gun and Pouring Grade Polysulphide SealantДокумент5 страницThioflex 600: Multi-Component, Gun and Pouring Grade Polysulphide Sealantalbukharir100% (1)

- Nitoproof 600Документ4 страницыNitoproof 600sandeepuaeОценок пока нет

- Thioflex 600 PDFДокумент4 страницыThioflex 600 PDFmilanbrasinaОценок пока нет

- Nitoproof 600Документ4 страницыNitoproof 600Venkata RaoОценок пока нет

- Nitocote EN901Документ4 страницыNitocote EN901kalidindivenkatarajuОценок пока нет

- Nitowrap EP (CF) : High Performance High Strength, Carbon Fibre System For Structural StrengtheningДокумент4 страницыNitowrap EP (CF) : High Performance High Strength, Carbon Fibre System For Structural StrengtheningkalidindivenkatarajuОценок пока нет

- Jotafloor: Traffic Deck SystemДокумент12 страницJotafloor: Traffic Deck SystemUnited Construction Est. TechnicalОценок пока нет

- Nitoseal 200Документ4 страницыNitoseal 200shanon33Оценок пока нет

- Nitoproof 600 PDFДокумент4 страницыNitoproof 600 PDFmilanbrasinaОценок пока нет

- Thioflex 600 24.1115Документ4 страницыThioflex 600 24.1115hunngurrОценок пока нет

- Nitoseal 125-130Документ2 страницыNitoseal 125-130shanon33Оценок пока нет

- Thioflex 600 Gun Grade TDSДокумент3 страницыThioflex 600 Gun Grade TDSDevendra100% (1)

- Conbextra EP10TGДокумент2 страницыConbextra EP10TGBambang SasikiranaОценок пока нет

- Conbextra EP10Документ2 страницыConbextra EP10MuhammedHafis100% (1)

- Nitocote NT550Документ4 страницыNitocote NT550Venkata Raju KalidindiОценок пока нет

- Nitofill EPLV: Low Viscous Epoxy Injection Resin GroutДокумент2 страницыNitofill EPLV: Low Viscous Epoxy Injection Resin GroutkalidindivenkatarajuОценок пока нет

- Nitoproof 600Документ4 страницыNitoproof 600Balasubramanian AnanthОценок пока нет

- Nitoproof 100Документ2 страницыNitoproof 100Balasubramanian AnanthОценок пока нет

- Nitoflor Tf120 UbДокумент3 страницыNitoflor Tf120 UbtalatzahoorОценок пока нет

- Nitoproof 100 PDFДокумент2 страницыNitoproof 100 PDFmilanbrasinaОценок пока нет

- Fosroc Nukote ST: Constructive SolutionsДокумент4 страницыFosroc Nukote ST: Constructive SolutionsRaj PatelОценок пока нет

- Nitomortar TC2000Документ3 страницыNitomortar TC2000MuhammedHafis100% (1)

- TDS Nitomortar TC2000 Saudi ArabiaДокумент3 страницыTDS Nitomortar TC2000 Saudi ArabiaHarry BawingОценок пока нет

- Nitobond Ep..Документ4 страницыNitobond Ep..budhikurniawanОценок пока нет

- Nitozinc PrimerДокумент4 страницыNitozinc Primervenkatasuri999Оценок пока нет

- Nitomortar TC2000Документ3 страницыNitomortar TC2000grtunaОценок пока нет

- Jotafloor Traffic Deck System BrochureДокумент12 страницJotafloor Traffic Deck System BrochurehutuguoОценок пока нет

- Nitoseal 290Документ4 страницыNitoseal 290Venkata RaoОценок пока нет

- 2537 Data Sheet Lok FixДокумент4 страницы2537 Data Sheet Lok FixkamalxdОценок пока нет

- Nitowrap FRP600Документ4 страницыNitowrap FRP600Venkata Raju KalidindiОценок пока нет

- Nitoflor FC150Документ4 страницыNitoflor FC150Venkata Raju KalidindiОценок пока нет

- Conbextra EP300Документ3 страницыConbextra EP300Tori SmallОценок пока нет

- (PDS) Conbextra EP300Документ4 страницы(PDS) Conbextra EP300Faizal HaziziОценок пока нет

- Sikaflex PRO 3 WFДокумент4 страницыSikaflex PRO 3 WFfrahliaОценок пока нет

- AG 15400 Steelmaster+120SB Euk GBДокумент10 страницAG 15400 Steelmaster+120SB Euk GBparathasiОценок пока нет

- Nitoprime 25 (M) : Epoxy Resin Based Primer For Concrete SurfacesДокумент2 страницыNitoprime 25 (M) : Epoxy Resin Based Primer For Concrete SurfacesVenkata Raju KalidindiОценок пока нет

- Application Guide - Jotafloor EP GlassFlakeДокумент8 страницApplication Guide - Jotafloor EP GlassFlakeKenji TanОценок пока нет

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionОт EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionОценок пока нет

- Understanding Dashboards in P6 PDFДокумент52 страницыUnderstanding Dashboards in P6 PDFsh2awaaОценок пока нет

- San Jose Police CalcsДокумент91 страницаSan Jose Police Calcscancery0707Оценок пока нет

- Bostik BoscolasticДокумент2 страницыBostik BoscolasticVenkata Raju KalidindiОценок пока нет

- CurtainДокумент257 страницCurtainvranceanu100% (13)

- Building AnalysisДокумент58 страницBuilding AnalysisVenkata Raju KalidindiОценок пока нет

- Electrical Estimation & Costing PDFДокумент36 страницElectrical Estimation & Costing PDFecruz_yhwh75% (12)

- Renderoc HSXtraДокумент2 страницыRenderoc HSXtraVenkata Raju KalidindiОценок пока нет

- Conplast SD110Документ2 страницыConplast SD110Venkata Raju KalidindiОценок пока нет

- Renderoc LAXtra PlusДокумент2 страницыRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- SP21Документ506 страницSP21Venkata Raju Kalidindi100% (1)

- SP40Документ135 страницSP40SourabhAdikeОценок пока нет

- Conplast SP430SRVДокумент2 страницыConplast SP430SRVVenkata Raju KalidindiОценок пока нет

- Conplast SP500Документ2 страницыConplast SP500Venkata Raju KalidindiОценок пока нет

- Hocut 795 Article by Hank LimperДокумент4 страницыHocut 795 Article by Hank LimperLORENZO GOMEZОценок пока нет

- Ball Bearing Manufacturing Process 130930021744 Phpapp01Документ15 страницBall Bearing Manufacturing Process 130930021744 Phpapp01Athul MuraliОценок пока нет

- Kalcret InsulationДокумент16 страницKalcret Insulationgechaves1Оценок пока нет

- The RMA Rubber HandbookДокумент62 страницыThe RMA Rubber Handbookjonathan6657Оценок пока нет

- Acid Resistant Tiles BricksДокумент6 страницAcid Resistant Tiles BricksDeboline MitraОценок пока нет

- Verbal Sample PaperДокумент8 страницVerbal Sample PaperSachin PratapОценок пока нет

- CH 12Документ2 страницыCH 12onlydlonly100% (2)

- PPC RKRczsДокумент68 страницPPC RKRczstrickytratzОценок пока нет

- Lubritech Range BrochureДокумент18 страницLubritech Range BrochurecakhokheОценок пока нет

- Job Costing: Mcgraw-Hill/IrwinДокумент17 страницJob Costing: Mcgraw-Hill/Irwinimran_chaudhryОценок пока нет

- Gleaming Zinc Coating: Trust Corium FORДокумент2 страницыGleaming Zinc Coating: Trust Corium FORFraz AhmadОценок пока нет

- Planetary Gearbox Reference Whole SetДокумент86 страницPlanetary Gearbox Reference Whole SetEncik Wan Janra SaflianОценок пока нет

- Wall Ties FormworkДокумент96 страницWall Ties FormworkJack Jeff0% (1)

- List of Smes in ChennaiДокумент32 страницыList of Smes in ChennaiThakkali Kuttu100% (1)

- Galvanizing Processes: Liquid Dip Process Electrolytic ProcessДокумент3 страницыGalvanizing Processes: Liquid Dip Process Electrolytic ProcessAlin MoicaОценок пока нет

- 32-SAMSS-004 Manufacture of Pressure VesselsДокумент50 страниц32-SAMSS-004 Manufacture of Pressure VesselsEhab HarbОценок пока нет

- 5 Benefits of Using An Mes For Pharma & Biotech ManufacturingДокумент4 страницы5 Benefits of Using An Mes For Pharma & Biotech ManufacturingsomethingОценок пока нет

- Improvement in Durability of Ferrocement Using Fly Ash and Silica Fume Modified MortarДокумент4 страницыImprovement in Durability of Ferrocement Using Fly Ash and Silica Fume Modified MortarijsretОценок пока нет

- Asahi India GlassДокумент12 страницAsahi India GlassAman ChandelОценок пока нет

- VS 6 - FlowserveДокумент8 страницVS 6 - FlowserveJung Jae YualОценок пока нет

- WMC568Документ30 страницWMC568vali_ecsОценок пока нет

- Report On Importing To South AfricaДокумент19 страницReport On Importing To South AfricaNadine KadriОценок пока нет

- ThermoFisher Company AnalysisДокумент14 страницThermoFisher Company AnalysisGijoОценок пока нет

- Plaster Assemblies Chapter 04 Three Coat Plaster Guide SpecificationsДокумент19 страницPlaster Assemblies Chapter 04 Three Coat Plaster Guide SpecificationsUzma Nooreen Vahidy ZainОценок пока нет

- Company Profile Krona Liquatec LTD: Providing WATER SOLUTIONS ForДокумент4 страницыCompany Profile Krona Liquatec LTD: Providing WATER SOLUTIONS Forkher_sumitОценок пока нет

- Sika PDS - E - SikaTop Armatec - 110 EpoCemДокумент2 страницыSika PDS - E - SikaTop Armatec - 110 EpoCemlwin_oo2435Оценок пока нет

- Business Model of ShipyardДокумент3 страницыBusiness Model of Shipyardpramod1989Оценок пока нет

- Space Frame AssemblyДокумент4 страницыSpace Frame Assemblymoytabura96Оценок пока нет

- Lecture 19 Rapid Prototyping Concept, Advantages PDFДокумент15 страницLecture 19 Rapid Prototyping Concept, Advantages PDFRishabh MendirattaОценок пока нет

- Sunken SlabДокумент2 страницыSunken SlabAlexLionОценок пока нет