Академический Документы

Профессиональный Документы

Культура Документы

Training: Safety: Weighing Options

Загружено:

babis1980Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Training: Safety: Weighing Options

Загружено:

babis1980Авторское право:

Доступные форматы

December 2000

!Valves and

the CE Mark

www.chemicalprocessing.com

Safety Training:

Weighing the Options

VA LV E S

Understanding the

CE Mark

By Michael C. Headley, P.E.

and Europes

Pressure Equipment Directive Whats all the fuss?

ou see it on toys, voltmeters and guitars. It seems the CE mark is on everything.

And the mark soon will be on some control valves as well. After May 29, 2002, all pressure equipment within the scope of the Pressure Equipment Directive (PED)1 will be required to have a CE mark to freely enter the European Economic Area (EEA).2 The PED will add some out-of-pocket expenditures for both EEA and non-EEA manufacturers. But what does this mean for valve customers in the United States? Will they get a different valve than what is shipped to Europe? Does the CE mark signify a higher quality product? Does it signify a safer product? Not since ISO has a simple acronym caused so much confusion. This article explains what the CE mark does and does not mean.

1. Directive 97/23/EC of the European Parliament. 2. Includes Austria, Belgium, Denmark, Finland, France, Germany, Great Britain, Greece, Iceland, Ireland, Italy, Liechtenstein, Luxembourg, Netherlands, Norway, Portugal, Spain and Sweden. 3. After publication, directives allow manufacturers a two-and-one-half-year transition period to gear up. During this time, no manufacturer can place a CE mark on their product. After this time period, manufacturers can place the CE mark on their products voluntarily. For the PED, the two-and-onehalf-year date was Nov. 30, 1999.

the treaty, the ability to trade goods freely still did not exist because the laws of each member state differed. A manufacturer was required to have its products tested and approved in several member states, which truly caused a trade barrier. Imagine not being able to ship from Iowa to Wisconsin because of different technical codes and standards! Directives became the mechanisms to overcome these trade barriers. Besides creating an open market for product movement, directives remove technical barriers by harmonizing standards and imposing consistent requirements for safety. Failure to meet a directive is a criminal offense that can result in fines, impounding of product or imprisonment. After acceptance by the European Commission and Parliament, a directive is published in the Official Journal of the European Community (OJEC). A directive becomes mandatory five years after its publication.3 There are many directives low-voltage (LVD), electromagnetic compatibility (EMC) and explosive atmospheres (ATEX), to name a few but the one that has most valve manufacturers concerned and end users confused is the PED. The directive was adopted on May 29, 1997, which means pressure equipment must be in compliance by May 29, 2002.

Explaining the CE mark A brief history

In 1957, a group of European countries, called member states, signed the Treaty of Rome to achieve a single European market. The treaty created what became known as the Four Freedoms, which established a system where people, finances, services and goods could move freely across borders. Following ratification of The CE acronym stands for Conformit Europenne, which is French for European Conformity. It represents a unified Europe in the Four Freedoms, one of which calls for the free movement of goods. The CE mark allows product access and free movement of goods throughout the EEA. It is not a certification or approval mark. It is not a quality mark, and it is not intended to be used as a tool for promotion. Instead, it indicates the product conforms to the essential requirements of the applicable directive(s). For the PED, the CE mark implies that the manufacturer of the pressure equipment has taken into account all hazards resulting from pressure and has met the safety requirements outlined in the directive.

Reprinted from Chemical Processing, December 2000

VA LV E S

PRESSURE EQUIPMENT DIRECTIVE

Product

-design -manufacture -materials

Inside the PED

There are 21 articles and six annexes in the PED. They cover areas that affect how a manufacturer designs; qualifies suppliers, weld and NDE personnel and procedures; sources and orders material; manufactures product; ensures traceability; provides operating instructions; and documents the process. Although it has similarities to ISO, the PED is much more comprehensive. Like ISO 9001, Annex I of the PED deals with both product design and the manufacturing process. Specifically, Annex I of the PED outlines the essential safety requirements (ESRs) that cover the products design, construction materials and manufacturing methods. Like ISO 9002, Annex III of the PED deals with the process and conformity assessment procedures (see the figure). But unlike ISO, the PED ensures products are produced at a consistent level of safety, not quality. The PED applies to the design, manufacture and conformity assessment of pressure equipment having a maximum allowable pressure greater than 0.5 bar (7.25 psig). The directive defines four types of pressure equipment: vessels, piping, safety accessories and pressure accessories. Control valves, for instance, fall under pressure accessories because they have a pressurebearing housing and operational function. Depending on its type, size4 and the type of fluid,5 the equipment is placed into a category that defines the degree of hazard resulting from pressure. The higher the category number, the higher the risk and level of required conformity assessment (see the table). Annex II includes conformity assessment procedures. These are modules6 levels of conformity assessment that detail what quality assessment (QA) criteria are required and classify auditing and inspection criteria. Equipment that is not seen as a significant risk because of pressure falls into the Sound Engineering Practice (SEP) category. Pressure equipment in the SEP category which is a function of the size and application must be designed and manufactured using recognized codes and standards. SEP products do not and cannot bear the CE mark. Notified bodies are responsible for assessing a manufacturers conformity. They are appointed by a member states government to act as independent third

Process

PED

ISO 9001

-conformity assessment

Ann

ex I

ISO 9002 III x e n n A

The PED encompasses more than ISO compliance requirements.

parties to ensure the design and manufacture of pressure equipment are safe. The notified bodies are the final authorities on interpretation of the PED and assessment. Their involvement varies, according to the category and chosen assessment module. Examples of notified bodies are Lloyds Register and TV.

CE and the end user

Both valve manufacturers and notified bodies are learning how to comply with the PED. Because the PED is now in the transitional period, manufacturers can comply voluntarily, but are not obligated to do so until the May 29, 2002, deadline. If the product falls into the SEP category, the product cannot bear the CE mark. For all practical purposes, a valve of 1 inch or smaller, regardless of pressure and application fluid, falls into the SEP category. Although customers may perceive it as such, the CE mark is not a certification, approval or mark of quality. While indirectly related to quality, the CE mark is primarily associated with safety. For the PED, it is associ4. If volume is more a factor than DN size, as in an ated with safety regarding actuator, then volume is used. pressure-related hazards. The CE mark is not to be 5. The PED defines two fluid groups: Group 1 as used as a marketing tool dangerous (toxic, flammable, etc.) and Group 2 as to enhance sales. not dangerous. The PED is a man6. Defines the quality requirements needed to satisfy date for products enterthe category level. ing the EEA, but what

Reprinted from Chemical Processing, December 2000

VA LV E S

Pressure-Related Hazard Categories

Level of hazard resulting from pressure SEP Explanation

Products with the lowest hazard resulting from pressure. Manufacturers simply must use good engineering practices with recognized codes and standards. The product must not bear the CE mark. Allows the manufacturer to self-certify, but it must keep a technical file and deliver a conformity certification. No notified body involvement. The product must bear the CE mark. Quality assurance (QA) approval or surveillance by a notified body. Requires the manufacturer to ensure the quality of the product by using a certified production QA system audited by a notified body. The product must bear the CE mark. Type examination or design examination and surveillance by a notified body or QA approval. Requires the manufacturer to have a QA system along with certification of the product design by a notified body. Having a full QA design and production system (ISO 9001) that has been audited by a notified body also can satisfy this level. The product must bear the CE mark. Type examination and verification by a notified body meet this requirement. This category poses the greatest pressure-related hazard. Safety relief valves automatically are placed into this category. The requirements are similar to those of Category III, with the addition of surveillance by a notified body and certified type tests.

Category I

Category II

Category III

Category IV

mandate from the European Commission to prepare Harmonized European Standards, not all of them will be issued before the May 29, 2002, deadline. So in reality, manufacturers of pressure equipment have only one option: to satisfy the ESRs outlined in Annex I of the PED. Multiple directives may apply to the same item. For example, an industrial process (I/P) transducer would need to comply with both the EMC and ATEX directives. Although there is some overlap, the PED goes into greater depth than ISO about how the manufacturer designs and qualifies suppliers, procedures, welders and NDE personnel. It also covers such items as material traceability, labeling and operating instructions. The general public and end users alike want to be free from fears related to pressure equipment failure. It is up to the manufacturer of such equipment to design and produce products that will not endanger others. The PED is the most comprehensive compliance vehicle in place, and by using European-appointed independent third parties to review the manufacturers design, manufacturing processes, materials and suppliers, the CE mark should help minimize the risk of hazards resulting from pressure.

Additional Guidance

More information about the CE mark and the PED can be found in the following resources:

q

about other countries? Can a non-EEA customer request it? It is possible, but because part of the goal of the directive is to harmonize technical standards for free trade across EEA borders, it makes no sense for non-EEA countries to require it. The CE mark should not become a boilerplate specification that is added because customers perceive they are getting a betterquality product. Non-EEA customers should not feel they are getting an inferior product if the product does 7. Published in the OJEC, they are a special subset not display the CE mark. of European standards that begin with the preface Unfortunately, achievEN, for European Norm. The EN standards ing compliance is not easy. have particular relevance to the ESRs. The use of a Manufacturers have only published harmonized standard (EN) in the design two ways to comply: They and manufacture of a product will give the precan meet the Harmonized sumption of conformity to those ESRs listed in European Standards7 or Annex ZA of the particular harmonized standard. follow the PED. Although If a harmonized standard exists, it may be used to CEN, the European standards-making body, has a comply with the PED.

D350812X012

q q

The Web site for ORGALIME, a European federation of national industry associations representing the mechanical, electrical, electronic and metals industries, www.orgalime.org. The PED Information Resources Centre, http://ped. eurodyn.com. The European Unions Web site, www.europa.eu.int. Valve Purchasers Guide to the European Pressure Equipment Directive, Engineering Equipment and Materials Users Association (EEMUA), Publication No. 196,1999. Official Journal of the European Communities, Directive 97/23/EC, 181, Vol. 40, July 9, 1997.

Headley is a senior engineer for Fisher Controls International Inc., Marshalltown, Iowa. He can be contacted by e-mail at michael.headley@frco.com.

Reprinted from Chemical Processing, December 2000

Вам также может понравиться

- PED and CE MarkingДокумент4 страницыPED and CE Markingdhanu_aquaОценок пока нет

- IPU Pressure Equipment Directive Handbook 2017 02Документ32 страницыIPU Pressure Equipment Directive Handbook 2017 02kanhuОценок пока нет

- CE Markings - SummaryДокумент2 страницыCE Markings - SummaryALOKE GANGULYОценок пока нет

- Pressure Equipment CBI - EU - CE - PEDДокумент12 страницPressure Equipment CBI - EU - CE - PEDShafqatiqbal100% (1)

- CE Markings GuideДокумент8 страницCE Markings GuideALOKE GANGULYОценок пока нет

- What Are The Directives That Allow For CE MarkingДокумент3 страницыWhat Are The Directives That Allow For CE MarkingALOKE GANGULYОценок пока нет

- CE Marking Guidance by UK GovtДокумент9 страницCE Marking Guidance by UK GovtMuhammad AtifОценок пока нет

- What Does The Ce Marking Process Look Like?Документ6 страницWhat Does The Ce Marking Process Look Like?Đặng ĐăngОценок пока нет

- CE Marking On Pressure GaugesДокумент3 страницыCE Marking On Pressure Gaugesssmith2007Оценок пока нет

- 247.01.0920.en - Ept Ped-Infosheet FinalДокумент2 страницы247.01.0920.en - Ept Ped-Infosheet Finalyasev63801Оценок пока нет

- Ce Marking ProcessДокумент3 страницыCe Marking ProcesszsmithОценок пока нет

- Ce Marking DirectivesДокумент3 страницыCe Marking DirectivesALOKE GANGULYОценок пока нет

- CE Marking Fact Sheet 12.17Документ2 страницыCE Marking Fact Sheet 12.17Manohar T MОценок пока нет

- 6 Steps To CE Marking in EuropeДокумент16 страниц6 Steps To CE Marking in EuropeEU Chamber Of Commerce in Canada-WestОценок пока нет

- CE Marking Does Our Product Qualify For CE Marking If It Has UL And/or CSA Approval?Документ4 страницыCE Marking Does Our Product Qualify For CE Marking If It Has UL And/or CSA Approval?44abcОценок пока нет

- Guidline For Medical Products To Be CE MarkedДокумент10 страницGuidline For Medical Products To Be CE MarkedMuhammad AtifОценок пока нет

- Pressure Equipment Directive: Certification and ConformityДокумент20 страницPressure Equipment Directive: Certification and ConformitymohdfirdausОценок пока нет

- Unit 05: 1. Risk Category and Assessment ModulesДокумент13 страницUnit 05: 1. Risk Category and Assessment ModulesJorgeОценок пока нет

- Ped Pressure Equipment Certification PDFДокумент8 страницPed Pressure Equipment Certification PDFProkopОценок пока нет

- CEAlertBrochure3 Latest Eg Main 017276Документ6 страницCEAlertBrochure3 Latest Eg Main 017276MarcTimОценок пока нет

- CEMarking PDFДокумент9 страницCEMarking PDFniteen123Оценок пока нет

- The European Pressure Equipment Directive (PED)Документ2 страницыThe European Pressure Equipment Directive (PED)ManivannanMudhaliarОценок пока нет

- Information Leaflet For Pressure Eguipment-EnДокумент8 страницInformation Leaflet For Pressure Eguipment-Enbabis1980Оценок пока нет

- OrgalimeДокумент18 страницOrgalimeRoger BoursОценок пока нет

- 2011 EU Legislation Transportable Pressure EquipmentДокумент8 страниц2011 EU Legislation Transportable Pressure EquipmentemilasanovskiОценок пока нет

- Learn More About PED, TPED and Hydrostatic Certificate: 2.1 Intention of The PEDДокумент4 страницыLearn More About PED, TPED and Hydrostatic Certificate: 2.1 Intention of The PEDEmdad YusufОценок пока нет

- Ped Training 2019Документ131 страницаPed Training 2019bmanojkumar16Оценок пока нет

- Cen TR 13480-7 (2002) (E)Документ6 страницCen TR 13480-7 (2002) (E)g9g9Оценок пока нет

- What Is ISO 17712Документ9 страницWhat Is ISO 17712arvindranganathanОценок пока нет

- Ce Marking: Bureau Veritas ServicesДокумент2 страницыCe Marking: Bureau Veritas ServicesanilОценок пока нет

- Tuv Rheinland Personal Protective Equipment Testing Faq enДокумент2 страницыTuv Rheinland Personal Protective Equipment Testing Faq enking_electricalОценок пока нет

- What Needs To Be in A Technical FileДокумент2 страницыWhat Needs To Be in A Technical FileAisha MughalОценок пока нет

- Safety Footwear Ce MarkingДокумент8 страницSafety Footwear Ce Markingmarius_brkt6284Оценок пока нет

- Ped - 1237-1-Uk (EC Direktiva Za Akumulatorje)Документ12 страницPed - 1237-1-Uk (EC Direktiva Za Akumulatorje)kocho79Оценок пока нет

- Formal Requirements For CE-marked ProductsДокумент2 страницыFormal Requirements For CE-marked ProductsEric GrdОценок пока нет

- Velosi Insert 1Документ4 страницыVelosi Insert 1api-3703379Оценок пока нет

- Which Products That Need CE Marking CertificationДокумент9 страницWhich Products That Need CE Marking CertificationECTОценок пока нет

- Guide For Securing of Fuel Dispensers: (Measuring Systems For Liquids Other Than Water)Документ12 страницGuide For Securing of Fuel Dispensers: (Measuring Systems For Liquids Other Than Water)ابوالحروف العربي ابوالحروفОценок пока нет

- Personnel Certification For ThermographersДокумент4 страницыPersonnel Certification For Thermographersg mailОценок пока нет

- CE Marking Information Sheet: A World Leader in CertificationДокумент4 страницыCE Marking Information Sheet: A World Leader in CertificationymagОценок пока нет

- European Product Safety Directives & CE Marking: A Guide For Manufacturers and ImportersДокумент6 страницEuropean Product Safety Directives & CE Marking: A Guide For Manufacturers and ImporterszaheerОценок пока нет

- PED Presentation MaterialДокумент39 страницPED Presentation Materialyoonchankim0911100% (1)

- CE Marking and Product Lab Testing A Practical GuideДокумент7 страницCE Marking and Product Lab Testing A Practical GuidezsmithОценок пока нет

- IECEE Brochure LRДокумент24 страницыIECEE Brochure LRjayantskatheОценок пока нет

- BS en 12266-1 PDFДокумент7 страницBS en 12266-1 PDFKaushik Sengupta20% (5)

- White Paper - IsO 13485Документ14 страницWhite Paper - IsO 13485Gisela Cristina MendesОценок пока нет

- 0E159 PressureEquipment 0912 FinalДокумент2 страницы0E159 PressureEquipment 0912 Finaljontylee87Оценок пока нет

- ISO Technical Committee 104, Freight Containers: Implementation of Tamper-Evident Testing in Accordance With ISO 17712Документ2 страницыISO Technical Committee 104, Freight Containers: Implementation of Tamper-Evident Testing in Accordance With ISO 17712LK BMKG TP2019Оценок пока нет

- 2019 May Bulk-OnlineДокумент12 страниц2019 May Bulk-OnlineRey Eduard Q. UmelОценок пока нет

- CE Marking: Apply To Your Specific Product)Документ4 страницыCE Marking: Apply To Your Specific Product)Oguz ErkulОценок пока нет

- PED LeafletДокумент4 страницыPED LeafletMalcolm DadinaОценок пока нет

- Pressure Equipment White Paper FinalДокумент8 страницPressure Equipment White Paper FinalarissaОценок пока нет

- Medical Devices and IVDs: Fit for the new EU-Regulations: Your complete seminar for projekt, study and jobОт EverandMedical Devices and IVDs: Fit for the new EU-Regulations: Your complete seminar for projekt, study and jobОценок пока нет

- Form Information Document Manufacturers ENG (Version 01032018) Finalized 2Документ13 страницForm Information Document Manufacturers ENG (Version 01032018) Finalized 2Ezgi BalciogluОценок пока нет

- IECEE - Brochure - Taking Conformity Assessment FurtherДокумент20 страницIECEE - Brochure - Taking Conformity Assessment FurtherPhoenix PhosphorescentОценок пока нет

- BS en 1090 Certification ProcessДокумент5 страницBS en 1090 Certification ProcessALOKE GANGULYОценок пока нет

- CR 13445-7-2002-OtklДокумент23 страницыCR 13445-7-2002-OtklVasko MandilОценок пока нет

- WP8 BSI MD ISO 13485 Proposed Changes Whitepaper UK enДокумент14 страницWP8 BSI MD ISO 13485 Proposed Changes Whitepaper UK endocuОценок пока нет

- 1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013Документ2 страницы1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013babis1980Оценок пока нет

- Non-Circular Pressure Vessels SquareДокумент27 страницNon-Circular Pressure Vessels SquareAbhilash Kurian100% (1)

- Plastic Pipe - PE - Chapter01Документ9 страницPlastic Pipe - PE - Chapter01garisa1963Оценок пока нет

- FUSION MANUAL - Rev IllustrationsДокумент36 страницFUSION MANUAL - Rev IllustrationsMehmet SoysalОценок пока нет

- FRL SIF 618 CompressedAirDryingДокумент36 страницFRL SIF 618 CompressedAirDryingbabis1980Оценок пока нет

- White Paper RBIДокумент12 страницWhite Paper RBImahesh070Оценок пока нет

- GF Type 546 BallДокумент10 страницGF Type 546 Ballbabis1980Оценок пока нет

- The Condensate, The Boiler Feed, and Their Auxiliary SystemsДокумент70 страницThe Condensate, The Boiler Feed, and Their Auxiliary Systemsbabis1980100% (1)

- StainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerДокумент14 страницStainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerbabis1980Оценок пока нет

- P&IDДокумент18 страницP&IDhectornicolauОценок пока нет

- Orifice Plate Flow MetersДокумент8 страницOrifice Plate Flow MetersGaurav Dhiman100% (1)

- How To Select A Pump-By Majid HamedyniaДокумент72 страницыHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Galvanic CorrosionДокумент2 страницыGalvanic CorrosionkeronsОценок пока нет

- PPG Minimizing The Effects of CorrosionДокумент9 страницPPG Minimizing The Effects of Corrosionbabis1980Оценок пока нет

- Tech Manual Electrical Power Plant DesignДокумент135 страницTech Manual Electrical Power Plant Designd_kabulpuriaОценок пока нет

- Energy Saving in Steam Systems.Документ34 страницыEnergy Saving in Steam Systems.babis1980Оценок пока нет

- Sa 312Документ1 страницаSa 312babis1980Оценок пока нет

- Ejector BrochureДокумент8 страницEjector Brochurebabis1980Оценок пока нет

- Ati 317Документ13 страницAti 317babis1980Оценок пока нет

- Chapter IIIДокумент19 страницChapter IIIghostamirОценок пока нет

- What's New in API 610 11th EditionДокумент4 страницыWhat's New in API 610 11th Editionshyam_anupОценок пока нет

- Brochure ACCДокумент8 страницBrochure ACCbabis1980Оценок пока нет

- Fundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Документ199 страницFundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Anshul JainОценок пока нет

- Advanced GE CCPPДокумент20 страницAdvanced GE CCPPR Krishna KumarОценок пока нет

- Introduction To Gas Turbines For Non-EngineersДокумент9 страницIntroduction To Gas Turbines For Non-EngineersKrishna MyakalaОценок пока нет

- Veizades Gas Removal Systems Liquid Ring VPДокумент3 страницыVeizades Gas Removal Systems Liquid Ring VPVenkatespatange RaoОценок пока нет

- Ideal Bearing Temp LimitsДокумент1 страницаIdeal Bearing Temp Limitsbabis1980Оценок пока нет

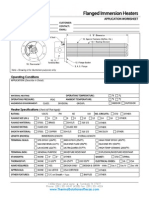

- Flanged Immersion Heaters: Operating ConditionsДокумент1 страницаFlanged Immersion Heaters: Operating Conditionsbabis1980Оценок пока нет

- ATEX Reference GuideДокумент2 страницыATEX Reference Guidebabis1980Оценок пока нет

- 4.24 Drains Systems Design PhilosophyДокумент8 страниц4.24 Drains Systems Design Philosophybabis1980Оценок пока нет

- Samandar Bagh SP College Road, Srinagar: Order No: S14DSEK of 2022Документ1 страницаSamandar Bagh SP College Road, Srinagar: Order No: S14DSEK of 2022Headmasterghspandrathan GhspandrathanОценок пока нет

- (Ebook - Health) Guide To Health InsuranceДокумент28 страниц(Ebook - Health) Guide To Health InsuranceAndrei CarlanОценок пока нет

- Rfso S A0011749958 1Документ3 страницыRfso S A0011749958 1Marian DimaОценок пока нет

- Case Report Cirilo Paredes V EspinoДокумент2 страницыCase Report Cirilo Paredes V EspinoJordan ProelОценок пока нет

- Directions: Answer The Following Questions. Write Your Final Answer in Simplest Form. 1Документ1 страницаDirections: Answer The Following Questions. Write Your Final Answer in Simplest Form. 1chad lowe villarroyaОценок пока нет

- K. A. Abbas v. Union of India - A Case StudyДокумент4 страницыK. A. Abbas v. Union of India - A Case StudyAditya pal100% (2)

- Information Assurance and Security II Lectures Quizzes and Activities Compress 1Документ26 страницInformation Assurance and Security II Lectures Quizzes and Activities Compress 1Jireh SalinasОценок пока нет

- En Banc G.R. No. L-16439 July 20, 1961 ANTONIO GELUZ, Petitioner, vs. The Hon. Court of Appeals and Oscar Lazo, RespondentsДокумент6 страницEn Banc G.R. No. L-16439 July 20, 1961 ANTONIO GELUZ, Petitioner, vs. The Hon. Court of Appeals and Oscar Lazo, Respondentsdoc dacuscosОценок пока нет

- Eada Newsletter-May-2015 (Proof3)Документ2 страницыEada Newsletter-May-2015 (Proof3)api-254556282Оценок пока нет

- AMCTender DocumentДокумент135 страницAMCTender DocumentsdattaОценок пока нет

- Professional Practice of Accounting With AnswerДокумент12 страницProfessional Practice of Accounting With AnswerRОценок пока нет

- Hydrostatic Testing of Control ValvesДокумент34 страницыHydrostatic Testing of Control ValvesMuhammad NaeemОценок пока нет

- Fraud Detection and Deterrence in Workers' CompensationДокумент46 страницFraud Detection and Deterrence in Workers' CompensationTanya ChaudharyОценок пока нет

- Family Budget': PSP 3301 Household Financial Management Assignment 4Документ2 страницыFamily Budget': PSP 3301 Household Financial Management Assignment 4DenzNishhKaizerОценок пока нет

- Filipino ValuesДокумент26 страницFilipino ValuesDan100% (14)

- ReservationsДокумент30 страницReservationsplasmadragОценок пока нет

- Julius Caesar - Gallic War Bilingual - 10 First PagesДокумент12 страницJulius Caesar - Gallic War Bilingual - 10 First PagesTyrex: Psychedelics & Self-improvementОценок пока нет

- Carta de Intencion (Ingles)Документ3 страницыCarta de Intencion (Ingles)luz maria100% (1)

- Subercaseaux, GuillermoДокумент416 страницSubercaseaux, GuillermoMarco Cabesour Hernandez RomanОценок пока нет

- Understanding The 2007-2008 Global Financial Crisis: Lessons For Scholars of International Political EconomyДокумент23 страницыUnderstanding The 2007-2008 Global Financial Crisis: Lessons For Scholars of International Political EconomyLeyla SaidОценок пока нет

- Hall 14 FOC Indemnity FormДокумент4 страницыHall 14 FOC Indemnity FormXIVfocОценок пока нет

- The Criminal Procedure (Identification) Act, 2022 A Constitutional CritiqueДокумент28 страницThe Criminal Procedure (Identification) Act, 2022 A Constitutional CritiqueArunОценок пока нет

- Interconnect 2017 2110: What'S New in Ibm Integration Bus?: Ben Thompson Iib Chief ArchitectДокумент30 страницInterconnect 2017 2110: What'S New in Ibm Integration Bus?: Ben Thompson Iib Chief Architectsansajjan9604Оценок пока нет

- UK (Lloyds Bank - Print Friendly Statement1)Документ2 страницыUK (Lloyds Bank - Print Friendly Statement1)shahid2opuОценок пока нет

- Sotto v. Mijares - 28 SCRA 17 (1969) & Meat Packing Corp.#59 SCRAДокумент4 страницыSotto v. Mijares - 28 SCRA 17 (1969) & Meat Packing Corp.#59 SCRANadzlah BandilaОценок пока нет

- EssayДокумент3 страницыEssayapi-358785865100% (3)

- Apostolic United Brethren Standards For Members/YouthДокумент60 страницApostolic United Brethren Standards For Members/YouthKatie JoyОценок пока нет

- Henry E. Prunier v. Commissioner of Internal Revenue, 248 F.2d 818, 1st Cir. (1957)Документ7 страницHenry E. Prunier v. Commissioner of Internal Revenue, 248 F.2d 818, 1st Cir. (1957)Scribd Government DocsОценок пока нет

- LR Approved Manufacturers of Steel Castings 100104 PDFДокумент41 страницаLR Approved Manufacturers of Steel Castings 100104 PDFmaxwell onyekachukwuОценок пока нет

- Position Paper in Purposive CommunicationДокумент2 страницыPosition Paper in Purposive CommunicationKhynjoan AlfilerОценок пока нет