Академический Документы

Профессиональный Документы

Культура Документы

Modes of Failure

Загружено:

Sagar PawarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Modes of Failure

Загружено:

Sagar PawarАвторское право:

Доступные форматы

MODES OF FAILURE IN FIBER REINFORCEMENT COMPOSITES Fibers are the principal load-carrying members, while the surrounding matrix

keeps them in the desired location and orientation, acts as a load transfer medium between them, and protects them from environmental damages due to elevated temperatures and humidity etc. Thus, even though the fibers provide reinforcement for the matrix, the latter also serves a number of useful function s in a fiber -reinforced composite material.

Modes of failure: For a body under the application of an arbitrary stress state the three most important modes of failure are; Axial tensile failure Transverse tensile failure Shear failure 01. Axial tensile Failure:

Fig 2.01: Axial tensile failure

It is assumed that both the fibers and matrix deform elastically and subsequently undergo brittle fracture. There are two cases of failure a) The matrix has the lower failure b) The fiber has the lower failure strain

a) The matrix has the lower failure strain When the strain reaches ultimate failure strain of the matrix, the matrix undergoes micro cracking and the load is progressively transferred to the fibers as cracking continues. During this stage there is little increase in composite stress with increasing strain. With further crack growth, if the entire load is transferred to the fibers before fiber fracture. If the fibers fail before the entire load is transferred onto them the composite strength is just the weighted average of the failure stress of the matrix, the matrix failure stress and the fiber stress at the onset of matrix cracking. b) The fiber has the lower failure strain When the strain reaches ultimate failure strain in fiber, the fibers fail. Beyond this point the load is progressively transferred to the matrix as the fibers fracture into shorter lengths. Assuming that the fibers bear no load when their aspect ratios are below the critical aspect ratio which is the critical ratio of the fiber length to its diameter below which the fiber cannot undergo any further fracture, and then composite failure occurs at an applied stress. Alternatively, if the matrix fracture takes place while the fibers are still bearing some load, i.e. the fiber aspect ratio is more than the critical value, then the composite failure stress is the weighted average of the fiber failure stress, and the matrix stress at the onset of fiber fracture.

02. Transverse tensile failure:

Fig 2.02: Transverse tensile failure

The presence of fibers reduces the transverse strength and the failure strain significantly relative to the unreinforced matrix. This observed tendency is largely due to high local stresses and strains around the fiber / matrix interface due to differences in the Young's Module of the two components. Because of that composites get fail

03. Shear failure

Fig 2.03: Shear Failure

When structural elements are subjected to compressive loads, the shear forces and stresses induced by second order effects may lead to shear failure prior to compressive failure this is particularly likely to occur in the case of glass fiber reinforced polymer profiles which normally exhibits low shear strength on relation to compressive strength.

Вам также может понравиться

- Advertisement For Walk-in-Interview For Appointment of Temporary Faculty MembersДокумент2 страницыAdvertisement For Walk-in-Interview For Appointment of Temporary Faculty MembersSagar PawarОценок пока нет

- Differentiation - GATE Study Material in PDFДокумент6 страницDifferentiation - GATE Study Material in PDFSupriya SantreОценок пока нет

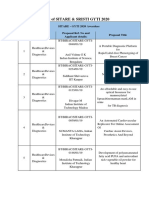

- Result of SITARE & SRISTI GYTI 2020: SITARE - GYTI 2020 Awardees Proposal Ref. No and Applicant Details: Proposal TitleДокумент10 страницResult of SITARE & SRISTI GYTI 2020: SITARE - GYTI 2020 Awardees Proposal Ref. No and Applicant Details: Proposal TitleSagar PawarОценок пока нет

- Ani Me Payaryanvar Vat Bagat Basen Tu Ghari YeiparyantДокумент1 страницаAni Me Payaryanvar Vat Bagat Basen Tu Ghari YeiparyantSagar PawarОценок пока нет

- Artificial Immune System Approach To Flexible Manufacturing SystemДокумент1 страницаArtificial Immune System Approach To Flexible Manufacturing SystemSagar PawarОценок пока нет

- Presentation Meraj Electromagnetic JoiningДокумент16 страницPresentation Meraj Electromagnetic JoiningSagar PawarОценок пока нет

- International Conference on Advancements in Mechanical and Materials Engineering (Dec 2019Документ1 страницаInternational Conference on Advancements in Mechanical and Materials Engineering (Dec 2019Sagar PawarОценок пока нет

- Ganeshostav IITG "Ganpati Bappa Morya"Документ3 страницыGaneshostav IITG "Ganpati Bappa Morya"Sagar PawarОценок пока нет

- Reeg Jobs Notification AMPRI Recruitment 2018 Scientist GR IV 10 Posts PDFДокумент6 страницReeg Jobs Notification AMPRI Recruitment 2018 Scientist GR IV 10 Posts PDFSagar PawarОценок пока нет

- Aluminum Properties Density Yield Stress ModulusДокумент1 страницаAluminum Properties Density Yield Stress ModulusSagar PawarОценок пока нет

- Computer Integrated ManufacturingДокумент6 страницComputer Integrated ManufacturingSagar PawarОценок пока нет

- First Acc Abstract ContainДокумент3 страницыFirst Acc Abstract ContainSagar PawarОценок пока нет

- Vertical Milling AttachmentДокумент30 страницVertical Milling AttachmentSagar PawarОценок пока нет

- Theoryproduct Design and DevelopmentДокумент9 страницTheoryproduct Design and DevelopmentSagar PawarОценок пока нет

- Report of Laser MachiningДокумент1 страницаReport of Laser MachiningSagar PawarОценок пока нет

- S HigleyДокумент592 страницыS HigleySagar PawarОценок пока нет

- Wind Power ApplicationДокумент13 страницWind Power ApplicationSagar PawarОценок пока нет

- Material HandlingДокумент5 страницMaterial HandlingSagar PawarОценок пока нет

- Matlab - An Introduction To MatlabДокумент36 страницMatlab - An Introduction To MatlabHarsh100% (2)

- Modes of FailureДокумент4 страницыModes of FailureSagar PawarОценок пока нет

- Industriam EnggДокумент29 страницIndustriam EnggSagar PawarОценок пока нет

- Euler Savary EquationДокумент21 страницаEuler Savary EquationVineeth S VinnyxtremeОценок пока нет

- Intro and Applications of Fiber Reinforcement CompositesДокумент3 страницыIntro and Applications of Fiber Reinforcement CompositesSagar PawarОценок пока нет

- Goal Setting - DeepakДокумент3 страницыGoal Setting - DeepakSagar PawarОценок пока нет

- Iugaza Tom2012 - CH1-5Документ95 страницIugaza Tom2012 - CH1-5Sagar PawarОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Biopolymers/Natural polymers structure and propertiesДокумент78 страницBiopolymers/Natural polymers structure and propertiesgautamahujaОценок пока нет

- Occurrence of Arsenic Contamination in Canada: Sources, Behavior and DistributionДокумент21 страницаOccurrence of Arsenic Contamination in Canada: Sources, Behavior and Distributionespirilo1659100% (1)

- 1.2. All Four Biomolecules V2Документ112 страниц1.2. All Four Biomolecules V2Clàudia VicenteОценок пока нет

- Kinetic Modeling of A Modified Claus Reaction Furnace: Pollock, Aaron EllsworthДокумент182 страницыKinetic Modeling of A Modified Claus Reaction Furnace: Pollock, Aaron Ellswortharmita rezapourОценок пока нет

- SPE 124733 Holistic Design of Cement Systems To Survive CO EnvironmentДокумент11 страницSPE 124733 Holistic Design of Cement Systems To Survive CO Environmentatilio martinezОценок пока нет

- BiokimiaДокумент3 страницыBiokimiaLilis TuslinahОценок пока нет

- CHAPTER 3 - Crystalline Structure of SolidsДокумент63 страницыCHAPTER 3 - Crystalline Structure of SolidsAlex HunterОценок пока нет

- CupramonniumДокумент5 страницCupramonniumAditya ShrivastavaОценок пока нет

- ZEOLITEДокумент13 страницZEOLITEShubham Yele100% (1)

- Solubility Product Constant and Gravimetric Analysis: Chem 2Документ53 страницыSolubility Product Constant and Gravimetric Analysis: Chem 2Mary Jane Libo-onОценок пока нет

- Micellar Catalysis Reaction RateДокумент4 страницыMicellar Catalysis Reaction RatedarkknightoneОценок пока нет

- Ace General Chemistry 1 and 2Документ187 страницAce General Chemistry 1 and 2Ari Singh100% (2)

- Cambridge International General Certificate of Secondary EducationДокумент4 страницыCambridge International General Certificate of Secondary EducationSOLOОценок пока нет

- Huckel's Rule and Aromatic CompoundsДокумент16 страницHuckel's Rule and Aromatic CompoundsOfudje Edwin AndrewОценок пока нет

- Week - q1 State of MatterДокумент21 страницаWeek - q1 State of Matterjustine alinaОценок пока нет

- Incompatible Chemicals: Safety Basics & RAMPДокумент2 страницыIncompatible Chemicals: Safety Basics & RAMPRei Paxley ChristofОценок пока нет

- Molecules: Mechanochemical and Size Reduction Machines For BiorefiningДокумент22 страницыMolecules: Mechanochemical and Size Reduction Machines For BiorefiningBryan AlbornozОценок пока нет

- Beneficiation of Azara Barite Ore Using A Combination of Jigging, Froth Flotation and LeachingДокумент6 страницBeneficiation of Azara Barite Ore Using A Combination of Jigging, Froth Flotation and LeachingPhilips UchennaОценок пока нет

- 10 5923 J Ijme 20140406 01 PDFДокумент7 страниц10 5923 J Ijme 20140406 01 PDFVizzy VishalОценок пока нет

- A-En MoviPol-5 IMДокумент58 страницA-En MoviPol-5 IMFabien CazesОценок пока нет

- CHM271 - Tutorial 6 - Phase EquilibriumДокумент5 страницCHM271 - Tutorial 6 - Phase Equilibriumfiefy zmrОценок пока нет

- 2021 ClassificationДокумент11 страниц2021 ClassificationSora RoseОценок пока нет

- Stoichiometry 5Документ5 страницStoichiometry 5sophiaccharlotte876Оценок пока нет

- 2012 Petruccietal Afeasibilitystudy CETДокумент7 страниц2012 Petruccietal Afeasibilitystudy CETMuhammad RehanОценок пока нет

- 6CH04 01 Que 20160614Документ17 страниц6CH04 01 Que 20160614snoopyОценок пока нет

- Enrichment, Isolation and Counting of Soil MicroorganismsДокумент69 страницEnrichment, Isolation and Counting of Soil MicroorganismsRedd ZhuangОценок пока нет

- SPE-164128-MS James JohnstoneДокумент20 страницSPE-164128-MS James JohnstoneOilfieldJimОценок пока нет

- Diagnostic Cytology Methods and Purpose: de Vera, Jim Ericson F. March 23, 2018 Bmls Histopathology: Tue / 7:00-9:00Документ3 страницыDiagnostic Cytology Methods and Purpose: de Vera, Jim Ericson F. March 23, 2018 Bmls Histopathology: Tue / 7:00-9:00Rashedah MartinОценок пока нет

- Análisis de Triclosán y 4n-Nonilfenol en El Reservorio Colombiano de Agua Por Cromatografía de Gases-Espectrometría de MasasДокумент9 страницAnálisis de Triclosán y 4n-Nonilfenol en El Reservorio Colombiano de Agua Por Cromatografía de Gases-Espectrometría de MasasMaria AlvarezОценок пока нет

- 120 Exam 2 Fa10 KeyДокумент4 страницы120 Exam 2 Fa10 KeymchdeleonОценок пока нет