Академический Документы

Профессиональный Документы

Культура Документы

Lo 5-6115-440-12

Загружено:

AdvocateИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lo 5-6115-440-12

Загружено:

AdvocateАвторское право:

Доступные форматы

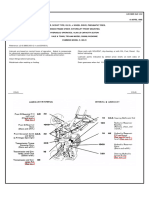

LUBRICATION

ORDER L05-6115-440-12 1 JULY 1968

GENERATOR SET, GASOLINE ENGINE 7.5 KW, DC, 28 V; TWO-WIRE;

AIR COOLED; WHEEL MOUNTED,(JOHN R HOLLINGSWORTH CO.

MODEL JHGV7.5A) W/ WISCONSIN ENGINE MODEL MVH4D

Reference: C9100-lL

IntervaIs are based on normal hours of operations. Adjust Clean parts with SOLVENT, dry-cleaning, or with OIL, fuel,

to compensate for abnormal operations and severe condi- DieseI. Dry before Iubricating.

tions. During inactive periods, sufficient Iubrication must

be performed for adequate preservation.

Lubricate points indicated by dotted arrow shafts on both

Clean fittings before lubricating. sides of equipment.

Relubricate after washing. Drain crankcase when hot. FIII and check level.

FOLD

. —

LUBRICANT ● INTERVAL INTERVAL ● L U B R I C A N T

Air Cleaner OE 10 OE Crankcase FiII Cap

(See key.) (Refill (See key)

oil reservoir to level CAUTION: When OES

mark. Every 100 hours, 0il iS used the level

dissassemble entire will be checked more

unit, clean, reoil, often.

and reassemble.)

10 Crankcase Level Goge

Starter Generator

(Check level.)

(Sealed Bearings;

No Lubrication Re-

quired)

100 0il Filter

(see note 3)

Wheel Bearings GAA 1000

(Remove wheel, clean,

Inspect and lubricate 50 Crankcase Drain Plug

bearings and reassem- (Drain md refill.)

ble)

(See note 4)

-KEY-

EXPECTED TEMPERATURES

LUBRICANTS CAPACITY INTERVALS

Above + 32 F 0

+ 40 F to - 10 0 F

o

O 0F tO - 6 50 F

OE-OIL, Engine, Heovy Duty

Cronkcase 5 qts. Intervals

OE 30 OE 10 OES given are

Air Cleaner 1 qt.

in hours of

Oil Can Points normal

operation

OES-OIL, Engine, Sub-zero

GAA-Grease, Automotive & Artillery ALL TEMPERATURES

NOTES:

1. FOR OPERATION OF EQUIPMENT IN PROTRACTED Copy of this Lubrication Order will remain with the equip-

COLD TEMPERATURES BELOW - 1 00F. Remove lubri- ment at alI times; instructions contained herein are mando-

cants prescribed in the key for temperatures above - 100F. tory.

Relubricate with lubricants specified in the key for tempe-

ratures below - 100F . BY ORDER OF THE SECRETARY OF THE ARMY:

2. OIL CAN POINTS. Every 50 hours, lubricate Iinkage

pins, clevises and all exposed threads with OE.

3. OIL FILTERS. Every 100 hours, remove filter ele-

HAROLD K. JOHNSON,

ments, clean housings; install new element, fill crankcase,

Generol, United States Army,

operote engine for 5 minutes, check for leaks, check crank-

Chief of Staff.

case oil level, and bring to a full mark.

4. WHEEL BEARINGS. Every 1000 hours, remove wheels,

inspect all parts, replace damaged or worn parts, repack

bearings and reassemble. OFFICIAL:

5. LUBRICANTS. The following is a list of lubricants

with the Military Symbols and applicable specification

numbers. KENNETH G. WICKHAM,

OE MIL-L-2104 GAA MIL-G-10924 Major General, United States Army,

OES MlL-L-10295 The Adjutant General.

FOLD

PIN: 020606-000

LO 5-6115-440-12

Вам также может понравиться

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- 029933Документ3 страницы029933Хелфор УкраинаОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Lubrication Order: Total Task-Hr Total Task-Hr Interval Task-Hr Interval Task-Hr 10 0.5 250 0.1 50 0.4 1000 0.5 100 0.5Документ6 страницLubrication Order: Total Task-Hr Total Task-Hr Interval Task-Hr Interval Task-Hr 10 0.5 250 0.1 50 0.4 1000 0.5 100 0.5SteveОценок пока нет

- 029934Документ3 страницы029934Хелфор УкраинаОценок пока нет

- 055508Документ8 страниц055508Хелфор УкраинаОценок пока нет

- 22 February 84: LO 10-3930-243-12 Card 1 of 4Документ10 страниц22 February 84: LO 10-3930-243-12 Card 1 of 4Хелфор УкраинаОценок пока нет

- 054930Документ8 страниц054930Хелфор УкраинаОценок пока нет

- Perkins-A4 318Документ29 страницPerkins-A4 318Mahdi JafaryОценок пока нет

- Laundry Unit, Single Trailer Mounted W/Canvas Cover Army Type M532 (Eidal MDL Elt9T & Edro MDL Ep120Ltu)Документ3 страницыLaundry Unit, Single Trailer Mounted W/Canvas Cover Army Type M532 (Eidal MDL Elt9T & Edro MDL Ep120Ltu)pavannnОценок пока нет

- Total Task-Hr Total Task-Hr: Card 1 of 2Документ6 страницTotal Task-Hr Total Task-Hr: Card 1 of 2SteveОценок пока нет

- 19 July 1984: Total Man-Hours Total Man-Hours Interval Man-Hours Interval Man-HoursДокумент6 страниц19 July 1984: Total Man-Hours Total Man-Hours Interval Man-Hours Interval Man-HoursХелфор УкраинаОценок пока нет

- 19 July 1994Документ8 страниц19 July 1994Хелфор УкраинаОценок пока нет

- Oil and Filter: InspectionДокумент36 страницOil and Filter: Inspectionkywheat3306Оценок пока нет

- 2AZ-FE LubricationДокумент22 страницы2AZ-FE LubricationAdedeji OluwatobilobaОценок пока нет

- MAINTENANCE CHECKLISTДокумент13 страницMAINTENANCE CHECKLISTPreett Rajin MenabungОценок пока нет

- Oil and FilterДокумент22 страницыOil and FilterAdhi NugrohoОценок пока нет

- Johnson 6HP 1965-68Документ8 страницJohnson 6HP 1965-68Brtnik1100% (1)

- Service Manual Susuki Baleno Sy418Документ395 страницService Manual Susuki Baleno Sy418juanmahepa75% (4)

- 055766Документ8 страниц055766Хелфор УкраинаОценок пока нет

- Engine Oil (Checking The Level) : WarningДокумент4 страницыEngine Oil (Checking The Level) : WarningPhạm Hoài MinhОценок пока нет

- 5vz Fe LubricationДокумент21 страница5vz Fe LubricationHenry SilvaОценок пока нет

- Basic MaintenanceДокумент23 страницыBasic MaintenancePedro Lucas Rodrigues QueirozОценок пока нет

- 015352Документ8 страниц015352Хелфор УкраинаОценок пока нет

- Lister Cs Manual PDFДокумент16 страницLister Cs Manual PDFMASSERONОценок пока нет

- Hydraulic Austoft9900 - ENДокумент146 страницHydraulic Austoft9900 - ENSugeng Ariyadi100% (1)

- Toyota Land Cruiser 1998 2007 Lubrication System Service ManualДокумент2 страницыToyota Land Cruiser 1998 2007 Lubrication System Service Manualadrienne100% (42)

- WBHE ManualДокумент3 страницыWBHE ManualBruno DelgadoОценок пока нет

- Lubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingДокумент159 страницLubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingpoiufdsapuroiqОценок пока нет

- MaintenanceДокумент30 страницMaintenanceVictor HemzОценок пока нет

- CPP Pagina 47Документ48 страницCPP Pagina 47LuisОценок пока нет

- 14H GraderДокумент1 страница14H GraderMohamed SaiedОценок пока нет

- SECTION 2-General Maintanance PDFДокумент18 страницSECTION 2-General Maintanance PDFDidin Delgado0% (1)

- 01 August 1984Документ6 страниц01 August 1984Хелфор УкраинаОценок пока нет

- Machinery Selection-Books14Документ16 страницMachinery Selection-Books14miningnova2Оценок пока нет

- Mio Amore - Final Transmission OilДокумент1 страницаMio Amore - Final Transmission Oilmotley crewzОценок пока нет

- Operation Manual For Wp4g95e221 EngineДокумент28 страницOperation Manual For Wp4g95e221 EngineCarlos Astudillo VargasОценок пока нет

- Maint Sched W32Документ9 страницMaint Sched W32enzobvОценок пока нет

- Scheduled Maintenance: Service IntervalДокумент1 страницаScheduled Maintenance: Service IntervalsilviaОценок пока нет

- Briggs & Stratton Engine Maintenance GuideДокумент6 страницBriggs & Stratton Engine Maintenance GuidenickОценок пока нет

- LU - 1NZ-FXE LubricationДокумент23 страницыLU - 1NZ-FXE LubricationCarlos MafudОценок пока нет

- Diesel Engine Appraisal-2Документ31 страницаDiesel Engine Appraisal-2hendra mmОценок пока нет

- 054933Документ9 страниц054933Хелфор УкраинаОценок пока нет

- Operating Instructions 430-0000-DOK001 en For Helical Gear and Bevel Helical Gear ReducersДокумент2 страницыOperating Instructions 430-0000-DOK001 en For Helical Gear and Bevel Helical Gear ReducersMahesh Daxini ThakkerОценок пока нет

- Lubrication System: GeneralДокумент5 страницLubrication System: GeneralLuis GarcíaОценок пока нет

- LB Series Asphalt Plant Maintenance ManualДокумент38 страницLB Series Asphalt Plant Maintenance ManualLai_Wei_Wah_7018Оценок пока нет

- .E.mfix - , R - SuffixДокумент2 страницы.E.mfix - , R - Suffixoscar bastidasОценок пока нет

- Kubota BX 2200 Operators ManualДокумент64 страницыKubota BX 2200 Operators ManualMark Dubravec63% (16)

- 420 Maintenance ScheduleДокумент4 страницы420 Maintenance Scheduleicyan.ahmad.tiОценок пока нет

- Oil Filter and Engine Oil InspectionДокумент20 страницOil Filter and Engine Oil InspectionChristian Linares AbreuОценок пока нет

- Ajuste Valvulas SuzukiДокумент3 страницыAjuste Valvulas SuzukiFRANCISCO ALVARADO VERGARAОценок пока нет

- 2GR-FE Oil Filter Replacement GuideДокумент20 страниц2GR-FE Oil Filter Replacement GuideNassar Al-EssawiОценок пока нет

- Lo 5 2350 262 12Документ29 страницLo 5 2350 262 12SteveОценок пока нет

- Article On Fuel InjectionДокумент44 страницыArticle On Fuel InjectionSurya ChandraОценок пока нет

- Lo 5 2350 262 12Документ29 страницLo 5 2350 262 12SteveОценок пока нет

- Checking The Engine Coolant LevelДокумент6 страницChecking The Engine Coolant LevelPhạm Hoài MinhОценок пока нет

- DIESEL OIL PURIFIER GEAДокумент16 страницDIESEL OIL PURIFIER GEAaymangamalsmeОценок пока нет

- Winchester 1200 Military ManualДокумент28 страницWinchester 1200 Military Manualblackjack33100% (1)

- 01 Leve' Waatnwnt: Oti Top Use Wear Eye and VotecüonДокумент1 страница01 Leve' Waatnwnt: Oti Top Use Wear Eye and VotecüonPabloОценок пока нет

- Maintain and Repair WD615 Diesel EngineДокумент134 страницыMaintain and Repair WD615 Diesel EngineGeorge Jhonson84% (51)

- 001Документ1 страница001AdvocateОценок пока нет

- TM 5-6115-304-15 1963Документ73 страницыTM 5-6115-304-15 1963Advocate100% (1)

- S 330a/trc 117Документ13 страницS 330a/trc 117AdvocateОценок пока нет

- S 583/TRC 151Документ8 страницS 583/TRC 151AdvocateОценок пока нет

- TM 9-4940-568-10 FRSДокумент404 страницыTM 9-4940-568-10 FRSAdvocate100% (3)

- S 591/TRC 175Документ11 страницS 591/TRC 175AdvocateОценок пока нет

- S 342/tya 27Документ16 страницS 342/tya 27AdvocateОценок пока нет

- TM 11-5895-366-15 January 1967 Incl. C1Документ144 страницыTM 11-5895-366-15 January 1967 Incl. C1Advocate100% (2)

- TM 11 5820 535 24PДокумент191 страницаTM 11 5820 535 24PAdvocateОценок пока нет

- S 667a/trc 138BДокумент49 страницS 667a/trc 138BAdvocateОценок пока нет

- TM 11-2405 S-13/TM Shelter and Instruments Met.Документ44 страницыTM 11-2405 S-13/TM Shelter and Instruments Met.Advocate100% (1)

- Shelter S-355/T...Документ8 страницShelter S-355/T...Advocate100% (1)

- S 187C.MRR 8Документ10 страницS 187C.MRR 8AdvocateОценок пока нет

- S 665.TRC 170 (V)Документ25 страницS 665.TRC 170 (V)AdvocateОценок пока нет

- TM 11-5840-345-34P - Radar - System - AN - FSQ-84 - 1978 PDFДокумент58 страницTM 11-5840-345-34P - Radar - System - AN - FSQ-84 - 1978 PDFWurzel1946Оценок пока нет

- S-805 GДокумент9 страницS-805 GAdvocateОценок пока нет

- S 70/uДокумент12 страницS 70/uAdvocateОценок пока нет

- S 615.MSC 64Документ9 страницS 615.MSC 64AdvocateОценок пока нет

- S 711.TRC 179 (V)Документ5 страницS 711.TRC 179 (V)AdvocateОценок пока нет

- S 734.MSC 74Документ23 страницыS 734.MSC 74AdvocateОценок пока нет

- Kniga # 3616 and # 3617Документ7 страницKniga # 3616 and # 3617AdvocateОценок пока нет

- S 141 GДокумент17 страницS 141 GAdvocate100% (1)

- Military Railways 1916Документ191 страницаMilitary Railways 1916Nancy CunninghamОценок пока нет

- S 389.msa 34Документ9 страницS 389.msa 34AdvocateОценок пока нет

- International Harvester F 1934Документ6 страницInternational Harvester F 1934AdvocateОценок пока нет

- TM 11-487C-1 1965Документ1 531 страницаTM 11-487C-1 1965Advocate100% (2)

- Cheat Sheet For EnginesДокумент192 страницыCheat Sheet For EnginesTerrence StaplesОценок пока нет

- TM 5-6115-599-14PДокумент444 страницыTM 5-6115-599-14PAdvocate0% (1)

- TM 11-487 October 1944Документ537 страницTM 11-487 October 1944Advocate100% (3)

- TM 11-900 1942 Pe-75a and Pe-75bДокумент63 страницыTM 11-900 1942 Pe-75a and Pe-75bAdvocateОценок пока нет

- Twin Cylinder OHV BRIGGS & STRATTON PDFДокумент101 страницаTwin Cylinder OHV BRIGGS & STRATTON PDFigrekqa100% (12)

- M696 Usa 2009 Ed00Документ101 страницаM696 Usa 2009 Ed0015081977100% (1)

- DC09 071A. 267-292 KW (304-328 kVA) : EU Stage IIIA, China Phase III and CPCB-IIДокумент2 страницыDC09 071A. 267-292 KW (304-328 kVA) : EU Stage IIIA, China Phase III and CPCB-IIHaidar Al MosawiОценок пока нет

- Service Station Manual Vespa LX 125 - 150 4t Euro 3Документ241 страницаService Station Manual Vespa LX 125 - 150 4t Euro 3Adèle Standard100% (1)

- Yamaha WR 250 Parts List 2Документ62 страницыYamaha WR 250 Parts List 2rositemaster100% (1)

- Mercedes Benz m102 Engine Service ManualДокумент843 страницыMercedes Benz m102 Engine Service Manualg1763970100% (6)

- Denomination Task for Engine Model 18V2000G63-TBДокумент9 страницDenomination Task for Engine Model 18V2000G63-TBNabesterNajamОценок пока нет

- SML Final Training ReportДокумент63 страницыSML Final Training ReportArjun BhardwajОценок пока нет

- Oculus: Free Plan: Oculus Supercap FFДокумент68 страницOculus: Free Plan: Oculus Supercap FFDarren-Edward O'NeillОценок пока нет

- SCOOTER PARTS CATALOGДокумент385 страницSCOOTER PARTS CATALOGnkj_nbpОценок пока нет

- Porsche 993 Workshop ManualsДокумент20 страницPorsche 993 Workshop Manualsmarilyn100% (50)

- Manual VN87Plus-EX V1.3Документ62 страницыManual VN87Plus-EX V1.3tomОценок пока нет

- SPC Pulsar NS 160 EURO Single & Twin Disc (2019 01 31)Документ89 страницSPC Pulsar NS 160 EURO Single & Twin Disc (2019 01 31)Willy Mansilla A92% (12)

- 2 4DuraTorqДокумент93 страницы2 4DuraTorqThành Sơn Đỗ100% (7)

- LPG Tanker WoolcottДокумент80 страницLPG Tanker WoolcottnickurfriendОценок пока нет

- Airtemp 50-100Ton Air Conditioning Unit Parts ListДокумент169 страницAirtemp 50-100Ton Air Conditioning Unit Parts ListAbdelmadjid BatirОценок пока нет

- Project Guide B32 - 40A 2018Документ145 страницProject Guide B32 - 40A 2018Guilherme Henrique FilhoОценок пока нет

- KZ650 Engine RebuildДокумент6 страницKZ650 Engine RebuildSenTTrox Rox100% (1)

- Sportsman 700 Twin PARTS MANUAL PN 9918743Документ60 страницSportsman 700 Twin PARTS MANUAL PN 9918743Donny SirmansОценок пока нет

- Service ManualДокумент16 страницService ManualgvankelecomОценок пока нет

- M19 508 eДокумент4 страницыM19 508 eFalgon IslamОценок пока нет

- Manual Engine Analyzer Pro v3.9 PDFДокумент323 страницыManual Engine Analyzer Pro v3.9 PDFAssisОценок пока нет

- Install Keihin PE28 Carburetor Kit PDFДокумент4 страницыInstall Keihin PE28 Carburetor Kit PDFJontu In-PhОценок пока нет

- Volvo Penta 7748089 5.0-5.7 Engine ManualДокумент176 страницVolvo Penta 7748089 5.0-5.7 Engine ManualJohn Dahl88% (26)

- 50 Cooperative Fuel Research Engine 1928Документ16 страниц50 Cooperative Fuel Research Engine 1928Er Gaurav ShandilyaОценок пока нет

- How To Repair Briggs & Stratton EnginesДокумент179 страницHow To Repair Briggs & Stratton EnginesChuck Achberger95% (22)

- Basic Engine (The Best)Документ104 страницыBasic Engine (The Best)MohamedSalah100% (2)

- F32 MNS 55kW Off-Road Engine Specs & FeaturesДокумент2 страницыF32 MNS 55kW Off-Road Engine Specs & Featuresmclares77Оценок пока нет

- Merlin XX EngineДокумент6 страницMerlin XX EngineIvan Kopić100% (2)

- Qip Ice 23 Lubrication SystemsДокумент24 страницыQip Ice 23 Lubrication SystemsMohan Kumar SОценок пока нет

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoОт EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoРейтинг: 5 из 5 звезд5/5 (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksОт EverandArizona, Utah & New Mexico: A Guide to the State & National ParksРейтинг: 4 из 5 звезд4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensОт EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensОценок пока нет

- New York & New Jersey: A Guide to the State & National ParksОт EverandNew York & New Jersey: A Guide to the State & National ParksОценок пока нет

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptОт EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptРейтинг: 5 из 5 звезд5/5 (1)