Академический Документы

Профессиональный Документы

Культура Документы

Filtros Rotatorios

Загружено:

Manuel Alejandro Gonzalez AguayoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Filtros Rotatorios

Загружено:

Manuel Alejandro Gonzalez AguayoАвторское право:

Доступные форматы

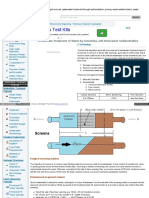

Hydrotech Drumlter

Type 1, with tank

6 5

Type 2, without tank open inlet

Type 3, without tank pipe inlet

Flow capacity: Up to 1000 I/s per lter. Filter opening: 10-1000 m. Over 2000 Hydrotech Drumlters have been installed worldwide.

M

The liquid is filtered through the periphery of the slowly rotating drum. Assisted by the lter panels special cell structure, the particles are carefully separated from the liquid. Separated solids are rinsed off the filter cloth into the solids collection tray and discharged.

Microscreening is an efcient and reliable technique for separation of particles from all kinds of liquids. Hydrotech develop and manufacture high performance microscreen lters for water purication and product recovery.

1. Inlet 2. Outlet 3. Solids outlet 4. Rinse water connection

5. Back-wash header 6. Drive unit 7. Filter panels 8. Rubber lip sealing

The tank of Hydrotech Drumlter Type 1 is provided with an internal emergency by-pass and a level weir to maintain the water level after the screen. The versions without tanks are designed for installation in a concrete channel or basin.

The Hydrotech Drumlter is a mechanical and self-cleaning lter specially designed with a view to achieving high performance in systems where it is essential to prevent the particles from fragmentation. The lter works without pressure and is robustly designed with few moving parts to ensure long life and low maintenance costs.

Modular design with very high exibility The modular design incorporates 6 different drum diameters from 0.5 m to 2.4 m with lter areas from 0.35 m2 for the HDF501 to 21.6 m2 for the HDF2408. In total there are 20 different drum lter sizes. The standard modular lter panel measures 1.2 x 0.4 m. As an example, the 1.6 m drum diameter series has from 1 up to 8 sections, with from 4 up to 32 lter panels.

Avaliable in three drive systems The Hydrotech Drumfilter is avaliable in three drive system versions; direct drive, chain transmission and belt transmission. The direct drive is used on the two smallest drum sizes with 0.5 and 0.8 m drum diameter. The chain drive version is Hydrotech's well proven solution with lters in operation for more than 10 years. The belt driven L-series is a relatively new design availabe for 1,6 and 2 m drum diameter.

Careful handling of the solids to prevent fragmentation is in many applications essential to achieve high ltration efciency. Hydrotech's unique design of the lter panels makes this possible.

Hydrotech's unique lter panels greatly simplify both the replacement and change out of the lter opening size. The drum is constructed in sections, each with up to 6 lter panels depending on diameter. This facilitates maintenance and makes it easy to adapt the lter to actual need of ow capacity and performance requirements of ltration.

Chain drive system.

Drum and tank are made of stainless (AISI304) or acidproof steel (AISI316L). For use in extremely corrosive surroundings, special alloys, GRP or titanium is used. The lter panels structure, bearing wheels and main shaft bearing are made of resistant plastics. The lter cloth is made of polyester or stainless steel. The operation of the drumlter can be continuous or automatically controlled. Different types of automatic control systems are available.

Moving back-wash system is availavle only on the belt driven drumlters. This patented innovation reduces the need off back-wash which in turn saves energy and lter media

Fields of application

Filtering intake water from streams and lakes for municipal and industrial water supply systems. Polishing efuent from municipal waste water treatment works. The Hydrotech Drumlter can also replace primary or secondary clariers. The Hydrotech Drumlter is suitable in sh farming systems where it is essential to prevent the particles from fragmentation. This is important specially in recirculated systems and in open systems for intake and outlet water. Food processing industries are using the Hydrotech Drumlter for treatment of waste water and process water. Other examples are ltering transport water in plastic industries and purication of scrubber water in power plants.

Drumlter

Picture showing a part of Hydrotech's wide drumlter product line.

Copyright 2001 Hydrotech AB. All rights reserved.

Industrigatan 1 SE-235 32 Vellinge Sweden Tel +46 (0)40-42 95 30 Fax +46 (0)40-42 95 31 mailbox@hydrotech.se www.hydrotech.se

Efciency Flexibility

Вам также может понравиться

- Bulletin 836T - Pressure Controls, Traditional Machine ToolДокумент25 страницBulletin 836T - Pressure Controls, Traditional Machine ToolAbdul AnisОценок пока нет

- Who TRS 970 Anexo 2 PDFДокумент23 страницыWho TRS 970 Anexo 2 PDFAnonymous guhSjjNWdP100% (1)

- SteelДокумент22 страницыSteels63et79jgeesdgОценок пока нет

- Biodek CatalogueДокумент17 страницBiodek CatalogueSourabh ManujaОценок пока нет

- Techniques OF Drip Irrigation and FertigationДокумент25 страницTechniques OF Drip Irrigation and FertigationBhuvnesh Kumar100% (2)

- Continuous Sand Filter - 11110Документ2 страницыContinuous Sand Filter - 11110ganeshОценок пока нет

- 3.0 Systems Division-FiltersДокумент8 страниц3.0 Systems Division-Filtersmatteo2009Оценок пока нет

- Vanne Batardeau ORBINOXДокумент17 страницVanne Batardeau ORBINOXtafisco5505Оценок пока нет

- Drip Irrigation and Fertigation Drip Irrigation SystemДокумент20 страницDrip Irrigation and Fertigation Drip Irrigation SystemRudra Goud100% (1)

- Filter Bag EnglishДокумент32 страницыFilter Bag EnglishArun Gupta100% (1)

- Preliminary Treatment Process of Waste WaДокумент9 страницPreliminary Treatment Process of Waste WaArjun MulluОценок пока нет

- Stream Filters For Industrial UseДокумент8 страницStream Filters For Industrial UseVasudev Water SolutionОценок пока нет

- FiltrationДокумент46 страницFiltrationSharmimi RazakОценок пока нет

- FLSmidthAFP Filter Press BrochureДокумент4 страницыFLSmidthAFP Filter Press BrochureLENINROMEROH4168Оценок пока нет

- Filter PressДокумент2 страницыFilter PresshassanalbhadlyОценок пока нет

- Cooling Tower Side Stream FiltrationДокумент6 страницCooling Tower Side Stream FiltrationVenkat DoraОценок пока нет

- EATON Filtration FilterCartridgesДокумент20 страницEATON Filtration FilterCartridgeschris110Оценок пока нет

- Aspects of Rotary Vacuum Filter Design and PerformanceДокумент19 страницAspects of Rotary Vacuum Filter Design and PerformanceMegananda Agmie Chandradhipa DwiearthaОценок пока нет

- Earth Science Week 4 PDFДокумент18 страницEarth Science Week 4 PDFAniahsNelet100% (2)

- JCI Process Filter Separator Technical BrochureДокумент8 страницJCI Process Filter Separator Technical BrochureVAN_JCIОценок пока нет

- Drip Irrigation BrochureДокумент6 страницDrip Irrigation BrochureHRagheb100% (1)

- Flottweg - Solid Bowl Decanter TechnologyДокумент24 страницыFlottweg - Solid Bowl Decanter Technologyzamburitti100% (2)

- Flottweg DecandersДокумент12 страницFlottweg DecandersRagha Rag100% (1)

- Decanter TechnologyДокумент24 страницыDecanter TechnologyMurali Krishna Indana100% (1)

- Aerodef India Manufacturing 2018, MumbaiДокумент13 страницAerodef India Manufacturing 2018, MumbaiLuv ShroffОценок пока нет

- Filtro Tambor RotatorioДокумент4 страницыFiltro Tambor Rotatoriocquibajo100% (2)

- Commercial Offer About The PET Washing Line, Capacity 1000 KG/HДокумент13 страницCommercial Offer About The PET Washing Line, Capacity 1000 KG/HAnkitОценок пока нет

- Drum Filter PDFДокумент8 страницDrum Filter PDFleroniusОценок пока нет

- Water Production and TreatmentДокумент8 страницWater Production and TreatmentSolMonteroОценок пока нет

- Micron S602 ECOДокумент4 страницыMicron S602 ECOTan Kang YaoОценок пока нет

- Baker Hydro Sparkling ClearДокумент2 страницыBaker Hydro Sparkling ClearBakerHydroОценок пока нет

- Round Des Il Terre V 122004Документ2 страницыRound Des Il Terre V 122004Yudha SatriaОценок пока нет

- Baker Hydro Top MountДокумент2 страницыBaker Hydro Top MountBakerHydroОценок пока нет

- ConstructionДокумент23 страницыConstructionetdeeiОценок пока нет

- Unit 4 Material - FinalДокумент10 страницUnit 4 Material - FinalSree JaniОценок пока нет

- Midterm Exam Answers 2-3-4Документ7 страницMidterm Exam Answers 2-3-4Aslıhan KayaОценок пока нет

- ZA EE FiltersДокумент3 страницыZA EE FiltersDiego CuevasОценок пока нет

- EUROWATER Bag Filters LeafletДокумент4 страницыEUROWATER Bag Filters LeafletAsteriaA.SusantoОценок пока нет

- Water Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian BrochureДокумент4 страницыWater Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian BrochurePromagEnviro.comОценок пока нет

- More Infohydro-Flo: Triden ScreensДокумент4 страницыMore Infohydro-Flo: Triden ScreensAnup KumarОценок пока нет

- Grundfos PDFДокумент8 страницGrundfos PDFDan PetricОценок пока нет

- Water Purification Plant 1000 GPH Capacity SSДокумент9 страницWater Purification Plant 1000 GPH Capacity SSHaiDer J MarWatОценок пока нет

- Product Catalogue PC7 Web PDFДокумент15 страницProduct Catalogue PC7 Web PDFjohnОценок пока нет

- Numatics FRLFlexiblok R072010Документ33 страницыNumatics FRLFlexiblok R072010Oscar ZavaletaОценок пока нет

- HYDROSWIM Bobbin Wound Polyester Filters - Key Features & Benefits 01 08Документ3 страницыHYDROSWIM Bobbin Wound Polyester Filters - Key Features & Benefits 01 08newbornlifeОценок пока нет

- Surface Electric Water Pumps PDFДокумент84 страницыSurface Electric Water Pumps PDFNick3105870000100% (1)

- Trickling Filters: Introduction: Trickling Filter (Otherwise Known As PercolatingДокумент4 страницыTrickling Filters: Introduction: Trickling Filter (Otherwise Known As PercolatingthebammanОценок пока нет

- Data Sartocell Filter Modules For F+B SR-2011-eДокумент2 страницыData Sartocell Filter Modules For F+B SR-2011-eJoshua JohnsonОценок пока нет

- Rainwater Harvesting Is The Gathering, or Accumulating and Storing, of RainwaterДокумент11 страницRainwater Harvesting Is The Gathering, or Accumulating and Storing, of Rainwatervishnu273Оценок пока нет

- Unidad de FiltradoДокумент4 страницыUnidad de FiltradoNestor SalasОценок пока нет

- Coalescer Separator General DescriptionДокумент1 страницаCoalescer Separator General DescriptionRanaweera AriyamanjulaОценок пока нет

- Inline Process FiltersДокумент7 страницInline Process FiltersDenis JimenezОценок пока нет

- Zenit Box Range Brochure en-US PDFДокумент11 страницZenit Box Range Brochure en-US PDFKadiri OlanrewajuОценок пока нет

- PT. Gapura Liqua Solutions ProductsДокумент12 страницPT. Gapura Liqua Solutions ProductsAnastasiaCMОценок пока нет

- Water Treatment Plant AccessoriesДокумент10 страницWater Treatment Plant AccessoriesecotechconsultantsОценок пока нет

- HariДокумент21 страницаHariHari ChigurupatiОценок пока нет

- AFP Brochure08Документ4 страницыAFP Brochure08YongoloooОценок пока нет

- What Is Drip ArticleДокумент8 страницWhat Is Drip ArticleGunasridharan LakshmananОценок пока нет

- IsyTech 31-10 - 31-11 - IngleseДокумент12 страницIsyTech 31-10 - 31-11 - InglesedmakaricОценок пока нет

- Filtration Systems With Pile Cloth Filter MediaДокумент8 страницFiltration Systems With Pile Cloth Filter MediaSagnik DasОценок пока нет

- Introduction To Strainer in PipingДокумент7 страницIntroduction To Strainer in PipingIntan Siti Hardianti IIОценок пока нет

- Comparison Chart: Sump TankДокумент2 страницыComparison Chart: Sump TankFitri ArdhianОценок пока нет

- SECTION PB-510 - InterceptorsДокумент2 страницыSECTION PB-510 - Interceptorsjames_chan2178Оценок пока нет

- Fabrications BrochureДокумент13 страницFabrications Brochurewish uОценок пока нет

- TADOPOLДокумент28 страницTADOPOLFrank DetchokulОценок пока нет

- Design and Construction of Food PremisesДокумент62 страницыDesign and Construction of Food PremisesAkhila MpОценок пока нет

- A194A194MДокумент11 страницA194A194Mrgi1780% (1)

- Winters FluidpowerДокумент8 страницWinters FluidpowerJOSE DEL CARMEN TOLEDOОценок пока нет

- Outokumpu Core Range Datasheet PDFДокумент16 страницOutokumpu Core Range Datasheet PDFMeow SuthidaОценок пока нет

- Stainless Steel and Elgiloy: G.Shekar Subramanian First Year PGДокумент67 страницStainless Steel and Elgiloy: G.Shekar Subramanian First Year PGShekar SubramanianОценок пока нет

- Catalogue Ulma FittingsДокумент7 страницCatalogue Ulma FittingsVeky PamintuОценок пока нет

- Metals Ferrous - Non FerrousДокумент15 страницMetals Ferrous - Non Ferrousapi-312316062Оценок пока нет

- 301 Stainless SteelДокумент1 страница301 Stainless SteelDanielОценок пока нет

- Masoneilan 51 52 53 Cylinder ActuatorДокумент24 страницыMasoneilan 51 52 53 Cylinder ActuatorEESL AACОценок пока нет

- Final Draft SS MagazinesДокумент3 страницыFinal Draft SS MagazinesbtjajadiОценок пока нет

- 10 TMSS 04 R1Документ29 страниц10 TMSS 04 R1infosaneeshssОценок пока нет

- Dextra Couplers - DatasheetДокумент18 страницDextra Couplers - DatasheetNick BesterОценок пока нет

- Numerical Investigation of Dissimilar Friction Stir Welding of AISI 304L and 410S Stainless SteelsДокумент13 страницNumerical Investigation of Dissimilar Friction Stir Welding of AISI 304L and 410S Stainless Steelsapt.dwdi.iitbОценок пока нет

- Cooling Water Analysis: by Ashutosh Mehndiratta Kribhco Shyam Fertilizers Limited Shahjahanpur Uttar Pradesh IndiaДокумент39 страницCooling Water Analysis: by Ashutosh Mehndiratta Kribhco Shyam Fertilizers Limited Shahjahanpur Uttar Pradesh IndiaJohnОценок пока нет

- Z 902 Carbon Specifications 0621 RGBДокумент2 страницыZ 902 Carbon Specifications 0621 RGBCuneyt PekОценок пока нет

- MoRTH 1000 Materials For StructureДокумент18 страницMoRTH 1000 Materials For StructureApurv PatelОценок пока нет

- LNG - Growing Challenges of Heat Exchanger's Operation & Maintenance in LNG PlantsДокумент16 страницLNG - Growing Challenges of Heat Exchanger's Operation & Maintenance in LNG PlantsR P SinghОценок пока нет

- Bulletin 103Документ8 страницBulletin 103guslohОценок пока нет

- Carbide Banding - Effect On FatigueДокумент15 страницCarbide Banding - Effect On FatigueSteve Green100% (1)

- Q100 General Welding RequirementsДокумент13 страницQ100 General Welding Requirementspragmatix100% (1)

- Regleta 6700 Liquid Level IndicatorДокумент4 страницыRegleta 6700 Liquid Level IndicatorJulio PCОценок пока нет

- Ujwal Steel Introduction LetterДокумент4 страницыUjwal Steel Introduction LettersamОценок пока нет

- SANDVIK 23.12.2.LR Covered Electrodes: DatasheetДокумент3 страницыSANDVIK 23.12.2.LR Covered Electrodes: DatasheetFilipe CordeiroОценок пока нет

- Luxury Railings 1Документ32 страницыLuxury Railings 1aroubi inphoОценок пока нет