Академический Документы

Профессиональный Документы

Культура Документы

T450 Hurricane Shutter Design

Загружено:

lesgiuОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

T450 Hurricane Shutter Design

Загружено:

lesgiuАвторское право:

Доступные форматы

One of the best ways to protect a home from damage in windstorms is to install shutters over all large windows

and glass

doors. Shutters protect windows from windborne objects. They also prevent structural damage caused by sudden pressure

changes when a window is broken.

Hurricane Shutter Designs

Refer to Form No. T460 for design considerations for Florida

85

90

100

110

120

130

140

150

FIGURE 1

HIGH WIND ZONES OF THE CONTIGUOUS UNITED STATES V

ASD

MPH

Notes:

1. Values are nominal design 3-second gust wind speeds, V

ASD

, in miles per hour at 33 ft above ground for Exposure C category.

2. Linear interpolation between contours is permitted.

3. Islands and coastal areas outside the last contour shall use the last wind speed contour of the coastal area.

4. Mountainous terrain, gorges, ocean promontories, and special wind regions shall be examined for unusual wind conditions.

Source: Figure R301.2(4)A, 2012 International Residential Code

2 Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

The following designs are presented as two basic alternatives: The first is to present the code minimum opening protec-

tion when such shutters are required. The requirements of the 2012 International Residential Code (IRC) and the 2012

International Building Code (IBC) are presented. They permit the use of minimum 7/16 Performance Category Rated

Sheathing as opening protection against the impact of windborne debris. Check with local building departments for

verification or clarification of requirements.

The second approach provides some design details for stronger and stiffer shutters than provided for by the code-

minimum requirements. It should be noted that these designs were developed prior to the adoption of specific standards

for shutter designs by any U.S. codes. The supports detailed for these shutters meet code requirements when mounted

according to the specifications in Table R301.2.1.2. The mounting brackets for the masonry block structures have been

tested for design wind loads but have not been impact or cyclic tested because they were developed as design guides

before these standards were developed.

1. CODE-MINIMUM SHUTTER DESIGN

IRC Section R301.2.1.2 Protection of openings. Exterior glazing in buildings located in windborne debris

regions shall be protected from windborne debris. Glazed openings protected from windborne debris shall meet the

requirements of the Large Missile Test of ASTM E1996 and ASTM E1886 referenced therein. The applicable wind

zones for establishing missile types in ASTM E1996 are shown on Figure R301.2(4)C. Garage door glazed opening

protection for windborne debris shall meet the requirements of an approved impact-resistant standard...

EXCEPTION: Wood structural panels with a minimum thickness of 7/16 inch and a maximum span of 8 feet shall be

permitted for opening protection in one- and two-story buildings. Panels shall be precut and attached to the framing

surrounding the opening containing the product with the glazed opening. Panels shall be predrilled as required for

the anchorage method and shall be secured with the attachment hardware provided. Attachments shall be designed

to resist the components and cladding loads determined in accordance with either Table R301.2(2) or ASCE 7, with

the permanent corrosion-resistant attachment hardware provided and anchors permanently installed on the building.

Attachment in accordance with Table R301.2.1.2 is permitted for buildings with a mean roof height of 33 feet or less

where located in Wind Zones 1 and 2 in accordance with Figure R301.2(4)C.

TABLE R301.2.1.2

WINDBORNE DEBRIS PROTECTION FASTENING SCHEDULE FOR WOOD STRUCTURAL PANELS

(a)(b)(c)(d)

Fastener Type

Fastener Spacing (inches)

(a)(b)

Panel Span 4 ft 4 ft < Panel Span 6 ft 6 ft < Panel Span 8 ft

No. 8 wood screw based anchor

with 2-inch embedment length

16 10 8

No. 10 wood screw based anchor

with 2-inch embedment length

16 12 9

1/4-inch lag screw based anchor

with 2-inch embedment length

16 16 16

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 pound = 4.448 N, 1 mile per hour = 0.447 m/s.

(a) This table is based on 130 mph (V

ASD

) wind speeds and a 33-foot mean roof height.

(b) Fasteners shall be installed at opposing ends of the wood structural panel. Fasteners shall be located a minimum of 1 inch from

the edge of the panel.

(c) Anchors shall penetrate through the exterior wall covering with an embedment length of 2 inches minimum into the building

frame. Fasteners shall be located a minimum of 2-1/2 inches from the edge of concrete block or concrete.

(d) Where panels are attached to masonry or masonry/stucco, they shall be attached using vibration-resistant anchors having a minimum

ultimate withdrawal capacity of 1500 pounds.

3 Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

FIGURE 2

WIND BORNE DEBRIS REGIONS OF THE UNITED STATES

Notes:

1. Wind Zone 3 applies in Wind Zone 2 areas that are within a mile of the Coastal Mean High Water Line.

2. Wind Zone 1 applies in Hawaii Special Wind Regions.

3. See Section 1609.1.2.2 of 2012 International Building Code for definitions of wind zones.

Source: Figure R301.2(4)C, 2012 International Residential Code

Section R202 defines Windborne Debris Regions as areas within hurricane-prone regions as designated in accordance

with Figure R301.2(4)C. This figure is reproduced in Figure 2 of this publication. This figure is based on the following

criteria: 1) within one mile of the coastal mean high water line where the basic wind speed is 110 mph or greater; or 2)

where the basic wind speed is equal to or greater than 120 mph; or 3) Hawaii. For Florida provisions, see Hurricane

Shutters: Design Considerations for Florida, Form T460.

Wind Zone 1 (1 mile from the

Coastal Mean High Water Line)

Wind Zone 2

Wind Zone 3

4 Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

Alternatively, Section 1609.1.2 of the 2012 International Building Code:

In windborne debris regions, glazing in buildings shall be impact-resistant or protected with an impact-resistant

covering meeting the requirements of an approved impact-resisting standard or ASTM E1996 and ASTM E1886

referenced therein as follows:

1. Glazed openings located within 30 feet of grade shall meet the requirements of the Large Missile Test of ASTM

E1996.

2. Glazed openings located more than 30 feet above grade shall meet the provisions of the Small Missile Test of

ASTM E1996.

EXCEPTIONS:

1. Wood structural panels with a minimum thickness of 7/16 inch and maximum panel span of 8 feet shall be permitted

for opening protection in one- and two-story buildings classified as Group R-3 or R-4 occupancy. Panels shall be

precut so that they shall be attached to the framing surrounding the opening containing the product with the glazed

opening. Panels shall be predrilled as required for the anchorage method and shall be secured with the attachment

hardware provided. Attachments shall be designed to resist the components and cladding loads determined in

accordance with the provisions of ASCE 7, with corrosion-resistant attachment hardware provided and anchors

permanently installed on the building. Attachment in accordance with Table 1609.1.2 with corrosion-resistant

attachment hardware provided and anchors permanently installed on the building is permitted for buildings with

a mean roof height of 45 feet or less where V

ASD

determined in accordance with Section 1609.3.1 does not exceed

140 mph. (Figure 3 is provided for determining the V

ASD

wind speed measured at 33 feet above ground for

Risk Category II Buildings (Group R-3 or R-4 occupancy). This figure is based on the wind contours for Risk

Category II Buildings from 2012 IBC Figure 1609A.

2. Glazing in Risk Category I buildings as defined in Section 1604.5, including greenhouses that are occupied for

growing plants on a production or research basis, without public access shall be permitted to be unprotected.

TABLE 1609.2.1.2

WINDBORNE DEBRIS PROTECTION FASTENING SCHEDULE FOR WOOD STRUCTURAL PANELS

(a)(b)(c)(d)

Fastener Type

Fastener Spacing (inches)

(a)(b)

Panel Span 4 ft 4 ft < Panel Span 6 ft 6 ft < Panel Span 8 ft

No. 8 wood screw based anchor

with 2-inch embedment length

16 10 8

No. 10 wood screw based anchor

with 2-inch embedment length

16 12 9

1/4-inch lag screw based anchor

with 2-inch embedment length

16 16 16

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 pound = 4.448 N, 1 mile per hour = 0.447 m/s.

(a) This table is based on 140 mph, V

ULT

(110 mph, V

ASD

) wind speeds and a 45-foot mean roof height.

(b) Fasteners shall be installed at opposing ends of the wood structural panel. Fasteners shall be located a minimum of 1 inch from

the edge of the panel.

(c) Anchors shall penetrate through the exterior wall covering with an embedment length of 2 inches minimum into the building

frame. Fasteners shall be located a minimum of 2-1/2 inches from the edge of concrete block or concrete.

(d) Where panels are attached to masonry or masonry/stucco, they shall be attached using vibration-resistant anchors having a minimum

ultimate withdrawal capacity of 1,500 pounds.

5 Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

FIGURE 3

V

ASD

CONTOURS FOR DETERMINING SUITABILITY OF WOOD STRUCTURAL PANEL GLAZING PROTECTION

DEVICES FOR RISK CATEGORY II STRUCTURES

Notes:

1. Values are nominal design 3-second gust V

ASD

wind speeds in miles per hour at 33 ft above ground for Exposure C category.

2. Linear interpolation between contours is permitted.

3. Islands and coastal areas outside the last contour shall use the last wind speed contour of the coastal area.

4. Mountainous terrain, gorges, ocean promontories, and special wind regions shall be examined for unusual wind conditions.

5. Wind speeds correspond to approximately a 7% probability of exceedance in 50 years (Annual Exceedance Probability = 0.00143,

MRI = 700 years).

Source: Derived from 2012 IBC Figure 1609A and Equation 16-33.

3. Glazing in Risk Category II, III or IV buildings located over 60 feet above the ground and over 30 feet above

aggregate surface roofs located within 1,500 feet of the building shall be permitted to be unprotected.

Section 202 defines a Windborne Debris Region as:

Areas within hurricane-prone regions located:

1. Within 1 mile of the coastal mean high water line where the ultimate design wind speed, V

ULT

, is 130 mph

(100 mph V

ASD

) or greater; or

2. In areas where the ultimate design wind speed, V

ULT

, is 140 mph (110 mph V

ASD

) or greater; or Hawaii.

Based on Equation 16-33, V

ASD

=

0.6 x V

ULT

maps for Risk Category II and Category III and IV are found in the 2012

IBC in Figures 1609A and B, respectively, and not provided herein.

85

90

95

100

110

120

125

132

140

150

6 Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

Section 202 defines Hurricane-Prone Regions as:

1. The U.S. Atlantic Ocean and Gulf of Mexico coast where the ultimate design wind speed, V

ULT

, for Risk Category

buildings is greater than 115 mph (90 mph V

ASD

); and

2. Hawaii, Puerto Rico, Guam, Virgin Islands and American Somoa.

2. CONSIDERATIONS FOR STRONGER, STIFFER DESIGNS

The following design pages describe how to construct stronger, stiffer shutters for attachment to wood and masonry

walls. The masonry attachments were designed prior to the adoption of specific test standards for shutter designs by

U.S. codes. The shutters have been tested to resist the design wind loads and impacts, but the attachments to masonry

have not been impact or cyclic-load tested. The masonry attachment details are therefore supplied as guides in devel-

oping individual designs.

The easiest designs are those that simply cover the opening with a wood structural panel. In wood-frame construction,

panels can be nailed over the openings when a hurricane approaches. Buildings made with concrete blocks, however,

require advance preparation.

In some cases, stiffeners may be necessary to limit deflection of the shutter with respect to the glass. Stiffeners function

best if they are on the outside of the shutter and oriented with the narrow edge against the shutter.

Tables 1 and 2 and Figures 4 and 5 on the following pages apply to most of the designs, and are referenced accordingly.

7 Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

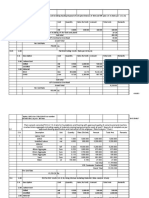

TABLE 2

WEIGHTS AND DEFLECTIONS OF SHUTTERS WITH STIFFENERS

(a)

(SEE FIGURE 3)

APA Panel Span Rating

Minimum Panel

Specification

Approximate Weight

Maximum Span

(Stiffener Bending)

Total Deflection

(Stiffener Plus Panel)

With 2x4

Stiffeners

(psf)

With 2x6

Stiffeners

(psf)

With 2x4

Stiffeners

(b)

at 16" o.c.

(in.)

With 2x6

Stiffeners

(b)

at 16" o.c.

(in.)

66" Span

with 2x4

Stiffeners

(in.)

96" Span

with 2x6

Stiffeners

(in.)

32/16, 15/32 Perf. Cat.

5-ply plywood or OSB

2.4 2.9 66 96 0.87 0.97

40/20, 19/32 Perf. Cat.

4-ply plywood or OSB

2.8 3.3 66 96 0.75 0.86

48/24, 23/32 Perf. Cat.

Plywood or OSB

3.2 3.7 66 96 0.66 0.79

48 o.c., 1-1/8 Perf. Cat.

Plywood or OSB

4.3 4.8 66 96 0.49 0.67

(a) Panels with 2x4 S-P-F (South) No. 2 stiffeners spaced 16 inches o.c., Exposure C, 3-second gust, Wall Zone 5, mean roof height = 45 ft,

V

ASD

150 mph, 2012 IBC.

(b) Maximum span governed by stiffener bending strength, wet stresses, duration of load factor = 1.6.

TABLE 1

MAXIMUM SPAN WITHOUT STIFFENERS STRENGTH AXIS PERPENDICULAR TO FASTENER ROWS (SEE FIGURE 2)

APA Panel

Span Rating

Approximate

Weight

(psf)

Maximum

Shutter Span

(in.)

Approximate Deflection at V

ASD

150 mph Design Wind Speed at

45-ft Height, Exp. C, Wet Panels

(in.)

32/16 1.5 22 0.22

40/20 2.1 30 0.38

48/24 2.4 34 0.35

48 oc 3.6 50 0.58

8 Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

Rows of fasteners

Panel shutter Shutter span

Panel strength axis

(perpendicular to

the fastener rows)

Orientation is based on Figure A1

FIGURE 4

SHUTTER INSTALLATION EXAMPLE SHOWING ORIENTATION OF PANEL STRENGTH AXIS

APA structural panel

No. 2 2x4 or No. 2 2x6

Cut if desired

Panel strength axis

3/16" x 3" lag screws with fender washers

Min. 16d box nails (0.135" x 3-1/2") @ 6" o.c.

FIGURE 5

SHUTTER STIFFENER ATTACHMENT IF REQUIRED

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

9

HURRICANE SHUTTER DESIGNS INDEX

A

B

C

D

E

A

B

C

D

E

A

B

C

D

E

A

B

C

D

E

A

B

C

D

E

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

10

DESIGN A

Shutters for Wood-Frame Buildings

This design from APA describes how to construct structural panel shutters for attachment to wood-frame buildings.

Steps to Constructing Shutters

1. Review Tables 1 and 2 to determine if stiffeners are needed. Attach stiffeners, if needed, as shown in Figures 5 and

A1.

2. Cut APA wood structural panels with adequate edge overlap to receive nails. Orient long panel axis (strength axis) of

the panel as shown in Figures 5 and A1.

3. Use a long brad, finishing or casing nails to locate the framing behind the wood siding. The nails used to attach the

shims and the shutters must hit the framing to be fully effective.

4. Nail shims to the framing with 12d nails (0.135- x 3-1/4-inch). Use 16d nails (0.135- x 3-1/2-inch) for shims over

3/4 inch thick. For spans up to 5 feet, space the nails 6 (4) inches o.c. at each shim. For spans over 5 feet, space nails

4 (3) inches o.c. at each shim. Stagger nails as shown in Figure A2. Refer to Figures A2 and A3. Shim attachment

schedules are based on a mean roof height of 33 feet. Corresponding schedules for a mean roof height of 45 feet are

shown in parenthesis, e.g., 12 (8).

5. Attach the shutters with double-headed nails as shown in Figures A2 and A3 for ease of later removal. Use 16d

(0.135- x 3-1/2-inch). For nail spacing at each end of the shutter panel, see Tables A1 and A2. Stagger nails spaced

3 inches on center. Nailing the panel on all four sides instead of just the two ends will further limit deflection and max-

imize strength.

TABLE A1

MINIMUM NAIL SPACING ALONG EACH END

OF THE SHUTTER PANEL (Span Ratings 32/16,

40/20, 48/24 plywood or OSB)

Shutter

Height (ft)

Mean Roof Height (ft)

33 45

5 6" o.c. 4" o.c.

8 3" o.c. 3" o.c.

TABLE A2

MINIMUM NAIL SPACING ALONG EACH END

OF THE SHUTTER PANEL (Span Rating 48 oc,

1-1/8" plywood or OSB)

Shutter

Height (ft)

Mean Roof Height (ft)

33 45

5 4" o.c. 4" o.c.

8 3" o.c. 3" o.c.

6. Any permanently installed hardware, shims or fastening devices must be installed using standard/acceptable methods

of waterproofing. All abandoned holes must be sealed.

7. After fabrication, each shutter should be marked for orientation and location to speed installation.

8. If shims are left in place, use galvanized nails and finish like siding or exterior trim.

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

11

16d (0.135" x 3-1/2") double-headed

nails in accordance with Tables A1 and A2

APA structural panel

No. 2 2x4s or

No. 2 2x6s (if needed)

Cut if desired

Panel strength axis

Span

FIGURE A1

SHUTTER ATTACHMENT VIEW FROM OUTSIDE

16d (0.135" x 3-1/2")

double-headed nails per

Table A1 or A2

Siding

Shim

Shutter

Finish wall

Flashing and caulk

Glass

Header

16d (0.135" x 3-1/2") nails

holding shims per Step 4

Interior casing

Maintain a minimum panel

edge distance of 1/2" 1"

FIGURE A2

SHUTTER ATTACHMENT TOP

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

12

Caulk (prior to

installing shim)

16d (0.135" x 3-1/2") nails

holding shims per Step 4

Shim

Siding

Finish sill

Finish wall

Shutter

Sill

Interior casing

Glass

Maintain a minimum panel

edge distance of 1/2" 1"

16d (0.135" x 3-1/2")

double-headed nails

per Table A1 or A2

FIGURE A3

SHUTTER ATTACHMENT BOTTOM

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

13

DESIGN B

Shutters for Masonry Block Structures

BARREL-BOLT LATCH SUPPORTS

This design from APA describes how to construct structural panel shutters for attachment to masonry block buildings

using barrel-bolt latch supports. The unique features of this design are the barrel bolt latches that support the shutter

at either end. Once made, the shutters can be mounted or removed without any additional hardware or tools. The

barrel-bolt latches should be mounted to the panel with bolts rather than the screws that usually come with them. Use

a washer under the nuts and heads of the bolts. Place the nut-end of the bolts to the outside (latch side) of the shutter

to allow for final adjustment of the latches.

Steps to Constructing Shutters

1. Use Tables 1 and 2 to determine if stiffeners are needed. Attach stiffeners, if needed, as shown in Figure 5.

2. Cut the panel 1/8 inch less than the window opening. The long-panel axis (strength axis) must be oriented perpendicular

to the supported ends (sides of the shutter with the barrel bolts), regardless of which shutter dimension is longer.

3. Make two templates that will help in mounting the latches and

drilling the barrel-bolt latch holes in the concrete blocks one

for each side of the window. The maximum distance between

the top of the shutter panel and the first barrel bolt, and the

maximum distance between barrel bolts shall be in accordance

with Table B1 and should miss the mortar joints between the

blocks by 1-1/2 inches or more. See Figure B1.

4. Mount 4-inch barrel bolts. The nuts go on the latch side (outside)

of the shutter. Make the nuts only finger tight because the latches

will be adjusted in the final fitting.

5. Drill latch-bolt holes in blocks. See Figure B2.

6. Mount the shutter in the window frame, and insert the barrel-

bolt latches into the holes in the concrete blocks. Tighten bolts holding barrel bolts in place.

7. The barrel-bolt holes in the concrete blocks may be filled with a removable plug when not in use as shown in Figure B3.

8. Any permanently installed hardware, shims or fastening devices must be installed using standard/acceptable methods of

waterproofing. All abandoned holes must be sealed.

9. After fabrication, each shutter should be marked for orientation and location to speed installation.

10. To prevent the bottom 2x4 anchor holes in the concrete block from becoming clogged with dirt between shutter

uses, insert 1/2-inch No. 14 pan- or flat-head screws into the anchor holes. Remove these screws prior to reattaching

the 2x4s.

TABLE B1

BARREL BOLT ATTACHMENT SCHEDULE

Shutter

Width

(ft)

Mean Roof Height (ft)

33 45

Distance to First Barrel Bolt (in.)

5 6 5

8 4 3

Barrel Bolt Spacing (in.)

5 12 10

8 8 6

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

14

FIGURE B1

LATCH BOLT PLACEMENT DETAILS

1-1/2"

Panel strength axis

TOP

NORTH SIDE

CENTER

4" barrel bolt

No. 8 machine screws

3/8" cut washers

APA structural panel

Hole for latch bolt

Masonry joints

Outside face of wall

Note: Be sure to mark the

location and orientation

of each shutter after fabrication

4'' Barrel bolt

Section view of barrel bolt

Wall end view

Front view

Distance to first

barrel bolt per Table B1

1-1/2"

Barrel bolt spacing per Table B1

FIGURE B2

LATCH-BOLT HOLE in SiDE

OF WINDOW OPENING

Block

Stucco

Holes for latch

bolts not greater

than 16" o.c.

1-1/2"

minimum

1"

FIGURE B3

TEMPORARY PLUG

FOR LATCH-BOLT HOLE

Stucco

Block

Hole for

latch bolt

Cork

Screw handle

Plug for

latch-bolt hole

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

15

DESIGN C

Shutters for Masonry Block Structures

STEEL OR ALUMINUM ANGLE AND SCREW SUPPORTS

This design from APA describes how to construct structural panel shutters for attachment to masonry block buildings,

using steel or aluminum angle and screw supports. The design is less costly to build than shutters with permanent

hardware for attachment and removal.

Anchorage to Masonry Block

The plastic anchors* referenced in this plan have sufficient lateral and withdrawal capacity to handle the expected

forces and are recommended because they are rated as being vibration resistant a characteristic that may be of some

value under buffeting wind loads. (Standard lead anchors are not usually rated as vibration resistant.)

Keep masonry anchors at least 1-1/2 inches from the block edges, joints and corners to minimize the danger of cracking the

concrete blocks.

Steps to Constructing Shutters

1. Use Tables 1 and 2 to determine if stiffeners are needed. Attach stiffeners, if needed, as shown in Figure 5.

2. In the dimension from support to support, cut the panel 3/8 inch less than the measurement of the window opening

(side to side in Figure C1). In the dimension from unsupported edge to unsupported edge, cut the panel 1/8 inch

less than the measurement of the opening. The long-panel axis (strength axis) must be oriented perpendicular to the

supported sides (side to side in Figure C1), regardless of which shutter dimension is longer.

3. Cut 1-1/2 x 1-1/2 x 1/8-inch steel or aluminum angles to the same length as the width of the shutter ends to be

supported.

4. Drill 1/4-inch diameter holes per Table C1 in one side of the angle. These holes are for bolts that hold the angle to

the panel and may be centered between the corner and the edge of the angle.

5. Drill 3/16-inch diameter holes per Table C2 in the remaining leg of the angle, offset 1 inch from the panel bolt holes.

Make the centerline of the holes 1/4 inch from edge of the angle. These holes are to receive No. 10 screws that will

go through the holes into masonry anchors in the concrete blocks. Refer to Figure C2.

TABLE C2

HOLE LOCATIONS IN ANGLE FOR ATTACHMENT

TO WALL

Shutter

Width

(ft)

Mean Roof Height (ft)

33 45

Concrete Anchor Spacing (in.)

5 8 8

8 6 4

Distance to First Concrete Anchor (in.)

5 4 4

8 3 2

TABLE C1

HOLE LOCATIONS IN ANGLE FOR ATTACHMENT

OF SHUTTER PANEL

Shutter

Width

(ft)

Mean Roof Height (ft)

33 45

Machine Bolt Spacing (in.)

5 12 12

8 12 12

Distance to First Machine Bolt (in.)

5 6 6

8 6 6

*Lateral ultimate value 350 lbs or greater in 4,000 psi concrete, with screws specified (1-1/2 inches with stucco).

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

16

6. Drill holes in blocks for the plastic anchors. Refer to Figure C3.

7. Mount the shutter, with angles mounted, to the window frame using No. 10 x 1-1/2" screws with washers.

See Figure C1.

8. Any permanently installed hardware, shims or fastening devices must be installed using standard/acceptable methods

of waterproofing. All abandoned holes must be sealed.

9. After fabrication, each shutter should be marked for orientation and location to speed installation.

10. To prevent the bottom 2x4 anchor holes in the concrete block from becoming clogged with dirt between shutter

uses, insert 1/2-inch No. 14 pan- or flat-head screws into the anchor holes. Remove these screws prior to reattaching

the 2x4s.

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

17

FIGURE C1

SHUTTER ATTACHMENT DETAIL

Panel strength axis

TOP

NORTH SIDE

CENTER

Block wall

Note: Be sure to mark the

location and orientation of

each shutter after fabrication

1-1/2"

minimum

APA structural panel

1/4" Dia. hole

3/32" Dia. hole

1-1/2" x 1-1/2" x 1/8"

Aluminum or steel angle

No. 10 wood or sheet metal screw

1/4" x 1" screw-in anchor

(1-1/2" screw-in anchor for stucco)

per Table C2

3/16" Dia. hole

Outside view of wall

Block wall

Block wall

top view

No. 8 machine screw with

1/4" x 1-1/4" fender washers per Table C1

Front or outside

FIGURE C2

AngLE-TO-SHuTTER ATTACHMEnT DETAiL

FIGURE C3

SCREW-in AnCHOR HOLE in SiDE OF WinDOW

OPENING

1/4" Dia. hole

per Table C1

3/32" Dia. hole

3/16" Dia.

hole per

Table C2

APA structural panel 1-1/2" x 1-1/2" x 1/8"

Aluminum or steel angle Stucco

Block

Hole for 1'' screw-in

anchor (1-1/2" screw-in

anchor for stucco)

per Table C2

1-1/2"

minimum

1"

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

18

DESIGN D

Shutters for Masonry Block Structures

SHUTTERS ATTACHED TO OUTSIDE WALL WITH PERMANENTLY MOUNTED BRACKETS

This design from APA describes how to construct structural panel shutters for attachment to masonry block buildings, using

permanently mounted brackets on the outside wall. Two layers of APA Exterior plywood are attached to the outside of the concrete

block wall with No. 10 flat-head screws in masonry anchors. Once the brackets are installed, no tools are required to install or

remove the shutters unless stiffeners are required. It has the advantage of moving the shutter almost 2 inches farther away from

the glass than shutters mounted to the interior of the window frame and is therefore less likely to require stiffeners.

Fasteners

Screws or bolts that will be permanently exposed to the weather should be made of stainless steel.

Anchorage to Masonry Block

The plastic anchors* referenced in this plan have sufficient lateral and withdrawal capacity to handle the expected

forces and are recommended because they are rated as being vibration resistant a characteristic that may be of some

value under buffeting wind loads. (Standard lead anchors are not usually rated as vibration resistant.)

Keep masonry anchors at least 1-1/2 inches from the block edges, joints and corners to minimize the danger of cracking the

concrete blocks.

Steps to Constructing Shutters

1. Use Tables 1 and 2 to determine if stiffeners are needed. Attach stiffeners, if needed, as shown in Figure 5.

2. Cut APA Exterior plywood for the shutter support/spacer and

for the trim that holds shutter against the supports (see Figure

D1). Make the thickness of the inner spacer slightly greater

than that of the shutter to allow the shutters to slide without

binding. (The inner trim spacer of plywood is left out of one

side of the window framing to allow for the insertion of the

shutters.) Orient the plywood face grain of the trim as indi-

cated in the diagram. (Plywood with four or more plies may

be oriented either direction.) Lap the corners to allow the

outer trim to be attached to the inner spacer at the corners.

Refer to Figure D1.

3. Drill 1/2-inch diameter vertical drain holes in bottom inner

spacer to allow rain water to escape out the bottom.

4. Cut the shutter to be 1/4 inch less than the distance from the bottom of the bottom slot to the top of the top slot, and

about 2 inches wider than the window opening width (assuming that the panels are supported top and bottom).

Orient the long-panel axis (strength axis) as shown in Figure D1. Slide the shutter into place.

5. Drill hole halfway down the trim and diagonally downward (at about 30 degrees from the surface) in the trim board

covering the shutter-entrance opening. The hole should be about 1/8 inch outside the edge of the installed shutter.

This hole will receive a 12d box (0.128 x 3-1/4-inch) nail to prevent the shutter panel or panels from getting blown

back out the entrance slot.

*Withdrawal ultimate value 490 lbs or greater in 4,000 psi concrete, with screws specified (1-1/2 inches with stucco).

TABLE D1

TRiM-TO-COnCRETE AnCHOR SPACing

Shutter

Height

(ft)

Mean Roof Height (ft)

33 45

Concrete Anchor Spacing (in.)

5 12 12

8 9 6

Distance to First Concrete Anchor (in.)

5 6 6

8 4 3

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

19

6. Any permanently installed hardware, shims or fastening devices must be installed using standard/acceptable methods of

waterproofing. All abandoned holes must be sealed.

7. After fabrication, each shutter should be marked for orientation and location to speed installation.

8. To prevent the bottom 2x4 anchor holes in the concrete block from becoming clogged with dirt between shutter uses,

insert 1/2-inch No. 14 pan- or flat-head screws into the anchor holes. Remove these screws prior to reattaching the 2x4s.

Design Alternative

As an alternative to Design D, the wood trim can be replaced with 1 x 1 x 1-inch (outside measurements) x 1/8-inch

aluminum channels (channel outside dimensions may be changed to better accommodate panels thicker than 5/8 inch i.e.,

1-1/8-inch-thick shutters will require a channel slot opening of about 1-1/4 inches) mounted approximately the same way as

the wood trim. See Figure D2. Make holes at both ends to hold a latching device to prevent shutters from being blown out.

APA structural panel shutter

1/2" Plywood face trim

No. 10 screw

1/4" x 1" Screw-in anchor

(1/4" x 1-1/2" for stucco) in

accordance with Table D1

Panel strength axis

Inner spacer

1-1/2" Minimum

Note: Using sawn lumber instead of plywood for the outer layer of trim may result in the failure of the trim when suction loads are applied

to the shutter.

Detail of

locking

device

Face trim

Not required for

reinforced shutters

Hole for

shutter stop

Side view

Lap trim at corners

Shutter location

marked on shutter

Shutter slot (3 sides)

Strength axis

Drain hole

Block

3" 4"

Thickness of shutter plus 1/8"

TOP

NORTH SIDE

CENTER

FIGURE D1

SHUTTER FRAME AND ATTACHMENT STRUCTURAL PANEL OPTION

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

20

FIGURE D2

SHUTTER FRAME AND ATTACHMENT ALUMINUM CHANNEL OPTION

1/4" x 1" screw-in anchor

(1/4" x 1-1/2" for stucco) in

accordance with Table D1

Stucco

Block

1-1/2"

Minimum

1/2"

Aluminum channel

1" x 1" x 1" x 1/8"

No. 10 screw

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

21

DESIGN E

Shutters for Masonry Block Structures

FOR OPENINGS WIDER THAN 8 FEET

This design from APA describes how to construct structural panel shutters for attachment to masonry block build-

ings, where glass windows and doors are wider than 8 feet. The shutters run from top to bottom and are attached to a

temporary 2x4 lumber strip at the top and bottom of the opening.

Anchorage to Masonry Block

The plastic anchors* referenced in this plan have sufficient lateral and withdrawal capacity to handle the expected

forces and are recommended because they are rated as being vibration resistant a characteristic that may be of some

value under buffeting wind loads. (Standard lead anchors are not usually rated as vibration resistant.)

Keep masonry anchors at least 1-1/2 inches from the block edges, joints and corners to minimize the danger of cracking

the concrete blocks.

Steps to Constructing Shutters

1. Use Table 2 to determine which panel to use.

2. Cut two 2x4s to a length that is 1 inch less than the width of the door opening to be covered. Rip the 2x4s length-

wise, if necessary, to the width of the distance of the door frame to the front of the wall. The outside edge of the 2x4

should be flush with the outside surface of the wall. (Note: If holes or hole plugs on the front of the building are not

a concern, the top 2x4 may be eliminated by extending the shutter above the opening and attaching the top of the

shutter directly to the front of the header.) Refer to Figure E1.

3. Predrill 1/4-inch diameter holes in the 2x4s in accordance with Table E1 and at least 1-1/2 inches from the front

edge of the 2x4s (outside surface of the wall).

4. Drill holes in the concrete blocks.

5. Tap vibration-resistant anchors into the holes in the concrete.

6. Attach the 2x4s to top and bottom of the opening using 2-1/2-inch No. 14 round or pan-head wood or sheetmetal

screws with washers. Refer to Figure E1.

7. Cut the shutter to span the opening (plus the width of the supports, 3 inches for two 2x4s). Orient the long-panel

axis (strength axis) as shown in Figure 5.

8. Drill holes at 16 inches o.c. along the supported panel edges and in the 2x4s.

9. Attach the shutter to the 2x4s with 2-inch No. 10 wood or sheetmetal screws in accordance with Table E2.

10. To prevent the bottom 2x4 anchor holes in the concrete block from becoming clogged with dirt between shutter

uses, insert 1/2-inch No. 14 pan- or flat-head screws into the anchor holes. Remove these screws prior to reattaching

the 2x4s.

11. Any permanently installed hardware, shims or fastening devices must be installed using standard/acceptable

methods of waterproofing. All abandoned holes must be sealed.

12. After fabrication, each shutter should be marked for orientation and location to speed installation.

* Withdrawal ultimate value 490 lbs or greater in 4,000 psi concrete, with screws specified (1-1/2 inches with stucco).

[RETURN TO INDEX]

Hurricane Shutter Designs

Form No. T450G

2013 APA The Engineered Wood Association

www.apawood.org

22

FIGURE E1

SHUTTER ATTACHMENT TO HEADER AND SLAB FLOOR

No. 10 x 2" screw with washer

in accordance with with Table E2

Concrete floor

APA structural panel

Header reinforcing

No. 14 x 2-1/2" screw with washer

in accordance with Table E1

3/16" x 3" lag screw with fender washer

16d nails 6" o.c.

Anchor

No. 14 x 2-1/2" screw with washer

in accordance with Table E1

2x4

2x4

Header

Shutter location and orientation

TOP

WEST SLIDER

LEFT SIDE

No. 2 2x4 16" o.c.

or No. 2 2x6 16" o.c.

Alternate means of attachment

No. 14 x 2-1/2" screw with washer and

anchor through 2x4 in accordance

with Table E3

Patio slab

No. 10 x 2" screw with washer

in accordance with Table E2

Alternate means of attatchment

No. 14 x 2-1/2" screw with washer and

anchor in accordance with Table E3

Anchor

Anchor

2x4 (if required)

Outside of shutter

Min.

1-1/2"

Min.

1-1/2"

Outside surface of wall

TABLE E2

SHUTTER TO TEMPORARY 2x4

Shutter

Width

(ft)

Mean Roof Height (ft)

33 45

no. 10 Screw Spacing

(in.)

5 8 8

8 4 4

Distance to First no. 10

Screw (in.)

5 4 4

8 2 2

TABLE E1

TEMPORARY 2x4 TO COnCRETE

Shutter

Width

(ft)

Mean Roof Height (ft)

33 45

no. 14 Screw Spacing

(in.)

5 12 12

8 8 6

Distance to First no. 14

Screw Anchor (in.)

5 6 6

8 4 3

TABLE E3

TOP OF SHUTTER TO HEADER

(Alternate Means)

Shutter

Width

(ft)

Mean Roof Height (ft)

33 45

Concrete Anchor

Spacing (in.)

5 6 6

8 4 4

Distance to First

Concrete Anchor (in.)

5 3 3

8 2 2

[RETURN TO INDEX]

Hurricane Shutter Design

We have field representatives in many major U.S. cities and in Canada

who can help answer questions involving APA trademarked products. For additional assistance

in specifying engineered wood products, contact us:

APA HEADQUARTERS

7011 So. 19th St.

Tacoma, Washington 98466

(253) 565-6600

Fax: (253) 565-7265

PRODUCT SUPPORT HELP DESK

(253) 620-7400

E-mail Address: help@apawood.org

DISCLAIMER

The information contained herein is based on APA The Engineered Wood Associations

continuing programs of laboratory testing, product research, and comprehensive field experi-

ence. Neither APA, nor its members make any warranty, expressed or implied, or assume any

legal liability or responsibility for the use, application of, and/or reference to opinions, findings,

conclusions, or recommendations included in this publication. Consult your local jurisdiction or

design professional to assure compliance with code, construction, and performance require-

ments. Because APA has no control over quality of workmanship or the conditions under which

engineered wood products are used, it cannot accept responsibility of product performance or

designs as actually constructed.

Form No. T450G/Revised September 2013

Вам также может понравиться

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Red Bug Complete Plans SetДокумент72 страницыRed Bug Complete Plans Setmantuga92% (26)

- Exterior Cladding DetailsДокумент13 страницExterior Cladding DetailsMuhammad irfan javaidОценок пока нет

- Plans Guide 2010Документ14 страницPlans Guide 2010Jessie O.Bechayda33% (3)

- Building-Technology-Notes WOOD TO CEMENTДокумент12 страницBuilding-Technology-Notes WOOD TO CEMENTJohn Milan Octeza100% (1)

- Roof Sheathing FasteningДокумент4 страницыRoof Sheathing Fasteningnumber_25Оценок пока нет

- Boq NewДокумент18 страницBoq NewPawan SutharОценок пока нет

- Syanja Rate AnalysisДокумент41 страницаSyanja Rate AnalysisAbinash MandalОценок пока нет

- Northwest Dowsing - Water LabyrinthДокумент20 страницNorthwest Dowsing - Water Labyrinthitounos100% (1)

- An Introduction To BS 5268 PDFДокумент8 страницAn Introduction To BS 5268 PDFSam11111Оценок пока нет

- TEK 03-04C Bracing CMU Walls Under ConstructionДокумент12 страницTEK 03-04C Bracing CMU Walls Under ConstructionAdam JonesОценок пока нет

- Jig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsДокумент6 страницJig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsJd Diaz100% (1)

- Finishing of WoodДокумент40 страницFinishing of WoodOsman Batur SalurОценок пока нет

- On Centuryply Case StudyДокумент10 страницOn Centuryply Case StudyNAUSHEEN HASAN67% (6)

- Reinforced Concrete Buildings: Behavior and DesignОт EverandReinforced Concrete Buildings: Behavior and DesignРейтинг: 5 из 5 звезд5/5 (1)

- Part of Nfpa 20 Handbook 2016Документ12 страницPart of Nfpa 20 Handbook 2016احمد الجزار200750% (2)

- Window SprinklerДокумент8 страницWindow SprinklerAhrian BenaОценок пока нет

- Suspended Ceiling Systems-10.24.2012Документ30 страницSuspended Ceiling Systems-10.24.2012Rica Jeremias CamachoОценок пока нет

- FM Global Property Loss Prevention Data Sheets: List of FiguresДокумент8 страницFM Global Property Loss Prevention Data Sheets: List of Figuresthongtn2007Оценок пока нет

- Summer Intership Project Report HRДокумент188 страницSummer Intership Project Report HRshilpa singhalОценок пока нет

- NFPA 22 (2003) Special RequirementsДокумент4 страницыNFPA 22 (2003) Special RequirementsLeslie Scott67% (3)

- Ancon Wall Ties and Restraint Fixings For Brick, Block and StoneДокумент32 страницыAncon Wall Ties and Restraint Fixings For Brick, Block and StoneGreg AceОценок пока нет

- 523 2R-96 PDFДокумент5 страниц523 2R-96 PDFsaeidcivil89Оценок пока нет

- T460 Hurricane Shutter DesignДокумент0 страницT460 Hurricane Shutter DesignlesgiuОценок пока нет

- 2006 Texas Revisions To The 2006 International Building CodeДокумент9 страниц2006 Texas Revisions To The 2006 International Building CodeEltigani HamadОценок пока нет

- Ansi-Spri RP-4-2008Документ33 страницыAnsi-Spri RP-4-2008Gertrudis MirandaОценок пока нет

- Section Struct 16909-12Документ10 страницSection Struct 16909-12johnОценок пока нет

- Esr 2397Документ5 страницEsr 2397murdicksОценок пока нет

- Code of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsДокумент14 страницCode of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsmazniseinОценок пока нет

- Legacy Report: ICC Evaluation Service, IncДокумент9 страницLegacy Report: ICC Evaluation Service, IncArvind AnchliyaОценок пока нет

- FEMA 499 - 6 - 2 Protection of Openings - Shutters and GlazingДокумент6 страницFEMA 499 - 6 - 2 Protection of Openings - Shutters and GlazingScribdemdОценок пока нет

- Building and Fire SafetyДокумент4 страницыBuilding and Fire SafetyBrianaCroninОценок пока нет

- Airport Noise Design StandardДокумент10 страницAirport Noise Design StandardLakshmiWijayasiriОценок пока нет

- SR-102 APA System Report 102 APA Simplified Wall Bracing Method PDFДокумент15 страницSR-102 APA System Report 102 APA Simplified Wall Bracing Method PDFAbdurrahman CinarОценок пока нет

- TB 34 - Steel Building Frames June 2020 EarthingДокумент8 страницTB 34 - Steel Building Frames June 2020 EarthingRethish KochukavilakathОценок пока нет

- ICC-ES Evaluation Report ESR-2218Документ12 страницICC-ES Evaluation Report ESR-2218Mark J LeingangОценок пока нет

- BE - SPEC - FD1600 11 - 2 Hour Dynamic Rated MultiBlade Fire Dampers120630Документ5 страницBE - SPEC - FD1600 11 - 2 Hour Dynamic Rated MultiBlade Fire Dampers120630Maria Gabriela BusteloОценок пока нет

- International Building Code But Utilizing The: Wind Loads Set Forth in 780 CMR 53.00Документ22 страницыInternational Building Code But Utilizing The: Wind Loads Set Forth in 780 CMR 53.00Valeriia KasОценок пока нет

- Chapter III Aaamsa 2017-11-10 Sans 10160 A Part 1 Basis of StructuralДокумент42 страницыChapter III Aaamsa 2017-11-10 Sans 10160 A Part 1 Basis of StructuralDavide MartiniОценок пока нет

- Section - 15910 Ductwork AccessoriesДокумент3 страницыSection - 15910 Ductwork AccessoriesalbrgmailОценок пока нет

- Commonly Used Residential Building Codes - Stevens CountyДокумент10 страницCommonly Used Residential Building Codes - Stevens CountyReymondo BundocОценок пока нет

- SteelДокумент19 страницSteelJohneey DeepОценок пока нет

- Durock DEFSДокумент5 страницDurock DEFSJose Antonio FigueroaОценок пока нет

- PRG.E1-27.2020.07.10.Automatic Sprinkler SystemsДокумент10 страницPRG.E1-27.2020.07.10.Automatic Sprinkler Systemshassanqr89Оценок пока нет

- Wall Ties (1) ANCONДокумент32 страницыWall Ties (1) ANCONEngr. Zohaib Hussain Kazi100% (1)

- Aluco21spec PDFДокумент12 страницAluco21spec PDFRené Galbraith BerraОценок пока нет

- Er-5414 (2001)Документ7 страницEr-5414 (2001)m0172Оценок пока нет

- Metal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsДокумент5 страницMetal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsAlvaro MejiaОценок пока нет

- Bridge Technical Note 1999006V21Документ4 страницыBridge Technical Note 1999006V21er_surajrpОценок пока нет

- Inclined Roof System Trimoterm SNV - 16755 PDFДокумент25 страницInclined Roof System Trimoterm SNV - 16755 PDFРостислав ВасилевОценок пока нет

- Significant Changes From The 2009 Icc To 2012Документ87 страницSignificant Changes From The 2009 Icc To 2012Vịt BầuОценок пока нет

- Safety Fence: STD & SPEC 3.01Документ5 страницSafety Fence: STD & SPEC 3.01gowtham reddyОценок пока нет

- Ancon Wall Ties & Restraint FixingsДокумент32 страницыAncon Wall Ties & Restraint FixingsAngela KeithОценок пока нет

- Aci523 - ImportanteДокумент5 страницAci523 - ImportanteCledson2Оценок пока нет

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersДокумент2 страницыDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimОценок пока нет

- Kingspan 20insulation Thermaroof 20tr22Документ8 страницKingspan 20insulation Thermaroof 20tr22Ady SasuОценок пока нет

- t049 TG 8.1 34 CorrugatedstainlesssteeltubingДокумент8 страницt049 TG 8.1 34 Corrugatedstainlesssteeltubingrafael.teixeir.casaisОценок пока нет

- 39HQM Guide SpecificationsДокумент8 страниц39HQM Guide SpecificationsAyman KamelОценок пока нет

- Ast, E580-02 Cielo Falso PDFДокумент5 страницAst, E580-02 Cielo Falso PDFEdgardoAnayaОценок пока нет

- Building Codes: Wind LoadsДокумент2 страницыBuilding Codes: Wind LoadsAmir ShaikОценок пока нет

- Rule 13: Electrical and Mechanical RegulationsДокумент5 страницRule 13: Electrical and Mechanical RegulationsFrank Louie MendozaОценок пока нет

- Asdma Bulletin BS8214Документ2 страницыAsdma Bulletin BS8214Raju KCОценок пока нет

- Building Fire SafetyДокумент9 страницBuilding Fire SafetyrishiОценок пока нет

- Obstructions in SprinklerДокумент28 страницObstructions in SprinklerMd Rafat ArefinОценок пока нет

- Wall Ties & Restraint Fixings: For The Construction IndustryДокумент32 страницыWall Ties & Restraint Fixings: For The Construction IndustryhemendraengОценок пока нет

- Disapro Collaspe PDFДокумент11 страницDisapro Collaspe PDFamz1231Оценок пока нет

- Specifications PDFДокумент30 страницSpecifications PDFRivaiОценок пока нет

- Barge Notice 3Документ11 страницBarge Notice 3Faidzy A RahmanОценок пока нет

- Certificate 032 96Документ9 страницCertificate 032 96ferdinandbataraОценок пока нет

- Tables: Home Office Built-In Cabinet Calculator and PlansДокумент41 страницаTables: Home Office Built-In Cabinet Calculator and PlansLonebeavОценок пока нет

- Duraplast MgO BrochureДокумент12 страницDuraplast MgO BrochureMujjo SahbОценок пока нет

- KP Sharma EstimateДокумент31 страницаKP Sharma EstimateSudip GhimireОценок пока нет

- In?uence of Curvature Geometry of Laminated FRP Composite Panelson Delamination Damage in Adhesively Bonded Lap Shear JointsДокумент10 страницIn?uence of Curvature Geometry of Laminated FRP Composite Panelson Delamination Damage in Adhesively Bonded Lap Shear Joints615513Оценок пока нет

- Yilmaz2011 Article InvestigationOfTwistedMonofilaДокумент8 страницYilmaz2011 Article InvestigationOfTwistedMonofilaAYOUB RHOUSNIОценок пока нет

- 3 Brand - Natures View Installation ManualДокумент6 страниц3 Brand - Natures View Installation ManualEli MatucadОценок пока нет

- QCS 2010 Part 18.03 Structural TimberДокумент5 страницQCS 2010 Part 18.03 Structural TimberRotsapNayrbОценок пока нет

- How To Build A Kennel: Note 1. About Pressure Treated TimberДокумент4 страницыHow To Build A Kennel: Note 1. About Pressure Treated Timber- yAy3e -Оценок пока нет

- Pradhan Mantri Awas Yojana Housing For All (Urban) in AP StateДокумент120 страницPradhan Mantri Awas Yojana Housing For All (Urban) in AP StateKishore Nayak kОценок пока нет

- African Teak A Technical Data SheetДокумент4 страницыAfrican Teak A Technical Data SheetSandesh Kumar0% (1)

- Kerto Manual Bolted ConnectionsДокумент17 страницKerto Manual Bolted ConnectionsM Refaat FathОценок пока нет

- Ardcc 5TH Module NotesДокумент10 страницArdcc 5TH Module NotesmonikaОценок пока нет

- Design 2005Документ21 страницаDesign 2005bugsy77Оценок пока нет

- Package II Part I.1 Civil BOQ For Transit House BuildingДокумент29 страницPackage II Part I.1 Civil BOQ For Transit House Buildingdox4useОценок пока нет

- Is 1003 2 1994 PDFДокумент19 страницIs 1003 2 1994 PDFSHAIK RABBANIОценок пока нет

- Development of Carbon Nanotube-Based Composite For Spacecraft ComponentsДокумент7 страницDevelopment of Carbon Nanotube-Based Composite For Spacecraft ComponentsSureshv SuriОценок пока нет

- Eco Bed Fitting MechanismДокумент3 страницыEco Bed Fitting MechanismPriyanka NemadeОценок пока нет

- Assignment No.1: College of Engineering Civil Engineering Timber DesignДокумент11 страницAssignment No.1: College of Engineering Civil Engineering Timber DesignMarc Edwin VergaraОценок пока нет

- Building Technology Market SurveyДокумент21 страницаBuilding Technology Market SurveyParmeet KaurОценок пока нет