Академический Документы

Профессиональный Документы

Культура Документы

Surface Treatment Selections For Automotive Applications

Загружено:

SasiKumar PetchiappanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Surface Treatment Selections For Automotive Applications

Загружено:

SasiKumar PetchiappanАвторское право:

Доступные форматы

Surface & Coatings Technology 200 (2005) 1962 1968 www.elsevier.

com/locate/surfcoat

Surface treatment selections for automotive applications

J. Vetter a,*, G. Barbezat b, J. Crummenauer a, J. Avissar c

a

Metaplas Ionon, Am Bo ttcherberg 30-38, 51427 Bergisch Gladbach, Germany b Sulzer Metco AG, Rigackerstr. 16, 5610 Wohlen, Switzerland c Sulzer Metaplas (US) Inc., 222 Goldstein Drive, Woonsocket, RI 02895, USA Available online 25 October 2005

Abstract Surface treatments used in daily manufacturing of parts for the automotive industry are selected to serve functional and decorative requirements achieved by mass production. Increased loads (mechanical, thermal, etc.), longer lifetime, weight reduction, friction reduction, and corrosion resistance are demanded for modern automotive systems. Within the last decade, improved and new deposition techniques were developed in PVD, PECVD, thermochemical heat treatment and thermal spraying. These new treatments are becoming more and more common in powertrain and engine applications. Generating optimized surfaces for different types of substrate materials (e.g. Al-alloys, case hardened steels, etc.) and geometries (e.g. bores) also impacts the running costs. Due to the new developments within these competing surface treatments, it becomes more and more common to substitute traditional treatment-substrate-systems with advanced treatments. Both the application potential and selected examples of different surface treatments will be shown. Aspects of the internal coating of bores inside the engine by plasma spraying, features of the corrosion protection of parts for the powertrain by the IONITOX process and piston ring treatments are discussed in more detail. D 2005 Elsevier B.V. All rights reserved.

Keywords: PVD; Nitriding; Thermal spraying; Automotive; Corrosion; Wear; Friction; Decoration

1. Introduction Automobile manufacturers have to consider in addition to the expectations and satisfaction of customers regarding the reliability, functionality, comfort and safety, additional aspects such as: production, consumption and environmental issues. The search continues for flexible manufacturing, new design concepts and vehicles that are easier to assemble. Regional environmental legislation and shorter product life cycles require higher quality and more stringent materials requirements. Even though these challenges affect all aspects of the industry, they can be met and overcome with the correct set of resources. In order to compete effectively in this fast paced and increasingly complex competitive environment, enterprising automotive executives will need to constantly optimize their business models and improve existing technical solutions or create new ones. Surface enhancement engineering solutions are becoming more and more the goal of the

* Corresponding author. Tel.: +49 2204 299 261; fax: +49 2204 299 266. E-mail address: joerg.vetter@salzer.com (J. Vetter). 0257-8972/$ - see front matter D 2005 Elsevier B.V. All rights reserved. doi:10.1016/j.surfcoat.2005.08.011

automotive industry in reduction of wear, friction and corrosion for powertrain parts and engine interiors [1]. New surface solutions are also applied for interior and exterior decoration. Surface enhancement engineering basically involves changes to the surface of a material by additive processes such as thermal spray (named TS), PVD, plasma enhanced CVD (named PECVD), thermochemical heat treatment (named TCHT) like nitriding or nitrocarburizing (with oxidation named IONITOX) [26]. In effect, this surface treatment creates a new material superior to the original. Also hard carbon overlays become a solution for increased demands in transmission parts (e.g. for synchronization rings).

2. Plasma assisted processes for surface treatments of automotive parts Plasma assisted surface treatments used for automotive parts include different methods of plasma generation in terms of the plasmas used, the material generated and the interaction between the material flow and the substrate

J. Vetter et al. / Surface & Coatings Technology 200 (2005) 1962 1968 Table 1 Summary of the treatment types of different plasma states, the materials used and typical substrate materials (GNC gas nitrocarburizing) Type of plasmas Atmospheric plasma spraying Plasma assisted TCHT LTE-plasma Material source Atmospheric arc discharge Pulsed glow discharge in gas mixtures, e.g. N2, H2 Plasma surface interaction Nearly no plasma activity at the surface Ion impact Surface acts as the cathode Species for diffusion are generated Ion impact Surface acts as the cathode Surface modification after GNC; before oxidation Ion impact Surface acts as the cathode Species for coating growth are generated Ion impact Extracted Ar-ions Sputtered atoms as growth materials Ion impact Extracted metal ions Evaporated atoms and ions as growth materials Substrate material

1963

Cold plasma

Metal alloys, e.g. Al-alloys Composite Metals, e.g. heat treatable steels Ti-alloys

IONITOX activation step

Cold plasma

Pulsed glow discharge in N gas mixtures

Metals, e.g. heat treatable steels

PECVD

Cold plasma

Pulsed glow discharge in precursors, e.g. C2H2

Metals, e.g. bearing steels

PVD sputtering

Cold plasma

Atomizing by sputtering due to glow discharge at a target Evaporation by vacuum arc discharge

Metal alloys Galvanized plastics

PVD vacuum arc

Cold plasma

Metal alloys Galvanized plastics

surface during the deposition of a coating or during the growth of a diffusion (and compound) layer. Two plasma types are applied: the local thermodynamic equilibrium plasma (LTE) and the thermodynamic nonequilibrium plasma (cold plasma). Plasmas in local thermodynamic equilibrium in which all temperatures (except the radiation temperature) are equal in each small volume of the plasma are the basis for plasma spraying at atmospheric pressures (thermal plasma). This thermal plasma is used for the melting of the material resulting in the coating. The plasma does not play a

dominant rule during coating growth. Cold plasmas are always generated by plasma assisted PVD and CVD processes and in plasma assisted thermochemical heat treatment (e.g. plasma nitriding processes). The cold plasma is characterized by hot electrons and cold ions. The ions are normally used during the coating growth or during the diffusion treatment. Table 1 shows a summary of the treatment types using different plasma states, the material used and typical substrate materials. Selected properties of the different treatments and typical applications are shown in Table 2. It should be

Table 2 Selected properties of the different treatments and typical applications PVD MeNCO Thickness [Am] Hardness (micro) Friction against steel Deposition temperature [-C] Typical application 2 50 1600 3500 Dry 0.5 0.8 50 (plastics) 500 Piston rings Pumps Decoration PVD/PECVD DLC 15 1000 3000 Dry 0.1 0.3 60 250 Injection systems Tappest Gears Thermochemical heat treatment PN/PNC DZ/CZ 50 500 600 1200 Dry 0.7 0.9 350 800 (Ti) Piston rings Syncroniz Clutches PNC + OX DZ/CZ + oxide 1 3 500 800 Dry 0.6 0.8 400 570 Ball pivots Gear selector shafts Pumps Spraying Metal 100 400 300 600 Lubricant 0.05 0.15 50 150 Piston rings Synchroniz Shift forks Metal + ceramics 200 500 400 1000 Lubricant 0.05 0.10 50 150 Piston rings Bores Break discs Bonding Carbon onlay 400 700 Not measured Lubricant 0.11 0.13 160 280 Shift forks Synchroniz Clutches

1964

J. Vetter et al. / Surface & Coatings Technology 200 (2005) 1962 1968

Fig. 1. Selected parts to be treated by surface technologies.

mentioned that the plasma assisted surface treatments are more or less in competition with the non-plasma surface treatments. The term Spraying in the table does not stand only for plasma spraying, but stands for the whole group of thermal spraying. The newer material carbon onlay which is bonded at selected functional surfaces is included for comparison. However, the main issue of the paper is the discussion of plasma assisted surface treatments to point out the specialities to generate new surface conditions for a variety of applications.

4. Selected application examples 4.1. Cylinder bores: low wear rates by rotating plasma torches The conventional Al cast alloys with 7% to 9% Si do not produce the necessary tribological properties for the piston group. The hypereutectic alloys with 17% to 20% Si present several disadvantages concerning manufacturing

Corrosion protection

3. Functional plasma assisted surface treatments Fig. 1 shows a variety of car parts treated by different surface technologies. Parts of the powertrain, the engine and components of the interior or exterior are finished by plasma assisted surface technologies. Different functional surface properties of various automotive parts require a variety of surface treatments. A rough classification of the four main required surface properties and typical application of plasma assisted surface treatments are shown in Fig. 2. The surface requirements (low friction, low wear, etc.) are often more or less overlapping. However it becomes clear that the adjustable properties of the surfaces within the above mentioned groups of surface treatments cover an enormously wide range (mechanical, electrical, tribological, corrosive properties).

e.g. Ball pivot IONITOX Wear reduction e.g. Piston rings Plasma spraying Decorative appearance e.g. Signs PVD Friction reduction e.g. Injection DLC PVD/PECVD

Properties Application Treatment

Fig. 2. Main functional properties required in automotive application.

J. Vetter et al. / Surface & Coatings Technology 200 (2005) 1962 1968 Table 3 Typical plasma coatings for cylinder bore and their characteristics Coating type A: Carbon steel with solid lubricant wustite and magnetite (XPT 512) B: Composite of tool steel and molybdenum Hardness [HV0.3] 400 Microstructure Ferrite with fine carbides, FeO (wustite) and Fe3O4 (magnetite) Ferrite with fine iron carbides and isolated phase of molybdenum. Low level in iron oxides Iron a with fine carbides and some oxides Material A with addition of about 20% discrete particle of ceramic Material C with addition of 20% discrete particle of ceramic

1965

costs. For these reasons galvanic solutions are used only for few special applications. The internal plasma spray coatings are now used in the production of a variety of gasoline and diesel engines [7,8]. The deposited plasma sprayed coatings show three significant advantages in comparison with cast iron sleeves or monolithic material cast iron with lamellar graphite [9,10]. The plasma sprayed coatings have the potential to reduce the friction of the piston groups by roughly 30%. The consequent fuel consumption reduction is around 3%. The oil consumption can also be significantly reduced in comparison with the cast iron (usually by a factor of two). The wear rate is extremely low, only some nanometers per service hour. During the coating deposition of the low alloyed carbon steel XPT 512 wustite FeO and magnetite Fe3O4 are produced. Both types of these crystals are working as solid lubricants. The amount of iron oxide is controlled by the choice of the spray parameters, primarily plasma gas composition, dwell time of the particle in the plasma, and plasma enthalpy. Table 3 shows typical deposited plasma coatings and their characteristics. The manufacturing steps of the cylinder bores finished by plasma spraying are shown in Fig. 3. 4.2. Ball pivot: high corrosion resistance by IONITOX The IONITOX process was developed as a combination of gas nitriding and plasma activation processes to generate surfaces with high corrosion resistance on carbon steels and heat treatable steels. The plasma activation step is carried out before the oxidation. Corrosion stability is reached due to a dense oxide layer (Fe3O4) of a thickness of about 2 um.

400

C: Stainless steels (Cr and Mo alloyed) D: Metal matrix composite MMC (type 1) E: Metal matrix composite MMC (type 2)

350 450

400

costs and inferior mechanical properties (low toughness). Today, the most frequently used tribological solution for engine blocks in aluminum cast alloys is the insert of cast iron sleeves. However the insertion of cast iron sleeves presents several disadvantages. The pitch distance is still relatively high in comparison with the bore diameter. The heat flow from cylinder bore to the cooling system is not regular. The oxides between the cast iron sleeves and the Al cast material have a negative influence, because they are not homogeneously distributed and some distortion of the bores results. The distortion of the bores increases the tendency for blow-by and has a negative influence on the power generated. There are some galvanic solutions but these also present several disadvantages in terms of environmental impact and

Fig. 3. Steps of bore coating solution: 1. Casting and machining, 2. Surface activation, 3. Coated cylinder bore, 4. Finish machining (diamond honing).

1966

J. Vetter et al. / Surface & Coatings Technology 200 (2005) 1962 1968

4.4. Decoration Customers prefer attractive cars. The cars interior and exterior need to be styled according to modern trends. More and more PVD coatings are deposited by sputtering and or vacuum arc evaporation, and are applied to different materials including galvanized plastics (ABS). The colours can be adjusted over a wide range.

5. New developments New developments in surface technologies, driven mainly by material aspects, provide opportunities for improving systems and their components. The new solutions have to be able to compete with the classical solutions. Even if there are apparent advantages, additional aspects such as financial, reliability, compatibility with existing manufacturing methods, etc., have to be considered. Newer developments are: plasma borizing of gears [11], coatings for gears, plasma sprayed bearing coatings, nitriding of powder metallurgical steels. Four examples of surface treatments from themore or less industrial development state will be discussed in more detail in the following. 5.1. Deposition of coating for connecting rod bearing The development of the internal plasma spraying technology enables new horizons of application. Connecting rod bores of 40 to 60 mm internal diameter can be coated using the internal plasma spraying technology [12,13]. Especially interesting is the spraying technology for the cracked connecting rod. The coating deposition can be considered before or after the cracking of the parts. The coating deposition is performed in stacks, so an interesting productivity can be obtained. Primarily lead free copper

Fig. 4. Improvements of ball pivots by IONITOX treatment.

Different parts are treated in industrial scale: gear selector shafts, pump cases, etc. Fig. 4 shows a typical application ball pivots with the improvements. 4.3. Piston rings: reduction of wear and seizure due to PVD coatings Piston rings have to seal the combustion gas and to control the lubrication oil. The surface treatment is used to reduce wear and to prevent seizure. A variety of piston rings exists for different applications. Besides the different substrate materials, also different surface treatments are used. Fig. 5 shows surface treatments developed and/or applied over the past 20 years. Today nearly all these treatments are in the industrial praxis. Depending on the application and the manufacturing costs, spraying, galvanizing, nitriding, PVD coatings and the combination nitriding plus PVD coating are used. The most expensive method is the PVD-method. About 10 50 um thick Cr-based coatings are deposited mostly by vacuum arc evaporation.

High performance engine

PVD Cr:N

Cr plat. + diam.

re

si st

an

Diesel

si s

ce

Cr plated + Cericam HVOF CrC/NiCr

we

Cr plat. PVD + diam. Cr:N Mo sprayed

ta nc

HVOF CrC/NiCr Cr plated + Ceramic

Nitrided Cr plated

ar

sc

uf

fin

re

Gasoline

Mo sprayed

Cr plated

Nitrided

Evolution of piston ring surfaces: wear / scuffing resistance

Fig. 5. Different piston ring treatments and the trend of the wear and scuffing resistance; HVOF: High Velocity Oxygen Fuel spray; Cr plat. + diam.: Cr plated + diamond.

J. Vetter et al. / Surface & Coatings Technology 200 (2005) 1962 1968

1967

Fig. 6. Typical microstructure of CuAlSn alloy deposited by internal APS on connecting rod (40 mm bore diameter): porosity: 2%, HV0.3=162, thickness 550 um.

base alloys can be deposited under good metallurgical conditions using the atmospheric spraying process APS. On the different heat treated steels for connecting rods reasonable bond strengths were measured to a thickness of 550 um. Bearing materials present different requirements concerning mechanical properties, seizure resistance and the possibility of embedding foreign particles for example. The plasma spray technology using powder as feedstock is characterized by an excellent flexibility regarding the choice of the materials. Fig. 6 shows an example of typical copper base material deposited by internal plasma spraying in a connecting rod of diameter 40 mm. 5.2. Thermal barrier coatings also for the engine? Thermal barrier coatings are used normally for turbine blades. First studies were made also for engine components.

In the case of high performance combustion engine the creep tendency of the aluminium piston head can be significantly decreased by the deposition of a thermal barrier in PSZ (partial stabilized zirconia). The coating system (MCrAlY bond coat and PSZ) is deposited by using the atmospheric plasma spray process. The coating allows also the use of cheaper aluminium material and decreases the sensibility to the material defects. 5.3. Gear coatings: lubrication reduction by DLC coatings DLC coatings in the form of a-C:H:Me coatings deposited by reactive PVD processes and a-C:H coatings deposited by PECVD have been applied in injection systems since about the year 2000. Fig. 7 shows the excellent improvements of the gear performance by a-C:H:Me coatings. These improvements are partially industrially realized, e.g. gears for wind

Fig. 7. Reduction of micro pitting and load increase by a-C:H:Me (W-C:H) coatings gears.

1968

J. Vetter et al. / Surface & Coatings Technology 200 (2005) 1962 1968

PN

PVD-coated

PN plus PVD

Hardness

Depth

CZ

DZ

Core

CrN

(1-50) m

Core

CrN

DZ

Core

(0-20) m (20-800)m

Fig. 8. Hardness versus distance from the surface for soft steels with a plasma nitriding treatment (PN), PVD coating, and combination nitriding plus PVD coating; CZ: compound zone, DZ: diffusion zone.

power transmissions. The potential of the gear coating to minimize the required lubrication and or to increase the specific loads is not utilized in industrial practice for the powertrain. One of the reasons might be the high cost factor of production due to the small lot production of coated gears. 5.4. Combination coatings: new properties by nitriding and PVD coating Plasma nitriding of metallic components of different materials is one of the well established treatments (for crankshafts, springs, synchronizers, etc.) resulting in improved performance due to an increase of the hardness, fatigue strength and creation of residual compressive stresses. However, PVD coatings are more wear resistant (adhesive wear, micro abrasion, oxidation, etc.). The combination of nitriding and PVD provides a product superior to both. Fig. 8 shows the change in hardness as a function of the distance from the surface for the separate treatments and the combined treatment. The nitriding before the deposition of the hard coating increases the load bearing capacity of the coating-substrate-system. This combination treatment is industrially used for high loaded piston rings (see also Fig. 5). However, more applications might be realized in the powertrain and engine.

3. The internal plasma spraying technology allows treating different inside diameters (bores) in the engine. 4. PVD coatings become more and more interesting not only for decoration, but also for high loaded parts like piston rings. 5. DLC coatings still have a high potential for lubrication reduction and or for the increase of the load, e.g. for gears. 6. The various surface treatments available for selected parts (e.g. synchronizers) are competing with each other, in terms of costs and functionality.

References

[1] T.H. Lampe, S. Eisenberg, E. Rodriguez Cameo, Surf. Coat. Technol. 174 175 (2003) 1. [2] L. Pawlowsk (Ed.), The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons Ltd, New York, 1995. [3] A. von Starck, A. Mu hlbauer, C. Kramer (Eds.), Handbook of Thermoprocessing Technologies, Vulkan Verlag Eifel, Essen, 2005. [4] R.L. Boxman, P.J. Martin, D.M. Sanders (Eds.), Handbook of Vacuum Arc Science and Technology, Noyes Publications, New Jersey, 1995. [5] S. Hoppe, Surf. Coat. Technol. 98 (1998) 1199. [6] J. Vetter, T. Michler, J.H. Steuernagel, Surf. Coat. Technol. 111 (1999) 210. [7] G. Barbezat, J. Automot. Technol. 2 (2001) 47. [8] G. Barbezat, J. Schmid, MTZ, Mot.Tech. Z. 62 (2001) ) 314. [9] M. Winterkorn, P. Bohre, L. Spiegel, G. So lke, ATZ, Automobiltech. Z. 102 (2000) 832. [10] E. Pape, M. Kro ll, M. Gerhardy, ATZ, Automobiltech. Z. 104 (2002) 2. [11] E.R. Cabeo, G. Laudien, S. Biemer, K.-T. Rie, S. Hoppe, Surf. Coat. Technol. 116 (1999) 229. [12] G. Barbezat, F.-G. Hermsen, J. Dohmen, MTZ, Mot.Tech. Z. 65 (2004) 15. [13] G. Barbezat, Coating deposition of bearing materials on connecting rod by thermal spraying, Proceeding DVS, May 2005, Basel, ITSC, 2005.

6. Summary 1. The variety of plasma assisted surface treatments applied in the automotive industry will increase in the upcoming years due to higher loads in the engine, injection systems and the power train. 2. Corrosion protection of different parts of the power train can be produced by the IONITOX process.

Вам также может понравиться

- Kitchen Improvised FertilizerДокумент68 страницKitchen Improvised Fertilizerjohn smith100% (1)

- SAE Material and Design Guidelines For Reinforces Thermoplastic Body PanelsДокумент16 страницSAE Material and Design Guidelines For Reinforces Thermoplastic Body PanelsRobby RenzОценок пока нет

- Electroplating of PlasticsДокумент4 страницыElectroplating of PlasticsislammughalОценок пока нет

- Final ExamДокумент1 199 страницFinal ExamCora V. Walter100% (4)

- Pile CapДокумент19 страницPile Caprsdoost1345Оценок пока нет

- Thermal Spray Coating For BoilerДокумент26 страницThermal Spray Coating For BoilerHoang Thang100% (1)

- Hardfacing or HardsurfacingДокумент15 страницHardfacing or HardsurfacingAchu BalachandranОценок пока нет

- Smart SYS S2301500R48 - DatesheetДокумент2 страницыSmart SYS S2301500R48 - DatesheetWill F Alves0% (1)

- Coatings and InhibitorДокумент23 страницыCoatings and Inhibitordip_maan100% (1)

- Chapter-4: 4.1 Matrix MaterialsДокумент17 страницChapter-4: 4.1 Matrix MaterialsSasiKumar PetchiappanОценок пока нет

- Mechanical Plating Process Training-Macdermid.Документ22 страницыMechanical Plating Process Training-Macdermid.stuart3962Оценок пока нет

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОт EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОценок пока нет

- Material Selection & Corrosion Resistance Alloys For Petroleum IndustryДокумент4 страницыMaterial Selection & Corrosion Resistance Alloys For Petroleum Industryعزت عبد المنعمОценок пока нет

- Gas SolubilityДокумент59 страницGas Solubilitysomsubhra100% (1)

- Artificial Intelligence - EdurekaДокумент37 страницArtificial Intelligence - EdurekaTechnical NoviceОценок пока нет

- The Principle of Sand Sweeping On White PDFДокумент16 страницThe Principle of Sand Sweeping On White PDFDimas BatamОценок пока нет

- Tundish RefractoryДокумент15 страницTundish RefractoryMashiur RahmanОценок пока нет

- Wear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueДокумент12 страницWear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueIJRASETPublicationsОценок пока нет

- Design Guide Fichtner PDFДокумент246 страницDesign Guide Fichtner PDFAnonymous knICax100% (1)

- Metallic Coatings For Corrosion PreventionДокумент9 страницMetallic Coatings For Corrosion PreventionDevashish JoshiОценок пока нет

- Thermal Barrier CoatingsДокумент11 страницThermal Barrier CoatingsNidhi VyasОценок пока нет

- ORM-II Theory+exercise+ Answer PDFДокумент58 страницORM-II Theory+exercise+ Answer PDFGOURISH AGRAWALОценок пока нет

- Surface Treatments and CoatingsДокумент4 страницыSurface Treatments and Coatingsmightym85Оценок пока нет

- Plasma Spray Coating MethodДокумент28 страницPlasma Spray Coating Methodvijay9994Оценок пока нет

- NSMC Project Report M.techДокумент32 страницыNSMC Project Report M.techSomak SahujiОценок пока нет

- Reduced Wear and Higher Corrosion Resistance by Combined Heat-Treatment and Coating Procedures Using Plasma-Assisted ProcessesДокумент3 страницыReduced Wear and Higher Corrosion Resistance by Combined Heat-Treatment and Coating Procedures Using Plasma-Assisted Processesmp87_ingОценок пока нет

- JO-AM-MGC-SP-203 (Rev. A1) Painting and Coating of Metal Surfaces SSДокумент43 страницыJO-AM-MGC-SP-203 (Rev. A1) Painting and Coating of Metal Surfaces SSpetronashscribdid100% (1)

- 9 Strip Casting Technology PYMenetДокумент5 страниц9 Strip Casting Technology PYMenetNikolas Kolasni Lakenir Ckerde DockosОценок пока нет

- Ngineering ATA: Protective Coating Guide For FansДокумент7 страницNgineering ATA: Protective Coating Guide For FansMohamed TahounОценок пока нет

- Surface Engineering: Submitted byДокумент13 страницSurface Engineering: Submitted byVarun Krishna PinnaОценок пока нет

- Cen TC 262 N 595Документ11 страницCen TC 262 N 595Luis SilvaОценок пока нет

- Young Modulus of Elasticity For Metals and AlloysДокумент3 страницыYoung Modulus of Elasticity For Metals and AlloysShiva Kumar MОценок пока нет

- Finite Element Indentation Analysis of AutomotiveДокумент7 страницFinite Element Indentation Analysis of AutomotiveytabakovОценок пока нет

- Mee4001-Tool Design Latest Developments On Cutting Tools and Coatings Name:Shrey S Jain REGNO:18BME1225 Faculty:Dr. Umasankar Slot:F1Документ13 страницMee4001-Tool Design Latest Developments On Cutting Tools and Coatings Name:Shrey S Jain REGNO:18BME1225 Faculty:Dr. Umasankar Slot:F1Shrey JainОценок пока нет

- Vehicle Body Engineering by M A Qadeer SiddiquiДокумент143 страницыVehicle Body Engineering by M A Qadeer SiddiquiAbdul Qadeer Siddiqui100% (12)

- Sample Paper TechnoareteДокумент4 страницыSample Paper Technoaretepreeti_v_baviskarОценок пока нет

- State of The Knowledge On Coating Systems For Hot Stamped PartsДокумент23 страницыState of The Knowledge On Coating Systems For Hot Stamped PartsFernando BarreraОценок пока нет

- Design, Fabrication and Testing of A Mno Based Catalytic ConverterДокумент8 страницDesign, Fabrication and Testing of A Mno Based Catalytic ConverterJimsОценок пока нет

- Alum Casting Alloys FEB05Документ8 страницAlum Casting Alloys FEB05b4upalaniОценок пока нет

- Structural Analysis of Disc Brake RotorДокумент4 страницыStructural Analysis of Disc Brake RotorseventhsensegroupОценок пока нет

- Surface Coatings1Документ16 страницSurface Coatings1bathinsreenivasОценок пока нет

- 19 Ijmperdapr201719Документ10 страниц19 Ijmperdapr201719TJPRC PublicationsОценок пока нет

- Thermal Spray V4Документ24 страницыThermal Spray V4eitvasОценок пока нет

- Unit-4 Unconventional Manufacturing ProcessДокумент18 страницUnit-4 Unconventional Manufacturing Processbrijkishor201767% (3)

- F. Repair TechnologyДокумент5 страницF. Repair Technologypushpak2312Оценок пока нет

- Es805-001 Rev 4 Decorative Chrome PlatingДокумент7 страницEs805-001 Rev 4 Decorative Chrome PlatingFrancisco BocanegraОценок пока нет

- New Trend of Metal CoatingДокумент16 страницNew Trend of Metal CoatingAjit BeheraОценок пока нет

- Optimization of Drilling Parameters On Surface Roughness of Al 1200-Sic Composites Using Taguchi AnalysisДокумент9 страницOptimization of Drilling Parameters On Surface Roughness of Al 1200-Sic Composites Using Taguchi AnalysisTHALUPULA PRASANTHОценок пока нет

- Application of Supported Perovskite-Type Catalysts For Vehicular Emission ControlДокумент10 страницApplication of Supported Perovskite-Type Catalysts For Vehicular Emission ControlKirti GadeОценок пока нет

- Productive Plastics Metal To Plastic Thermoforming GuideДокумент14 страницProductive Plastics Metal To Plastic Thermoforming Guidesuroyo bimantoroОценок пока нет

- Mil-Std-171f - Finishing of Metal and Wood Surfaces (31may2011)Документ65 страницMil-Std-171f - Finishing of Metal and Wood Surfaces (31may2011)JumpfastОценок пока нет

- Anti-Corrosion Coatings For Different Service Exposures: Shivananda PrabhuДокумент10 страницAnti-Corrosion Coatings For Different Service Exposures: Shivananda Prabhurohit yadavОценок пока нет

- FEA Analysis and Experimental Investigation of The Ceramic Coating On Aluminum PistonДокумент14 страницFEA Analysis and Experimental Investigation of The Ceramic Coating On Aluminum PistonIJRASETPublicationsОценок пока нет

- Experimental Investigation of Mechanical PropertieДокумент9 страницExperimental Investigation of Mechanical PropertieSreejith S NairОценок пока нет

- The Application of Monoliths For Gases Phase Catalytic ReactionsДокумент8 страницThe Application of Monoliths For Gases Phase Catalytic ReactionsManh CuongОценок пока нет

- 530.352 Materials Selection: Lecture #30 Friction and Wear Monday November 28, 2005Документ20 страниц530.352 Materials Selection: Lecture #30 Friction and Wear Monday November 28, 2005Amit PandeyОценок пока нет

- Eng-Improved Erosion - Lubna AlaaДокумент12 страницEng-Improved Erosion - Lubna AlaaImpact JournalsОценок пока нет

- Silicon NitrideДокумент8 страницSilicon NitrideVikas KharbОценок пока нет

- Nptel WeldingДокумент233 страницыNptel WeldingThasarathan Ravichandran100% (2)

- Experimental Investigation of Coasting On Piston by Thermal Torch MethodДокумент31 страницаExperimental Investigation of Coasting On Piston by Thermal Torch MethodĐįñêśh ĎkОценок пока нет

- ASE 02 FundamentalДокумент62 страницыASE 02 FundamentalsriОценок пока нет

- Problems in Repair-Welding of Duplex-Treated Tool Steels: T. Muhi, J. Tu (Ek, M. Pleterski, D. BombaДокумент4 страницыProblems in Repair-Welding of Duplex-Treated Tool Steels: T. Muhi, J. Tu (Ek, M. Pleterski, D. Bombaabraham silva hernandezОценок пока нет

- Welding Reading MaterialДокумент33 страницыWelding Reading MaterialAMAN NOHWALОценок пока нет

- Sunny Manohar 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012132 PDFДокумент10 страницSunny Manohar 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012132 PDFParitosh ParasharОценок пока нет

- Jarak SprayДокумент6 страницJarak SprayIhsanulfajar MulyantoОценок пока нет

- Metallic Bipolar Plates For PEM Fuel Cells 02Документ5 страницMetallic Bipolar Plates For PEM Fuel Cells 02api-3709675Оценок пока нет

- Work Permit (Ra Puram) - 28-Nov - 2013Документ1 страницаWork Permit (Ra Puram) - 28-Nov - 2013SasiKumar PetchiappanОценок пока нет

- Chapter-5: 5.1 Fabrication Techniques of Composite MaterialsДокумент6 страницChapter-5: 5.1 Fabrication Techniques of Composite MaterialsSasiKumar PetchiappanОценок пока нет

- User Manual 5 PDFДокумент518 страницUser Manual 5 PDFSasiKumar PetchiappanОценок пока нет

- Grade 3 MathsДокумент3 страницыGrade 3 MathsSasiKumar PetchiappanОценок пока нет

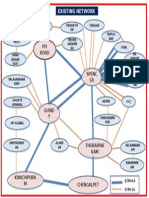

- Existing NetworkДокумент1 страницаExisting NetworkSasiKumar PetchiappanОценок пока нет

- Institution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)Документ34 страницыInstitution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)SasiKumar PetchiappanОценок пока нет

- Front Pagels and BonofideДокумент2 страницыFront Pagels and BonofideSasiKumar PetchiappanОценок пока нет

- Design Fundamentals, Methods and Material Selection 9Документ1 страницаDesign Fundamentals, Methods and Material Selection 9SasiKumar PetchiappanОценок пока нет

- Quality ConceptДокумент2 страницыQuality ConceptSasiKumar PetchiappanОценок пока нет

- Write The Procedure To Compile and Install Linux Kernel From SourceДокумент1 страницаWrite The Procedure To Compile and Install Linux Kernel From SourceSasiKumar PetchiappanОценок пока нет

- KathirДокумент1 страницаKathirSasiKumar PetchiappanОценок пока нет

- Time Table For EngДокумент1 страницаTime Table For EngSasiKumar PetchiappanОценок пока нет

- Anish FinalДокумент6 страницAnish FinalSasiKumar PetchiappanОценок пока нет

- LDP ExeДокумент4 страницыLDP ExeSasiKumar PetchiappanОценок пока нет

- Rainwater Harvesting Basic ComponentsДокумент3 страницыRainwater Harvesting Basic ComponentsSasiKumar PetchiappanОценок пока нет

- SSM Users GuideДокумент56 страницSSM Users GuideSasiKumar PetchiappanОценок пока нет

- PD Measurements On Power TransformersДокумент3 страницыPD Measurements On Power TransformersJuan Sebastian Juris ZapataОценок пока нет

- Adverse WeatherДокумент13 страницAdverse WeathermurugeshunivОценок пока нет

- Downloaded From Manuals Search EngineДокумент13 страницDownloaded From Manuals Search EngineSandro CoelhoОценок пока нет

- Delhi Metro Project Report IpДокумент195 страницDelhi Metro Project Report IpAnuj MauryaОценок пока нет

- Calculus IIIvectorcalculus 2011Документ82 страницыCalculus IIIvectorcalculus 2011Alfi LouisОценок пока нет

- Tutorial 4Документ3 страницыTutorial 4chinnu rokzОценок пока нет

- Switchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Документ62 страницыSwitchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Suvendu Sekhar SabatОценок пока нет

- Open Development EnvironmentДокумент16 страницOpen Development EnvironmentMihaiNeacsuОценок пока нет

- Code Reason Effect: Step 1. Step 1AДокумент2 страницыCode Reason Effect: Step 1. Step 1AAhmedmahОценок пока нет

- MyLabX8 160000166 V02 LowRes PDFДокумент8 страницMyLabX8 160000166 V02 LowRes PDFhery_targerОценок пока нет

- gp2 Speed IncreaserДокумент2 страницыgp2 Speed Increasermayur22785Оценок пока нет

- Section 5 Section 5: Weight and Balance Weight and BalanceДокумент36 страницSection 5 Section 5: Weight and Balance Weight and Balanceandres felipe sandoval porrasОценок пока нет

- 1.0 Intro To Aircon (Properties of Moist Air) With Sample ProblemДокумент10 страниц1.0 Intro To Aircon (Properties of Moist Air) With Sample ProblemRenneil De PabloОценок пока нет

- Chapter - 20 3-6-05Документ30 страницChapter - 20 3-6-05samandondonОценок пока нет

- CF 2Документ114 страницCF 2Vishnu VardhanОценок пока нет

- Second Periodical ExamДокумент19 страницSecond Periodical ExamMaynard Lee Estrada GomintongОценок пока нет

- BFC3042 BFC31802Документ13 страницBFC3042 BFC31802Zuliyah ZakariaОценок пока нет

- Specalog For Cat 938K Sugarcane Handler AEHQ8046-02Документ1 страницаSpecalog For Cat 938K Sugarcane Handler AEHQ8046-02diegosoareshotmail.frОценок пока нет

- RBK-PROC-MK3 Raychem MK3Документ83 страницыRBK-PROC-MK3 Raychem MK3VictorОценок пока нет

- SB Erv Arvu123zea2 03 20Документ2 страницыSB Erv Arvu123zea2 03 20Mohammed Tausif AhmedОценок пока нет

- Research On The Formation of M1-Type Alite Doped With MgO and SO3-a Route To Improve The Quality of Cement Clinker With A High Content of MgOДокумент11 страницResearch On The Formation of M1-Type Alite Doped With MgO and SO3-a Route To Improve The Quality of Cement Clinker With A High Content of MgODerekОценок пока нет

- Modbus RegisterДокумент7 страницModbus RegisterZuniiga AndersonОценок пока нет