Академический Документы

Профессиональный Документы

Культура Документы

155 - Supalux Water Resistant Shaftwall PDF

Загружено:

odemircioglu2Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

155 - Supalux Water Resistant Shaftwall PDF

Загружено:

odemircioglu2Авторское право:

Доступные форматы

Promat have developed a fire resistant shaftwall system that can be installed prior to the building being dry.

Using specially treated Promat SUPALUX

boards, it is now possible to install the shaftwalls as soon as the

concrete cores and floors have been constructed. This allows other trades to start earlier, thus speeding up the

building programme.

This system is applicable for use in those areas requiring 60 minute and 120 minute integrity and insulation

performance, but where access for construction is possible from one side only e.g. lift shaft walls and risers.

Up to 120 minutes fire resistance.

System can be built in an open environment.

System can be built from one side only removing the need

for scaffolding in the shaft.

No latent defects due to water.

Releases building cores for services significantly earlier.

Overall programme saving.

Comparable installation time to traditional dry lining.

Shaft wall nominal thickness of 122mm.

Designed for wall heights of up to 5.5 metres.

An NBS for the SUPALUX

shaftwall system is available.

Acoustic data: 60 minute system R

w

43-44 dB.

120 minute system R

w

44-45 dB.

Construction details:

Promat SUPALUX

IMPREGNATED boards 9mm thick

Steel DOUBLE E profile channel 92.8 x 50 x 0.7mm located at 600mm centres.

Steel SINGLE E profile channel 92.8 x 25 x 0.7mm located at corners and wall abutments.

Steel FLOOR TRACK channel 60 x 94 x 40 x 0.7mm fixed at maximum 600mm centres using M6 steel anchor bolt.

Steel HEAD TRACK channel 60 x 94 x 60 x 0.7mm fixed at maximum 600mm centres using M6 steel anchor bolt.

Promat SUPALUX

cover strip 9mm thick x 100mm wide at all horizontal board joints.

Rock wool 80mm thick, applied in staggered layers, fitted between channels.

- 2 x 40mm x 45 kg/m

3

for 60 minutes fire protection.

- 2 x 40mm x 100 kg/m

3

for 120 minutes fire protection.

Promat SUPALUX

fillet, 20mm thick x 100mm wide fixed through steel channels with 4.2mm self tapping or self

drilling screws at 200mm centres.

All perimeter channels to be bedded onto Promat PROMASEAL

Intumescent Acrylic Sealant. Promaseal

Intumescent

acrylic sealant also to be used to seal all gaps and abutments.

Shaft side:

9mm x 600mm wide SUPALUX

IMPREGNATED boards friction fitted between studs. Boards butt jointed together and

horizontal board joints backed using 9mm x 100mm wide SUPALUX

coverstrip, fixed using 25mm x M3.5 steel self drilling

and tapping screws at 200mm centres, fixed on both sides of the joint.

Corridor side:

20mm SUPALUX

fillet strip fixed to face of E-profile channels using 32mm drywall screws at 500mm centres.

9mm SUPALUX

boards butted together and screw fixed through the 20mm fillet to all framework members using 42mm x

M3.5 steel self drilling and tapping screws at 200mm centres.

Horizontal board joints backed using 9mm x 100mm wide SUPALUX

coverstrip, fixed using 25mm x M3.5 steel self drilling

and tapping screws at 200mm centres, fixed on both sides of the joint.

NOTES:

For the 120 minute system, the temperature of the exposed metal, on the shaft side of the construction, may exceed the

requirements of BS 476: Part 22: 1987 within the fire test period.

Relaxation should be sought on the basis that no combustible materials are likely to be stored adjacent to the structure.

Alternatively, for full fire insulation, SUPALUX fillet 15mm thick x 100mm wide should be fixed to exposed metal on the

shaft side of the construction. Cover strip fixed with M3.5 steel self drilling & tapping screws at nominal 200mm centres.

Maximum height 5.5 metres. Contact Promat Customer Relations team if shaftwall height above 4 metres is required.

Promat SUPALUX

Water Resistant Shaftwall -

EI60 and EI120 Systems

Promat UK Limited

Customer Relations Team

The Sterling Centre, Eastern Road

Bracknell, Berkshire RG12 2TD

Tel: 01344 381 400

Fax: 01344 381 401

E-mail: technicaluk@promat.co.uk

Technical Data

Sheet 155

Page 1 of 2

AUTHORITY: Exova Warringtonfire WF195196

(Nov 2011)

Shaftwall System

Double E profile fabricated by joining two single E profile channels, screw fixed using 13mm x M4 (No.8) steel self tapping

screws or M4 blind rivets at 300mm centres, applied in two rows. 2 continuous beads of Promaseal

intumescent Acrylic

sealant applied to back of studs before fixing them together.

Single and double E-studs at nominal 600mm centres may be fixed to the base channel but are a sliding fit in the head

channel, with an allowance for longitudinal thermal expansion of at least 5mm per metre height.

Supalux Shaftwall

Corner detail

It is assumed that the shaftwall system is supported from appropriate masonry/concrete or steel constructions that have

a fire resistance of at least the same as that required by the partition system and are capable of providing adequate

support to the constructions for the required period of fire resistance.

Where partitions are erected against a steel structure, it is a requirement that the steelwork is fire protected with a

product to maintain steel protection and compartmentation.

Please contact Promat UK Customer Relations team for details of suitable products to provide this required fire

protection.

Fire resistant penetrations can be achieved using the Promat PROMASEAL

range of fire stopping products.

Promat UK Limited

Customer Relations Team

The Sterling Centre, Eastern Road

Bracknell, Berkshire RG12 2TD

Tel: 01344 381 400

Fax: 01344 381 401

E-mail: technicaluk@promat.co.uk

Promat SUPALUX

Water Resistant Shaftwall -

EI60 and EI120 Systems

Technical Data

Sheet 155

Page 2 of 2

(November 2011)

AUTHORITY: Exova Warringtonfire WF195196

Вам также может понравиться

- Rockwool BeamClad SystemsДокумент4 страницыRockwool BeamClad SystemstwinpixtwinpixОценок пока нет

- SUPALUX Application GuideДокумент32 страницыSUPALUX Application Guidekbarakat3155Оценок пока нет

- DATA Fire Duct SystemsДокумент8 страницDATA Fire Duct SystemsRithwik T. HariОценок пока нет

- Ductwork SystemДокумент8 страницDuctwork SystemrkssОценок пока нет

- Typ 5 EngДокумент4 страницыTyp 5 Engsasan49Оценок пока нет

- Suspended Ceilings Construction GuideДокумент4 страницыSuspended Ceilings Construction GuideHassan RahilОценок пока нет

- Norguard Eagle - Horizontal and Vertical Lifeline SystemsДокумент4 страницыNorguard Eagle - Horizontal and Vertical Lifeline SystemsnorguardОценок пока нет

- Lamatherm CW-FS Curtain Walling Firestop 179 1Документ9 страницLamatherm CW-FS Curtain Walling Firestop 179 1Naveen KarkiОценок пока нет

- Sandwich Panels en Lo RUUKKIДокумент8 страницSandwich Panels en Lo RUUKKIszeestherОценок пока нет

- NSW Roofing Walling Rainwater and Structural Products BrochureДокумент8 страницNSW Roofing Walling Rainwater and Structural Products BrochurebarouniamineОценок пока нет

- Fireclad System BoralДокумент8 страницFireclad System BoralSuciul E ViuОценок пока нет

- Brosur CoatingДокумент4 страницыBrosur CoatingMuhammad AlfianОценок пока нет

- Brosur Fire StopДокумент13 страницBrosur Fire StopSaidAnwarОценок пока нет

- ACS Full Catalogue 6 Jun 11Документ150 страницACS Full Catalogue 6 Jun 11FOX_23Оценок пока нет

- RFA-TECH Technical Solutions Brochure 2012 LRДокумент32 страницыRFA-TECH Technical Solutions Brochure 2012 LRsplaw9484Оценок пока нет

- Promat TD BoardДокумент6 страницPromat TD BoardAlex BrustanОценок пока нет

- Ppecoforte: PP-HM System For SewersДокумент12 страницPpecoforte: PP-HM System For SewersDo BuiОценок пока нет

- Installation Advice - System 150Документ7 страницInstallation Advice - System 150Giuseppe AlibertiОценок пока нет

- Brochure Stay Cables PDFДокумент32 страницыBrochure Stay Cables PDFJulio Rafael Terrones VásquezОценок пока нет

- Cable Tray 27Документ37 страницCable Tray 27Sri Ravindra Yadav PattapogulaОценок пока нет

- Brosura Busbar EatonДокумент8 страницBrosura Busbar EatonTibor DanielОценок пока нет

- Fire Barrier & Cavity Systems Stop Fires!: KillerДокумент4 страницыFire Barrier & Cavity Systems Stop Fires!: KillerMedhat ElhagrasiОценок пока нет

- Cembrit Multi Force (FR) Building BoardsДокумент12 страницCembrit Multi Force (FR) Building BoardsVladoiu SorinОценок пока нет

- Purlin & Cladding RailДокумент67 страницPurlin & Cladding RailPrima AdhiyasaОценок пока нет

- Uni Span FormworkДокумент30 страницUni Span FormworkHans JonesОценок пока нет

- 12P Freyssibolt 1Документ12 страниц12P Freyssibolt 1Ed MateiОценок пока нет

- 01 Catalogue Cable EntriesДокумент58 страниц01 Catalogue Cable Entriesauras177Оценок пока нет

- Steel DetailingДокумент32 страницыSteel Detailingveeba100% (1)

- Freyssibar: The Prestressing Bar For Civil WorksДокумент12 страницFreyssibar: The Prestressing Bar For Civil WorksJustin CorbettОценок пока нет

- Solidwall: Solid IBS Straight Wall System and PartitionДокумент4 страницыSolidwall: Solid IBS Straight Wall System and Partitionchung_kee_3Оценок пока нет

- Technical Data :: System Details Hollow Floor Combi T MERO Hollow Floor Combi TДокумент6 страницTechnical Data :: System Details Hollow Floor Combi T MERO Hollow Floor Combi Tadventure11111Оценок пока нет

- Expansion Joint StripДокумент2 страницыExpansion Joint StripGeorge GeorgianОценок пока нет

- IWS Cepro Leaflet 2011Документ6 страницIWS Cepro Leaflet 2011InlaboОценок пока нет

- CW-FS Cavity Barriers & Fire Stops For Curtain Walling 2120Документ9 страницCW-FS Cavity Barriers & Fire Stops For Curtain Walling 2120Najib KiwanОценок пока нет

- TechnicalDatasheetDexune Mineral Fibre - 2 12082015 0410Документ1 страницаTechnicalDatasheetDexune Mineral Fibre - 2 12082015 0410Avan SinghОценок пока нет

- TENSACCIAI - Stay CablesДокумент0 страницTENSACCIAI - Stay Cablesnovakno1Оценок пока нет

- Confort 125 - Aluminium Sliding Doors - Sapa Building SystemДокумент12 страницConfort 125 - Aluminium Sliding Doors - Sapa Building SystemSapa Building SystemОценок пока нет

- 3.6.3 Column and Beam Fire ProtectionДокумент10 страниц3.6.3 Column and Beam Fire Protectionodemircioglu2Оценок пока нет

- Epoxy Bonded Reinforcement To Concrete Decks and BeamsДокумент2 страницыEpoxy Bonded Reinforcement To Concrete Decks and BeamsFrancisco Javier Martinez BurgoОценок пока нет

- Gyprock 949 Strata Wall 201202Документ24 страницыGyprock 949 Strata Wall 201202duckeОценок пока нет

- Katalog E Vollversion - 07 PDFДокумент15 страницKatalog E Vollversion - 07 PDFChristian HinostrozaОценок пока нет

- Simple, Robust, Fast - The Complete Wall Connecting System: Pfeifer Seil-Und Hebetechnik GMBHДокумент0 страницSimple, Robust, Fast - The Complete Wall Connecting System: Pfeifer Seil-Und Hebetechnik GMBHadc26Оценок пока нет

- Tech Bulletin 4 Cladding InstallationДокумент4 страницыTech Bulletin 4 Cladding InstallationAbu NijamОценок пока нет

- Rockwool Intumescent PillowsДокумент3 страницыRockwool Intumescent PillowsBobana AdamovicОценок пока нет

- PROMASEAL® FlexiWrapДокумент4 страницыPROMASEAL® FlexiWrapavacansОценок пока нет

- Fiber Glass ProtectionДокумент679 страницFiber Glass Protectionsohebam100% (1)

- General Brochure Strata (1) OsborneДокумент23 страницыGeneral Brochure Strata (1) Osbornejulio1051Оценок пока нет

- Corus Panels Profiles SystemsДокумент22 страницыCorus Panels Profiles SystemsMiruna MaziluОценок пока нет

- UGC DurastrongLightSteelFrames 04252023 2pm-3Документ2 страницыUGC DurastrongLightSteelFrames 04252023 2pm-3Roy PerochoОценок пока нет

- Puddle Flange 2011Документ12 страницPuddle Flange 2011andy_ramblaОценок пока нет

- Technical Specification: Fire and Acoustically Rated WallsДокумент24 страницыTechnical Specification: Fire and Acoustically Rated WallsLima EghlimaОценок пока нет

- Now Africa Has A Proven Alternative!: Mitek MitekДокумент2 страницыNow Africa Has A Proven Alternative!: Mitek MitekDaniel DincaОценок пока нет

- PeДокумент9 страницPeMekhmanОценок пока нет

- Promat Intumex SB (Single Sheet) 1 (Impor)Документ8 страницPromat Intumex SB (Single Sheet) 1 (Impor)Rani RahmadaniОценок пока нет

- Atlantic Wire Walls: We Support YouДокумент6 страницAtlantic Wire Walls: We Support Youmatt_friendОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965От EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Оценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Battery Thermal Runaway Testing MethodsДокумент15 страницBattery Thermal Runaway Testing Methodsodemircioglu2Оценок пока нет

- Asphalt Pavements TunnelsMay2008Документ23 страницыAsphalt Pavements TunnelsMay2008odemircioglu2Оценок пока нет

- Standpipe NFPA 14 CalculationДокумент3 страницыStandpipe NFPA 14 Calculationodemircioglu2Оценок пока нет

- Fuel TankДокумент4 страницыFuel Tankodemircioglu2Оценок пока нет

- Pyroswiss Sbs Smoke Barrier System enДокумент4 страницыPyroswiss Sbs Smoke Barrier System enodemircioglu2Оценок пока нет

- Pocket Guide For Firestopping Inspection Manual PDFДокумент40 страницPocket Guide For Firestopping Inspection Manual PDFodemircioglu2100% (1)

- Pocket Guide For Firestopping Inspection ManualДокумент12 страницPocket Guide For Firestopping Inspection Manualodemircioglu2Оценок пока нет

- Asphalt Pavements TunnelsMay2008Документ23 страницыAsphalt Pavements TunnelsMay2008odemircioglu2Оценок пока нет

- Fire DuctДокумент8 страницFire Ductodemircioglu2Оценок пока нет

- TechTalk EquipmentGroundingДокумент8 страницTechTalk EquipmentGroundingodemircioglu2Оценок пока нет

- Electrical ConduitsДокумент32 страницыElectrical Conduitsodemircioglu2Оценок пока нет

- CFPA E Guideline No 19 2009 EVACUATION FROM BUILDINGS PDFДокумент99 страницCFPA E Guideline No 19 2009 EVACUATION FROM BUILDINGS PDFodemircioglu2Оценок пока нет

- Ctu-N12 Eng WindowfireprotectionДокумент4 страницыCtu-N12 Eng WindowfireprotectionMaryam NaserОценок пока нет

- Fuel TankДокумент4 страницыFuel Tankodemircioglu2Оценок пока нет

- Lorient ATG BrochureДокумент24 страницыLorient ATG Brochureodemircioglu2Оценок пока нет

- Combination Standpipe - Sprinkler Risers - Nfpa PDFДокумент10 страницCombination Standpipe - Sprinkler Risers - Nfpa PDFodemircioglu2Оценок пока нет

- LVLP Series Datasheet (SLC, IDC, NAC Hatları Için)Документ1 страницаLVLP Series Datasheet (SLC, IDC, NAC Hatları Için)odemircioglu2Оценок пока нет

- 3.6.3 Column and Beam Fire ProtectionДокумент10 страниц3.6.3 Column and Beam Fire Protectionodemircioglu2Оценок пока нет

- HW Series Datasheet (120 VAC Veya 240 Vac Panel Besleme Için)Документ1 страницаHW Series Datasheet (120 VAC Veya 240 Vac Panel Besleme Için)odemircioglu2Оценок пока нет

- En 16005Документ58 страницEn 16005odemircioglu2Оценок пока нет

- Valve BoxДокумент1 страницаValve Boxodemircioglu2Оценок пока нет

- EST EST3 Intelligent Control For Large and Medium Sized ApplicationsДокумент58 страницEST EST3 Intelligent Control For Large and Medium Sized Applicationsjavierchapa75100% (1)

- Firecel - General Catalogue 100 - 2 (English) - Light VersionДокумент36 страницFirecel - General Catalogue 100 - 2 (English) - Light Versionodemircioglu2Оценок пока нет

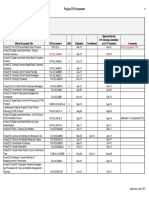

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Designing Smoke Control System SimplexДокумент102 страницыDesigning Smoke Control System Simplexodemircioglu2Оценок пока нет

- Speaker DesignДокумент18 страницSpeaker Designodemircioglu2Оценок пока нет

- DIPvs HDPEДокумент15 страницDIPvs HDPEKahar DahlawyОценок пока нет

- Worked Examples Ec2 Def080723Документ120 страницWorked Examples Ec2 Def080723dan_ospir67% (3)

- EUR22859ENДокумент38 страницEUR22859ENodemircioglu2Оценок пока нет

- Pharmd CurriculumДокумент18 страницPharmd Curriculum5377773Оценок пока нет

- SCIENCEEEEEДокумент3 страницыSCIENCEEEEEChristmae MaganteОценок пока нет

- LighthouseДокумент4 страницыLighthousejaneborn5345Оценок пока нет

- Astm A194 2020Документ12 страницAstm A194 2020rolando cuadro blancoОценок пока нет

- SR6 Core Rulebook Errata Feb 2020Документ6 страницSR6 Core Rulebook Errata Feb 2020yrtalienОценок пока нет

- JHS 182Документ137 страницJHS 182harbhajan singhОценок пока нет

- PTP S3Документ8 страницPTP S3Yongyin SHENGОценок пока нет

- Cell Wall Synthesis InhibitorsДокумент6 страницCell Wall Synthesis InhibitorsRPh Krishna Chandra JagritОценок пока нет

- MATLAB Fundamentals Quick ReferenceДокумент43 страницыMATLAB Fundamentals Quick ReferenceCarlos Manuel Cardoza EspitiaОценок пока нет

- 10th ORLIAC Scientific Program As of 26 Jan 2018Документ6 страниц10th ORLIAC Scientific Program As of 26 Jan 2018AyuAnatrieraОценок пока нет

- ASCE Snow Loads On Solar-Paneled RoofsДокумент61 страницаASCE Snow Loads On Solar-Paneled RoofsBen100% (1)

- 09 Passport 7K 15K Performance Guidelines PCR 3 0Документ44 страницы09 Passport 7K 15K Performance Guidelines PCR 3 0thed719Оценок пока нет

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Документ29 страниц10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- How To Eat WellДокумент68 страницHow To Eat WelleledidiОценок пока нет

- Tran-Effects of Assisted JumpingДокумент5 страницTran-Effects of Assisted JumpingyoungjessОценок пока нет

- Dialog Bahasa InggirsДокумент2 страницыDialog Bahasa InggirsKeRtha NeghaRaОценок пока нет

- Abdominal Examination OSCE GuideДокумент30 страницAbdominal Examination OSCE Guideزياد سعيدОценок пока нет

- QuantAssay Software Manual 11-Mar-2019Документ51 страницаQuantAssay Software Manual 11-Mar-2019LykasОценок пока нет

- Datasheet Ark XH Battery System EngДокумент2 страницыDatasheet Ark XH Battery System EngLisa CowenОценок пока нет

- Chennai To Vishakhapatnam El6Vvd: Indigo 6E-6835Документ3 страницыChennai To Vishakhapatnam El6Vvd: Indigo 6E-6835VENKATESH POONDRUОценок пока нет

- 412 X 7 Va CJ CSДокумент1 страница412 X 7 Va CJ CSRajesh KumarОценок пока нет

- Marvell 88F37xx Product Brief 20160830Документ2 страницыMarvell 88F37xx Product Brief 20160830Sassy FiverОценок пока нет

- Approved Project 25 StandardsДокумент5 страницApproved Project 25 StandardsepidavriosОценок пока нет

- Manual Nice9000v A04Документ151 страницаManual Nice9000v A04hoang tamОценок пока нет

- MioPocket ReadmeДокумент30 страницMioPocket Readmelion78Оценок пока нет

- 09.tracheostomy Management by Speech Language Pathologists in SwedenДокумент12 страниц09.tracheostomy Management by Speech Language Pathologists in SwedenCarlonchaCáceresОценок пока нет

- Aesculap Saw GD307 - Service ManualДокумент16 страницAesculap Saw GD307 - Service ManualFredi PançiОценок пока нет

- The Joy Luck Club Book 1Документ12 страницThe Joy Luck Club Book 1loronalicelОценок пока нет

- Chapter 10 - The Mature ErythrocyteДокумент55 страницChapter 10 - The Mature ErythrocyteSultan AlexandruОценок пока нет