Академический Документы

Профессиональный Документы

Культура Документы

Nickel and Nickel Alloys

Загружено:

idienОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Nickel and Nickel Alloys

Загружено:

idienАвторское право:

Доступные форматы

Nofrijon Sofyan, Ph.D.

Introduction

Nickel has a face-centered cubic crystal structure up

to its melting point; in this respect, nickel and

copper are similar.

Cobalt, however, undergoes a transition from a

close-packed hexagonal crystal structure to a face-

centered cubic structure above approximately

750

0

F.

3

As with iron, the addition of nickel to cobalt

stabilizes the face-centered cubic crystal structure to

below room temperature.

Most complex cobalt alloys are designed to retain

this cubic structure to take advantage of its inherent

ductility.

Nickel and some of its alloys are magnetic at room

temperature.

4

Unalloyed cobalt is magnetic but its alloys are not.

Commercially pure nickel is weldable by most

common welding processes.

Typical applications are food processing equipment,

caustic handling equipment, chemical shipping

drums, and electrical and electronic parts.

There are relatively few applications for pure

cobalt, and none for welded structures.

Properties of nickel and cobalt

5

Nickel alloys

6

Nickel is alloyed with a number of other metals to

impart specific properties.

These may include improved mechanical properties

as well as corrosion or oxidation resistance at room

and elevated temperatures.

Alloying significantly decreases thermal and

electrical conductivities.

7

Nickel alloys are representative of the large number of

available alloys, some of which, are referred to as

superalloys.

Nickel can be strengthened by solid-solution alloying

and by dispersion strengthening with a metal oxide.

Some nickel alloys may be further strengthened by a

precipitation-hardening heat treatment or by dispersion

strengthening.

The type of strengthening is a convenient means of

classifying nickel alloys.

8

In practice, some of the alloys classified as solid-

solution types may contain minor amounts of

elements that contribute to precipitation hardening.

Their presence may cause some strengthening

during heat treatment or service.

Consequently, the classification of such alloys is

somewhat arbitrary.

Solid-solution alloys

9

All nickel alloys are strengthened by solid solution.

Additions of aluminum, chromium, cobalt, copper, iron,

molybdenum, titanium, tungsten, and vanadium to nickel

contribute to solid solution strengthening.

Aluminum, chromium, molybdenum, and tungsten

contribute strongly while the others have a lesser effect.

Molybdenum and tungsten provide improved strength

at elevated temperatures.

Nickel-copper alloys

10

Nickel and copper form a continuous series of solid

solutions with a face-centered cubic crystal structure.

Commercial alloys contain from about 30 to 45 percent

copper.

They are tough and ductile.

Except for free-machining (high sulfur) alloys, they are

readily joined by welding, brazing, and soldering with

proper precautions.

Nickel-chromium alloys

11

Alloys of this family are used primarily for

applications involving high temperatures, oxidation,

and corrosion.

Some alloys are designed for thermocouples or for

electrical resistance applications.

Other alloys are designed for structural

applications at elevated temperatures.

12

Some of the alloys contain iron, molybdenum, tungsten,

cobalt, and copper in various combinations to enhance

specific properties.

These include improved corrosion resistance and high

temperature strength.

In general, nickel-chromium alloys can be welded by

processes and procedures that adequately protect the

weld zone from oxidation.

They may be brazed using special techniques to

promote wetting of the base metal.

Nickel-iron-chromium alloys

13

These alloys contain about 20 to 45 percent nickel,

13 to 22 percent chromium, and the remainder iron.

They are generally used for corrosion- or oxidation-

resistant applications that can be fabricated by

welding.

Nickel-molybdenum alloys

14

These are nickel alloys that contain from 16 to 28

percent molybdenum and lesser amounts of chromium

and iron.

The alloys are used primarily for their corrosion

resistance.

They are not normally used for elevated temperature

service.

The nickel-molybdenum alloys are in general readily

weldable.

Nickel-chromium-molybdenum alloys

15

These alloys are designed primarily for corrosion

resistance at room temperature as well as resistance to

oxidizing and reducing atmospheres at elevated

temperatures.

They are not particularly strong at elevated

temperatures and, therefore, are used for low stress

applications.

All have good weldability.

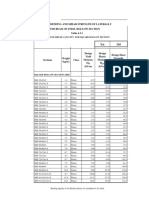

Composition of typical nickel alloys

16

Precipitation-hardenable alloys

17

These alloys are strengthened by controlled

precipitation of a second phase, known as gamma

prime, from a supersaturated solid solution.

Precipitation occurs upon reheating a solution-

treated and quenched alloy to an appropriate

temperature for a specific time.

18

Some cast alloys will age directly as the solidified

casting cools in the mold.

The most important phase from a strengthening

standpoint is the ordered face-centered cubic

gamma prime that is based upon the compound

Ni

3

Al.

This phase has a rather high solubility for titanium

and columbium.

19

Consequently, its composition will vary with the alloy

composition and the temperature of formation.

Aluminum has the greatest hardening potential, but

this is moderated by titanium and columbium.

The latter has the greatest effect on decreasing the

aging rate.

Weldability

20

Precipitation of nickel types of alloys are normally

welded in the solution-treated condition.

During welding, some portion of the heat-affected

zone is heated into the aging temperature range.

21

As the weld metal solidifies, the aging metal

becomes subjected to welding stresses.

Under certain postweld combinations of

temperature and stress, the weld heat-affected

zone may crack known as strain-age cracking.

Alloys high in aluminum are the most sensitive to this

type of cracking.

22

The problem is much less severe in those alloys

where columbium has been substituted for a

significant portion of the aluminum because

columbium retards the aging reaction.

Consequently, the weld heat-affected zone can

remain sufficiently ductile and yield during heat

treatment to relieve high welding stresses without

rupture.

Composition of typical nickel alloys

23

Nickel-copper alloys

24

The principal alloy in this group contains 66 percent

nickel, 30 percent copper, 2.7 percent aluminum and

0.6 percent titanium.

The recommended heat-treating procedures should be

followed to avoid strain-age cracking when welding this

alloy.

The corrosion resistance of this alloy is similar to the

solid-solution nickel-copper alloy of similar composition.

Nickel-chromium alloys

25

The nickel-chromium alloys are strengthened by the

addition of aluminum and titanium, and sometimes

columbium.

Chromium content ranges from about 13 to 20 percent

for good high-temperature oxidation resistance.

The strength of these alloys after heat treatment is

related to the combined aluminum, titanium, and

columbium content.

26

The higher this content, the higher is the strength of

the alloy.

Alloys that contain relatively large amounts of

aluminum and titanium are considered unweldable

because of their strain-age cracking tendencies.

Carefully applied preweld and postweld heat-

treating sequences can be used to reduce the strain-

age cracking tendencies of these alloys.

27

One of the principal advantages of columbium

additions for strengthening is the improved

weldability of such alloys compared to those alloys

containing only aluminum and titanium.

This is due to the sluggish formation of the

columbium precipitate compared to the more

rapidly forming aluminum precipitate.

28

Molybdenum and cobalt are often added to

improve high-temperature strength.

Their effect on weldability is minor.

The principal areas of application for these alloys

are gas turbine components, aircraft parts, and

spacecraft.

Nickel-iron-chromium alloys

29

These alloys nominally contain 40 to 45 percent nickel, 13 to 15

percent chromium, 30 to 40 percent iron and small amounts of

aluminum and titanium.

Their weldability is similar to that of the nickel-chromium alloys.

However, most applications involve forgings that require little

welding.

The same precautions necessary to avoid strain-age cracking with

other aluminum-titanium-hardened nickel alloys apply to these alloys

as well.

Weldability of some ppt hardenable nickel alloys

30

Dispersion-strengthened nickel

31

Nickel and nickel-chromium alloys can be

strengthened by the uniform dispersion of very fine

refractory oxide (ThO

2

) particles throughout the

matrix.

This is done using powder metallurgy techniques.

When these metals are fusion welded, the oxide

particles will agglomerate during solidification.

32

This will destroy the original strengthening

mechanism afforded by dispersion within the matrix.

The weld metal will be significantly weaker than the

base metal.

The high strength of these metals can be retained

by joining them with processes that do not involve

melting of the base metal.

Cast nickel alloys

33

Many nickel alloys can be used in cast as well as

wrought forms.

Some alloys are designed specifically for casting.

Casting alloys are strengthened by both solid-

solution and precipitation hardening.

34

Precipitation-hardening alloys high in aluminum

content, such as Alloy 713C, will harden during slow

cooling in the mold and are essentially unweldable

by fusion processes.

However, defects or service damage in some of

these alloys may be repaired by welding.

Many cast nickel alloys contain significant amounts

of silicon to improve fluidity and castability.

35

Most of these cast alloys are weldable by

conventional means, but as the silicon content

increases so does the weld cracking sensitivity.

Cracking can often be avoided using welding

techniques that minimize base metal dilution.

The nickel casting alIoy that contains 10 pecent

silicon and 3 percent copper (Hastelloy D) is

considered unweldable by arc welding methods, but

it may be welded with the oxyacetylene process.

36

Nickel alloys containing about 30 percent copper

are considered unweldable when the silicon content

is over about 2 percent because of their sensitivity

to cracking.

Defective castings of weldable alIoys may be

repaired by suitable welding procedures.

Generally, a filler metal of the same composition as

the base metal is used.

37

In some applications, the casting may be welded to

a wrought product, such as a cast valve body to

wrought pipe.

In such cases, the filIer metal must be compatible

with both base metals and suitable for the intended

service.

Composition of nickel casting alloys

38

Effects of minor elements on weldability

39

The presence of very small quantities of some elements can

have a profound effect on the weldability of nickel alloys.

The presence of sulfur frequently is related to hot cracking

because it forms a low melting eutectic with nickel that will

segregate to the grain boundaries of the weld metal.

Manganese and magnesium are frequently added to

combine with sulfur and prevent the formation of nickel

sulfide.

Effect of Ca, Ce, Al, and Ti

40

Calcium and cerium are used as deoxidizers and

also as malleabilizers interacting with sulfur.

Small additions of aluminum and titanium also serve

as deoxidizers.

41

All of these elements tend to contribute to the

formation of oxide films, islands, and slag spots,

which form on the weld surface.

In multipass welding, such tenacious slag films should

be removed between passes to avoid discontinuities

in the weld metal.

Effect of P, S, B, and Zr

42

Phosphorus also forms a low melting eutectic with

nickel that segregates to the grain boundaries that

contributes to hot cracking.

Sulfur, phosphorus, and similar impurity elements

tend to have an additive effect, and the total of all

of these elements should be kept low.

43

Boron and zirconium are frequently added to nickel

alloys to improve their hot malleability and to enhance

stress-rupture life.

However, they also tend to segregate at the grain

boundaries and increase the tendency for cracking in

the fusion and heat-affected zones in the base metal.

The tendency for cracking is also increased if the base

metal has a grain size coarser than ASTM No. 5.

The effect of boron and zirconium tends to be additive.

Effect of C

44

Carbon is an interstitial strengthening element in

nickel.

During welding, the carbon in the heat-affected

zone is dissolved at elevated temperature.

45

When nickel is used in the 600 F range, the carbon

will reprecipitate as graphite at the grain

boundaries.

This reduces the ductility of the heat-affected zone.

This is not a problem with low carbon nickel or

alloys that contain strong carbide-forming elements

such as chromium, columbium, and titanium.

Effect of Si and Pb

46

Silicon causes hot-short cracking in nickel alloys.

The severity of cracking varies with the alloy

composition and the joining process, but it is

especially severe in the high nickel-chromium alloys.

47

Filler metals containing columbium are often used

for welding castings with high silicon content to

prevent hot cracking of the weld metal.

Lead will cause hot-shortness in nickel alloy weld

metal.

However, it is seldom found in high quality base and

filler metals.

Sensitization

48

Some nickel-chromium and nickel-chromium-iron

alloys, like the austenitic stainless steels, exhibit

carbide precipitation (sensitization) in the weld

heat-affected zone.

Sensitization can make the alloys susceptible to

intergranular corrosion.

49

Those alloys stabilized with titanium and columbium

are not sensitized by welding.

An alternate approach is to use an extra low

carbon version of the selected alloy.

References

W.D. Callister, Jr.. Fundamentals of Materials Science

and Engineering, John Wiley & Sons, Inc., New York,

2001

R.C. Reed: The Superalloys, Fundamentals and

Applications, Cambridge University Press, Cambridge,

UK, 2006.

J.R. Davis: Heat-Resistant Materials, ASM Specialty

Handbook, 1997.

Вам также может понравиться

- Corrosion and Heat Resistant Nickel AlloysДокумент14 страницCorrosion and Heat Resistant Nickel AlloysWahid Muhamad Furkon RahmatullohОценок пока нет

- Nickel Base Alloys: Topics To Discuss .Документ15 страницNickel Base Alloys: Topics To Discuss .Muhammad Zam-zamОценок пока нет

- Corrosion Resistance of Nickel Alloys To HalogensДокумент8 страницCorrosion Resistance of Nickel Alloys To HalogensHeanjiaAlloysОценок пока нет

- 1.the Basics of Ferrous MetallurgyДокумент83 страницы1.the Basics of Ferrous MetallurgyfenasikerimОценок пока нет

- Grain Refinement of Permanent Mold Cast Copper Base AlloysДокумент124 страницыGrain Refinement of Permanent Mold Cast Copper Base Alloyschris nelson100% (1)

- Decomposition of Austenite in Austenitic Stainless SteelsДокумент13 страницDecomposition of Austenite in Austenitic Stainless SteelsregistrosegОценок пока нет

- Durham Foundry NiResistДокумент1 страницаDurham Foundry NiResistTerminatorX75Оценок пока нет

- Hsla SteelДокумент22 страницыHsla SteelriteshbarmanОценок пока нет

- Pub 42 Copper and Copper Alloy CastingsДокумент62 страницыPub 42 Copper and Copper Alloy CastingsHardik GandhiОценок пока нет

- A Brief Study On Nickel Based SuperalloysДокумент22 страницыA Brief Study On Nickel Based SuperalloysVIMAL JOSHYОценок пока нет

- Advances in Research on the Strength and Fracture of Materials: An OverviewОт EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD.M.R. TaplinОценок пока нет

- Basic Metallurgy: Numbering Systems For Metals and AlloysДокумент15 страницBasic Metallurgy: Numbering Systems For Metals and AlloysAcid BurnsОценок пока нет

- InTech-Copper and Copper Alloys Casting Classification and Characteristic MicrostructuresДокумент29 страницInTech-Copper and Copper Alloys Casting Classification and Characteristic MicrostructuresCarlos Ortega JonesОценок пока нет

- Alloy And Microstructural DesignОт EverandAlloy And Microstructural DesignJohn TienОценок пока нет

- Controlled Atmospheres for Heat Treatment: The Pergamon Materials Engineering Practice SeriesОт EverandControlled Atmospheres for Heat Treatment: The Pergamon Materials Engineering Practice SeriesОценок пока нет

- Segregation and Banding in SteelДокумент2 страницыSegregation and Banding in SteelskluxОценок пока нет

- Strength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985От EverandStrength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985H. J. McQueenОценок пока нет

- Revealing Prior-Austenite Grain Boundaries in Heat-Treated SteelsДокумент5 страницRevealing Prior-Austenite Grain Boundaries in Heat-Treated Steelsmp87_ingОценок пока нет

- Embrittlement of Engineering AlloysОт EverandEmbrittlement of Engineering AlloysC. L. BriantОценок пока нет

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelОт EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelОценок пока нет

- The Precipitation Hardening SSsДокумент3 страницыThe Precipitation Hardening SSsClaudia MmsОценок пока нет

- Austral Wright Metals: CuttingДокумент10 страницAustral Wright Metals: CuttingScribdSnake123100% (1)

- Effects of MN Content and Heat TreatmentДокумент5 страницEffects of MN Content and Heat TreatmentTrần Xuân VịnhОценок пока нет

- Niobium in Cast IronДокумент13 страницNiobium in Cast IronTayyab HussainОценок пока нет

- Duplex Stainless Steel 329 or 1.4460 PDFДокумент2 страницыDuplex Stainless Steel 329 or 1.4460 PDFtien100% (1)

- Austenitic Stainless SteelsДокумент23 страницыAustenitic Stainless SteelsAndrea VieyraОценок пока нет

- Nickel Based SuperalloysДокумент20 страницNickel Based SuperalloysKarthik 029CSK100% (1)

- Ni Resist and Ductile Ni Resist Alloys 11018Документ40 страницNi Resist and Ductile Ni Resist Alloys 11018Prasad Aher100% (1)

- Inclusion Evolution and Removal in Ladle Refining: R. J. O'MalleyДокумент20 страницInclusion Evolution and Removal in Ladle Refining: R. J. O'MalleyemregnesОценок пока нет

- Precipitation in The Ni-Cu-Base Alloy Monel K-500Документ13 страницPrecipitation in The Ni-Cu-Base Alloy Monel K-500farhadeeОценок пока нет

- Guideline To Nickel AlloysДокумент8 страницGuideline To Nickel AlloysHeanjiaAlloysОценок пока нет

- Stress Corrosion Cracking Issues in Syngas PlantsДокумент12 страницStress Corrosion Cracking Issues in Syngas PlantsciaoОценок пока нет

- HeatResistantAlloys RolledAlloysДокумент150 страницHeatResistantAlloys RolledAlloysAon Hemmatad100% (1)

- Different Forms of Corrosion - Microbiologically Influenced Corrosion MIC - Microbial CorrosionДокумент2 страницыDifferent Forms of Corrosion - Microbiologically Influenced Corrosion MIC - Microbial CorrosionHarry NuryantoОценок пока нет

- The Structures of Alloys of Iron: An Elementary IntroductionОт EverandThe Structures of Alloys of Iron: An Elementary IntroductionОценок пока нет

- Metallurgical Properties of Cast IronsДокумент21 страницаMetallurgical Properties of Cast IronsAleš NagodeОценок пока нет

- Clean Steel Practices in The Melt ShopДокумент3 страницыClean Steel Practices in The Melt Shopmp87_ingОценок пока нет

- Non-Ferrous Process Principles and Production Technologies: H.Y. SohnДокумент1 страницаNon-Ferrous Process Principles and Production Technologies: H.Y. SohnCarlosОценок пока нет

- BS6615 1996Документ18 страницBS6615 1996petervisser100% (1)

- Foundry of Non-Ferrous Metal AlloysДокумент59 страницFoundry of Non-Ferrous Metal AlloysNarender KumarОценок пока нет

- Accelerated CoolingДокумент7 страницAccelerated CoolingHarikrishnan N SivaprasadОценок пока нет

- Review of Creep Resistant SteelsДокумент4 страницыReview of Creep Resistant SteelsAleš NagodeОценок пока нет

- Nickel and Other Super Alloys: TSUF 06 Materiales AeronauticosДокумент28 страницNickel and Other Super Alloys: TSUF 06 Materiales AeronauticosFam HandmОценок пока нет

- Use of Silicon Carbide in Induction in Induction FurnaceДокумент2 страницыUse of Silicon Carbide in Induction in Induction FurnacemkraijadaОценок пока нет

- Ironmaking and Steelmaking Theory and PracticeДокумент9 страницIronmaking and Steelmaking Theory and PracticeRasul BzОценок пока нет

- Aluminum Alloy WeldabilityДокумент208 страницAluminum Alloy WeldabilityThirumaranОценок пока нет

- Binders ComparisionДокумент8 страницBinders Comparisionavutu_kunduruОценок пока нет

- The Use of VanadiumДокумент182 страницыThe Use of VanadiumRavjManjunathОценок пока нет

- Corrosion in Hydrochloric AcidДокумент2 страницыCorrosion in Hydrochloric AcidbbmokshОценок пока нет

- A 732/a732m-02Документ8 страницA 732/a732m-02mutluОценок пока нет

- Steel Making - Open-Hearth TehniqueДокумент5 страницSteel Making - Open-Hearth TehniqueMarcelo Rodriguez FujimotoОценок пока нет

- Template of Energy Audit ReportДокумент18 страницTemplate of Energy Audit ReportidienОценок пока нет

- Design of Structures & Foundations For Vibrating MachinesДокумент212 страницDesign of Structures & Foundations For Vibrating MachinesOvidiu Genteanu97% (30)

- Weld Metal Slag HAZ HAZ: Co CoДокумент1 страницаWeld Metal Slag HAZ HAZ: Co CoidienОценок пока нет

- Rumus Welding PDFДокумент8 страницRumus Welding PDFidienОценок пока нет

- Aluminum and Aluminum AlloysДокумент0 страницAluminum and Aluminum AlloysidienОценок пока нет

- Low Alloy Steels For Cryogenic ApplicationsДокумент0 страницLow Alloy Steels For Cryogenic ApplicationsidienОценок пока нет

- Direct Tensile Test of ConcreteДокумент7 страницDirect Tensile Test of ConcreteBunkun15100% (1)

- Copper Alloy C52400Документ9 страницCopper Alloy C52400Sivaram Kottali100% (1)

- Nanomagnetism Principles, Nanostructures, and Biomedical ApplicationsДокумент8 страницNanomagnetism Principles, Nanostructures, and Biomedical ApplicationsHaposan YogaОценок пока нет

- Kaloper - Zivalj - Medic - Experimental and Numerical Assessment of Reinforced Concrete Column Under Cyclic Loading - CroCEEДокумент8 страницKaloper - Zivalj - Medic - Experimental and Numerical Assessment of Reinforced Concrete Column Under Cyclic Loading - CroCEEsenad medicОценок пока нет

- Void Swelling StraalsundДокумент7 страницVoid Swelling StraalsundAzif Ali MoothantevileyilОценок пока нет

- Chapter 4 - Bending & Shear Capacity - 4.3.1Документ2 страницыChapter 4 - Bending & Shear Capacity - 4.3.1NIBEDITA DEYОценок пока нет

- Motion of Particles in FluidДокумент26 страницMotion of Particles in FluidSubakti HungОценок пока нет

- Bending of Beams: Pure Bending Timoshenko Beam TheoryДокумент12 страницBending of Beams: Pure Bending Timoshenko Beam TheoryChad FreemanОценок пока нет

- High Temperature Service Equipment and Piping Maintenance in PlantДокумент22 страницыHigh Temperature Service Equipment and Piping Maintenance in Plantvaratharajan g rОценок пока нет

- (Computational and Experimental Methods in Structures 6) Aliabadi, Mohammad H - Woven Composites (2015, Imperial College Press)Документ248 страниц(Computational and Experimental Methods in Structures 6) Aliabadi, Mohammad H - Woven Composites (2015, Imperial College Press)Andres CastilloОценок пока нет

- All Metals - Glossary of Metallurgical and Materials Testing TermsДокумент22 страницыAll Metals - Glossary of Metallurgical and Materials Testing TermshjoutipОценок пока нет

- Investigation of tungsten/EUROFER97 Diffusion Bonding Using NB InterlayerДокумент4 страницыInvestigation of tungsten/EUROFER97 Diffusion Bonding Using NB InterlayerHARIMETLYОценок пока нет

- Reckon Civil Academy Strength of Material Mains PaperДокумент4 страницыReckon Civil Academy Strength of Material Mains PaperAbhishek ChoudharyОценок пока нет

- Shape Memory Alloy Heat Engine DesignДокумент107 страницShape Memory Alloy Heat Engine Designagabatti100% (1)

- Biomaterials 2009 Fall Home Work No4Документ2 страницыBiomaterials 2009 Fall Home Work No4_Ariane_Enaira_5613Оценок пока нет

- 07 Coconut Fiber Reinforced Compressed Earth BlocksДокумент2 страницы07 Coconut Fiber Reinforced Compressed Earth BlocksBilly SchipperОценок пока нет

- K.S. Birdi - Self-Assembly Monolayer Structures of Lipids and Macromolecules at Interfaces-Kluwer Academic - Plenum Publishers (1999)Документ391 страницаK.S. Birdi - Self-Assembly Monolayer Structures of Lipids and Macromolecules at Interfaces-Kluwer Academic - Plenum Publishers (1999)RAKESH RANJANОценок пока нет

- Experimental Stress AnalysisДокумент27 страницExperimental Stress AnalysisJustin RajaОценок пока нет

- CM 425 - Properties of Fresh Concrete PDFДокумент14 страницCM 425 - Properties of Fresh Concrete PDFTran Huynh NamОценок пока нет

- Referat Radiologi Fraktur Antebrachii PDFДокумент3 страницыReferat Radiologi Fraktur Antebrachii PDFbobfaisalОценок пока нет

- Polymer PPT FinalДокумент36 страницPolymer PPT FinalkbnarkhedeОценок пока нет

- Underwater Friction Stir Welding An OverviewДокумент6 страницUnderwater Friction Stir Welding An OverviewSabry S. YoussefОценок пока нет

- FEEG1002 Formula Sheet S1 and S2 2015-16Документ5 страницFEEG1002 Formula Sheet S1 and S2 2015-16GeorgeОценок пока нет

- Bridges Class 70R 26M Span ROB R3Документ37 страницBridges Class 70R 26M Span ROB R3Goutam ChakrabortyОценок пока нет

- Unit 1 Solid StateДокумент30 страницUnit 1 Solid StateTr Mazhar PunjabiОценок пока нет

- Metalcor 1.3917 Alloy 42Документ1 страницаMetalcor 1.3917 Alloy 42imtiyazОценок пока нет

- Ube Nylon 5034bДокумент1 страницаUbe Nylon 5034bDiegoTierradentroОценок пока нет

- Failure and Root Cause Analysis of Vehicle Drive ShaftДокумент10 страницFailure and Root Cause Analysis of Vehicle Drive ShaftMuhammad Al-HafiezОценок пока нет

- As 4600 Supplement 1Документ122 страницыAs 4600 Supplement 1Anh Do VoОценок пока нет