Академический Документы

Профессиональный Документы

Культура Документы

LANL Engineering Standards Manual PWHT Procedure

Загружено:

victorbirlanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LANL Engineering Standards Manual PWHT Procedure

Загружено:

victorbirlanАвторское право:

Доступные форматы

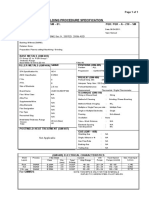

LANL Engineering Standards Manual ISD 341-2

Volume 1, General Welding Standards GWS 1-08 Post Weld Heat Treatment

Chapter 13, Welding & Joining Rev. 1, 10/27/06

TABLE OF CONTENTS

Volume 1, GENERAL WELDING STANDARDS

GWS 1-08 POST WELD HEAT TREATMENT...................................................................................... 2 1.0 PURPOSE AND SCOPE ....................................................................................................................... 2 2.0 REFERENCES .................................................................................................................................... 2 3.0 ACRONYMS AND DEFINITIONS ......................................................................................................... 2 4.0 GENERAL .......................................................................................................................................... 2 5.0 PROCEDURE...................................................................................................................................... 2 6.0 ATTACHMENTS................................................................................................................................. 6 Attachment 1: Post Weld Heat Treatment Instruction Sheet .................................................................... 6 Attachment 2: Thermocouple Placement Sketches................................................................................... 6

RECORD OF REVISIONS

Rev 0 1 Date 8/16/04 10/27/06 Initial issue. Organization updates from LANS transition. IMP and ISD number changes based on new Conduct of Engineering IMP 341. Other administrative changes. Description POC Kelly Bingham, FWO-DECS Kelly Bingham, FM&E-DES OIC Gurinder Grewal, FWO-DO Kirk Christensen, CENG

Contact the Welding Standards POC for upkeep, interpretation, and variance issues GWS 1-08 Welding POC/Committee

Page 1 of 6

LANL Engineering Standards Manual ISD 341-2

Volume 1, General Welding Standards GWS 1-08 Post Weld Heat Treatment

Chapter 13, Welding & Joining Rev. 1, 10/27/06

GWS 1-08 POST WELD HEAT TREATMENT 1.0 PURPOSE AND SCOPE

A. The purpose of this procedure is to provide instructions for Post Weld Heat Treatment (PWHT) of welded joints. B. The scope of this section applies to Post Weld Heat Treatment activities conducted and in connection with welding activities performed at LANL.

2.0 3.0

REFERENCES

None.

ACRONYMS AND DEFINITIONS

Acronym / Term Description

PWHT Post Weld Heat Treatment

PWHT is stress-relief heat treatmentthe uniform heating of a structure (component) or a portion thereof to a sufficient temperature to relieve the major portion of the residual stresses, followed by uniform cooling. (from AWS A3.0, italics added)

4.0

4.1

GENERAL

Responsibilities

A. The assigned LANL Facility, Project, Program Manager or SSS designee is responsible for ensuring that PWHT is performed in accordance with this procedure and the temperature range specified on the appropriate Welding Procedure Specification (WPS) or Welding Technique Sheet (WTS).

5.0

5.1

PROCEDURE

General

A. The LANL Facility, Project, Program Manager, or SSS designee shall complete a PWHT Instruction Sheet (Attachment 1) prior to each PWHT operation. Instructions for completing the PWHT Instruction Sheet are included in Attachment 1.

5.2

Temperature Measurement

A. Thermocouples shall be attached so that there is firm contact between the sensing tip and the assembly being heat treated by use of thermocouple attachment devices or capacitor discharge attachment devices.

Page 2 of 6

LANL Engineering Standards Manual ISD 341-2

Volume 1, General Welding Standards GWS 1-08 Post Weld Heat Treatment

Chapter 13, Welding & Joining Rev. 1, 10/27/06

B. Thermocouple attachment devices shall be tack welded by a qualified welder using a WPS / WTS compatible with the material to be welded. When using capacitor discharge attachment devices, the manufacturers instructions should be followed and qualification of the operator is not required. C. A minimum of 6 thermocouples are required on pipe diameters over NPS 8 (DN 200): 2 recording and 2 recording spares, plus 1 control and 1 control spare. Additional control and control spare thermocouples may be added to allow for zone or quadrant control. D. A minimum of 4 thermocouples are required on pipe diameters NPS 8 (DN 200) and less: 1 recording and 1 recording spare; 1 control and 1 control spare. Additional control and control spare thermocouples may be added to allow for zone or quadrant control. E. Thermocouples shall be placed in accordance with the appropriate sketches identified in Attachment 2. F. The temperature recorder shall be calibrated in accordance with the manufacturers recommendations.

5.3

Heating Elements / Furnaces

A. The required number of heating elements and power supplies shall be determined. This may be accomplished by referring to the manufacturers requirements and/or by using the following formulas as a guide: Kilowatts Required = Diameter x Thickness One Heating Element = 3.2 Kilowatts 24 Heating Elements = One 500 Amp Power Supply

B. Locate and fasten heating elements in accordance with the manufacturers instructions and the following requirements: 1. For fabrication codes other than ASME Section III and Section VIII, welds shall be post weld heat treated by heating a circumferential band around the pipe or component. The width of the band shall be at least 3 times the thickness at the weld of the thicker member being joined. 2. For ASME Section VIII, post weld heat treatment may be accomplished by heating the vessel as a whole in an enclosed furnace or by heating shell sections, portions of vessels, longitudinal joints, or complicated welded details before joining to make a completed vessel. Any circumferential welds not previously post weld heat treated may be thereafter locally post weld heat treated by heating a circumferential band around the vessel. The width of the heated band on each side of the greatest width of finished weld shall not be less than 3 times the shell thickness. For heating a circumferential band containing nozzles or other welded attachments that require post weld heat treatment, the circumferential band shall extend around the entire vessel, shall include the nozzle or welded attachment, and shall extend at least 6 times the plate thickness beyond the weld which connects the nozzle or other attachment to the vessel.

Page 3 of 6

LANL Engineering Standards Manual ISD 341-2

Volume 1, General Welding Standards GWS 1-08 Post Weld Heat Treatment

Chapter 13, Welding & Joining Rev. 1, 10/27/06

3. For ASME Section III, post weld heat treatment may be accomplished by heating the vessel as a whole in an enclosed furnace or by heating a circumferential band around the pipe or component. The width of the band shall be at least three times the thickness at the weld of the thicker member being joined. Heating the item in a closed furnace in one heat is the preferred method and should be used whenever practical. The furnace atmosphere shall be controlled so as to avoid excessive oxidation and direct impingement of flame on the component or item is prohibited. The item may be heated in more than one heat in a furnace, provided the overlap of the heated sections of the item is at least 5 ft. (1.5 m). When this procedure is used, the portion of the component or item outside the furnace shall be shielded so that the temperature gradient is not harmful. The cross section where the component or item projects from the furnace shall not intersect a nozzle or other structural discontinuity. Note: Use of ASME Section III is not anticipated. C. On pipe diameters greater than NPS 12 (DN 300), the heating elements shall be placed to provide 4-quadrant control. D. Wrap at least one layer of insulation around the joint for all wall thicknesses, leaving only the thermocouple leads and heater element leads exposed.

5.4

Heating Process

A. For ASME / ANSI fabrication codes, other than ASME Section III and VIII, heat-up and cool-down shall be controlled above 600 F (315 C) at a rate not exceeding 600 F/hr (315 C/hr) for thicknesses less than or equal to 2 in. (50 mm). On materials greater than 2 in. (50 mm) in thickness, the rate shall not exceed 600 F/hr (315 C/hr) divided by one-half the thickness of the thicker joint member. B. For ASME Section III and Section VIII, heat-up and cool-down shall be controlled above 600 F (316 C) at a rate not exceeding 400 F/hr. (205 C/hr.) for thicknesses less than or equal to 1 in. (25 mm). On materials greater than 1 in. (25 mm) in thickness, the rate shall not exceed 400 F/hr (205 C/hr) divided by the thickness of the thicker material being heat treated. The rate need not be less than 100 F (38 C) in any hourly interval. During the heating and cooling period there shall not be a greater variation in temperature than 250 F (120 C) within any 15 ft. (4.5 m) interval of weld length. Note: The WPS / WTS and/or fabrication code may establish heating and cooling rates that are more restrictive for some materials and service conditions. C. For AWS D1.1 1. The temperature of the furnace shall not exceed 600F (315C) at the time the welded assembly is placed in it. 2. Above 600F the rate of heating shall not be more than 400F (220C) per hour divided by the maximum metal thickness of the thicker part, in inches, but in no case more than 400F per hour. During the heating period, variation in temperature throughout the portion of the part being heated shall be no greater than 250F (140C) within any 15 ft interval of length. The rates of heating and cooling need not be less than 100F (55C) per hour. However consideration of closed chambers and complex structures may indicate reduced heating and cooling to avoid structural damage due to excessive thermal gradients.

Page 4 of 6

LANL Engineering Standards Manual ISD 341-2

Volume 1, General Welding Standards GWS 1-08 Post Weld Heat Treatment

Chapter 13, Welding & Joining Rev. 1, 10/27/06

3. After a maximum temperature of 1100F (600C) is reached on quenched and tempered steels, or a mean temperature range between 1100F and 1200F (650C) is reached on other steels, the temperature of the assembly shall be held within the specified limits for not less than specified in AWS D1.1 Table 5.2 based on weld thickness. When the specified stress relief is for dimensional stability, the holding time shall be not less than specified in AWS D1.1 Table 5.2 based on the thickness of the thicker part. During the holding period there shall be no difference greater than 150F (85C) between the highest and the lowest temperature throughout the portion of the assembly being heated. 4. Above 600F, cooling shall be done in a closed furnace or cooling chamber at a rate no greater than 500F (260C) per hour divided by the maximum metal thickness of the thicker part in inches, but in no case more than 500F per hour. From 600F the assembly may be cooled in still air. 5. Alternative PWHT - Alternatively, when it is impractical to PWHT to the temperature limitations stated in 5.M.1 through 5.M.4 above, welded assemblies may be stressrelieved at lower temperatures for longer periods of time as given in AWS D1.1 Table 5.3 D. For AWS D1.6 - PWHT requirements must be specified in the WPS and is limited to nonprequalified welding procedures. E. For ASME B31.8 1. Welds in carbon steel having carbon content in excess of 0.32% (ladle analysis) or a carbon equivalent (C+ Mn) in excess of 0.65% ladle analysis shall be stress relieved as prescribed in ASME BPV Code, Section VIII. Stress relieving may also be advisable for welds having lower carbon content or carbon equivalent when adverse conditions cool the weld too rapidly. 2. Welds in all carbon steels shall be stress relieved when the nominal wall thickness exceeds 1 inch. 3. When welded joint connects parts of different thicknesses but similar materials, the thickness to be used in applying the rules in paragraphs 5.0.1 and 5.0.2 shall be: The thicker of the two parts being joined, measured at the weld joint. The thickness of the pipe run or header in case of branch connections, slip-on flanges, or socket weld fittings. 4. If either material in welds between dissimilar materials requires stress relieving, the joint shall require stress relieving. 5. A welding of connections and attachments shall be stress relieved when the pipe is required to be stress relieved by the rules of 5.0.3 with the following exceptions: Fillet and groove welds not over 1/2 inch leg size that attach connections not over NPS 2 inch pipe size. Fillet and groove welds not over 3/8 inch groove size that attach supporting members or other non-pressure attachments. 6. Stress Relieving Temperature Stress relieving shall be performed at a temperature of 1100F or greater for carbon steel and 1200 F or greater for ferritic alloy steels. The exact temperature range shall be stated in the procedure specification. When Stress relieving takes place in a joint between dissimilar metals having different stress relieving requirements, the material requiring the higher stress relieving temperature shall govern.

Page 5 of 6

LANL Engineering Standards Manual ISD 341-2

Volume 1, General Welding Standards GWS 1-08 Post Weld Heat Treatment

Chapter 13, Welding & Joining Rev. 1, 10/27/06

The parts heated shall be brought slowly to the required temperature and held at that temperature for a period of time proportioned on the basis of at least 1hr/in. of pipe wall, but in no case less than 1/2 hr, and shall be allowed to cool slowly and uniformly. 7. Methods of Stress Relieving Heat the complete structure as a unit Heat a complete section containing the weld or welds to be stress relieved before attachment to other sections of work Heat a part of the work by slowly heating a circumferential band containing the weld at the center. The width of the band that is heated to the required temperature shall be at least 2 in. greater than the width of the weld reinforcement. Care should be taken to obtain a uniform temperature around the entire circumference of the pipe. The temperature shall diminish gradually outward from the edges of this band. Branches or other welded attachments for which stress relief is required may be locally stress relieved by heating a circumferential band around the pipe on which the branch or attachment is welded with the attachment at the middle of the band. The width of the band shall be at least 2 in. greater than the weld joining the branch or attachment to the header. The entire band shall be brought up to the required temperature and held for the time specified.

5.5

Records

A. Upon completion of the PWHT operation, the LANL Facility, Project, Program Manager or SSS designee shall attach the PWHT Instruction Sheet (Attachment 1) to the recorder chart and file along with the associated weld records in the construction site files.

5.6

Subcontracted Services

A. Subcontracted PWHT services shall be performed in accordance with this Section or in accordance with the Subcontractor's procedures as accepted by LANL. B. The LANL Facility, Project, Program Manager or SSS designee shall monitor the PWHT Subcontractor to assure compliance with the engineering specification and applicable procedures.

6.0

ATTACHMENTS

Attachment 1: Post Weld Heat Treatment Instruction Sheet Attachment 2: Thermocouple Placement Sketches

Page 6 of 6

Вам также может понравиться

- Shell's Post-Weld Heat Treatment GuideДокумент17 страницShell's Post-Weld Heat Treatment GuideSiva RamОценок пока нет

- Post Weld Heat Treatment ProcedureДокумент20 страницPost Weld Heat Treatment Proceduresherviny100% (2)

- Post Weld Heat Treatment Procedure PWHTДокумент12 страницPost Weld Heat Treatment Procedure PWHTchiragОценок пока нет

- PWHTДокумент13 страницPWHTcv100% (2)

- Jpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Документ9 страницJpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Anoop N Kutty100% (1)

- PWHTДокумент3 страницыPWHTharishcsharmaОценок пока нет

- Pro PWHT 006 Rev 1 - Procedure For PWHTДокумент6 страницPro PWHT 006 Rev 1 - Procedure For PWHTsugumar100% (1)

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- ARL-AL-WPS-001 welding procedureДокумент2 страницыARL-AL-WPS-001 welding procedurerajuajiОценок пока нет

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- All Materials DocumentsДокумент1 страницаAll Materials DocumentsRonit PatelОценок пока нет

- WPSДокумент1 страницаWPSNidhinkorothОценок пока нет

- WPS 316 L PDFДокумент4 страницыWPS 316 L PDFIrinaОценок пока нет

- All Materials DocumentsДокумент1 страницаAll Materials DocumentsHarnish BariaОценок пока нет

- Asme Sec Ix Guide PDFДокумент144 страницыAsme Sec Ix Guide PDFCHARLES Anthonyraj100% (1)

- Generic Repair Procedure For Grinding and Build-UpДокумент8 страницGeneric Repair Procedure For Grinding and Build-UpRafiqKuОценок пока нет

- SIRIM-AWS Certified Welding Engineer (CWEng.) Brochure 2013Документ2 страницыSIRIM-AWS Certified Welding Engineer (CWEng.) Brochure 2013sutimankemin100% (1)

- API 510 PWHT RequirementsДокумент30 страницAPI 510 PWHT RequirementsKandregula Mohan BabuОценок пока нет

- Erection & Welding of P91 Pipe MaterialДокумент10 страницErection & Welding of P91 Pipe MateriallightsonsОценок пока нет

- Material GradesДокумент1 страницаMaterial GradesshisОценок пока нет

- WPS Asme IxДокумент4 страницыWPS Asme Ixjcarlosherrerac7100% (1)

- PWHT Procedure PDFДокумент9 страницPWHT Procedure PDFAbhishek AnandОценок пока нет

- GMAWДокумент12 страницGMAWsushant47Оценок пока нет

- Metrode - P92 WPS PDFДокумент3 страницыMetrode - P92 WPS PDFXing ChenОценок пока нет

- FILL COURSE ENROLMENT FORMДокумент3 страницыFILL COURSE ENROLMENT FORMRaja Guru100% (1)

- PWHT PROCEDURE (11) Rev 0Документ14 страницPWHT PROCEDURE (11) Rev 0AbdulNeyasОценок пока нет

- Scan Preheat and PWHT ProcedureДокумент11 страницScan Preheat and PWHT ProcedureGandhi Kusuma100% (1)

- WPS - EngineerДокумент20 страницWPS - Engineerhunghoanglong100% (1)

- MIZAT PWHT Procedure Ensures Welded Joints Meet StandardsДокумент9 страницMIZAT PWHT Procedure Ensures Welded Joints Meet StandardsM. R. Shahnawaz KhanОценок пока нет

- Submerged Arc Welding Fluxes BasicityДокумент3 страницыSubmerged Arc Welding Fluxes Basicitylram70Оценок пока нет

- Welding Inspection Consumables PDFДокумент28 страницWelding Inspection Consumables PDFJoseph PeterОценок пока нет

- Deviations During PWHT and ResponseДокумент2 страницыDeviations During PWHT and ResponseEIL NDT100% (1)

- PWHT Procedure by FurnaceДокумент5 страницPWHT Procedure by Furnacerustamriyadi0% (1)

- Tube Expansion ProcedureДокумент3 страницыTube Expansion Procedurerudi 01100% (1)

- Welding Procedure Specification: Page 1 of 1Документ2 страницыWelding Procedure Specification: Page 1 of 1Anderson Perez MartinezОценок пока нет

- Asme Sec Viii Div 1 2017 Ucs 56Документ1 страницаAsme Sec Viii Div 1 2017 Ucs 56Anonymous hBBam1nОценок пока нет

- NPCIL Tube Fitting SpecificationsДокумент22 страницыNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayДокумент1 страницаWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Welded Tube Joint SpecДокумент8 страницWelded Tube Joint SpecAvinash ShuklaОценок пока нет

- Sample Wps-Carbon Steel GTAW+SMAWДокумент2 страницыSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- PWHTДокумент103 страницыPWHTChetan B KapadiaОценок пока нет

- WPS 11A Welding ProcedureДокумент1 страницаWPS 11A Welding ProcedureM. R. Shahnawaz KhanОценок пока нет

- AWS D1.1 - Example PQR & WPS DocumentsДокумент4 страницыAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Method Statement For Titanium PipeworkДокумент3 страницыMethod Statement For Titanium Pipeworkprem nautiyalОценок пока нет

- Asme PQR DemoДокумент3 страницыAsme PQR DemoMuthusamy AyyanapillaiОценок пока нет

- PQR Wps WPQ FormatДокумент12 страницPQR Wps WPQ FormatessnelsonОценок пока нет

- Esab Inconel 625 InfoДокумент1 страницаEsab Inconel 625 InforinshadОценок пока нет

- Heat Treatment Manual for Power Sector ComponentsДокумент21 страницаHeat Treatment Manual for Power Sector ComponentsAnonymous lmCR3SkPrK100% (2)

- Intro To RadiographyДокумент37 страницIntro To RadiographySaleemSahabОценок пока нет

- WPS, PQR and WPQДокумент31 страницаWPS, PQR and WPQDhrumil Chauhan100% (1)

- P numbers welding guideДокумент20 страницP numbers welding guideMOHANОценок пока нет

- Heat TreatmentДокумент5 страницHeat TreatmentsheikmoinОценок пока нет

- Sample Heat Treatment ProcedureДокумент13 страницSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- Heat Treatment GuidelinesДокумент3 страницыHeat Treatment GuidelinesInoCastilloОценок пока нет

- PWHT ProcedureДокумент10 страницPWHT ProcedureMohammed Kamal100% (11)

- Giude Lines For Heat TreatmentДокумент91 страницаGiude Lines For Heat TreatmentMassimo FumarolaОценок пока нет

- Procedure For Post Weld Heat Treatment (PWHT PROCEDURE)Документ10 страницProcedure For Post Weld Heat Treatment (PWHT PROCEDURE)Senthil Kumaran100% (2)

- Installation and Maintenance Instructions Ball Valves, Fully WeldedДокумент6 страницInstallation and Maintenance Instructions Ball Valves, Fully WeldedvictorbirlanОценок пока нет

- Drip BarrelДокумент8 страницDrip Barrelvictorbirlan50% (2)

- MJ 1964 Us Ballvalve MJДокумент16 страницMJ 1964 Us Ballvalve MJMOHAMMAD ASIFОценок пока нет

- Kuwait Labor Law 2010 DetailedДокумент39 страницKuwait Labor Law 2010 DetailedvictorbirlanОценок пока нет

- API 610 HighlightsДокумент26 страницAPI 610 Highlightsmmihai_popa2006Оценок пока нет

- Pipelayer: PreliminaryДокумент2 страницыPipelayer: PreliminaryvictorbirlanОценок пока нет

- ASME/ANSI 831.3 Interpretations SummaryДокумент15 страницASME/ANSI 831.3 Interpretations SummaryvictorbirlanОценок пока нет

- LANL Engineering Standards Manual PWHT ProcedureДокумент6 страницLANL Engineering Standards Manual PWHT ProcedurevictorbirlanОценок пока нет

- Pipeline Fires and DamagesДокумент18 страницPipeline Fires and DamagesvictorbirlanОценок пока нет

- Fish MornayДокумент1 страницаFish MornayvictorbirlanОценок пока нет

- Drip BarrelДокумент8 страницDrip Barrelvictorbirlan50% (2)

- LANL Engineering Standards Manual PWHT ProcedureДокумент6 страницLANL Engineering Standards Manual PWHT ProcedurevictorbirlanОценок пока нет

- European Welding New-StandardsДокумент39 страницEuropean Welding New-StandardsJOECOOL67100% (3)

- Index Map: Northern Colorado Fort Collins MainlineДокумент1 страницаIndex Map: Northern Colorado Fort Collins MainlinevictorbirlanОценок пока нет

- Fish MornayДокумент1 страницаFish MornayvictorbirlanОценок пока нет

- Europe Ref 2010Документ1 страницаEurope Ref 2010Bogdan WhiteОценок пока нет

- Bending Moment On Valves, Flanges and Mechanical JointsДокумент1 страницаBending Moment On Valves, Flanges and Mechanical JointsvictorbirlanОценок пока нет

- Europe Ref 2010Документ1 страницаEurope Ref 2010Bogdan WhiteОценок пока нет

- Fish MornayДокумент1 страницаFish MornayvictorbirlanОценок пока нет

- Review ManualДокумент36 страницReview ManualvictorbirlanОценок пока нет

- European Welding New-StandardsДокумент39 страницEuropean Welding New-StandardsJOECOOL67100% (3)

- Europe Ref 2010Документ1 страницаEurope Ref 2010Bogdan WhiteОценок пока нет

- European Welding New-StandardsДокумент39 страницEuropean Welding New-StandardsJOECOOL67100% (3)

- European Welding New-StandardsДокумент39 страницEuropean Welding New-StandardsJOECOOL67100% (3)

- European Welding New-StandardsДокумент39 страницEuropean Welding New-StandardsJOECOOL67100% (3)

- European Welding New-StandardsДокумент39 страницEuropean Welding New-StandardsJOECOOL67100% (3)

- Europe Ref 2010Документ1 страницаEurope Ref 2010Bogdan WhiteОценок пока нет

- Europe Ref 2010Документ1 страницаEurope Ref 2010Bogdan WhiteОценок пока нет

- Europe Ref 2010Документ1 страницаEurope Ref 2010Bogdan WhiteОценок пока нет

- Astm A 335Документ10 страницAstm A 335Fabian Andrey DiazОценок пока нет

- The 4 Types of Heat Treatment Steel Undergoes - Kloeckner MetalsДокумент5 страницThe 4 Types of Heat Treatment Steel Undergoes - Kloeckner MetalsSrivishnu vemulaОценок пока нет

- The Effects of Heating Rate On Austenite Grain Growth in A Ti-Modified SAE 8620 Steel With Controlled Niobium AdditionsДокумент8 страницThe Effects of Heating Rate On Austenite Grain Growth in A Ti-Modified SAE 8620 Steel With Controlled Niobium AdditionsjavadmohammadiОценок пока нет

- Implant Materials - Wrought 18 - Chromiickel - 2.5 - Molybdenum Stainless Steel.5 - Molybdenum Stainless SteelДокумент32 страницыImplant Materials - Wrought 18 - Chromiickel - 2.5 - Molybdenum Stainless Steel.5 - Molybdenum Stainless SteelGagan BajpaiОценок пока нет

- MAT E 202 Fall 2009 Final ExamДокумент18 страницMAT E 202 Fall 2009 Final ExamStone RricОценок пока нет

- Incoloy 909 PDFДокумент13 страницIncoloy 909 PDF孙俊磊Оценок пока нет

- A511 96 PDFДокумент7 страницA511 96 PDFJohano AraújoОценок пока нет

- Steps in production of titanium from ore to ingotsДокумент4 страницыSteps in production of titanium from ore to ingotsUyGrEdSQОценок пока нет

- H11 Mod PDFДокумент50 страницH11 Mod PDFsunsirОценок пока нет

- Is 613 PDFДокумент11 страницIs 613 PDFSamОценок пока нет

- Astm F3001 - 14Документ6 страницAstm F3001 - 14SergiyОценок пока нет

- 32 Steel PDFДокумент1 страница32 Steel PDFIrfan DzakyОценок пока нет

- MT 010 601 Non Ferrous Physical MetallurgyДокумент2 страницыMT 010 601 Non Ferrous Physical Metallurgyവിഷ്ണു സിОценок пока нет

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10084Документ2 страницыEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10084farshid KarpasandОценок пока нет

- Outokumpu Corrosion Management News Acom 3 2014Документ11 страницOutokumpu Corrosion Management News Acom 3 2014Joshua WalkerОценок пока нет

- Project Report: Metal FormingДокумент14 страницProject Report: Metal FormingohcomeonОценок пока нет

- Asme Sa 161 Grade T 1 TubesДокумент1 страницаAsme Sa 161 Grade T 1 TubesFerroPipEОценок пока нет

- Naval Architecture II Theory Detailed NotesДокумент96 страницNaval Architecture II Theory Detailed NotesAnkit Maurya100% (1)

- SYBTech Syllabus MechanicalДокумент42 страницыSYBTech Syllabus MechanicalswapnillkОценок пока нет

- Steel Heat Treatment Handbook Chapter 12Документ46 страницSteel Heat Treatment Handbook Chapter 12Syed Shoaib Raza100% (1)

- ASTM A182A-182M-05aДокумент17 страницASTM A182A-182M-05aNadhira100% (1)

- Nature 14144Документ6 страницNature 14144BoB bobОценок пока нет

- BH Curve PropertiesДокумент3 страницыBH Curve PropertiesSaravanan NallaОценок пока нет

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10225Документ2 страницыEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10225farshid KarpasandОценок пока нет

- Steel Grade: Material Data SheetДокумент6 страницSteel Grade: Material Data SheetFlorinFlorinОценок пока нет

- Asme Sa 213 Grade t92 TubesДокумент1 страницаAsme Sa 213 Grade t92 TubesFerroPipEОценок пока нет

- European Steel and Alloy Grades: About Us EN 10207Документ2 страницыEuropean Steel and Alloy Grades: About Us EN 10207farshid KarpasandОценок пока нет

- TechnicalspecificationsofheatexchangeralongwithSOI 20200314062818.362 XДокумент78 страницTechnicalspecificationsofheatexchangeralongwithSOI 20200314062818.362 XAvinash ShuklaОценок пока нет

- Engineering Metallurgy CourseДокумент2 страницыEngineering Metallurgy CoursevinaysammОценок пока нет

- Thermal CuttingДокумент18 страницThermal CuttingSarah100% (1)