Академический Документы

Профессиональный Документы

Культура Документы

FDA Fines American Red Cross

Загружено:

LansingStateJournal0 оценок0% нашли этот документ полезным (0 голосов)

220 просмотров32 страницыThis letter describes the results of FDA inspections into American Red Cross blood centers and the resulting fines of more than $9.6 million for violations. For the full story on blood safety and the business of blood, visit www.lsj.com.

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis letter describes the results of FDA inspections into American Red Cross blood centers and the resulting fines of more than $9.6 million for violations. For the full story on blood safety and the business of blood, visit www.lsj.com.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

220 просмотров32 страницыFDA Fines American Red Cross

Загружено:

LansingStateJournalThis letter describes the results of FDA inspections into American Red Cross blood centers and the resulting fines of more than $9.6 million for violations. For the full story on blood safety and the business of blood, visit www.lsj.com.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 32

( " ~ DEPARTMENT OF HEALTH AND HUMAN SERVICES

Food and Drug Administration

' ~ ~ ' -

Baltimore District Office

Central Region

6000 Metro Drive, Suite 101

Baltimore, MD 21215

Telephone: (410) 779-5455

FAX: (410) 779-5707

January 13, 2012

ADVERSE DETERMINATION LETTER

BY FACSIMILE AND CERTIFIED MAIL

RETURN RECEIPT REQUESTED

Mr. J. Chris Hrouda

Executive Vice President

Biomedical Services

American National Red Cross

2025 E Street, N. W.

Washington, D.C. 20006

RE: United States v. American National Red Cross, Civil Action No. 93-0949 (JGP)

Dear Mr. Hrouda:

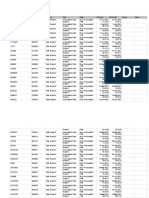

From April through October 2010, United States Food and Drug Administration (FDA) investigators

inspected sixteen American National Red Cross (ARC) Blood Services facilities and observed

significant violations ofthe law, regulations, and the Amended Consent Decree ofPermanent Injunction,

entered on April15, 2003 (Decree). At the conclusion of each inspection, the investigators issued

Forms FDA 483, Inspectional Observations (FDA 483), attached hereto (Attachment A). FDA is now,

pursuant to paragraph VIII ofthe Decree, notifying ARC of its determination that ARC has violated the

Federal Food, Drug, and Cosmetic Act, FDA regulations, and the Decree, specifically 21 U.S.C.

351(a)(2)(B), paragraphs IV.A., IV.B.l, IV.B.IO, and XIX ofthe Decree and Title 21, CFR 210-211

and 600-680.

The 2010 inspections cited herein were conducted at the following ARC facilities on the following

dates:

Badger Hawkeye Region, 4860 Sheboygan Avenue, Madison, WI, 4/5-23/10

Great Lakes Region, 1800 East Grand River Avenue, Lansing, MI, 4/5-27110

Penn Jersey Region, 700 Spring Garden Street, Philadelphia, P A, 5/24/10 - 6/4110

Connecticut Region, 209 Farmington Avenue, Farmington, CT, 5/4110- 6115/10

Detroit National Testing Laboratory, 100 Eliot Street, Detroit, MI, 5/25/10-6/16/10

Indiana-Ohio Region, 1212 East California Road, Ft. Wayne, IN, 7/12-21/10

Southwest Region, 10151 East 11th Street, Tulsa, OK, 7/26/10- 8/9110

Appalachian Region, 352 Church Avenue, SW, Roanoke, VA, 8/3-13/10

Heart ofAmerica Region, 405 West John H. Gwynn Jr. Avenue, Peoria, IL, 6/21/10- 8/18/10

Page 2- Mr. J. Chris Hrouda

Northern California Region, Fixed Collections/Distribution Site, 2731 North First Street, San Jose, CA,

917-13110

Arizona Region, Broadway Fixed Collection Site, 7139 East Broadway Blvd., Tucson, AZ, 9/7-15110

Northern Ohio Region, 3747 Euclid Avenue, Cleveland, OH, 8/27/10- 9/23/10

Southern California Region, 100 Red Cross Circle, Pomona, CA, 8/9/10 - 9/24/10

Greater Alleghenies Region, 250 Jari Drive, Johnstown, PA, 9/7-24/10

Southeastern Michigan Region, 100 Mack Avenue, Detroit, MI, 8/24110-9/27/10

Donor and Client Support Center, 700 Spring Garden Street, Philadelphia, PA, 9/2/10- 10/29110

The Decree requires ARC to establish and properly implement appropriate quality assurance (QA) and

quality control (QC) measures. Proper QA and QC programs by blood establishments include measures

to prevent, detect, investigate, evaluate, and correct errors. The goals ofthese programs include

preventing the distribution of unsuitable blood products, and preventing the causes of recurrent

problems. The proper implementation of a strong QA program is essential to ensure the safety ofthe

nation's blood supply.

Decree paragraph IV requires ARC to "establish, implement, and continuously maintain adequate

methods, facilities, systems, and controls to ensure that ARC does not collect, manufacture, process,

pack, hold, or distribute any article ofdrug as defined in 21 U.S.C. 321(g), including any article of

blood, blood component, or other biological product as defined in 42 U.S.C. 262, that is adulterated,

within the meaning of21 U.S.C. 351(a)(2)(B); misbranded, within the meaning of21 U.S.C. 352(a)

or 42 U.S.C. 262(b); or otherwise in violation ofthe FD&C Act, the PHSAct, and regulations

promulgated thereunder, including, but not limited to, 21 C.F.R. Parts 210-211 and Parts 600-680."

ARC is also required to "take steps necessary to ensure continuous compliance with this Order, the law,

and ARC SOPs ..." and "establish, document, and continuously maintain managerial control over

training and quality assurance in all regions and laboratories." Decree paragraph IV.A.1. & 2. ARC is

also required to appoint a director of quality assurance who shall "prepare and submit quarterly quality

assurance reports in writing to ARC senior management and ARC Biomedical Services senior

management . ..that completely and accurately: (i) describe the steps that have been and will be taken,

with specific dates for implementation of each step, to establish, implement, and continuously maintain

the QAIQC program; and (ii) describe all unresolved potential system (systemic) problems, system

(systemic) problems, and trends and their corrective action status; and (iii) assess whether ARC is in

compliance with the law, ARCSOPs, and this Order." Decree paragraph IV.A.2.

1

Violations observed and/or documented during the 2010 inspections include the items listed below.

This is not intended to be an all-inclusive list ofviolations in ARC facilities.

DECREE VIOLATIONS:

Decree Violations: Inadequate Managerial Control

1. Failure to establish, implement and continuously maintain managerial control over QA in all

regions and laboratories as required by paragraph IV.A.2. The development of written procedures and

processes that are appropriately managed and implemented are essential components of an effective QA

1

Decree paragraph III.B.57 defines the QNQC program as the "written SOPs for quality assurance and quality control that ARC must establish, implement,

and continuously maintain under paragraph IV of this Order to ensure that bloodand blood components are collected, manufactured, processed, packed,

held, and distributed by ARC in accordance with the law, ARC SOPs, and this Order, and have thepurity that they purport or are represented to possess."

(The italics in the quotations from the Decree are in the original and indicate that the italicized word is defined in paragraph Ill ofthe Decree.)

Page 3 - Mr. J. Chris Hrouda

program. ARC management, however, merged certain QA functions into centralized facilities without

ensuring that the new facilities were adequately staffed to perform these functions in a timely or

effective manner.

Beginning May 2008, ARC began to consolidate certain donor management activities,

2

which were

previously performed in 35 ofits 36 regional offices, into the Donor Client Support Center (DCSC).

The DCSC is located in two facilities, one in Charlotte, North Carolina, and one in Philadelphia,

Pennsylvania. The consolidation began in May 2008 and was completed in March 2010. During the

consolidation, multiple internal audits and Problem Management (PM)/QA assessments were performed

at the two DCSC facilities.

3

The results ofthe internal audits and assessments and the subsequent

internal investigations indicated that the DCSC was chronically understaffed and lacked the process

controls to ensure timely and adequate performance ofthe donor management functions. In response to

the internal audits, the DCSC repeatedly promised corrective actions, some ofwhich had not been

completed or were ineffective at the time ofthe FDA inspection in September and October 2010.

During the consolidation phase, ARC had periodic senior management meetings, Quality and

Compliance Oversight Committee (QCOC) meetings, and Board of Governors meetings in which the

DCSC consolidation project was discussed.

4

Quarterly and annual QA and training reports were also

submitted to ARC's senior management.

5

The meeting minutes indicate that ARC management was

aware ofthe audit findings and the staffing and training deficiencies and that the QCOC was monitoring

the situation to determine whether the consolidation should continue as scheduled. Despite the

repeated, significant internal audit findings, the consolidation was permitted to continue with only one

delay. After the consolidation was completed in March 2010, the meeting minutes indicate that ARC

management continued to have concerns about the DCSC performance. The DCSC continued to be

understaffed and had a backlog of what ARC reported as being approximately 18,000 donor

management cases

6

that had not been process-verified as required in Work Instruction 11.3.028, Process

Verification, Version 1.1, and Forml5.4.frm015, Donor Reaction and Injury Record, Version 1.2.

Additional internal records that detail the DCSC's management control deficiencies include the

following:

2

Activities being performed at the DCSC include donor care and qualification functions, such as answering eligibility questi ons

from the donors; donor deferrals; post donation and call back activities, donor complications and complaints; receipt oftest results and entry of the results

into the NBCS software; management of follow up testing with the donor; donor reentry/reinstatement; deferral and surveillance management; managing

donor requests for test results and blood types; donor notification of reactive test results and donor counseling; and military, state, and health department

notifications. DCSC also performs client support services that include the management of blood product retrievals; consignee notification for the release of

unsuitable blood components; case investigations for possible transfusion transmitted infections, adverse reactions and bacterial contaminations; lookbacks;

and serving as the liaison for regional/divisional medical directors. DCSC' s data management functions include the management of the National Donor

Deferral Registry and the Donor File Check process. Problem management tasks for the Philadelphia DCSC are performed in Philadelphia as well as in the

Charlotte DCSC and includes the detection, investigation, evaluation, correction, and monitoring of all problems, trends, and system problems.

3

Facility Audits: 10/14-17/08 (Philadelphia), 10/14-16/08 (Charlotte), 3124-27/09 (Charlotte), 612-5/09 {Philadelphia), 12115/09-1/6/10 (Philadelphia), 10/6

22/09 (Charlotte), 4/20-22110 (Charlotte), 5/18-21110 (Charlotte); Problem Management Assessment 4/9/1 0; Quality Assurance Assessment 4/10.

4

Management Review Minutes for Collections and Donor Management: 2110/09, 5/15/09, 8nt09, 1218/09, 3/19/10, and 6/8/10; QCOC Meetings: 6127/08,

5/19/09, 8/27/09, 9124/09, 10/9/09, 10122/09, 11/13/09, 12111/09, 2/25/10, 3124/10, 4/9/ 10, 4122110, 6/11110, 6/24/10 and 8/13/10; Board ofGovernors'

Meetings: 4/23/08, 6/6/08, 3/26/09, 5127/09, 6/18/09, 7122109, 8127/09, 9/23/09, 10/5/10, 12/14/09, 1127/10, 2124/10, 3124/ 10, 4120/10, 6/9/10 and 8/25/10

5

Quarterly QA Reports: ApriVJune 2008, 2008 Annual QA Report October 2007/September 2008, October/December 2008, January/March 2009,

April/June 2009, 2009 Annual QA Report October 2008/September 2009, October/December 2009 and January/March 20I 0; Quarterly Training Reports:

April/June 2008, July/September 2008, October/December 2008, January/March 2009, April/June 2009, July/September 2009, October/December 2009 and

January/March 2010.

6

At the time ofFDA' s inspection ofthe DCSC, FDA determined that the backlog ofdonor management cases requiring process review was approximately

15,000 ( II ,531 in the Charlotte facility and 3,552 in the Philadelphia faci lity) and approximately 5,200 unreviewed DRIRs ( 4,949 in the Charlotte facility

and 306 in the Philadelphia facility).

Page 4- Mr. J. Chris Hrouda

a. Two DCSC staffing documents (July and September 2009) state that "the organization is

currently operating under the fa<;ade that the DCSC is self supportive in its QA and PM

functions... Regions routinely provide support in problem closure and quality process review, both of

which are major functions ...over 50% of all problems are closed by non-DCSC QA staff located in the

regions....any time something occurs in the field that strains the regional resources, assistance has to be

withdrawn...this can immediately cause the DCSC to become unsustainable and fall into a

backlog... another large concern is that every five weeks additional regions continue to transfer to the

DCSC. Therefore, the situation is escalating to a point where the field will not be able to support the

volume." Despite these staft1ng concerns, ARC management allowed the consolidation to continue.

b. In April 2010, the Biomedical Headquarters (BHQ)/QCOC meeting minutes indicate that the

DCSC had a backlog of approximately 18,000 donor management cases that had not been process

verified as required by ARC's Work Instruction 11.3.028, Process Verification, Version 1.1.

c. ARC's report from the April2010 DCSC problem management audit states that the root cause

ofthe repeat observation pertaining to timely problem management is, "The DCSC Problem

Management Department does not have the resources to consistently manage problems in a timely

manner."

d. The May 2010 Donor Client Service Specialist (DCSS) staffing report indicates that "without

additional staff dedicated to answering eligibility calls, the DCSS position would be understaffed. This

understaffing could create a situation of a continually growing backlog, overtime pay required, and a

decreased ability to handle natural spikes in incoming work."

e. In July 2010, ARC senior management placed the DCSC on a Compliance Improvement

Strategy (CIS) because it was determined to be a "high compliance risk" based on internal audits and

FDA 483s received since March 2009. The CIS was not fmalized until 9/29/ 10, after FDA began the

Philadelphia DCSC inspection. The final CIS states, ' 'Numbers and proficiency of staff are not

adequate to effectively execute assigned tasks and responsibilities in a compliant manner; inadequate

supervision and oversight." The CIS further states, "The Back-log Plan will provide the details ofhow

any back-log will be managed and monitored, including defined commitments for reducing the back-log

while appropriately managing new cases."

In its 12/ 15110 response to the FDA 483, ARC stated, "BHQ did not effectively manage consolidation of

the donor management functions into the DCSC. BHQ managed the donor management consolidation

using existing mechanisms, including the system Quality and Compliance Oversight Committee

(QCOC) and the Field Operations Group (FOG), to provide oversight. However, in retrospect, these

mechanisms proved to be inadequate ...." The response also states that ARC "now recognizes that the

DCSC management reports were insufficient in determining a complete and accurate picture ofDCSC

performance."

Decree Violations: Inadequate QA

2. Failure to comply with paragraph IV .A.2.a., which requires that the "director ofquality

assurance shall be responsible for all ARC Biomedical Services quality assurance functions including,

but not limited to, ensuring the establishment, implementation, and continuous maintenance of

comprehensive QA/QC programs .. .. " Specifically, the BHQ and DCSC QA programs were not

Page 5 - Mr. J. Chris Hrouda

adequate to ensure that all regulated donor management operations were being performed effectively at

the Philadelphia DCSC. Proper management oversight is essential to effectively implement a QA

program; without it, the causes oferrors may not be promptly corrected and unsuitable blood products

may be released. For example,

a. At the beginning ofthe September - October 2010 inspection, the DCSC had a backlog of

open cases that had not received the required review. Donor Status Change Records, Component Status

Change Records, and Component Information Forms are required to have process verification prior to

closure ofa case per ARC's Work Instruction 11.3.028, Process Verification, Version 1.1. A backlog of

3,552 cases, dating as far back as July 2009, existed at the Philadelphia DCSC facility. Additionally,

Donor Reaction/Injury Records (DRIRs) require a Medical Director (MD) review and a final quality

review. A backlog of 306 open DRIRs, dating as far back as August 2009, existed at the Philadelphia

DCSC facility. The backlogs were even larger at the Charlotte DCSC facility -- 11,531 DRIR.s requiring

process verification and 4,949 DRIRs requiring MD review and/or final quality review.

b. Quality Process Reviews have not been consistently performed by the DCSC QA staff

since the Philadelphia DCSC was created in 2008. Quality Process Reviews are required in Directive

02.2.012, Quality Process Reviews, Version 2.1 , and are to be conducted by the QA staff on an ongoing

basis to review the systems and processes being performed by the DCSC operations staff. In addition,

these reviews are to "identify process improvement opportunities, possible procedure or compliance

violations, and confirmation ofprocesses operating in a state ofcontrol." During the inspection ofthe

DCSC, FDA repeatedly requested documentation that Quality Process Reviews had been completed at

the DCSC, but no documentation was provided. ARC stated that only some ofthe reviews were

completed through December 2009 and that others were not completed due to loss of QA staff.

c. The Quarterly QA reports, required by paragraph IV.A.2.b. to be submitted in writing by the

QA director to ARC senior management and ARC Biomedical Services senior management, did not

portray the seriousness of the staffing and proficiency problems occurring in the DCSC and identified by

ARC internal audits and other internal assessments. For example, eight Quarterly QA reports were

submitted to ARC senior management and ARC Biomedical Services senior management beginning in

April 2008 through March 2010. However, it was not until the October-December 2009 report that the

"capacity for problem management" and the backlog ofopen problems were mentioned in the quarterly

QA report. In its 12/ 15/10 response to the FDA 483, ARC acknowledged that the "seriousness ofthe

DCSC issues were not clearly documented in the Red Cross Quarterly Quality Assurance reports until

the January - March 2010 report."

d. A QA Assessment ofthe DCSC was performed in October 2009 and a PM Assessment ofthe

DCSC was performed in November 2009. The reports identified staffing and workload issues due to the

continuous consolidation of more regions into the DCSC. One report identified that the QA staff in

Philadelphia had no donor management experience; some QA staff members already employed at the

DCSC for six months were not fully trained; and staff was "struggling" with a lack of support from QA

management. The reports also indicate that there had been inadequate planning and inadequate change

control associated with the consolidation of donor management functions from the regions into the DCSC.

Despite these conditions, ARC continued with the consolidation until it was completed in March 2010.

The QA and PM assessment reports were then issued to ARC senior management in April2010.

e. In multiple Board of Governors Committee meeting notes, ARC' s QA (through the

QCOC) stated that it was closely monitoring all corrective actions related to internal DCSC audit

Page 6 - Mr. J. Chris Hrouda

observations and ensuring that staffing levels were adequate to continue merging the regions' donor

management functions into the DCSC. FDA reviewed numerous problems opened as a result ofthe

internal audit findings and observed that corrective actions were not developed and/or implemented

promptly. However, the merging ofregions into the DCSC continued. For example, FDA' s review of

ARC' s internal audits ofthe DCSC problem management function found the following deviations from

the Decree and the Problem Management Standard Operating Procedure (PM SOP)

7

:

i. ARC's October 2008 audit ofthe Philadelphia and Charlotte DCSC facilities cited

untimely problem management. In response, the DCSC opened Exception E-0455175 (Issue I

00 17862-FC) (discovered 10/22/08 and closed on 3/31110) and determined root causes that

included inadequate staffing levels, inexperienced staff, inadequate training, and a lack of

tracking mechanisms to ensure timely problem management. The corrective action plan

included hiring and training additional staff, developing tracking queries for the DCSC, and

establishing a group to manage post donation information problems. QA approved the corrective

action plan on 2/3/ 10 and implementation is documented as having been completed on 2/4/10

and 3/23/10. Issue I-0017862-FC states that the effectiveness check would be performed under

Exception E-0680169 (Issue I-0017441-FC). ARC took approximately 17 months (from

10/22/08 to 3/23/ 1 0) to approve and implement a corrective action to address untimely problem

management at the DCSC.

ii. ARC' s June 2009 audit ofthe Philadelphia DCSC facility cited untimely

management ofproblems. The audit report indicated that staff had been hired and that all

moderate and major risk problems were being managed in Charlotte because Philadelphia was

not fully staffed. It further stated that the DCSC continued to have a backlog ofproblems. In

response, the DCSC opened Exception E-0595168 (Issue I-0015324-FC) (discovered 6/5/09) and

determined that root causes included inadequate monitoring processes, lack ofstaffing

proficiency, and a heavy workload. QA approved the corrective action plan on 8/24/09 after two

corrective action plan extensions. The corrective action plan was not fully implemented until

2/24/ 10. The final effectiveness check had not been completed as of 10/11/10, approximately 16

months after discovery ofthe problem, and the problem remained open.

111. ARC' s January 2010 audit ofthe Philadelphia DCSC facility cited untimely

management ofproblems. The DCSC response referred to previously developed corrective

action plans documented in Issue I-0017862-FC (the corrective action plan for the October 2008

audit) and Issue I-0017441-FC (the corrective action plan for the October 2009 audit). The root

cause described in the DCSC response was a lack ofresources to consistently manage problems

in a timely manner. The corrective action plan included hiring staff, including a problem

management manager, and establishing a separate post donation information problem group.

iv. ARC's March 2009 audit ofthe Charlotte DCSC facility cited untimely

management ofproblems. The auditor reported a backlog of more than 200 minor, moderate,

and major risk problems. In response, the DCSC opened Exception E-0551794 (Issue I

0013588-FC) (discovered 3/27/09, closed 5/4/ 10) and determined that the root causes included

inadequate staffmg, noting that only two staff members had experience with moderate and major

The two DCSC facilities have overlapping problem management responsibilities; therefore, BHQ audit observations and corrective actions affected both

locat ions. For example, one audit report states that all moderate and major problems were being managed in Charlotte because Philadelphia was not fully

staffed. QA management also stated that al l post donation information problems are managed by staff in Philadelphia.

7

Page 7- Mr. J. Chris Hrouda

risk problems and a lack ofoversight by the DCSC. The corrective action plan included training

more staff to handle moderate and major risk problems, assigning oversight responsibilities, and

tracking the age of problems. QA approved the corrective action plan on 4/29/09. Issue 1

0013588-FC documented the corrective action plan as implemented between 4/30/09 and

7/30/09. The sustained effectiveness check was not completed until 4/ 16/10, more than a year

after discovery ofthe problem. ARC deemed the corrective action plan effective at that time.

v. ARC's October 2009 audit of the Charlotte DCSC facility cited untimely

management of problems. The DCSC opened Exception E-0680 169 (Issue I -0017 441-FC)

(discovered 1 0/23/09, closed 6/111 0) and documented the root causes as lack ofan adequate

tracking mechanism, problems not always being assif:,7Jled as they were discovered, and the

outsourcing of problem management cases due to staffing levels. The proposed corrective action

plan included developing tracking mechanisms and hiring QA and problem management staff by

12/ 1/09. QA approved the corrective action plan on 11/30/09. One tracking mechanism was

implemented on 10/26/09 and a second was implemented on 1/29/10. Staff positions were

opened on 1/29/1 0. The effectiveness check was completed on 5/3/ 10 and the problem closed

6/1/10, eight months after the problem was discovered.

f. ARC's June 2009 audit of the Philadelphia DCSC facility cited observations pertaining to

the DCSC failure to review donor management records in a timely manner. For example,

i. ARC's internal audit report includes the observation that post donation

information and donor ca11 back cases were not being process-verified in "a reasonable time

period." In response, the DCSC opened Exception E-0595192 (Issue 1-0020482-FC) (di:;covered

615109, still open as of 10/8/1 0) and determined the DCSC did not consider process verification a

priority because there is no deadline, there were competing priorities, and there was a lack of

staff proficiency. The DCSC audit response states that they were already aware of the process

verification backlog and had developed a plan to address it. The corrective action plan included

slowing down the consolidation and changing the work flow. The proposed effectiveness check

states that QA would do periodic case reviews to ensure that process verification is timely and

that cases are completed. QA approved the corrective action plan on 7/20/10. Only one part of

the corrective action plan is documented as having been completed on 8/30/10. The Exception

Report states that the corrective action plan was ineflective, but at the time of the FDA

inspection, there was no documentation of any fo llow-up corrective action investigation to

address this problem.

ii. ARC's internal auclit report includes the observation that the DCSC failed to

ensure timely and accurate management ofDRIRs. The DCSC opened Exception E-0595184

(Issue I-0011152-NF and Issue I-0020136-FC) (discovered 6/5/09, closed 8/3/1 0). (The problem

was later linked to Exception E-0794874, Issue I-0010881-FC, which addresses the FDA 483

observation issued at the Badger Hawkeye Region on 4/2311 0.) The DCSC determined the root

cause included Lack ofstaff proficiency and lack of a well defmed process. The DCSC response

stated that it was aware of the problem and had held workshops and proposed to establish a

DRIR group by 8/1/09, and to conduct another workshop. Additionally, the corrective action

plan included time studies by a ' lean engineer, ' development of a backlog plan, clarifying DRIR

time frames, and the hiring of. staffmembers to handle donor eligibility calls. QA approved

the corrective action plan on 6/2/10. Issue I-0020136-FC indicates the corrective action plan was

Page 8 - Mr. J . Chris Hrouda

not fully implemented until 7/21110. There was no due date documented for one ofthe

effectiveness checks, which was not completed as of 912110, 15 months after the problem was

identified.

Decree Vwlations: Failure to Comply with Reporting Requirements

3. Paragraph XJX requires ARC to report in writing to FDA any partial or complete suspensions of

operations ofone or more regions and/or laboratories. On 5/10/10, ARC notified FDA ofa complete

suspension of operations at a mobile blood drive held in the Connecticut Region on 5/8/10 (Exception E

0802346). The report stated that the collections operations were suspended at 1 :30 p.m. due to extreme

temperature conditions, two donor reactions, and staff feeling ill. However, during an inspection ofthe

Connecticut Region in May-June 2010, FDA discovered that the 5/10110 report was inaccurate because

the operations had not been suspended and ARC collected 16 blood donations at that drive between 1:30

and 2:59p.m.

Decree Violations: Inadequate National Donor Deferral Register

8

4. Decree paragraph IV.B.lO requires ARC to maintain a National Donor Deferral Register

(NDDR) that contains an accurate and complete list of all ARC nationally deferred donors from each

region. The safety of the blood supply depends on effective screening ofdonors to identify risk factors

for diseases transmissible by blood and blood components, and the deferral of high-risk potential donors.

Because of the mobility of the population of potential donors, the effective implementation ofa national

register of deferred donors is necessary to help ensure that accurate and current deferral information is

available to ARC facilities nationwide. During an inspection ofthe Southern California Region in

August-September 2010, FDA's review of records pertaining to permanently deferred donors revealed

that ARC has not established an accurate and complete list ofall permanently deferred donors, as

required at 21 CFR 606.160( e). Information pertaining to permanently deferred donors from each ARC

region is sent- to the DCSC to be incorporated into the ARC's NDDR. The NDDR was created

because the ARC's National Blood Computer System, which services its 36 regional facilities, does not

share donor deferral information among regions. The- ufdates to the NDDR are shared with all

regions in a table format referred to as an NDDR "pushed table" so that any region can identify

pem1anently deferred donors during the donor registration process, regardless of which region deferred

the donor.

ARC NDDR is not adequate because, for example: ( 1) permanently deferred donors may not be

identified during donor registration at the regions because the NDDR "pushed tables" only contain the

donor's current infonnation and not the "before images"

10

for donors who previously donated under

different names; and (2) permanently deferred donors usjng hyphenated names may not be identified if

attempting to donate using just one part ofthe hyphenated last name. FDA's record review identified

nine permanently deferred donors listed on pushed tables that did not include their previously used last

names. The absence of such information prevents ARC from performing an adequate evaluation ofits

NDDR records in order to prevent the distribution of subsequently donated blood products from donors

whose blood should not be accepted for donation. For example,

8

21 CfR 606.1 60(c) requires lhlll a record be available from which oosuitable donors may be identitied so that products made from the blood ofsuch

individuals will not be distributed. ACR refers to this record as the Donor Deferral Register.

9

"Pushed tables" are the mecllanism used to share information on permanently deferred donors among regions. If that information is not shared, regions are

unaware when another region has pennanenlly deferred donors.

10

A "before image" is a historical record ofchallges made to the donor record in National Biomedical Computer System.

Page 9 - Mr. J. Chris Hr ouda

a. A donor with a merged record had a newer identity under the initials- and an original

identity under the initials. However, the NDDR contains the donor's current name only (initials

-

b. Donors with hyphenated names are assigned multiple soundex codes.

11

For example, the

soundex code for has a hyphenated name, is different for the first part, second part and

entire hyphenated three parts ofDonor. s name were given different soundex codes.

Therefore, the NDDR only contains the donor's current information.

Decree Violations: Inadequate Problem Management

5. Paragraph IV .B.l. requires ARC to establish and submit to FDA a PM SOP to detect, investigate,

evaluate, correct, and monitor all problems, trends, and systemic problems.

12

The Decree directs that the

PM SOP include specific instructions to implement and document problem management requirements at

ARC's BHQ as well as at the regional and laboratory facilities.

Decree Violations: Problem Management [Management of Suspect Blood Products]

Failure to promptly implement adequate corrective actions to prevent recurrence of the failure to control

suspect

13

blood or blood components. FDA has repeatedly cited ARC for this deviation, in letters issued

pursuant to paragraph VI.A. ofthe original Consent Decree of Permanent Injunction entered on May 12,

1993, and in ADLs issued pursuant to the Decree entered on April15, 2003. ARC has repeatedly

promised to implement and monitor corrective actions, but the corrective actions have not prevented

recurrence ofthe problem.

14

The failures described below are particularly serious because the failure to

control suspect products and to correct the causes oferrors increases the likelihood that unsuitable blood

products will be transfused. For example,

a. The DCSC identified trends related to the improper management of suspect blood

products and inventory management, but failed to promptly and thoroughJy correct the problems. For

example,

i. A trend was identified for Biological Product Deviation (BPD) code QC-96-01-25

(product in wrong physical location, wrong electronic location) in October 2009. The trend was

discovered on 11/30/09, and Exception E-0707671 (Issue 1-00 18721-FC) was created. The

problem was closed on 2/1 8/ 10. The docwnented root cause was "Current process flows and

functional roles do not meet System 11 requirements as they include hand-offs with steps that

should be performed consecutively and immediately." The Issue report states that no formal

A soundex code is a. igit code. The soundcx algorithm calculates .. ..........

12

Paragraph 01.8 .52 defines "problem" as "any deviation from the law, ARC SOPs, or this Order, however discovered, recorded, or reported, including, but

not limited to deviations rep011cd in ARC Clarify repons (andlor in any other successor or similar deviation-reporting systems andlor reports), biological

product deviation reports, internal deviation reporu, trends, adverse reaction reports, lookhack cases, cases ofsuspectedtran.sfusion fran.smifted disease,

potential system (systemic) problems, system (systemic) problems, SUpply and equipment problem reports, FDA-483s, compliancerclatcd FDA

correspondence, internal and extcmol audit reports, and retrievals." Paragraph lll.S.63 defines "system (systemic) problem" as "a problem that results from

a defect in ARC policies, procedures, or supplies and affects either more than oneARC region and/or laboratory, or warrants corrective action

which, when implemented, could affect more than oneARCregion andlor /aborOU>ry." Paragraph 111.8.64 defi nes ''trend" as "the recurrence or multiple

contemporaneous occurrences ofthe same or similarproblems in one or more than one ARC region and! or laboratory."

ll ARC defines "suspect" blood products as those which "may or may not meet safety, quality, identity, purity, and potency (SQUJPP) requirements and are

potentially non-confonning." Directive: Mismanagement ofSuspect Products, 11.2.002, version 1.6.

14

See Attacb01tnt B for details ofcompliance history related to failure to control suspect blood or blood

11

Page 10- Mr. J. Chris Hrouda

corrective action will be taken due to the corrective actions implemented under another problem

on 11/ 18/09 (Exception 0599613/lssue 1-0015339-FC) which QA approved on 2/ 16/ 10.

ii. A trend was identified for the same BPD code in February 2010. The trend was

discovered on 3/24/ 10, and Exception E-0774042 (Issue 1-0019647-FC) was created. As of

10/1110, the problem was still open. The documented root cause was, "Due to the original

design ofthe Donor and Client Support Center (DCSC) workflow, there is a waiting period from

the point when unsuitable components are identified to the time when they are managed or

retrieved." The Issue report indicates that QA approved the corrective action plan on 5/27/ 10,

and it was implemented the same day; however, the approved corrective action plan is only a

reference to corrective actions related to another problem. The interim effectiveness checks were

deemed effective on 7/27/ 1 0; however, as of 10/111 0, there was no record that the sustained

effectiveness check, which was due 8/26/10, was completed. Additionally, the records related to

the other referenced problem indicate that implementation ofthe corrective action plan was not

fully completed until10/5/10.

m. A trend was identified for BPD code QC-90-0 1-05 (failure to adequately manage

potentially non-conforming products, product not released) in May 2010. The trend was

discovered on 6/30/10, and Exception E-08311 04 (Issue I -00 11219-NF) was created. The

problem was closed on 8/2/ 10. The root cause was identified as, "The original process flows

associated with these gain control and retrieval processes did not provide staff with the

experience and responsibility to perform their required functions as a suspect product identifier."

The problem was closed without developing a corrective action plan, but instead referenced

corrective actions and effectiveness checks addressed under four other Issue reports (Issue 1

0020891-FC, Issue 1-0016426-FC, Issue 1-0019143-FC, and Issue 1-0019389-FC). A review of

Exception E-0625538 (discovered 7 /31109) and Exception E-0780785 (discovered 3/31/1 0),

which are both associated with Issue 1-0019389-FC, found that a corrective action plan extension

was approved for both problems on 4/30/ 10 and an additional corrective action plan extension

was reque&ted for Exception E-0625538 on 8/ 17/09. QA approved the corrective action plan

under Issue 1-0019389-FC on 5/ 19/10. One part ofthe corrective action plan was implemented

by 5/31110, but the other three parts were not implemented until 10/5/1 0. Both problems

remained open as of 10/ 14/10--one for more than 15 months and one for more than six months.

b. ARC discovered approximately 18 major risk problems coded as QC-90-01-05 (failure to

manage potentially non-conforming products, product not released) that occurred at the Philadelphia

DCSC facility during calendar year 2010. A review ofthose problem records found problem

management deficiencies. For example,

i. ARC did not conduct an adequate root cause analysis, develop an appropriate

corrective action plan, or conduct an effectiveness check for Exception E-0790730 (Issue 1

0020041-FC), which was discovered on 4/ 16110 and remained open as of 10/7/10. The problem

description states that a hold was not applied to an in-date product for a donor with an XW3

assertion.

15

The root cause is described as "Due to the peculiarity ofthis case, [a supervisor] was

puzzled which resuited in unclear guidance to a new staff." The corrective action plan stated that

the supervisor "recognizes how to appropriately handle these types of cases so that he can better

15

An XW3 assertion is ARC' s donor indefinite deferral code for donors with a history of hepatitis, bleeding conditions, blood diseases and/or who tested

positive for the HIV/AIDS virus by a non-ARC facility.

Page 11 - Mr. J. Chris Hrouda

communicate to staff the appropriate actions that are required." QA approved the corrective

action plan on 5/21/ 10 and Issue I-0020041-FC states the corrective action plan was

implemented on 5/21/10; however, a corrective action plan was not listed in the report. The

effectiveness check was due on 8/27/ 10, but as of 10/7/ 10 had not been completed.

ii. ARC failed to implement a corrective action plan in a timely manner for

Exception E-0751845 (Issue 1-0019143-FC), which was discovered 2/17/10 and remained open

as of 10/7/ 10. The problem description states that no immediate effort was made to regain

physical control ofthe blood products for a possible DRJR-related infection. The documented

root cause was that the staff is feeling overwhelmed and frustrated. The corrective action plan

was to develop a process to ensure a more structured management of DRJR cases and to develop

a phone schedule. QA approved the corrective action plan on 3/17/ 10, but it was not

implemented until9/27110.

111. ARC failed to implement a corrective action plan and complete an effectiveness

check in a timely manner for Exception E-0746476 (Issue I-0018941-FC), which was discovered

on 2/5/10 and remained open as of 10/8/10. The problem description states that no hold was

applied and the receiving region was not notified to gain physical control ofa component

imported from another ARC region. The documented root cause was the staff failed to identify

the importance of gaining physical and electronic control ofthe component, "due to her lack of

knowledge with the American Red Cross and DCSC." The corrective action plan was that staff

will be counseled and will continue to gain experience; and the training department will develop

a communication to all staff and will conduct a training refresher. QA approved the corrective

action plan on 3110/ 10. Implementation of all corrective actions was not completed until

7/27/10, more than five months after discovery. Effectiveness checks due dates were 9/7/ 10 and

919110, but were not completed as of 10/8/10, more than eight months after discovery of the

problem.

6. Failure to promptly, thoroughly, and adequately investigate and correct problems in accordance

with the Decree and with ARC' s PM SOP. For example,

Decree Violations: Problem Management [Donor Reaction/Injury Records (DRIRs)]

a. During the inspection ofthe DCSC, FDA observed that ARC identified trends

16

related to

DRIRs beginning in June 2009, but failed to promptly and thoroughly correct and prevent recurrence of

DRIR documentation problems. For example:

i. On 9/30/09, ARC identified a trend, which occurred in June 2009, related to BPD

code BC-40-01-02 (adverse reaction donor: incorrect/missing documentation on Donor

Reaction/Injury Reports). Exception E-0664347 was created on 9/30/09. The root cause

investigation and corrective action plan development (Issue I-0018632-FC) did not begin until

2/5/10, four months after discovery ofthe trend problem. An extension ofthe 30-day corrective

action plan development time frame was granted by QA on 2/6/10. The documented justification

for the extension was that the original corrective action plan was due on 10/30/09, but the

problem was not assigned to a Problem Investigator untill/12/10. The root cause is documented

16

"Trend" is defmed in note II above. The DCSC began trending in accordance with the Decree and with WI 1 0.3. 13, Trend Identification by Facilities, in

September 2009.

Page 12 - Mr. J. Chris Hrouda

as "staffare hurried and rushing to complete the form and overlook errors and omissions. The

DRJR is filled out electronically and it is easy to overlook omissions on the form." The Issue

further states that "no additional corrective actions are necessary at this time" and refers to

corrective actions implemented on 11/24/09 and 1/31/10 under BHQ system trend Exception E

0603 257. The DCSC Q A staff approved the proposed corrective action plan on 2/1811 0 and

closed the trend on 2/24110, five months after the trend was discovered.

ii. ARC BHQ system trend (referenced in 6.a.i above) was discovered on 6/23/09.

Exception report E-0603257 (Issue I-0000334-EFC) was created on 6/23/09 and was closed on

6/29/10. The described problem is incomplete or incorrect documentation ofDRIRs. The root

causes cited in Issue I-0000334-EFC include: "donor adverse reactions are rare stressful events

and staff busy attending to the donor fail to document all required information... ;" "staff

inattention to detail and lack offocus .. . ; misinterpretation of the Work Instructions; failure to

refer to the form instructions; gaps in DRJR instructions; and the format ofthe DRIR form." The

corrective action plan was approved by QA on 12/2/09, approximately five months after

discovery of the trend. The corrective action plan included the release of a communication in

November 2009 to remind staff ofrequirements and clarify instructions. The effectiveness check

success criterion was - mprovement. On 6/15110, ARC used data from 2/1110 through

4/30/10 to perform the effectiveness check. They deemed the corrective action effective with

only a 41% improvement. However, 41% is not sufficient and. is clearly inadequate as a

goal.

111. On 5/25/10, a trend was discovered again at the DCSC for BPD code BC-40-0 1

02 (adverse reaction donor: incorrect/missing documentation on Donor Reaction/Injury Record).

The trend occurred in April2010. Exception E-0811555 (Issue I-0020944-FC) was created and

was still open as of I 0/1/10. The root causes cited include staffnot reviewing their work and

"shortage ofdedicated DRIR staff." An extension for the corrective action plan development

was requested on 6/17110 and was granted by the DCSC QA the same day. A second extension

was requested on 7113110 and was granted on 7/14/10. The corrective action plan, which was

approved by QA on 9/8110, included a reminder to affected staff of the DRJR requirements,

hiring additional DRIR staff, and providing refresher training to other staff members that

perform DRJR tasks. The staff reminder is documented as completed on 9/27/ 10, four months

after discovery ofthe trend.

Decree Violations: Problem Management [DRIRs Failing to Reach the DCSC from the Regions]

b. On 7/911 0, ARC discovered a problem related to missing DRIRs that were sent by the

regions to the DCSC. Exception E-0836426 was created on 7/12/10. As of 10/8/10, ARC had not

completed an investigation into the root cause of missing DR1Rs and had granted two extensions for the

development ofa corrective action plan untilll/12/1 0, four months after initially discovering the

problem. A record review was completed in July 2010 for the period 12/ 1109 through 6/30/10. and

identified 292 donor adverse reaction or injury cases with missing DRIR.s. The safety of donors depends

on the prompt investigation into the causes of donor injuries and reactions, to correct causes ofsuch

injuries where possible, and to implement training for appropriate staffintervention. The

mismanagement of records interferes with that process.

Page 13- Mr. J. Chris Hrouda

Decree Violations: Problem Management [Confirmatory Test Results and the Donor Deferral

Register]

c. During the inspection of the DCSC, FDA observed that ARC identified trends related to

management ofconfirmatory infectious disease test results and Donor Deferral Registry (DDR) entry,

but failed to promptly and thoroughly investigate, correct, and prevent the problems. For example,

i. On 10/29/09, ARC identified a trend for BPD code DD-30-01-10 (confirmatory

results/DDR entry not performed/not timely) that began in September 2009. Exception E

0683307 (Issue I-00 17599-FC) was created and was closed on 2/23110. The root causes were

cited as inattention to detail due to staff being new, not understanding, or rushing. The proposed

corrective action plan refers to corrective action taken under another problem (Issue I-00 16921

FC). QA approved the corrective action plan on 12118/09 and the Issue report shows the

corrective action plan was implemented on 12/18/09. It is described as "Reiterate the need for

staff to slow down and pay closer attention to information being entered and to make sure that

they go back and review entries prior to moving to the next step." The corrective action plan

also required supervisors to observe the involved staff while performing test result entry. The

effectiveness check was performed and the corrective action was deemed effective by ARC on

2/19/10. However, the records for Issue I-0016921-FC, which was referenced as the corrective

action plan for the trend problem, indicate that it was not fully implemented until4/27110 and the

effectiveness check was not completed until 6/23/ 10.

ii. On 10/29/09, ARC identified a trend for BPD code DD-30-01-12 (incorrect/no

computer property/assertion applied, no product released) for September 2009. Exception E

0683302 (Issue I-00 17306-FC) was created 10/29/09. The root causes included misinterpretation

ofinstructions, staff new to task, staff not aware they could remove assertions, and limited

experience with holds. The investigation did not address why staff had been released to perform

tasks they did not understand, yet QA approved the corrective action plan on 11118/09. The

Issue report shows that the corrective action plan included the development ofa communication

document for staff as well as the development and implementation of a new operational team.

The problem was closed on 5/ 11110. However, because ofthe inadequacy ofthe corrective

action plan, the DCSC subsequently had a trend recurrence for BPD code DD-30-01-12 in

August 201 0.

Decree Violations: Problem Management [Consignee Notification

17

]

d. During the inspection ofthe DCSC, FDA observed that ARC identified trends related to

consignee notification, but failed to promptly and thoroughly correct and prevent the problems. Prompt

notification to consignees regarding the distribution ofunsuitable blood products is essential to

preventing such products from being transfused. For example,

i. On 9/30/09, ARC identified a trend for BPD code MI-00-01-19 (48 hour

notification to consignee not performed/complete/timely for distributed expired products) in June

17

Paragraph X.E ofthe Decree requires ARC to notify consignees and FDA's Baltimore District Office within 48 hours after initially learning that a unit of

unsuitable blood or blood component has been distributed. Paragraph X.F. ofthe Decree requires ARC, within 10 days of initially discovering a problem

that may have resulted in the release for distribution of units of unsuitable blood or blood components, to review and document the review ofall records

necessary to determine whether distribution of units of unsuitable blood or blood components in fact occurred and to identify all related units of unsuitable

blood or blood components that were, may have been, or may be distributed.

Page 14 - Mr. J. Chris Hrouda

2009. Exception E-0664458 (Issue I-0020096-FC) was created on 9/30/09 for missed 48 hour

consignee notification and missed follow up timelines. Corrective action plan development

extensions were approved by QA on 10/20/09, 12/1/09, and 4/28/10. The justification for the

4/28/10 extension was "staff issues and lack of good tracking mechanisms ...." No investigation

of the trend problem was documented until 5/ 18/10. QA approved the corrective action plan on

7/611 0, ten months after discovery of the trend. The root causes are cited as "poor work

practices/work flow including poor follow-up, insufficient reviews, and oversight." The

described corrective action plan included restructuring the DCSC into functional teams and

revising work flows to standardize gain control activities. Approximately one year after

discovery ofthe trend, the corrective action plan has not been fully implemented. Functional

teams were not implemented at the Philadelphia DCSC as late as June 2010 and at the Charlotte

DCSC as late as September 2010, as described in the Issue report. The status ofthe work flow

revisions is not documented. The trend problem remained open as of 10/ 1/ 10, twelve months

after identifying the trend.

ii. On 9/24/ 10, ARC identified a trend for MI-00-01-23 (recall/market withdrawal

records incorrect/incomplete/not timely, including late follow up letters to consignees) in August

2010. Exception E-0878847 was created on 9/27/10. The problem description refers to the June

2009 MI-00-01-19 trend being managed under Exception E-0664458, as described in the item

above. The trend problem remained open as of 10/1/ 10, twelve months after identifying the

trend, with no documentation ofan investigation or corrective action.

Decree Violations: Problem Management [Lookback Investigations]

e. During the inspection ofthe DCSC, FDA observed that ARC had discovered problems

related to the management oflookback cases dating back to 3/ 15/10, but failed to promptly correct those

problems. When a person donates blood early in an infection, screening and testing may not detect the

presence of an infectious agent (the "window period"). After the infection is discovered, it is important

to identify and "lookback" at prior donations that might have been collected during the "window period"

in order to identify, notify and test any recipient of a transfusion ofblood or blood components collected

during the "window period." Such process is necessary for the protection of blood product recipients.

For example,

i. Issue I-0019746-FC was created 4/26/10 to implement a formal corrective action

for 17 different problems involving management of lookback investigations. The oldest ofthose

problems was discovered on 3/15/10, yet a corrective action plan was not approved by QA until

6/25/10, more than three months after the initial date ofdiscovery. The root causes of these

problems are identified as "supervisors are not consistently reviewing with their staff the open

cases report generated from the Access Lookback Log" and "Operations Staff ofthe involved

Supervisors may not have been trained to generate and use reports in the Lookback log

database." The effectiveness checks were not due until 12/ 10/10, nine months after the oldest

problem was discovered.

ii. A trend related to the management oflook back investigations was discovered on

6/30/10. Exception E-0831094 (Issue I-0011220-NF) was created on 6/30/10 and was closed on

8/2/10. No formal corrective action plan was required by ARC and the Issue report references

the formal corrective action implemented in Issue I-0019746-FC discussed in the item above.

However, Issue I -00197 46-FC remained open at the time ofthe September-October 2010

Page 15 - Mr. J. Chris Hrouda

inspection because the effectiveness checks were not due until 12/10/10, nine months after the

oldest problem involving the management oflookback investigations was discovered.

111. On 8/31/10, ARC discovered another trend related to the management of

lookback investigations. Exception E-0864242 (Issue I-0011479-NF) was created on 8/31/ 10.

The Issue report also referenced the formal corrective action implemented in Issue I-0019746

FC, discussed in the item above, which remained open at the time ofthe September-October

2010 inspection, because the effectiveness checks were not due unti112/ 10/ 10, nine months after

the oldest problem involving the management oflookback investigations was discovered.

Decree Violations: Problem Management [Failure to Meet Established Timeframes]

f. During the DCSC inspection, FDA investigators requested a search ofARC's automated

problem management system for the period 111110 through 9/22/ 10. A review ofthe results revealed

that the DCSC does not always meet the established time frames required in ARC' s PM SOP and in the

Decree. For example, FDA observed that the query showed 90 problems in which the DCSC failed to

comply with the paragraph X.E requirement to notify consignees within 48 hours "after initially learning

that a unit of unsuitable blood or blood component has been distributed."

g. During an inspection ofthe Indiana-Ohio Region in July 2010, FDA discovered that ARC

failed to promptly correct a problem related to the late entry of a donor into the NDDR. For example, a

donor was confirmed positive for anti-HTL V on 116/ 10, but the result was not promptly entered into

ARC' s National Biomedical Computer System until4/4/10 and was not promptly submitted for entry

into the NDDR by the DCSC until4/5/ 10. Exception E-0781884 was opened on 4/6/10. It was merged

with 27 other problems (in Issue I-0019116-FC, created 3/ 11/ 10) involving similar occurrences in other

regions. The investigation determined the root causes were a lack of defined processes and

misinterpretation oftimeframes for reconciliation oftest results. QA approved the corrective action plan

on 5/11110, yet there was no documentation that the corrective action plan was implemented as of

7/16/ 10, four months after Issue I-0019116-FC was created. The corrective action plans that were

approved by QA did not adequately address the identified root causes and the effectiveness checks were

not adequate to assess effectiveness ofthe corrective action plan.

Decree Violations: Problem Management {Overweight Units]

h. During an inspection ofthe Heart ofAmerica Region in June-August 2010, FDA's

review of monthly trend records for BPD code BC-43-03 ( overbleed; not discovered prior to component

preparation) in December 2009 revealed that ARC did not follow Work Instruction 10.3.013, Trend

Identification by Facilities, Version 2.1, when analyzing data for the effectiveness checks for the

corrective action plans implemented for Exception E-0717565 (discovered in December 2009) (Issue I

0018377-FC). For example, the effectiveness check query found 13 additional overweight units during

the queried period. ARC eliminated six ofthose occurrences from its effectiveness check calculation

because their failure modes were "unknown." ARC deemed the corrective action plan effective and

closed the trend problem. FDA requested a query for March through June 2010 and found there were

five additional occurrences of overweight units.

Page 16- Mr. J. Chris Hrouda

Decree Violations: Failure to Follow Standard Operating Procedure

7. Failure to comply with paragraph IV.A.l., which requires "continuous compliance with this

Order, the law, and ARC SOPs." For example, during an inspection of the Southwest Region in July

August 2010, FDA observed that ARC did not follow its written procedures pertaining to consignee

notification in order to determine the fmal disposition of a blood product. The region held 25 imported

components out ofcontrolled storage in excess of 30 minutes. The region opened Exception E-07 48767

(Issue I-0004237) and Biological Product Deviation Report E-0748767 was opened on 2/12/10 and the

region notified the DCSC to manage the components. The DCSC placed holds on the components and

notified consignees. FDA's review from the DCSC found that the DCSC had no

final disposition for five components and two components had a final disposition of"Q" (quarantine).

According to Work Instruction 11.3.011, Sending Retrieval Letters and Notifications, Version 1.5, ifthe

consignee does not respond to the first notification, a second notice must be sent in order to obtain the

final disposition ofthe recalled component. The DCSC failed to send the second letters. Additionally,

FDA noted during a subsequent review ofthe records that the Component Status Change Record for the

recall found that it had not been process-verified five months after being created.

GMP VIOLATIONS:

GMP Violations: Inadequate System for the Distribution or Receipt of Blood Products

8. Failure to establish and maintain a distribution and receipt procedure that includes a system by

which the distribution or receipt of each unit of blood can be readily determined to facilitate its recall, if

necessary [21 CFR 606.165(a)]. This procedure is necessary to ensure that unsuitable products are

promptly recalled and not transfused. For example,

a. During an inspection of the Heart of America Region in June-August 2010, FDA

discovered that on 12/15/08, ARC changed the manner in which it assigns a unique number to the label

ofeach unit of pooled cryoprecipitate. Prior to that date, each unit was assigned a four digit number,

and after that date a nine digit number was assigned. The nine digit unique number is applied to the

label on each unit of pooled however, the computer record for each such unit continued

to use the four digit format. ARC's relevant written procedures still do not provide adequate

instructions to ensure that staff responsible for blood product retrieval and consignee notification

consider whether the unit was distributed prior to or after the change to the numbering format.

Beginning February 2009, the Heart ofAmerica Region's donor management functions, including blood

component retrieval and consignee notification, were consolidated with the DCSC. FDA's review of

records pertaining to consignee notification for units ofpooled cryoprecipitate found that the DCSC

notified consignees using the incorrect unit number format for four units. For example, pooled

cryoprecipitate unit 2399 was distributed on 5/30/08. It was subsequently determined to require

retrieval by ARC due to high risk behavior by one of the donors. On 12/2/2009, the DCSC notified the

consignee ofthat unit by letter, using the erroneous nine-digit number 040C02399. The DCSC

documented the unit's final disposition on a Component Status Change Record (CSCR) as discarded;

however, the FDA investigator was informed during the inspection that the documentation to support

that final disposition was misplaced. During the inspection, ARC again notified the consignee with the

correct four digit unit number and the consignee responded that the unit had been transfused into a

patient on 6/26/08.

Page 17 - Mr. J. Chris Hrouda

During the inspection, ARC reported to FDA that as a result ofthis observat ion, it had opened an

investigation and identified an additional 62 cases that were managed by the DCSC using the wrong unit

number format. Those cases involved regions other than the Heart ofAmerica. In its 9/8/10 response to

the FDA 483, ARC stated that the problem was caused by a procedural gap and that it was a system

wide problem.

b. During an inspection ofthe Northern California Region in September 2010, FDA

discovered that the DCSC was unable to locate documentation for the final dispositions of 31 Red Blood

Cell units that were subject to retrieval. A Material Review Board decided to retrieve the products after

it was discovered that the storage temperature of the units, documented at the time ofreceipt, was

unacceptable. ARC contacted the consignee ofthe units to request a copy ofthe missing notification

documentation. The CSCR form documented that all 31 units were destroyed. However, the consignee

reported that eight units had been transfused into patients. The CSCR, with the incorrect dispositions,

had been process-verified by the DCSC on 3/4/10, but the discrepancies were not detected.

GMP Violations: Failure to Follow Manufacturer's Instructions

9. Failure to ensure that supplies are used in a manner consistent with the manufacturer' s

instructions, as required at 21 CFR 606.65(e); and failure to prepare the phlebotomy site using a

method that gives maximum assurance of a sterile container ofblood [21 CFR 640.4(f)]. For example,

During an inspect ion ofthe Southern California Region in August-September 2010, FDA observed

collection staff placing hand warmers directly on Whole Blood donors' arms over prepared phlebotomy

sites. Only a piece of gauze separated the hand warmer from the area where the venipuncture was

performed. This action may have compromised sterility during the collection procedure. FDA' s review

of the manufacturer's instructions for the hand warmer found that they specifically stated, "***Do not

use***on parts ofthe body other than the hand***." ARC's 11/4/ 10 response to the FDA 483

acknowledged that this use ofhand warmers was inappropriate and could bum donors' skin.

GMP Violations: Failure to Maintain and/or Follow Written Procedures

10. Failure to establish, maintain and follow written procedures that include all steps to be followed

in the collection, processing, compatibility testing, storage, and distribution ofblood and blood

components for transfusion and further manufacturing purposes [21 CFR 606.1 OO(b)]. For example,

a. During the inspection ofthe DCSC, FDA reviewed ARC's management of recipient

complication cases, in which a patient had difficulty with a blood transfusion. ARC' s Job Aid

11.4.ja056, Timing Guidelines for Recipient Complication Investigations, Version 1.0, requires that the

DCSC complete a recipient complication case investigation within three months ofit being opened or

document why the case remains open. In addition, the Job Aid requires that a monthly review of each

opened case file be performed, to ensure that actions are being appropriately managed. However, FDA

reviewed nine recipient complication investigations during the inspection ofthe Philadelphia DCSC

facility and discovered the following:

i. Case ID DCSC-P-053-TR-TRL00375 was opened on 11/04/09 and was closed

5/25/10, 202 days later. The case file did not have a justification for exceeding the 90 day time

frame documented in the case notes until2/ 16/ 10, the date ARC documented why the case was

Page 18- Mr. J. Chris Hrouda

open for more than three months. The file also contained no documentation that the case was

reviewed on a monthly basis to "ensure that actions are being appropriately managed."

ii. Case ID DCSC-P-053-TII-HBV00429 was opened on 12/28/09 and was closed

5/25/ 10, 158 days later. The case file did not have ajustification for exceeding the 90 day time

frame documented in the case notes until 5/25/ 10, the date ARC documented why the case was

open for more than three months. The file also contained no documentation that the case was

reviewed on a monthly basis to "ensure that actions are being appropriately managed."

m. Case ID DCSC-P-053-TTI-HBV00651 was opened on 4/28/10 and was closed

during the inspection on 10/611 0, 157 days later. The case file contained no j ustification for

exceeding the 90 day time frame documented inthe case notes Wltil 8/1 2/10, the date ARC

documented why the case was open for more than three months.

b. During an inspection of the Southeastern Michigan Region in August - September 2010,

FDA reviewed 26 transfusion reaction/recipient complication cases and discovered 11 that were not

managed according to ARC's written procedures. For example,

i. The DCSC opened a transfusion reaction/recipient complication case on 7/9/09

and closed it on 5/22/10, without justification for why the case was open for more than three

months.

ii The DCSC documented inaccurate final component dispositions on CSCRs.

Form 11.4.frm9, Component Status Change Records, Version 1.1, provides a component fmal

disposition section and states that if it mu::;L with "a valid disposition to the

fmal disposition." DCSC-C-013-TR-ORX00246 indicates that one component was marked

destroyed, but had in fact been shipped to a consignee. Another component was marked as

expired in-house, but in fact had been destroyed by the consignee.

c. During the inspection ofthe DCSC, FDA discovered that the DCSC has not established

adequate procedures to ensure that donor health history deferred reports are generated daily and that

failure to generate such reports will be detected promptly. According to the DCSC management, it has

been operating with only draft work flows for the health history deferred report review process. During

the inspection ofthe Philadelphia DCSC facility, FDA requested health history deferral records for July

2010 for three regions. The DCSC informed FDA that it had failed to generate five requested reports;

therefore, it failed to conduct a review ofeach listed donor with prior donations for potentially

unsuitable blood components requiring quarantine, retrieval, and consignee notification, when

necessary. Upon discovery during the inspection, the DCSC opened Exception report E-0869169 to

address the problem and review the omitted reports. Their review found that, due to the omission, prior

donations from five donors had not been managed appropriately. In addition, ARC discovered an

additional 18 omitted donor health history reports.

d. During an inspection ofthe Greater Alleghenies Region in September 2010, FDA

observed that during the blood donation process, the region provided donors with hand warmers prior to

collecting a blood sample using the finger stick method. The blood samples were collected for

hemoglobin determination as part ofthe donor health assessment to determine

management said the hand warmers are used in the winter with the ----

- ARC bas not established a written standard operating procedure for use of hand warmers to

Page 19 - Mr. J. Chris Hrouda

increase blood flow when a donor's hands are cold. In addition, ARC has not provided training to the

collections staff regarding their use.

e. During an inspection of the Heart ofAmerica Region in June-August 2010, FDA

observed that ARC does not consistently follow Work Instruction 10.3.011, External Customer

Complaint Management, Version 1.1 and Directive 10.2.9, Managing Customer Concerns, Version 1.0.

For example, ARC's recruitment staff distributes "Blood Drive Sponsor Satisfaction Survey" forms to

mobile blood drive coordinators and/or chairpersons. A portion ofthe survey requests feedback

regarding the ARC blood drive staffing level. It also includes a space for comments. FDA's review of

survey forms found that complaints related to FDA-regulated functions were not investigated as

concerns or complaints, in accordance with established written procedures as required by 21 CFR

211.100(b) and 21 CFR 606.100(b). For example,

Survey cards for two mobile blood drives conducted on 11/4/09 and 12111/09 reported complaints

pertaining to a donor sprayed with blood and pertaining to donor injuries during phlebotomy.

During the inspection, ARC informed the FDA investigator that it believes complaints on the survey

cards are not complaints because they are solicited information and that Directive 1 0.2.9 only applies

when the donor takes the initiative to inform the staff ofthe complaint. Yet, Work Instruction 10.3.011

states that a complaint is "any written, electronic, or oral communication that alleges deficiencies related

to the identity, durability, reliability, safety, effectiveness, or performance of any device, blood

component, blood product, process, procedure, or employee performance that impacts donor or product

safety." ARC also solicits donor feedback through the internet and does not evaluate those to determine

whether there is an issue that should be managed as a concern or complaint, in accordance with its

written procedures and regulations. In its 9/8110 response to the FDA 483, ARC maintains that the

surveys are "proactive methods to improve business," that they are not "designed to assess regulatory

compliance," and that they are "outside the scope ofthe Problem Management SOPs." The response

further states that subsequent to the Heart of America inspection, it modified the survey to remove the

comment section and to add a statement directing the user to report donor issues to the collections lead

and to provide a contact number. ARC's response does not state how it modified the survey with

respect to complaints about staffing or how it will address staffing complaints that may appear on future

surveys.

f. During the inspection ofthe Penn Jersey Region in May-June 2010, FDA observed a

failure ofthe DCSC to follow written procedures to obtain final dispositions (January 2009 and March

201 0) for four components that were subject to retrieval because they were collected from a male donor

who was registered as a female. The DCSC also had no documentation to support the final dispositions

for the components. One CSCR had been process-verified, but the errors were not detected by the staff

performing the verification.

g. During inspections ofnine ARC regions and the Philadelphia DCSC, FDA discovered

multiple failures by ARC to follow written procedures pertaining to managing adverse donor reactions,

as required by 21 CFR 606.170(a). For example,

i. During an inspection ofthe Heart ofAmerica Region in June-August 2010, FDA

discovered that the region failed to conduct a thorough investigation of each reported adverse

reaction, as required by 21 CFR 606.170(a). For example, on 5/20/10, ARC received a report

of an adverse donor reaction from a high school blood drive coordinator regarding a blood drive

Page 20 - Mr. J. Chris Hrouda

on 5/19/10. During the blood drive, a 16-year-old donor's hemoglobin test result was

unacceptable and a second blood sample was collected to re-test the donor' s hemoglobin level.

The donor was accepted for donation based on the results ofthe second test. The donor lost

consciousness and hit his/her head after a unit ofblood was collected. The report included

injuries sustained by the donor subsequent to falling in the canteen area. In an ARC document, a

collection staff member stated he/she had concerns about the donor's weight and was aware of

the loss of consciousness, but did not believe a DRIR was necessary. Even after the region

received the report from the high school coordinator on 5/20/10, it failed to document the event

on a DRIR and investigate the adverse reaction. It was not until 6/29/10, after FDA reviewed the

complaint from the high school, that the region addressed the adverse reaction and the failure to

document and investigate it. At that time, the region opened a problem report to investigate the

failure to initiate a DRIR upon receipt ofthe 5/20/10 report, but the problem report did not

address the failure ofthe collection staff to initiate a DRIR on 5/19/1 0, when the event occurred