Академический Документы

Профессиональный Документы

Культура Документы

Curriculum Vitae: Marital Status: No

Загружено:

Luan NguyenИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Curriculum Vitae: Marital Status: No

Загружено:

Luan NguyenАвторское право:

Доступные форматы

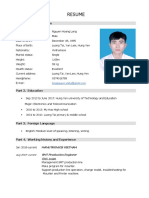

CURRICULUM VITAE 1.

PERSONAL DETAIL - Full name: Nguyen Van Hon - Date of birth: 12/12/1989 - Gender: Male - Marital status: Not married - Tel: 01682486247 - Email: nguyenvanhon1989@gmail.com - Nationality: Vietnamese - Address: Phuoc Hau quarter, Xuan Dai precinct, Song Cau town, Phu Yen province 2. EDUCATION BACKGROUND - Name of university: Ha Noi University of Science and Technology - Major: Organic and Petrochemical Technology Range of time: 2007 - 2012 Training about - Petroleum Refinery Engineering - Petroleum chemistry - Petroleum Products - Gas Processing - Petrochemical Synthesis - Synthesis of Intermediate Compounds - Equipments in Petrochemical Synthesis - Coal Processing Technology - Clean Fuels Thematic - Catalytic Kinetics Apply line balancing and simulation engineering to improving and increasing capacity of ATV assembly line at Vietnam Precision Industrial Co.,Ltd. - Can read major document well - Good English communication Microsoft Office tools: Word, Excel, Power point, Visio - Graphic: Auto cad 2D, Sketch up 3D - ERP software: Microsoft Dynamic - Responsibility - Discipline

Thesis Foreign language Computer skills

Other skills & competences

- Term Work - Organizational skills - Creativity

3. PROFESSIONAL EXPERIENCES COMPANY Company type Location Product Company size Duration Position ANP VIETNAM Multinational company Saigon Hi-Tech park Electronic 1500 03/2010 until now Production Line Manager -Ensure Weekly, monthly output. -Maintain, improve yield, Min/pc, Productivity. -Maintain 5S program and Lean Production. -Organizing and controlling the production resources. -Aim at decreasing of the production costs. -Close cooperation between and open communication with production, maintenance and quality departments as well as other departments in the company. -Achieving the company goals. MNT CO.,LTD Joint venture company Ho Chi Minh city Electronics 500 08/2007 to 03/2010 Fabrication Section Manager * FROM 06/2009 TO 07/2010: Fabrication Section Manager - Control, maintain, develope operation of Fabrication Section. - Analyze, improve, optimize to efficiently use material, labor, equipment... to finish orders on time, increase productivity, save cost.

Jo description

COMPANY Company type Location Products Company size Duration Position Job description

- Monitor products standard and implement quality control program. - Train, encourage, motivate happiness, fervor and creation of staffs. - Plan and monitor Fabrication Operation Weekly Plan, Fabrication Operation Monthly plan. - Plan and monitor Fabrication Yearly Action Plan (increase capacity, quality, reduce material cost, develop new products, improve production line, recruit labors, buy machines and equipments) * FROM 08/2007 TO 05/2009: Production Planning Staff - Receive Technical Drawing, check and prepare material follow Bill Of Material. - Check production line situation, arrange orders to production line to ensure delivery time. - Control material level in warehouse, determine Safety Inventory Level to minimize material in stock. - Periodically order material from parent company in Thailand.

4. GOALS IN NEXT 2 YEARS Cultivating major knowledge. Attempt to build and develop company.

5. HOBBIES Listening to music, swimming, jogging, reading news paper.

Вам также может понравиться

- Very GoodДокумент9 страницVery GoodNguyễn Tiến DũngОценок пока нет

- CV EnglishДокумент3 страницыCV Englishdreamingscientist3393Оценок пока нет

- Tran Ho Van TienДокумент2 страницыTran Ho Van TienTiếnTrầnHồVănОценок пока нет

- 1 Leduclinh CVДокумент3 страницы1 Leduclinh CVThanh X TranОценок пока нет

- Curriculum Vitae Ashish KaushikДокумент3 страницыCurriculum Vitae Ashish KaushikTourist GuideОценок пока нет

- Nguyen-Ngoc-Quynh-Nhung - Apply For An AccountantДокумент8 страницNguyen-Ngoc-Quynh-Nhung - Apply For An AccountantNguyen RyanОценок пока нет

- Nguyen Quang Vinh-Process Engineer PDFДокумент2 страницыNguyen Quang Vinh-Process Engineer PDFNguyễn Tiến DũngОценок пока нет

- Kent Expressway ProejectДокумент7 страницKent Expressway ProejectTrang NguyễnОценок пока нет

- Minutes of Industry Advisory Board Meeting: Ministry of Education and TrainingДокумент5 страницMinutes of Industry Advisory Board Meeting: Ministry of Education and TrainingCarotОценок пока нет

- Curriculum Vitae: Full Name: PH M Trư NG LongДокумент3 страницыCurriculum Vitae: Full Name: PH M Trư NG LongHung Nguyen ManhОценок пока нет

- CV Tran Le NamДокумент2 страницыCV Tran Le NamHuy. Do QuangОценок пока нет

- Luu Van Hung ProfileДокумент3 страницыLuu Van Hung ProfileNICK KОценок пока нет

- Industrial Engineering: Võ Minh KhúcДокумент3 страницыIndustrial Engineering: Võ Minh KhúcPeter SonОценок пока нет

- Quality Assurance Engineer - Hoan Cong Pham-Tell (+84) 355444197Документ2 страницыQuality Assurance Engineer - Hoan Cong Pham-Tell (+84) 355444197Nguyễn Tiến DũngОценок пока нет

- CV - 2022Документ4 страницыCV - 2022Antex ChekolОценок пока нет

- CV Nguyen Huu Thang May-23Документ4 страницыCV Nguyen Huu Thang May-23HieuОценок пока нет

- Resume Rupesh BorseДокумент3 страницыResume Rupesh BorseSagar BhamreОценок пока нет

- TTP19th - 23rd Nov 2019261019034811Документ3 страницыTTP19th - 23rd Nov 2019261019034811Vikrant Lal DasОценок пока нет

- Production & Document Controller - M. Alif Akbar BДокумент5 страницProduction & Document Controller - M. Alif Akbar BLuthfie ZulkarnaenОценок пока нет

- CV Zulkifliandi 2021Документ5 страницCV Zulkifliandi 2021Randy NetofaОценок пока нет

- CV - Sr. Mechanical Design Engineer - Khanh Nguyen - ENДокумент2 страницыCV - Sr. Mechanical Design Engineer - Khanh Nguyen - ENNguyễn Tiến DũngОценок пока нет

- Bimal Resume-1Документ6 страницBimal Resume-1SWSS DWGОценок пока нет

- Akhilesh CVДокумент3 страницыAkhilesh CVUma MaheshwarОценок пока нет

- CURRICULUM VITAE Anh+Viet MRДокумент4 страницыCURRICULUM VITAE Anh+Viet MRVu Duy PhuocОценок пока нет

- I.Personal Information: Curriculum VitaeДокумент3 страницыI.Personal Information: Curriculum Vitaeavandetq15Оценок пока нет

- Resum - ENG de CuongДокумент2 страницыResum - ENG de CuongLam HanОценок пока нет

- Givi - Production Manager - Nguyen Phuoc Lam VienДокумент3 страницыGivi - Production Manager - Nguyen Phuoc Lam VienLâmViênОценок пока нет

- Service Manager: Mô Tả Công ViệcДокумент5 страницService Manager: Mô Tả Công Việchoangoclan_trang090891Оценок пока нет

- Open CycleДокумент6 страницOpen CycleMORSHEDОценок пока нет

- PPC Resume (3 + Experience)Документ3 страницыPPC Resume (3 + Experience)bhushanОценок пока нет

- Mohamed-Ibrahem CV 2021Документ4 страницыMohamed-Ibrahem CV 2021Mohamed IbrahemОценок пока нет

- Abhay Krishna ResumeДокумент6 страницAbhay Krishna Resumesawantpavan47Оценок пока нет

- Mohammad Hassan Sayed Mohammad: EducationДокумент5 страницMohammad Hassan Sayed Mohammad: EducationMohammad HassanОценок пока нет

- Ah - Adel CVДокумент3 страницыAh - Adel CVNourhan KamelОценок пока нет

- Curriculum Vitae: Ofanny Ferdian RahmansyahДокумент5 страницCurriculum Vitae: Ofanny Ferdian Rahmansyahgd sutawijayaОценок пока нет

- LÝ HOÀNG TÂN - CV - EnglishДокумент1 страницаLÝ HOÀNG TÂN - CV - EnglishNguyễn Tiến DũngОценок пока нет

- Umesh Lakade - Admin & HR - CV 2019Документ3 страницыUmesh Lakade - Admin & HR - CV 2019Anonymous c4W4ooEjfОценок пока нет

- CV DohaДокумент4 страницыCV DohaHa Do VanОценок пока нет

- Eng. Shady Essam CVДокумент5 страницEng. Shady Essam CVShady Essam ElkilanyОценок пока нет

- Resume-B N RautДокумент6 страницResume-B N RautBalaji RautОценок пока нет

- CV - Cheng Tu TaiДокумент9 страницCV - Cheng Tu TaiTai ChengОценок пока нет

- Naukri NitinNamdevRane. 18315862 - 06 06 - 1Документ3 страницыNaukri NitinNamdevRane. 18315862 - 06 06 - 1Jerish JohnОценок пока нет

- Munendra Kumar: ProfileДокумент3 страницыMunendra Kumar: ProfileM K KUMARОценок пока нет

- Curriculum Vitae: Permanent Employees InternshipДокумент4 страницыCurriculum Vitae: Permanent Employees InternshipDennyFernandesОценок пока нет

- Sambit Kumar Patri: Professional SummaryДокумент3 страницыSambit Kumar Patri: Professional Summarymanas3sОценок пока нет

- Subject: Job Application: HRD Dept-RecruitmentДокумент10 страницSubject: Job Application: HRD Dept-RecruitmentJoe GrosirОценок пока нет

- Resume Rupesh BorseДокумент4 страницыResume Rupesh BorseSagar BhamreОценок пока нет

- Data Management and Statistical Analysis Using SPSSДокумент4 страницыData Management and Statistical Analysis Using SPSSKhairol Anuar MohammedОценок пока нет

- Curriculum Vitae: I. Individual Information: Võ Tuấn GiangДокумент2 страницыCurriculum Vitae: I. Individual Information: Võ Tuấn GiangjiangjinwuОценок пока нет

- Resume RAJATДокумент3 страницыResume RAJATSAPPHIREОценок пока нет

- Le Anh DuyДокумент7 страницLe Anh DuyAnh Ba KhíaОценок пока нет

- Curriculum VitaeДокумент3 страницыCurriculum VitaeLâmViênОценок пока нет

- Shantilal Aher - CVДокумент3 страницыShantilal Aher - CVEr Prem AaherОценок пока нет

- Muhammad Hussain: Industrial KnowledgeДокумент2 страницыMuhammad Hussain: Industrial KnowledgeM hussain imranОценок пока нет

- Plant Operations - Product Development - Production & Operations - Customer Support Professional SummaryДокумент4 страницыPlant Operations - Product Development - Production & Operations - Customer Support Professional SummarySrinivasan ThukkaramОценок пока нет

- Curriculum Vitae: Saurabh TripathiДокумент2 страницыCurriculum Vitae: Saurabh TripathipratikОценок пока нет

- Intern CV Pheaktra TiengДокумент3 страницыIntern CV Pheaktra TiengTieng PheaktraОценок пока нет

- Chandrahash Sahoo ResumeДокумент4 страницыChandrahash Sahoo Resumec_h_sahooОценок пока нет

- Nitesh Kumar Tiwari: Career ObjectiveДокумент2 страницыNitesh Kumar Tiwari: Career ObjectiveA SОценок пока нет

- Nust Entrance TestДокумент16 страницNust Entrance TestShawn Parker80% (30)

- GAPS Guidelines: Deep Fat FryersДокумент4 страницыGAPS Guidelines: Deep Fat FryersAsad KhanОценок пока нет

- CFPA E Guideline No 19 2009 EVACUATION FROM BUILDINGS PDFДокумент99 страницCFPA E Guideline No 19 2009 EVACUATION FROM BUILDINGS PDFodemircioglu2Оценок пока нет

- Battery CatalogueДокумент6 страницBattery CataloguerantaroОценок пока нет

- INSPECTION-REPORT-OF-RIVER-CHANNEL-IN-BRGY Ponong in Magarao, Camarines SurДокумент3 страницыINSPECTION-REPORT-OF-RIVER-CHANNEL-IN-BRGY Ponong in Magarao, Camarines SurBerp OnrubiaОценок пока нет

- CRX Seat Diassembly & Assembly 1Документ9 страницCRX Seat Diassembly & Assembly 1ocdank19806116Оценок пока нет

- 2 Related Topics Automatic IrrigationДокумент13 страниц2 Related Topics Automatic IrrigationSftvsn Giovanni TandogОценок пока нет

- Guinness Case StudyДокумент3 страницыGuinness Case StudyMunyaradzi T HotoОценок пока нет

- Control Panel STD Design PDFДокумент71 страницаControl Panel STD Design PDFDuy ThaiОценок пока нет

- PR 1-2Документ7 страницPR 1-2mech bhabhaОценок пока нет

- 33R 15Документ10 страниц33R 15Ingenieria Ec100% (5)

- Fatwa Darul Uloom Deoband - Vol 1Документ276 страницFatwa Darul Uloom Deoband - Vol 1Ahlehaq100% (3)

- Designs of Canals and CM&CD WorksДокумент61 страницаDesigns of Canals and CM&CD WorksVenkataLakshmiKorrapatiОценок пока нет

- AAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Документ10 страницAAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Benjamín AlainОценок пока нет

- ADBCДокумент12 страницADBCJaspal KumarОценок пока нет

- Q45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetДокумент8 страницQ45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetMohammad IsmailОценок пока нет

- Stereo Magazine Issue 02Документ66 страницStereo Magazine Issue 02LipsticОценок пока нет

- Noise and VibrationДокумент14 страницNoise and VibrationABHISHEK V GOWDAОценок пока нет

- Código BoogaДокумент138 страницCódigo BoogaJazmin SeguelОценок пока нет

- BEP Pages 5 16Документ12 страницBEP Pages 5 16Amy LauОценок пока нет

- Raman Spectroscopy SetupДокумент13 страницRaman Spectroscopy SetupRafael RamosОценок пока нет

- Legend:-: General Arrangement ACS550-124A-4 YN3A205086-GAAДокумент12 страницLegend:-: General Arrangement ACS550-124A-4 YN3A205086-GAANeeraj SharmaОценок пока нет

- ABB I RWEДокумент1 страницаABB I RWEPredrag VucinicОценок пока нет

- Depth of InvestigationДокумент8 страницDepth of InvestigationGogot Pantja ParijogoОценок пока нет

- Harbor GlenДокумент31 страницаHarbor GlenElvis Felix fernandesОценок пока нет

- A Simulation of Attempts To Influence Crowd Dynamics'Документ6 страницA Simulation of Attempts To Influence Crowd Dynamics'KhairulОценок пока нет

- PSD Installation Manual Moore IndustriesДокумент16 страницPSD Installation Manual Moore IndustriesnohjadОценок пока нет

- Newton Laws of Motion JeopardyДокумент19 страницNewton Laws of Motion JeopardyJessiel GueribaОценок пока нет

- Polylux WebkatalogДокумент96 страницPolylux WebkatalogNesil Abiera50% (2)

- Potsdam Village Police Dept. Blotter April 12, 2018Документ2 страницыPotsdam Village Police Dept. Blotter April 12, 2018NewzjunkyОценок пока нет