Академический Документы

Профессиональный Документы

Культура Документы

TL245 English 2004

Загружено:

Elliott RussellОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TL245 English 2004

Загружено:

Elliott RussellАвторское право:

Доступные форматы

The English translation is believed to be accurate. In case of discrepancies the German version shall govern.

Non-Electrolytically Applied Zinc-Flake Coatings

Surface Protection Requirements

TL 245

Konzernnorm Descriptors: corrosion protection, surface protection, zinc, aluminum, flake, Delta-Protekt, Delta-Tone, Geomet Changes The following changes have been made as compared to Technical Supply Specification TL 245, 2002-10: Scope revised New descriptions of surface protection (Table 1) Section 3.11.1 Test according to DIN 50 017 KK: Permitted corrosion level changed from Ri 0 to Ri 1 to Ri 0 Section 3.11.2 Test according to DIN 50021 SS: Separation between barrel-coated and rack-coated goods introduced Requirements for corrosion resistance reduced for Ofl-t610 Section 3.12 Resistance to chemicals: This section was updated, and the separation between components of the engine compartment and components from outside the engine compartment was eliminated Surface protection type Ofl-t615 added Assignment of Cr(VI)-free alternatives changed Referenced standards updated Previous issues 1987-08; 1989-10; 1990-01; 1991-03; 1991-11; 1992-10; 1993-07; 1997-12; 2002-10 1 Scope

This standard defines the requirements on Cr(VI)-free surface protection types made of zinc and aluminum flakes non-electrolytically applied to ferrous materials. Silver-gray flake coatings shall be used as heavy-duty corrosion protection for components with a high corrosion load. With an appropriate layer structure, the zinc-flake coatings are able to withstand temperatures, such as those occurring in the area of the engine compartment and brake (details see Table 1). Since this coating process poses no risk of hydrogen-induced brittling, it is preferably used as corrosion protection for hardened and high-strength steel parts with tensile strength values > 1,000 MPa or surface hardness values > 320 HV. The protection system shall be chosen such that the strength and hardness are not impaired by the treatment temperatures.

The coating is not suitable for parts that serve as electrical conductors (e.g. ground connections), have multipoint sockets according to Volkswagen standard VW 010 43 < N8 and hexalobular sockets according to VW 010 48 < T30, have hexagon sockets < 5 and cross recesses according to DIN EN ISO 4757 < H3, have a thread of < M6.

Form FE 41 - 01.03

In order to avoid clogging caused by coating particles that come loose, zinc-flake coatings should only be used inside units (e.g. oil chamber) in exceptional cases. Page 1 of 8

Fachverantwortung/Responsibility K-QS-32/2 Ackermann Tel: -38255 Laudien Dr. Eisenberg Normung/Standards (EZTD, 1733) Wiesner Tel: +49-5361-9-29064 Sobanski

VOLKSWAGEN AG

Confidential. All rights reserved. No part of this document may be transmitted or reproduced without the prior written permission of a Standards Department of the Volkswagen Group. Parties to a contract can only obtain this standard via the responsible procurement department.

QUELLE: NOLIS

Zinc-flake coatings are also suitable for use as a coating for ferrous materials in contact with aluminum components (however, not for those in contact with magnesium components).

Norm vor Anwendung auf Aktualitt prfen / Check standard for current issue prior to usage.

Klass.-Nr. 50 22 3

December 2004

Page 2 TL 245: 2004-12

Designation

See VW 137 50, Section 2. 3 3.1 Requirements Surface protection types

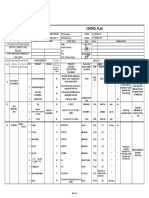

The surface protection types listed in Table 1 apply; for replacement of surface protection types that are no longer permitted, see Table 2. Examples of systems that were previously released part-specifically are listed in Appendix A.1. Table 1 Surface protection type Ofl-t602 Characteristics and appearance Basic coating with topcoat (inorganic), without lubricant additive. Zinc-flake coating, Cr(VI)-free, silver-gray; use in exposed installation positions, e.g. in the engine compartment and chassis areas. Burn-in temperature up to max. +300 C, Endurance service temperature max. +180 C (short-term temperature peaks up to +300 C). Basic coating without topcoat, without lubricant additive. Zinc-flake coating, Cr(VI)-free, silver-gray; corrosion protection preferably for components that are to be painted (body construction). Standard surface protection for threaded parts with microencapsulation. Burn-in temperature up to max. +200 C, Reduced corrosion resistance (see Section 3.11), Reduced endurance service temperature without additional coatings (+125 C). As for Ofl-t602, but with lower burn-in temperature. Consequently, suitable for components that cannot be exposed to high temperatures, e.g. spring elements, low-temperature formed and hardened sheets or high-strength steel parts. Burn-in temperature max. +230 C, Endurance service temperature max. +200 C (short-term temperature peaks up to +300 C). As for Ofl-t610, but additionally lubricant (greenish) according to TL 521 65. Standard surface protection for self-locking nuts with plastic locking element. Ofl-t647 Burn-in temperature up to max. +200 C, Reduced corrosion resistance (see Section 3.11), Reduced endurance service temperature without additional coatings (+125 C).

Ofl-t610

Ofl-t611

Ofl-t615

Basic coating with topcoat (inorganic), with lubricant additive. Zinc-flake coating, Cr(VI)-free, silver-gray, standard surface protection for threaded parts with metric ISO standard threads (see VW 011 10) Burn-in temperature up to max. +300 C, Endurance service temperature max. +180 C (short-term temperature peaks up to +300 C).

Page 3 TL 245: 2004-12

Table 2 Impermissible surface protection type for new designs Components of a general nature Ofl-t300 Ofl-t310 Ofl-t320 Ofl-t600 Ofl-t620 Ofl-t300 Ofl-t310 Ofl-t320 Ofl-t345 Ofl-t600 Ofl-t620 Ofl-t645

1) 2) 3)

Protection type designated for new designs

Ofl-t610 Ofl-t610 Ofl-t611 Ofl-t602 1) Ofl-t602 1) Ofl-t647 2) Ofl-t647 2) Ofl-t647 3) Ofl-t647 3) Ofl-t647 2) Ofl-t647 3) Ofl-t647 3)

Threaded parts with metric ISO standard threads

Ofl-t611, if operating temperatures of up to 200 C and/or if lower burn-in temperatures up to max. 230 C are required Ofl-t610, if component is installed in the body construction before painting or for threaded parts with microencapsulation Ofl-t615, if self-locking nut with plastic locking element

3.2

General requirements

Approval of first supply and changes according to VW 011 55. Avoidance of hazardous substances according to VW 911 01. 10 finished parts are required for complete testing. For first-sample release of small parts, e.g., threaded fastening elements, a test production of > 50 kg shall be performed. The coating materials must not contain any Cr(VI) compounds in order to ensure that the resultant coatings are likewise Cr(VI)-free. Unless certain sections of a part that are marked in the drawing are excluded from the surface coating, the entire surface of the parts must comply with the required surface protection type and display the prescribed properties. There shall be firm adhesion between coatings and base material (see Section 3.10); there shall be no flaking of the coating or cracks under elastic deformation. The protective coatings must not exhibit any pores, cracks, damage, or other flaws that impair the corrosion protection and/or function. The production process and its control shall not impair the functional characteristics of the finished part. Thus for example, the coating must not flake or crack when the springs or spring washers are mounted or used as intended. With proper mounting, the coating shall not be damaged in a way that would result in impairment of function and/or decrease in the specified corrosion protection.

Page 4 TL 245: 2004-12 The selection of supplier and coating system is subject to agreement with the VW Group Central Laboratory (K-QS-32) and/or the AUDI Group Test Laboratories (I/GQ-32 and N/GQ-55) prior to usage of the given part. 3.3 Threaded parts with metric ISO standard threads

The coating process shall not impair the mechanical and physical properties specified for joining elements. Therefore, the manufacturer has to check whether the baking conditions specified by the coating company are suitable for the parts to be coated. An essential functional property of threaded parts with metric ISO standard threads is their compliance with specified coefficients of friction. In order to ensure that the coefficients of friction comply with VW 011 29, a topcoat with integrated lubricant additive is prescribed for surface protection type Ofl-t647, in addition to the base flake coating. In the case of screws and bolts, the test requirements listed below only apply to the head and/or the wrench bearing surfaces, in the case of nuts, they apply only to the nut body with the exception of the thread. For threaded and similar shaped parts, such as studs, the test requirements only apply to the face surfaces. Reduced requirements (see Sections 3.9 and 3.11.2) apply to process- or geometry-related weak spots of coating areas on joining elements and quick fastening elements. Prior to coating, threaded parts shall exhibit tolerances corresponding to the coating thickness. Metric threaded parts shall preferably be designed according to VW 116 24 (internal threads) or VW 116 27 (external threads). After the coating process, the zero line must not be exceeded in the case of external threads, and it must not be fallen below in the case of internal threads. For further information see VW 011 10, Section 2. 3.4 Base coating

Repeated treatment would be useful to produce an even and opaque coating. It is compulsory for barrel coating. The coating systems corrosion protection performance is enhanced by repeated coating. Type and number of the coating processes for flake coating should be specified in the drawing if this is important for the quality of the basic layer in addition to the specified layer thickness. 3.5 Topcoats/lubricant additives

In order to observe the anti-corrosion requirements and to guarantee the defined coefficients of friction, additional system-specific topcoats, optionally with integrated lubricant additive, may be used. The topcoats must be coordinated to suit the base coating. They must not cause any functional impairment. If, in addition to corrosion protection, further functional surface characteristics such as paintability, compatibility with other agents, friction properties, threading behavior, vulcanizability or temperature behavior are required, part-specific tests or functional tests must be performed. 3.6 Base material

See drawing.

Page 5 TL 245: 2004-12

3.7

Pretreatment

Principally metallically bright. Alternatively (depending on the coating system) micro-crystalline thin layer phosphating (1 to 3 g/m) is permissible. Prior to coating, hot alkaline and/or mechanical cleaning (e.g. abrasive blasting) shall be carried out on hardened or high-strength steel parts with a tensile strength > 1,000 MPa. Special treatments that could lead to hydrogen absorption are only possible in individual cases upon provision of verification of the process management in coordination with the responsible QA laboratory of the Volkswagen Group. 3.8 Dry film

Composition, see International Material Data System (IMDS). 3.9 Dry coating thickness

Testing according to DIN EN ISO 1463, DIN EN ISO 2064 and DIN EN ISO 2178; measuring point position for threaded parts with metric ISO standard thread according to DIN EN ISO 4042. Requirement: minimum coating thickness 8 m; maximum coating thickness 18 m. If due to the process or geometry, the minimum coating thickness is not achieved, this is permitted as long as the corrosion protection and functionality, e.g. threading behavior, are not impaired. 3.10 Adhesion

Adhesive tape with an adhesive strength of (7 1) N per 25 mm width is used for the adhesion test acc. to DIN EN ISO 10683. It is firmly pressed onto the specimen surface and then removed with a jerk-like motion perpendicular to the surface. There must be no large-area removal of the coating. Small particles of the coating that adhere to the tape are permissible. 3.11 3.11.1 Corrosion behavior Test according to DIN 50017-KK (only for first-sample test)

The scribing line is applied on the basis of DIN EN ISO 7253, component dimensions permitting. After a test duration of 720 h and evaluation according to DIN EN ISO 4628-3, the following minimum requirements must be adhered to at all times: base metal corrosion on surface: Ri 0, base metal corrosion permissible in the scribing line, but no rust creep.

Page 6 TL 245: 2004-12

3.11.2

Test according to DIN 50021 SS

General requirements (not for Ofl-t610 and barrel-coated goods with thread): no base metal corrosion (Ri 0) after a test duration of 720 h without thermal conditioning, no base metal corrosion (Ri 0) after a test duration of 480 h with thermal conditioning for 96 h at +180 C (for Ofl-t611: +200 C). Deviating requirement for Ofl-t610: no base metal corrosion (Ri 0) after a test duration of 480 h without thermal conditioning. Deviating requirements for barrel-coated goods with thread (see also Section 3.3): no base metal corrosion (Ri 0) after a test duration of 600 h without thermal conditioning, no base metal corrosion (Ri 0) after a test duration of 480 h with thermal conditioning for 96 h at +180 C (for Ofl-t611: +200 C). 3.12 Resistance to chemicals (only for first-sample test)

Testing according to VDA1) 621-412 in the following media: FAM test fuel according to VDA 621-412, test A 4.1.1 Y, Diesel fuel according to TL 788 and VDA 621-412, test A 4.1.2 X, Biodiesel (FAME) according to DIN EN 14214 and VDA 621-412, test A 4.1.2 X, Premium unleaded gasoline according to DIN EN 228 and test according to VDA 621-412, test A 4.1.3 Y, Factory-fill engine oil according to TL 521 73 (Burmah Castrol Oil code A97075PBC) and VDA 621-412, test A 4.1.4 X, Hydraulic fluid according to TL 521 46 and VDA 621-412, test A 4.1.6 X, Automatic transmission fluid according to TL 521 62 and VDA 621-412, test A 4.1.7 X, Coolant according to TL 774 and VDA 621-412, test A 4.2.2 X. A surface change is not permitted (max. characteristic value 1 according to DIN EN ISO 4628-1). Additionally, tests are performed in the following medium: Brake fluid according to TL 766 and VDA 621-412, test A 4.2.1 X. The following requirement applies to this medium: swellings that have returned to normal after 24 h are permitted. For small parts, test B must be used instead of test A. Small parts can be submersed completely and compared with a new part from the same manufacturing batch. 4 TL 766 TL 774 TL 788 TL 521 46 TL 521 62 TL 521 65 TL 521 73 Referenced standards2) Brake Fluid; Material Requirements Ethylene Glycol-Based Coolant Additive; Material Requirements Dieselkraftstoff, Kraftstoffanforderungen (currently only available in German) Central Hydraulic System Fluid; Lubricant Requirements Factory-Fill-for-Life Automatic Transmission Fluid; Lubricant Requirements Lubricant (Greenish) for Threaded Fasteners; Material Requirements Factory Fill Engine Oil SAE 0W-30 with Fuel-Saving Properties for Extended Oil Change Intervals; Requirement, Testing

1) 2)

VDA = German Association of the Automotive Industry In this section, terminological inconsistencies may occur as the original titles are used.

Page 7 TL 245: 2004-12 VW 010 43 VW 010 48 VW 011 10 VW 011 29 VW 011 55 VW 116 24 VW 116 27 VW 137 50 VW 911 01 VDA 621-412 Multipoint Socket Profile; Drive Shape for Threaded Parts Round Hexagon Socket; Drive Shape for Threaded Parts Threaded Joints; Design, Assembly and Process Assurance Limit Values for Coefficients of Friction; Mechanical Joining Elements with Metric ISO Thread Vehicle Supply Parts; Approval of First Supply and Changes Metric ISO Thread; Limit Dimensions for Tolerance Class 6f/6G Thread Limit Dimensions for External Threads of Tolerance Class 6e; Metric ISO Threads Surface Protection of Metal Parts; Degrees of Protection, Codes, Requirements Environmental Standard for Vehicles; Vehicle Parts, Materials, Operating Fluids; Avoidance of Hazardous Substances Anstrichtechnische Prfungen; Chemikalienbestndigkeit von Kraftfahrzeug-Lackierungen (Tests for Coating Methods; Resistance to Chemicals of Motor Vehicle Paints; only available in German) Atmospheres and their Technical Application; Condensation Water Test Atmospheres Spray Tests with Different Sodium Chloride Solutions Automotive Fuels Unleaded Petrol Requirements and Test Methods Automotive Fuels Fatty Acid Methyl Esters (FAME) for Diesel Engines Requirements and Test Methods Metallic and Oxide Coatings Measurement of Coating Thickness Microscopical Method Metallic and Other Non-Organic Coatings Definitions and Conventions Concerning the Measurement of Thickness Non-Magnetic Coatings on Magnetic Substrates Measurement of Coating Thickness Magnetic Method Fasteners Electroplated Coatings Paints and Varnishes Evaluation of Degradation of Coatings Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance Part 1: General Introduction and Designation System Paints and Varnishes Evaluation of Degradation of Coatings Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance Part 3: Assessment of Degree of Rusting Cross Recesses for Screws Paints and Varnishes Determination of Resistance to Neutral Salt Spray (Fog) Fasteners Non-Electrolytically Applied Zinc Flake Coatings

DIN 50017 DIN 50021 DIN EN 228 DIN EN 14214 DIN EN ISO 1463 DIN EN ISO 2064 DIN EN ISO 2178 DIN EN ISO 4042 DIN EN ISO 4628-1

DIN EN ISO 4628-3

DIN EN ISO 4757 DIN EN ISO 7253 DIN EN ISO 10683

Page 8 TL 245: 2004-12

Appendix A (informative) A.1 A.1.1 Released surface protection systems Ofl-t602

Any system, e.g.: DELTA-PROTEKT KL100 + DELTA-PROTEKT VH300 GEOMET 321 PLUS 10 A.1.2 Ofl-t610

DELTA-TONE 9000 A.1.3 Ofl-t611

DELTA-PROTEKT KL100 + DELTA-PROTEKT VH300 A.1.4 Ofl-t615

DELTA-TONE 9000 + lubricant (greenish) according to TL 521 65 A.1.5 Ofl-t647

Any system. However, for joining elements only: DELTA-PROTEKT KL100 + DELTA-PROTEKT VH301GZ GEOMET 321 PLUS VL

Вам также может понравиться

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsДокумент5 страницCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- Non-Electrolytically Applied Zinc Flake Coatings RequirementsДокумент9 страницNon-Electrolytically Applied Zinc Flake Coatings RequirementsJuan José Viñas MéndezОценок пока нет

- Ti SPC Ohe Fasteners 0120 PDFДокумент31 страницаTi SPC Ohe Fasteners 0120 PDFCounter RoverОценок пока нет

- Fastener PDFДокумент12 страницFastener PDFdiegomilitojОценок пока нет

- FORD WX200 Rev2014Документ4 страницыFORD WX200 Rev2014Amandeep SinghОценок пока нет

- WSS-M1A346-A - Calidad de ChapaДокумент12 страницWSS-M1A346-A - Calidad de ChapaDANIEL DIAZОценок пока нет

- VW 50019 PDFДокумент4 страницыVW 50019 PDFSujay Nahalde100% (1)

- Geomet 500 PDFДокумент2 страницыGeomet 500 PDFKaran Chadha100% (1)

- Data Sheet HV-HR ItДокумент3 страницыData Sheet HV-HR ItKemo TufoОценок пока нет

- GUIA DE MATERIALES ACEROДокумент11 страницGUIA DE MATERIALES ACEROGracielaОценок пока нет

- ASTM A563 - Portland BoltДокумент5 страницASTM A563 - Portland BoltamrОценок пока нет

- M6x1.0x23 Long HHS Control PlanДокумент2 страницыM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsОценок пока нет

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgДокумент9 страницFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresОценок пока нет

- Effect of Boron PDFДокумент8 страницEffect of Boron PDFKishan krОценок пока нет

- Hexalubulour BoltДокумент20 страницHexalubulour BoltMitesh MakvanaОценок пока нет

- Harmonized "Cluster" Document: Fasteners Property Classes of Special ServiceДокумент7 страницHarmonized "Cluster" Document: Fasteners Property Classes of Special ServiceIBRОценок пока нет

- Corrosion Testing and MeasurementsДокумент9 страницCorrosion Testing and MeasurementsVaish NaviОценок пока нет

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Документ13 страницNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresОценок пока нет

- VW01155 en 2005-02-01Документ8 страницVW01155 en 2005-02-01koalaboi0% (1)

- GMW 14057Документ10 страницGMW 14057JOECOOL67Оценок пока нет

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedДокумент7 страницAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzОценок пока нет

- CS-11000Документ17 страницCS-11000Engenharia APedro100% (1)

- FastenerДокумент46 страницFastenerTechproОценок пока нет

- Mpaps G-20Документ6 страницMpaps G-20PANKAJ CHAUHANОценок пока нет

- Complete Immersion Phosphating LineДокумент8 страницComplete Immersion Phosphating LineStay AwayОценок пока нет

- DBL 4023 2012-08Документ7 страницDBL 4023 2012-08Fernando MartínОценок пока нет

- 2430 & TB2448 ComarisionДокумент6 страниц2430 & TB2448 ComarisionpiyushОценок пока нет

- Material Specification: Specification: Revision Date: Revision LevelДокумент2 страницыMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- BMW GS 90010-1 2020-01 EN (Metallic Coatings and Inorganic Coating Systems)Документ12 страницBMW GS 90010-1 2020-01 EN (Metallic Coatings and Inorganic Coating Systems)Adrian Graciano100% (2)

- GM500M - September 2010Документ8 страницGM500M - September 2010JOVANY LOPEZОценок пока нет

- Hammer Drive ScrewДокумент1 страницаHammer Drive ScrewNisa BN QAОценок пока нет

- Fabory Fasteners Basic StandardsДокумент12 страницFabory Fasteners Basic Standardsjuan carlos galvez abantoОценок пока нет

- 2370 Ed1 ENДокумент5 страниц2370 Ed1 ENanhthoОценок пока нет

- Jed-257 008 en LДокумент4 страницыJed-257 008 en LcroplaninecОценок пока нет

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Документ5 страницTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺Оценок пока нет

- TSB1503G 9 P 1Документ18 страницTSB1503G 9 P 1kk_pammu_915176926Оценок пока нет

- Hes B008-03 Hexagon NutsДокумент5 страницHes B008-03 Hexagon NutsPreetam KumarОценок пока нет

- AQL 2.5 acceptance sampling tableДокумент3 страницыAQL 2.5 acceptance sampling tableJahidul IslamОценок пока нет

- Silicon Nitride Bearing Balls: Standard Specification ForДокумент8 страницSilicon Nitride Bearing Balls: Standard Specification ForkrutikОценок пока нет

- BMS 0000147Документ15 страницBMS 0000147方綵樺Оценок пока нет

- WSS M1P94 AДокумент9 страницWSS M1P94 AAleks SenaОценок пока нет

- Automotive Gray Iron Castings: Standard Specification ForДокумент5 страницAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezОценок пока нет

- 521+technical Data Sheet V-6Документ2 страницы521+technical Data Sheet V-6TeenTeen GaMingОценок пока нет

- Sae J82-2013Документ6 страницSae J82-2013Marcos RosenbergОценок пока нет

- VW 011 03Документ22 страницыVW 011 03Alexandre UrquizaОценок пока нет

- Iso 9717 2010 en FR - PDF Phosphate CoatingДокумент11 страницIso 9717 2010 en FR - PDF Phosphate CoatingGANESH AОценок пока нет

- M 3031 (2013-06)Документ16 страницM 3031 (2013-06)Hatada FelipeОценок пока нет

- TSH7702GДокумент8 страницTSH7702GEmir AkçayОценок пока нет

- AluminizedДокумент4 страницыAluminizedmarkengineerОценок пока нет

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetДокумент6 страницCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITОценок пока нет

- AdvancesДокумент20 страницAdvancesZeeshan MohamedОценок пока нет

- Tennant 1550 Parts ManualДокумент528 страницTennant 1550 Parts ManualUmar ShamsudinОценок пока нет

- Astm B555-86 (2018)Документ5 страницAstm B555-86 (2018)Reshan Viduranga100% (1)

- TL 233, 11-2010, enДокумент8 страницTL 233, 11-2010, enMiguel QueirosОценок пока нет

- Zn-Ni coating passivation steel corrosion protectionДокумент5 страницZn-Ni coating passivation steel corrosion protectionPaulo Henrique NascimentoОценок пока нет

- TL - 260 - en 2015Документ11 страницTL - 260 - en 2015hand42100% (1)

- TM-0010F-M Rev 3 Non-Electrodeposited Zinc Flake CoatingsДокумент8 страницTM-0010F-M Rev 3 Non-Electrodeposited Zinc Flake Coatings方綵樺Оценок пока нет

- TL 260 Engl 20040501 PDFДокумент4 страницыTL 260 Engl 20040501 PDFAniruddha HawalОценок пока нет

- TL 162 en 2017Документ5 страницTL 162 en 2017Michal BílekОценок пока нет

- Aalco Metals LTD Stainless Steel S34700 347 270Документ1 страницаAalco Metals LTD Stainless Steel S34700 347 270Elliott RussellОценок пока нет

- Norsok ExtractДокумент2 страницыNorsok ExtractElliott RussellОценок пока нет

- Ansi b18.2.3.7m Hex BoltsДокумент2 страницыAnsi b18.2.3.7m Hex BoltsElliott RussellОценок пока нет

- SCF1 Fastener CoatingДокумент1 страницаSCF1 Fastener CoatingElliott RussellОценок пока нет

- BMW E90 Computer ArchitectureДокумент41 страницаBMW E90 Computer Architecturekrrakesh5Оценок пока нет

- Din 472Документ12 страницDin 472Elliott RussellОценок пока нет

- Is 2393 2010Документ11 страницIs 2393 2010Elliott RussellОценок пока нет

- 31003Документ4 страницы31003Elliott RussellОценок пока нет

- MILACRON OPERATING MANUAL (Rexonavn - Com)Документ405 страницMILACRON OPERATING MANUAL (Rexonavn - Com)Cempeireng Iyalah100% (3)

- Yokota MhiДокумент35 страницYokota MhiElliott Russell100% (1)

- Hiduron 191 BrochureДокумент8 страницHiduron 191 BrochureElliott RussellОценок пока нет

- S31803Документ2 страницыS31803Elliott RussellОценок пока нет

- Din 472Документ12 страницDin 472Elliott RussellОценок пока нет

- Ti 6al 4V PropertiesДокумент4 страницыTi 6al 4V Propertiesadibhardwaj18100% (1)

- Checkcontrol BMWДокумент28 страницCheckcontrol BMWfmazevedo2011100% (6)

- Langley Ferralium 255 UNS 32550 SpecificationДокумент4 страницыLangley Ferralium 255 UNS 32550 SpecificationellisforheroesОценок пока нет

- ANSI B18.3 ExtractДокумент2 страницыANSI B18.3 ExtractElliott RussellОценок пока нет

- Parts Manual PDFДокумент19 страницParts Manual PDFDavid Gaytán SmithОценок пока нет

- Kiseka Ivan Project ReportДокумент29 страницKiseka Ivan Project ReportOtim geoffrey okotОценок пока нет

- Air Compressor Script AUX MACHДокумент5 страницAir Compressor Script AUX MACHRalph Jay M. TaladroОценок пока нет

- Addition of Naoh To Water: Sodium Hydroxide Pellets AreДокумент38 страницAddition of Naoh To Water: Sodium Hydroxide Pellets ArePatriceОценок пока нет

- API Catalogue ListДокумент10 страницAPI Catalogue ListTayyab Iftikhar100% (1)

- Solution of Sheet 2 ICEДокумент10 страницSolution of Sheet 2 ICEMahmoud NaderОценок пока нет

- TBG 632 Limit Values List PDFДокумент23 страницыTBG 632 Limit Values List PDFRaul MontoyaОценок пока нет

- 02 EngineДокумент17 страниц02 EngineSantosa NagoyaОценок пока нет

- 4082 ArticleText 20334 1 10 20210105Документ15 страниц4082 ArticleText 20334 1 10 20210105AxBDОценок пока нет

- 6th Grade Science QuizДокумент5 страниц6th Grade Science QuizJaqueGadinMontales100% (1)

- Fly Ash Bricks: A Sustainable Alternative to Clay BricksДокумент3 страницыFly Ash Bricks: A Sustainable Alternative to Clay Bricksbarik.biswaranjan1666Оценок пока нет

- Significant Small Ships 2006Документ60 страницSignificant Small Ships 2006nf_azevedo100% (2)

- Continental IO 520 Manual PDFДокумент96 страницContinental IO 520 Manual PDFJose100% (1)

- HHO Generator: An Experimental Study On The Effectivity of Electrolyte Solution and Number of Cells in Hydroxy ProductionДокумент51 страницаHHO Generator: An Experimental Study On The Effectivity of Electrolyte Solution and Number of Cells in Hydroxy ProductionLance Angelo100% (1)

- Not for Reproduction: en - English ar-es - Español et - Eesti keel fr - Français ru - Pусский sw - KiswahiliДокумент52 страницыNot for Reproduction: en - English ar-es - Español et - Eesti keel fr - Français ru - Pусский sw - KiswahilifosterОценок пока нет

- CPL PlogДокумент2 страницыCPL PlogJacob KnightОценок пока нет

- Eco Mapping Env 2Документ20 страницEco Mapping Env 2Ricardo CabreraОценок пока нет

- 2013 Australian Mine Ventilation Conference HalimДокумент7 страниц2013 Australian Mine Ventilation Conference HalimDiegoОценок пока нет

- Reading Pump Curves: by James Mcdonald, Pe, CWT Originally Published CSTN - September/October 2004Документ3 страницыReading Pump Curves: by James Mcdonald, Pe, CWT Originally Published CSTN - September/October 2004kirmaniОценок пока нет

- Design and Fabrication of Red Skin Removing MachineДокумент32 страницыDesign and Fabrication of Red Skin Removing MachineSathiya UdumalpetОценок пока нет

- 416C Backhoe Loader Pump OperationДокумент10 страниц416C Backhoe Loader Pump OperationLeandro SalОценок пока нет

- Motordatenblatt IVECO F32SM1A - enДокумент3 страницыMotordatenblatt IVECO F32SM1A - enGoran AnakioskiОценок пока нет

- CPCB Industry Standards Effluent EmissionДокумент2 страницыCPCB Industry Standards Effluent EmissionVaishnavi JayakumarОценок пока нет

- Mazda MPV Service HighlightsДокумент324 страницыMazda MPV Service HighlightsWen Ma100% (1)

- Anp Oil, Natural Gas and Biofuels Statistical Yearbook 2013Документ65 страницAnp Oil, Natural Gas and Biofuels Statistical Yearbook 2013Hayden VanОценок пока нет

- Fuel Storage Tanks As Per NFPA 11Документ1 страницаFuel Storage Tanks As Per NFPA 11Adil MominОценок пока нет

- Balaa Pdms CVДокумент4 страницыBalaa Pdms CVnmraman6224Оценок пока нет

- Sample Sundowner 30 Trawler SurveyДокумент20 страницSample Sundowner 30 Trawler SurveyTihomir MarkovicОценок пока нет

- Irs 1041 FormДокумент4 страницыIrs 1041 FormcaliechОценок пока нет

- Osb 613 e IiДокумент180 страницOsb 613 e Iidanish khanОценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationОт EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationРейтинг: 4 из 5 звезд4/5 (18)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (50)

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionОт EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionРейтинг: 2.5 из 5 звезд2.5/5 (3)

- Handbook of Mechanical and Materials EngineeringОт EverandHandbook of Mechanical and Materials EngineeringРейтинг: 5 из 5 звезд5/5 (4)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationОт EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationРейтинг: 1 из 5 звезд1/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsОт EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsОценок пока нет

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastОт EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastРейтинг: 4 из 5 звезд4/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Operational Amplifier Circuits: Analysis and DesignОт EverandOperational Amplifier Circuits: Analysis and DesignРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeОт EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeРейтинг: 3.5 из 5 звезд3.5/5 (4)

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansОт EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerРейтинг: 4 из 5 звезд4/5 (1)