Академический Документы

Профессиональный Документы

Культура Документы

1q07 Beat Freq Back To Basics

Загружено:

Hatem AbdelrahmanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1q07 Beat Freq Back To Basics

Загружено:

Hatem AbdelrahmanАвторское право:

Доступные форматы

BACK TO BASICS

Beat Frequencies

Beating occurs when there are two dynamic excitation sources (forces) very close together in frequency and a pathway allowing the two excitation forces to transfer to one another. The so-called beating effect results because the frequencies are so close to one another that the waveforms alternately reinforce one another at some times and cancel one another at other times. During times when the vibration from each source adds constructively, the vibration increases; during times when the vibration adds destructively, the vibration decreases. An example of this occurred when the author was diagnosing two condensate pumps (Figure 1), located side by side and running at almost exactly the same rotational speeds. The prime movers for the pumps were induction motors where slight differences in speed will always be present as a function of how much slip occurs under varying load conditions. The residual unbalance in the pumps gave rise to fairly large excitation forces. Also, the piping and mounting details provided the necessary mechanical transmission path for the vibration from each pump to affect the other. Figure 2 shows the resulting vibration trend when both pumps were running simultaneously. Note that at the tail end of Figure 2, when the second pump had been stopped, the beat effect ceased and the vibration consequently assumed a stable trend. Another machine type in which beating can be common is the centrifuge (Figure 3), where the bowl and screw rotate with slightly different speeds. When sufficiently large excitation forces exist, which is often the case with centrifuges due to build-up of material and subsequent unbalance, beating can occur. The beat frequency may arise from either the differences in speed between the bowl and the screw, or between the rotating fluid and the bowl. Figure 1 Side-by-side condensate pumps. Piping and mounting details allowed vibration from one pump to signicantly affect the other, particularly when the residual unbalance forces were high.

Arthit Phuttipongsit Principal Engineer Machinery Diagnostics GE Energy Thailand arthit.phuttipongsit@ge.com

6 2 O R B I T Vo l.27 N o.1 2007

BACK TO BASICS

Figure 2 Amplitude modulation on condensate pump of Figure 2, arising due to beating effect. Note that vibration trend becomes steady at the tail end of the plot, after the second pump has been turned off.

Figure 3 Cross-sectional view of centrifuge machine showing two main rotating parts (bowl and screw) with slightly different in speed (image courtesy of TEMA/Seibtechnik).

Vo l . 27 N o. 1 2007 ORB I T 63

BACK TO BASICS

To ascertain whether beating frequencies are present, the simplest method is the use of a high-resolution spectrum plot, as shown in Figure 4. Clearly, the sampling frequency must be chosen to give sufficient resolution between spectral components and prevent so-called spectral smearing from occurring. For the example of Figure 4, the data was collected from a centrifuge and the two frequencies differ by 38 rpm as can be noted by the amplitude/speed labels at the top of the two predominant spectral peaks. Because the resolution has been set for 7.5 cpm (0.125 Hz), it can easily distinguish between these two spectral components which are 38 rpm apart. However, had the frequencies been closer together (such as 1 or 2 rpm apart), a spectral resolution of 0.016 Hz or better would have been required.

When performing field or shop balancing on machines in which a beat effect is present, it is likewise important to configure instrumentation with suitably sharp filter roll-off so that only the spectral component of exact running speed (1X) will be present and all other frequencies will be filtered out. Otherwise, the phase and amplitude readings will be distorted by the adjacent beat frequency spectral component, making balance measurements and results erratic.

Figure 4 Spectrum showing two frequencies very close to one another (38 rpm apart). The beat frequency is the difference between these two frequencies; in this case 38 rpm or 0.63 Hz.

6 4 O R B I T Vo l.27 N o.1 2007

Вам также может понравиться

- Practical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetДокумент2 страницыPractical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetHatem AbdelrahmanОценок пока нет

- Understandingamp - Phaseinrotatingmachineryvibinst 07 20pgsДокумент20 страницUnderstandingamp - Phaseinrotatingmachineryvibinst 07 20pgsHatem Abdelrahman100% (1)

- Field Balancing Large Rotating MachineryДокумент26 страницField Balancing Large Rotating MachineryShantanu SamajdarОценок пока нет

- The Magnetic Center Finding Using Vibrating Wire TechniqueДокумент6 страницThe Magnetic Center Finding Using Vibrating Wire TechniqueHatem AbdelrahmanОценок пока нет

- WEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishДокумент40 страницWEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishHatem AbdelrahmanОценок пока нет

- Dynamic Stresses Hydro Power Plant RKAggarwalДокумент22 страницыDynamic Stresses Hydro Power Plant RKAggarwalDheeraj DhimanОценок пока нет

- 19 KKKKKKKKKKKKKKKKKKДокумент4 страницы19 KKKKKKKKKKKKKKKKKKHatem Abdelrahman100% (1)

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYДокумент46 страницEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- Kingsbury Leg ComponentsДокумент3 страницыKingsbury Leg ComponentsHatem Abdelrahman100% (1)

- Huang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDДокумент130 страницHuang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDHatem AbdelrahmanОценок пока нет

- Fault Zone - : Air GapДокумент0 страницFault Zone - : Air GapHatem AbdelrahmanОценок пока нет

- Prec Maint March 2007Документ9 страницPrec Maint March 2007Hatem AbdelrahmanОценок пока нет

- Article 6hy JytjuytДокумент7 страницArticle 6hy JytjuytHatem AbdelrahmanОценок пока нет

- Gei 100351Документ32 страницыGei 100351Hatem Abdelrahman100% (1)

- Icmtech435435 345435 43543Документ63 страницыIcmtech435435 345435 43543Hatem Abdelrahman100% (1)

- Article 6hy JytjuytДокумент7 страницArticle 6hy JytjuytHatem AbdelrahmanОценок пока нет

- V106 Relative Motion Record FormДокумент0 страницV106 Relative Motion Record FormHatem Abdelrahman100% (1)

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYДокумент46 страницEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- Don't Get Soft: Cover Series: Installation Best PracticesДокумент6 страницDon't Get Soft: Cover Series: Installation Best PracticesHatem Abdelrahman100% (1)

- Best Practices: Asset Condition ManagementДокумент2 страницыBest Practices: Asset Condition ManagementHatem AbdelrahmanОценок пока нет

- Customer Application Centers: Global Accessibility To Our TechnologyДокумент1 страницаCustomer Application Centers: Global Accessibility To Our TechnologyHatem AbdelrahmanОценок пока нет

- Vibrations NotesДокумент43 страницыVibrations NotesNicolas LuchmunОценок пока нет

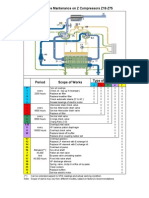

- Preventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsДокумент1 страницаPreventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsHatem AbdelrahmanОценок пока нет

- Ontario Power Generation's Nanticoke Power PlantДокумент3 страницыOntario Power Generation's Nanticoke Power PlantHatem AbdelrahmanОценок пока нет

- 2 Q 01 HanifanДокумент2 страницы2 Q 01 HanifanHatem AbdelrahmanОценок пока нет

- IBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsДокумент4 страницыIBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsHatem AbdelrahmanОценок пока нет

- Why Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsДокумент2 страницыWhy Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsHatem AbdelrahmanОценок пока нет

- 1q03 3500 22mДокумент4 страницы1q03 3500 22mscribdkhatnОценок пока нет

- Helping You ... : Fourth Quarter 1999 Vol. 20 No. 4Документ1 страницаHelping You ... : Fourth Quarter 1999 Vol. 20 No. 4Hatem AbdelrahmanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Lecture Notes On Medium Access ControlДокумент41 страницаLecture Notes On Medium Access ControlRohit BhardwajОценок пока нет

- 4N35 OptocouplersДокумент7 страниц4N35 OptocouplersattapapaОценок пока нет

- v1 0415 Triominos RulesДокумент2 страницыv1 0415 Triominos RulesCIGAMF0% (1)

- Air Cleaner Spec & Tech DataДокумент4 страницыAir Cleaner Spec & Tech DataainОценок пока нет

- The Basics of Insulation TestingДокумент6 страницThe Basics of Insulation TestingbhpОценок пока нет

- USB Fast Charging ModuleДокумент2 страницыUSB Fast Charging ModuleFuture is Now Amazing World VideosОценок пока нет

- Harmonic Source IdentificationДокумент8 страницHarmonic Source IdentificationMuhammad Syukri100% (1)

- Design and Development of An Infant Incubator Pic ControllerДокумент8 страницDesign and Development of An Infant Incubator Pic ControllerAhmedSaadОценок пока нет

- Satexpander Demodulator User Guide v4 2 PDFДокумент116 страницSatexpander Demodulator User Guide v4 2 PDFdhiewardОценок пока нет

- CG 818 ManualДокумент44 страницыCG 818 ManualVictor Javelosa Azuelo Jr.40% (5)

- Actaris SL 7000 ManualДокумент2 страницыActaris SL 7000 ManualNoorAhmad50% (2)

- Sony 46hx800 SettingsДокумент10 страницSony 46hx800 SettingsAnand RamineniОценок пока нет

- Enhanced Initialization Method For LBG Codebook Design Algorithm in Vector Quantization of ImagesДокумент4 страницыEnhanced Initialization Method For LBG Codebook Design Algorithm in Vector Quantization of ImagesphucAOneОценок пока нет

- Pivotell Advance GSM Instruction Book 130418Документ16 страницPivotell Advance GSM Instruction Book 130418Eira HammondОценок пока нет

- Face Detection SystemДокумент2 страницыFace Detection SystemWagner Quezada IparraguirreОценок пока нет

- Exp 11 Voltage Regulator Using IC 723Документ5 страницExp 11 Voltage Regulator Using IC 723Savio Pereira67% (3)

- PriceList User QSemarangДокумент1 страницаPriceList User QSemarang78858799Оценок пока нет

- Class 12 Physics Derivation From All LessonДокумент1 страницаClass 12 Physics Derivation From All LessonAnsuman PadhiОценок пока нет

- Final Report Smart StreetlightingДокумент22 страницыFinal Report Smart StreetlightingpaulkorirОценок пока нет

- Ltn141at13 001Документ30 страницLtn141at13 001andymustopaОценок пока нет

- Alcatel One Touch 535 735 User ManualДокумент49 страницAlcatel One Touch 535 735 User ManualEdgar Jose Aranguibel MorilloОценок пока нет

- Adaptoare AudioДокумент5 страницAdaptoare AudiostelianlazaroiuОценок пока нет

- Conductive Surface Layer On Wind Turbine Blade As PDFДокумент6 страницConductive Surface Layer On Wind Turbine Blade As PDFMICHEL RAJОценок пока нет

- Unit 25 Selecting and Using Programmable Controllers PDFДокумент12 страницUnit 25 Selecting and Using Programmable Controllers PDFahmed357Оценок пока нет

- ESE 570: Digital Integrated Circuits and VLSI Fundamentals: Lec 1: January 12, 2017 Introduction and OverviewДокумент42 страницыESE 570: Digital Integrated Circuits and VLSI Fundamentals: Lec 1: January 12, 2017 Introduction and OverviewRavi PeramОценок пока нет

- Diagram AДокумент1 страницаDiagram AAndrés Núñez SilvaОценок пока нет

- Microsoft Word - What Is An LEDДокумент2 страницыMicrosoft Word - What Is An LEDprasoon1234Оценок пока нет

- Industrial Plugs and SocketsДокумент20 страницIndustrial Plugs and Socketsrajinikanth19Оценок пока нет

- Ineo 360 - Brochure - Eng - FinДокумент8 страницIneo 360 - Brochure - Eng - FinAnonymous WD109UakyОценок пока нет