Академический Документы

Профессиональный Документы

Культура Документы

Eko4000-4100 Web

Загружено:

Subramanian SaravananИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Eko4000-4100 Web

Загружено:

Subramanian SaravananАвторское право:

Доступные форматы

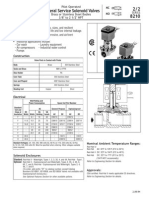

eko4000 & eko4100 PN16 & PN40 FLANGED GLOBE VALVE

GENERAL FEATURES

eko4000 refers to PN16 Cast Iron Globe Valve DESIGN STANDARDS eko4100 refers to PN40 Cast Steel Globe Valve Valve Design EN 13789 Body & Bonnet: EN GJL 250 Cast Iron Wafer, acc to Connection Stem: Stainless Steel EN 1092-2 Disc: Up to DN 50: Fully Stainless Steel Face to Face EN 558-1 F1 Dimensions Greater than DN 65: Steel with Stainless Steel Ring Valve Test EN 12266-1 Liquid epoxy paint on outer surface Marking EN 19 Oblique body structure Metal-Metal application Rising Stem TECHNICAL ADVANTAGES Metal-metal applications are suitable especially for high temperatures (Steam etc.) FAF 4000 Globe valve is excellent choice for avoiding water-hammers and reducingadjustment purposes. Suitable for controlling flow, stopping and starting flow & frequent valve operation REMARKS From DN 65 to 200, the discs can also be supplied in stainless steel fully upon customer request

www.ekoval.com

eko4000 & eko4100 PN16 & PN40 FLANGED GLOBE VALVE

DIMENSIONS AND PRODUCT DATA (eko4000)

PARTS AND MATERIALS

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Part Name Body Seat Disc Pin Gasket Packing Compression Nut Bonnet Brass Nut Stem Handwheel Nut Washer Bolt Nut Set Screw Material GG 25 Cast Iron SAE 420 SS 304 Stainless Steel Graphite Graphite GG 25 Cast Iron GG 25 Cast Iron MS58 Brass Stainless Steel SAE 304 GG 25 Cast Iron DIN 934 DIN 127 DIN 933 DIN 914

DIMENSION TABLE (PN16 GLOBE VALVE)

DN mm 15 20 25 32 40 50 65 80 100 125 150 200 TS 10873 / EN 558-1 DIMENSIONS H 160 175 185 230 235 265 300 355 365 435 495 570 H1 180 190 210 255 260 290 340 400 415 490 550 660 L 130 150 160 180 200 230 290 310 350 400 480 600 d 15 20 25 32 40 50 65 80 100 125 150 200 CONNECTIONS ISO 7005-2 / EN 1092 - 2 D 95 105 115 140 150 165 185 200 220 250 285 340 k 65 75 85 100 110 125 145 160 180 210 240 295 g 46 56 65 76 84 99 118 132 156 184 211 266 f 2 2 3 3 3 3 3 3 3 3 3 3 b 14 16 16 18 18 20 20 22 24 26 26 30 I 14 14 14 19 19 19 19 19 19 19 23 23 Number of Holes 4 4 4 4 4 4 4 8 8 8 8 12 PRODUCT DATA KV m3/h 5 8 11 18 28 46.3 72 126 170 267 380 683 Weight (Kg) 3.6 4.9 5.2 7.5 9.5 12 23.5 28 36 61 88 129

www.ekoval.com

DIMENSIONS AND PRODUCT DATA (eko4100 PN40 GLOBE VALVE)

PARTS AND MATERIALS

No. 1 2 3 4 5 Part Name Body Disc Stem Wedge Disc Sealing Face Seat Ring Sealing Face Material GS-C25 (Cast Steel) GS-C25 (Cast Steel) 13%Cr. 13%Cr. 13%Cr.

DIMENSION TABLE (PN40 GLOBE VALVE)

Pressure (MPa) Size 15 20 25 32 40 50 65 PN4.0 Mpa 80 100 125 150 200 250 300 350 400 L 130 150 160 180 200 230 290 310 350 400 480 600 730 850 980 1100 H 240 260 276 285 300 325 370 430 480 532 589 783 888 965 1285 1512 W 120 140 160 160 180 200 200 250 300 350 400 450 500 550 600 600 Weight (Kg) 6 7.5 8 9 15 24 30 41 60 85 110 225 460 670 830 1120

eko4000 & eko4100 PN16 & PN40 FLANGED GLOBE VALVE

GENERAL INSTRUCTIONS AND INSTALLATION

Handle valve with precaution Take care of the coatings and protections. Do not drag the valves, avoid shocks and frictions which may cause starters of corrosion. Store the equi pment under good conditions The valves must be protected from; Humidity and rain to avoid corrosion; Wind, sand: to avoid the penetration of sold particles whose presense is catastrophic for the tightness; Sunshine and heat; they damage the coatings, particularly harmful for plastic valves and fittings very sensitive to the ultraviolet. Valves with rubber seat must always be stored half-opened. The aparatuses with metal seat must be stored closed (except particular specifications) to avoid the penetration of the particles in internal volumes. Ball valves must be stored in open position. Preserve the aparatuses with their plastic caps which should be taken away when mounting the valves. Clean the pi pes Rinsing the pipes is essential (water, air, steam if compatible) before testing and starting of the installations. It is critical to eliminate all the particles and several objects which could remain in the pipes and especially welding residues which could definitively damage the valve seat. Clean the gasket seat Be sure that the gasket seats are perfectly clean and free from stripes. Align pi pings Control piping alignment. For correcting bad alignments do not rely on the valves: this may cause leakage and operating defect or even of breaking. Avoide Water Hammers A rise in pressure of extreme brutality can be generated by a water hammer. A water hammer can cause the damage: butterfly valve disc splits, destroyed various aparatus, axes deformed. There are very varied causes of the water hammers but generally: the starting of pump and the sudden closing of valve. Respect assembly direction Certain valves are one-way (non-return valve, knife gate valves, etc.) Take care of an assembly in conformity with the arrow direction or of the instructions of assembly. Use support for heavy valves In certain cases, valves of large lenght, heavy servo-motor, it can be essential to provide for supports which will avoid tensions prejudicial with the operating risking the fast deterioration of the stem and of the tightness. Maintenance and control - Control the valves yearly. - Change the gaskets after each disassembling. Any maintanance action must be carried out when the installation is in the atmospheric pressure. Cut energy supply of the actuators. Respect the recommended positions of assembly. Respect the disassembling direction. In the event of prolonged storage or of weak frequency of operation, lubricate the valve stem regularly.

www.ekoval.com | *All Rights Reserved

Document No: EK1 | Revision Date & No : 30.04.2007/01

Вам также может понравиться

- Válvulas Bola SegmentadaДокумент12 страницVálvulas Bola SegmentadarehynaldoОценок пока нет

- 03 Ovalni I Pljosnati ZatvaraciДокумент4 страницы03 Ovalni I Pljosnati ZatvaracisalicurriОценок пока нет

- MasterSeries 876V Specification SheetДокумент4 страницыMasterSeries 876V Specification SheetFEBCOОценок пока нет

- MasterSeries 850 Specification SheetДокумент2 страницыMasterSeries 850 Specification SheetFEBCOОценок пока нет

- Two BallДокумент5 страницTwo Ballchartwithsam0041653Оценок пока нет

- AVT Ball & Butterfly Brochure 05 Latest 12 PageДокумент12 страницAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyОценок пока нет

- Control Choke Valve 9000Документ8 страницControl Choke Valve 9000sabi_shi100% (2)

- 'C' Series Control ValvesДокумент12 страниц'C' Series Control Valvesابزار دقیق100% (1)

- Virgo Welded Valve BrochureДокумент8 страницVirgo Welded Valve BrochureHerrera Jorge AgustínОценок пока нет

- Lead Free Series SS009 Specification SheetДокумент2 страницыLead Free Series SS009 Specification SheetWattsОценок пока нет

- Gate Valve CataogueДокумент4 страницыGate Valve CataogueAditya B. RyantoОценок пока нет

- Aloyco Stainess Steel ValvesДокумент26 страницAloyco Stainess Steel Valvescristi_molins100% (1)

- AV-C Butterfly ValveДокумент20 страницAV-C Butterfly ValveSopon SrirattanapiboonОценок пока нет

- Vctds-02233 Model 171c (Asme) - enДокумент12 страницVctds-02233 Model 171c (Asme) - enDGWОценок пока нет

- Pilot Operated Solenoid Valves for Industrial ApplicationsДокумент6 страницPilot Operated Solenoid Valves for Industrial ApplicationsMARACO46Оценок пока нет

- Series TDV Specification SheetДокумент2 страницыSeries TDV Specification SheetWattsОценок пока нет

- TYCO Keystone F14.Lined - Butterfly.valve enДокумент4 страницыTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuОценок пока нет

- Econ Gate ValvesДокумент22 страницыEcon Gate ValvesRiyas Udheen100% (1)

- Full Lift Spring Loaded Open PDFДокумент4 страницыFull Lift Spring Loaded Open PDFVenkatespatange RaoОценок пока нет

- Mech Van Catalogue PDFДокумент26 страницMech Van Catalogue PDFVan Nguyen Huu VanОценок пока нет

- Valve0114 PDFДокумент14 страницValve0114 PDFbinhjukiОценок пока нет

- Sewage Air ValveДокумент10 страницSewage Air ValveAhmed TalaatОценок пока нет

- Series 825YD Specification SheetДокумент2 страницыSeries 825YD Specification SheetFEBCOОценок пока нет

- 15 Metal Seated Butterfly ValvesДокумент8 страниц15 Metal Seated Butterfly ValvesrajfmcОценок пока нет

- Es LF919 PDFДокумент4 страницыEs LF919 PDFWattsОценок пока нет

- 11422Документ10 страниц11422balajivangaruОценок пока нет

- Catalog Pak KuntoДокумент10 страницCatalog Pak Kuntopt tabОценок пока нет

- Rotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceДокумент36 страницRotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceSaurav DasОценок пока нет

- General Service Solenoid Valves: NC NOДокумент6 страницGeneral Service Solenoid Valves: NC NOAngel Azathoth GoetzОценок пока нет

- KAT-A 2014-EA RIKO-EA Edition11 04-12-2012 ENДокумент7 страницKAT-A 2014-EA RIKO-EA Edition11 04-12-2012 ENpalanaruvaОценок пока нет

- Butterfly Valve TorqueДокумент8 страницButterfly Valve TorqueShyam KrishnanОценок пока нет

- Gate Valve Operation GuideДокумент17 страницGate Valve Operation GuidedieferjimenezОценок пока нет

- Typenreihe NE enДокумент6 страницTypenreihe NE encspivetta6095Оценок пока нет

- AUTOMAX Supernova BrochureДокумент12 страницAUTOMAX Supernova BrochureEnrique Domingo RubioОценок пока нет

- Double Block Bleed TOSVДокумент8 страницDouble Block Bleed TOSVplanet123Оценок пока нет

- Válvula DurcoДокумент12 страницVálvula DurcoJames Henrry López EspejoОценок пока нет

- D o U B L e F L A N G e D B U T T e R F L y V A L V eДокумент9 страницD o U B L e F L A N G e D B U T T e R F L y V A L V eAnonymous j3Le4n3bОценок пока нет

- AAP S18 Butterfly Valves E2 SДокумент9 страницAAP S18 Butterfly Valves E2 SPete KardumОценок пока нет

- Series 805YD Specification SheetДокумент2 страницыSeries 805YD Specification SheetFEBCOОценок пока нет

- BallValues PDFДокумент12 страницBallValues PDFDevdatt WaghuleОценок пока нет

- Rotex Rotary ActuatorДокумент20 страницRotex Rotary ActuatorMayank Talwar100% (1)

- Typical Ball Valve Material SelectionДокумент12 страницTypical Ball Valve Material SelectionabsherlockОценок пока нет

- Fisa Tehnica Pompe MultifreeДокумент10 страницFisa Tehnica Pompe MultifreeOčtáv VátčoОценок пока нет

- Series 3 & 4 U BonnetedДокумент9 страницSeries 3 & 4 U BonnetedBaskaran RathinamОценок пока нет

- Technical Bulletin: Valtek Mark One Control ValvesДокумент20 страницTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzОценок пока нет

- Toyo Butterfly Valve PDFДокумент20 страницToyo Butterfly Valve PDFJimmy Adi100% (2)

- F501e 0309 LP LH BrochureДокумент4 страницыF501e 0309 LP LH BrochureHoracio RodriguezОценок пока нет

- Silent Check Valve - Wafer and Globe Style - 2012Документ8 страницSilent Check Valve - Wafer and Globe Style - 2012james_chan2178Оценок пока нет

- Model 2100bДокумент4 страницыModel 2100bkeyur1109Оценок пока нет

- Flowserve ValvesДокумент144 страницыFlowserve ValvesRockny2011Оценок пока нет

- High-Tech Block & Bleed ValvesДокумент20 страницHigh-Tech Block & Bleed ValvesMayur PatelОценок пока нет

- Series 825Y Specification SheetДокумент2 страницыSeries 825Y Specification SheetFEBCOОценок пока нет

- Product Specifications for FOXTOP Control Valve System PSS 4-24A1 FДокумент0 страницProduct Specifications for FOXTOP Control Valve System PSS 4-24A1 Fcico_ctОценок пока нет

- Series 406NRSRW Specification SheetДокумент2 страницыSeries 406NRSRW Specification SheetWattsОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryОт EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryОценок пока нет

- Short Form of Contract General Conditions (Green) PDFДокумент16 страницShort Form of Contract General Conditions (Green) PDFgeniusganyОценок пока нет

- CP 6.4 F2 Document Revision RecordДокумент1 страницаCP 6.4 F2 Document Revision RecordSubramanian SaravananОценок пока нет

- Conversion 629060475Документ1 страницаConversion 629060475Subramanian SaravananОценок пока нет

- dc16 14Документ24 страницыdc16 14Subramanian SaravananОценок пока нет

- CP 6.4 F3 Document Disc ListДокумент1 страницаCP 6.4 F3 Document Disc ListSubramanian SaravananОценок пока нет

- CP 6.11 Project HandoverДокумент7 страницCP 6.11 Project HandoverSubramanian Saravanan100% (1)

- CP 6.4 F4 Drawing RegisterДокумент2 страницыCP 6.4 F4 Drawing RegisterSubramanian Saravanan100% (1)

- Appendix B Project Completion ReportДокумент16 страницAppendix B Project Completion ReportSubramanian Saravanan100% (1)

- dc16 14Документ24 страницыdc16 14Subramanian SaravananОценок пока нет

- Form 中国港湾(新加坡)工程有限公司: China Harbour (Singapore) Engineering Company Pte LtdДокумент1 страницаForm 中国港湾(新加坡)工程有限公司: China Harbour (Singapore) Engineering Company Pte LtdSubramanian SaravananОценок пока нет

- dc16 14Документ24 страницыdc16 14Subramanian SaravananОценок пока нет

- Appendix A Proforma of Method StatementДокумент6 страницAppendix A Proforma of Method StatementSubramanian SaravananОценок пока нет

- JANUARY 2020: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayДокумент20 страницJANUARY 2020: Sunday Monday Tuesday Wednesday Thursday Friday SaturdaySubramanian SaravananОценок пока нет

- China Harbour Singapore Subcontracting ScheduleДокумент2 страницыChina Harbour Singapore Subcontracting ScheduleSubramanian SaravananОценок пока нет

- Appendix A Proforma of Method StatementДокумент6 страницAppendix A Proforma of Method StatementSubramanian SaravananОценок пока нет

- WNS00 PP PC 0001Документ11 страницWNS00 PP PC 0001Subramanian Saravanan100% (1)

- Pre-Commencement Meeting AgendaДокумент2 страницыPre-Commencement Meeting AgendaSubramanian SaravananОценок пока нет

- China Harbour Singapore Subcontracting ScheduleДокумент2 страницыChina Harbour Singapore Subcontracting ScheduleSubramanian SaravananОценок пока нет

- Appendix A Proforma of Method StatementДокумент6 страницAppendix A Proforma of Method StatementSubramanian SaravananОценок пока нет

- Form 中国港湾(新加坡)工程有限公司: China Harbour (Singapore) Engineering Company Pte LtdДокумент1 страницаForm 中国港湾(新加坡)工程有限公司: China Harbour (Singapore) Engineering Company Pte LtdSubramanian SaravananОценок пока нет

- C2B - Response Log - Baseline Programme For The Works Rev.2Документ112 страницC2B - Response Log - Baseline Programme For The Works Rev.2Subramanian SaravananОценок пока нет

- C2B Comments Sheet - Submittal 000039-1Документ2 страницыC2B Comments Sheet - Submittal 000039-1Subramanian SaravananОценок пока нет

- 2014 P6 Tamil-HMT SA1 CombinedДокумент178 страниц2014 P6 Tamil-HMT SA1 CombinedSubramanian SaravananОценок пока нет

- 2014 P6 Tamil-HMT SA1 CombinedДокумент178 страниц2014 P6 Tamil-HMT SA1 CombinedSubramanian SaravananОценок пока нет

- Ook Nswers: Grammar Rules! Answers Book 2Документ5 страницOok Nswers: Grammar Rules! Answers Book 2Subramanian Saravanan100% (1)

- Ook Nswers: Grammar Rules! Answers Book 6Документ6 страницOok Nswers: Grammar Rules! Answers Book 6Subramanian SaravananОценок пока нет

- 2015 P6 Tamil SA2 CombinedДокумент281 страница2015 P6 Tamil SA2 CombinedSubramanian SaravananОценок пока нет

- Ook Nswers: Grammar Rules! Answers Book 6Документ6 страницOok Nswers: Grammar Rules! Answers Book 6Subramanian SaravananОценок пока нет

- Project Controls Audit Check List PDFДокумент1 страницаProject Controls Audit Check List PDFSubramanian SaravananОценок пока нет

- Project Cost Forecasting ChecklistДокумент3 страницыProject Cost Forecasting ChecklistSubramanian SaravananОценок пока нет

- Delivery Line Systems Eng PDFДокумент24 страницыDelivery Line Systems Eng PDFTimothy Mcmillan0% (1)

- Catálogo General Medidor para Agua WoltmanДокумент8 страницCatálogo General Medidor para Agua WoltmanLuis David LopezОценок пока нет

- Guidelines For EwaterДокумент6 страницGuidelines For EwaterRhey CostalesОценок пока нет

- Wadena Closed LandfillДокумент4 страницыWadena Closed LandfillNathan BoweОценок пока нет

- CLASS 31451: DEP 31.38.01.15-Gen Class 31451, Rev. G Page 1 of 13Документ13 страницCLASS 31451: DEP 31.38.01.15-Gen Class 31451, Rev. G Page 1 of 13SaguesoОценок пока нет

- Types of Flanges-Definition of FlangesДокумент4 страницыTypes of Flanges-Definition of FlangesindikumaОценок пока нет

- Orange County Utilities Standards ManualДокумент3 страницыOrange County Utilities Standards ManualAssetОценок пока нет

- Broshure CromaglassДокумент12 страницBroshure CromaglassMarthy Bastet100% (2)

- Sewerage: Marie Raphelle T. DeloriaДокумент11 страницSewerage: Marie Raphelle T. DeloriaKyLa CeriaLes ÜОценок пока нет

- Sewage Disposal 19 03 17Документ6 страницSewage Disposal 19 03 17Vikash ChoudharyОценок пока нет

- 50MLD Materials Price QuotationДокумент5 страниц50MLD Materials Price QuotationjungzkiОценок пока нет

- Sanitary Report AshenfiДокумент10 страницSanitary Report AshenfiJaspergroup 15Оценок пока нет

- Pmi Louis Proserv 3Документ6 страницPmi Louis Proserv 3Ebit TrisnoОценок пока нет

- Monterrey VI Project1Документ7 страницMonterrey VI Project1Alexander BaishОценок пока нет

- Tech Spe FireДокумент11 страницTech Spe FireChristopher BrownОценок пока нет

- Automatic Water Flow ControlДокумент18 страницAutomatic Water Flow ControlssgjmlimОценок пока нет

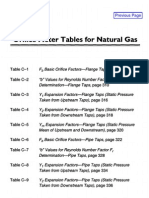

- Orifice Meter TablesДокумент35 страницOrifice Meter TablesilublessingОценок пока нет

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsДокумент4 страницыKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniОценок пока нет

- Jackson Water OrderДокумент1 страницаJackson Water Orderthe kingfishОценок пока нет

- Islam BarrageДокумент25 страницIslam BarrageAsad KareemОценок пока нет

- Vertical Split Case Pump: Key Features and BenefitsДокумент2 страницыVertical Split Case Pump: Key Features and BenefitsTimОценок пока нет

- Orifice Intake Design DetailsДокумент2 страницыOrifice Intake Design Detailsujjwal sapkotaОценок пока нет

- Installation of Electrical Equipment, and Building Electrical SystemsДокумент5 страницInstallation of Electrical Equipment, and Building Electrical SystemssitheeqОценок пока нет

- The Affinity Laws of Centrifugal PumpsДокумент8 страницThe Affinity Laws of Centrifugal PumpsArunkumar SubramanianОценок пока нет

- Bomba C101-C102 PDFДокумент2 страницыBomba C101-C102 PDFJuan Carlos Bermudez CardenasОценок пока нет

- DIY Outdoor ShowerДокумент10 страницDIY Outdoor ShowerDejan RancicОценок пока нет

- Water Supply DesignДокумент13 страницWater Supply DesignF Fahim KhanОценок пока нет

- Maspion PVC Pipe and FittingДокумент6 страницMaspion PVC Pipe and FittingValentVeeОценок пока нет

- Combined & Separate Sewer SystemsДокумент9 страницCombined & Separate Sewer SystemsKhairylle JuanОценок пока нет

- Attached Growth SystemДокумент42 страницыAttached Growth SystemRiyad ArafatОценок пока нет