Академический Документы

Профессиональный Документы

Культура Документы

13

Загружено:

daviko313Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

13

Загружено:

daviko313Авторское право:

Доступные форматы

BUILDING NO. PROJECT NAME SECTION 412213.

13 BRIDGE CRANES

SC#

PART 1 - GENERAL

SCHEDULE 0 - SUMMARY PRODUCT DATA SHEET 0 - Related Documents: 0.1 Drawings and general provisions of the Subcontract apply to this Section. 0.2 Review these documents for coordination with additional requirements and information that apply to work under this Section. PRODUCT DATA SHEET 1 - Section Includes: 1.1 The Subcontractor shall provide all materials, labor, equipment, and services required to install a 15-ton top riding double bridge crane system at Building 51. The crane system shall include bridge, trolley, hoist, power and control circuit conductors, safety and control mechanisms, and all other parts and services as defined in this specification. The crane system shall be installed on the runway girders provided by the University in Building 51 Room 8. In addition to material and equipment specified, the Subcontractor shall provide incidental materials to effect a complete installation. PRODUCT DATA SHEET 2 - Related Sections: 2.1 Division 01 Section "General Requirements." 2.2 Division 01 Section "Special Procedures." 2.3 Division 01 Section "Lateral Force Procedures". 2.4 Division 05 Section "Structural Steel Framing." 2.5 Division 05 Section "Metal Fabrications". 2.6 Division 21 Section "Identification for Fire-Suppression Piping and Equipment". 2.7 Division 22 Section "Identification for Plumbing Piping and Equipment". 2.8 Division 23 Section "Identification for HVAC Piping and Equipment". 2.9 Sections in Division 26. PRODUCT DATA SHEET 3 - Related Work not Included in This Section: 3.1 The building structure complete, up to and including the runway girders provided by the University on which the crane shall run.

SCHEDULE 1 - REFERENCES PRODUCT DATA SHEET 0 - General: 0.1 The following documents form part of the Specifications to the extent stated. Where differences exist between codes and standards, the one affording the greatest protection shall apply. 0.2 Unless otherwise noted, the referenced standard edition is the current one at the time of commencement of the Work. 0.3 Refer to Division 01 Section "General Requirements" for the list of applicable regulatory requirements. PRODUCT DATA SHEET 1 - American National Standards Institute (ANSI): 1.1 ANSI B15.1 - 1972 Safety Standard for Mechanical Power Transmission Apparatus 1.2 ASME B30.2 - 1996 Overhead and Gantry Cranes 1.3 ASME B30.10 - 1993 Hooks 1.4 ASME B30.19 - 1993 Cableways 1.5 ASME HST-1M - 1995 Performance Standards for Electric Chain Hoists 1.6 ASME HST-4M - 1996 Performance Standards for Overhead Electric Wire Rope Hoists 1.7 ASME NOG-1 - 1989 Rules for Construction of Overhead and Gantry Cranes 1.8 ASME NUM-1 - 1996 Rules for Construction of Cranes, Monorails, and Hoists PRODUCT DATA SHEET 2 - AWS American Welding Society: 2.1 AWS D1.1 - 1998 Structural Welding Code - Steel 2.2 AWS D14.1 - 1991 Specifications for Welding Industrial and Mill Cranes PRODUCT DATA SHEET 3 - NFPA 70-1996 National Electric Code

LBNL Facilities Master Specifications Bridge Cranes

412213.13-1

Revised 09/04/09

BUILDING NO. PROJECT NAME PRODUCT DATA SHEET 4 - California Administrative Code Title 8, Chapter 7, General Industry Safety Orders PRODUCT DATA SHEET 5 - Crane Manufacturers Association of America: 5.1 Specifications for Electric Overhead Traveling Cranes - CMAA Specification Number 70.

SC#

PRODUCT DATA SHEET 6 - 29 CFR 1910, Subpart N, OSHA General Industry Standards, Materials Handling and Storage Subpart. PRODUCT DATA SHEET 7 - 29 CFR 1926, Subpart H, OSHA Construction Standards, Materials Handling, Storage, Use, and Disposal Subpart PRODUCT DATA SHEET 8 - 29 CFR 1926, Subpart N, OSHA Construction Standards, Cranes, Derricks, Hoists, Elevators, and Conveyors Subpart. PRODUCT DATA SHEET 9 - American Institute of Steel Construction, The Manual of Steel Construction, latest edition

SCHEDULE 2 - DEFINITIONS PRODUCT DATA SHEET 0 - Terms used in this specification shall be used as in the Definitions of ANSI/ASME B30.2 1996 Overhead and Gantry Cranes.

SCHEDULE 3 - PERFORMANCE REQUIREMENTS PRODUCT DATA SHEET 0 - Vertical Impact: An impact allowance shall be included in design calculations for carriers (trolleys) and cranes. The impact shall be 0.5 percent of the rated load for each foot per minute of hoisting speed with a minimum allowance of 15 percent and a maximum of 50 percent.

SCHEDULE 4 - SUBMITTALS PRODUCT DATA SHEET 0 - Submit under provisions of Divisions 01 Section "General Requirements" and "Special Procedures." A. 0.1 0.2 Pre-Construction Submittals: Submit under provisions of Division 01 Section "General Requirements" for all equipment prior to ordering or fabrication. No deviations from the submittals as approved shall be permitted and any materials purchased prior to approval shall be at the sole risk of the Subcontractor. All submittal data shall be the same size for any group of information and shall be bound or in a three-ring binder as appropriate. All information shall include a Table of Contents and be indexed and tabbed with reference to the specific section of the specification. If catalog cut sheets or published materials include information not applicable to the item furnished, the Subcontractor shall rule out all superfluous data. Indicate all options or accessories to be provided and cross out or strike through those not to be provided. Indicate part numbers to be ordered with all options. Administrative Data: Submit name, address and telephone number of the local representative; a general sales and engineering bulletin covering the full line of products manufactured; a certification that the line of products proposed for this contract have been in continuous and successful use for not less than 5 years; general catalog information covering the characteristics of the systems proposed for this contract; and a statement that the components and the systems proposed will be maintained and supported by the manufacturer for parts and service for not less than 10 years. Shop Drawings and Calculations: Submit all drawings required for the construction of the system which are in addition to the subcontract drawings. Shop drawings shall be to scale and fully dimensioned and shall provide sufficient detail to clearly indicate the arrangement of equipment and its components. The drawings shall show plan, elevation and sectional views along with all other pertinent data. All drawings prepared by the Subcontractor shall be developed using the AutoCADTM computer-aided drafting program version 14. All drawings shall be a maximum ANSI size D and use LBNL layering conventions. Submit structural calculations for the bridge. Shop drawings and calculations shall be signed by a California Registered Professional Engineer.

0.3

0.4

LBNL Facilities Master Specifications Bridge Cranes

412213.13-2

Revised 09/04/09

BUILDING NO. PROJECT NAME 0.5 0.6 0.7 0.8 0.9

SC#

0.10

Product Data: Submit technical product specification sheets for each system component and device which include all data needed to prove compliance with this specification. Clearly indicate the exact model of each component to be provided. Mill Test Reports: Submit mill test reports for the bridge. Inspection and Rated Load Test Reports: Submit inspection reports and operational and rated load test reports in accordance with ANSI B30.2. Manufacturer's Installation Instructions: Submit for all components being provided under this section. Paint: Submit a complete list of manufacturers and products required throughout the work. Submit manufacturer's specifications for each product, including product description, features, composition, specifications, special surface preparation procedures, substrate conditions requiring special attention, and recommended method of application. Include the manufacturer's recommended dry mil thickness for each coat of each scheduled finish. Manufacturer's Directions: Follow manufacturer's directions covering items not shown on the drawings or specified herein. Manufacturer's directions do not take precedence over the Subcontract drawings and specifications. Where these are in conflict with the drawings and specifications, notify the Project Manager for clarification before installing the work.

PRODUCT DATA SHEET 1 - Pre-Commissioning Submittals: 1.1 Submit under provisions of Division 01 Section "General Requirements" prior to performing functional testing. 1.2 Operator's manuals: Submit for the specific crane furnished. 1.3 Testing Procedure: Submit a testing procedure to be used to verify compliance with this specification. PRODUCT DATA SHEET 2 - Project Record Documents: 2.1 Submit under provisions of Division 01 Section "General Requirements." 2.2 The subcontract drawings shall be submitted with the Subcontractors' markings which record the installed conditions from which the University will produce the "as-builts". Show actual locations of all system components and affected equipment. 2.3 Submit all electronic files developed for this project including shop drawings, operator's manuals, and test procedures. 2.4 Submit the crane certification documentation. PRODUCT DATA SHEET 3 - Operating and Maintenance Data: 3.1 Submit under provisions of Division 01 Section "General Requirements." 3.2 Include a project information sheet including project name, building(s), and Subcontractor contact information. Include name, address, and phone number of the service representative to be called in the event of equipment failure. Include a Statement of Guarantee including date of termination. 3.3 Include operation and maintenance documentation for all equipment and devices, including the bridge, trolley, hoist, power and control circuit conductors, safety and control mechanisms, and all other parts and services as defined in this specification. Documentation shall include manufacturer's model number, manufacturer's installation instructions, frequency of inspection, recommended cleaning methods and materials, testing methods, and calibration tolerances. In the event such manuals are not obtainable from the manufacturer, it shall be the responsibility of the Subcontractor to compile and include them. Advertising brochures shall not be used in lieu of the required technical manuals. 3.4 The maintenance and operating manuals shall include key component breakaway pictures for ease of parts ordering, catalog cut pages, part numbers, and sub-assembly details. 3.5 Include copies of all testing forms completed for this project. PRODUCT DATA SHEET 4 - Warranty Period:t 4.1 Submit written reports on each service or inspection to the LBNL Project Manager during the warranty period. 4.2 During he warranty period, all copies of the drawings and manuals shall be updated to include all changes which were required to solve problems covered by the warranty.

SCHEDULE 5 - QUALITY ASSURANCE PRODUCT DATA SHEET 0 - Inspections: Comply with Division 01 Section "Special Procedures", Part 1.15 - Inspections. PRODUCT DATA SHEET 1 - Workmanship and Supervision: Comply with General Conditions, Article 9 - Material and Workmanship and Article 12 - Superintendence by Subcontractor. PRODUCT DATA SHEET 2 - Qualifications:

LBNL Facilities Master Specifications Bridge Cranes

412213.13-3

Revised 09/04/09

BUILDING NO. PROJECT NAME 2.1

SC#

2.2 2.3

The manufacturer shall have a minimum of five years documented product development, testing, and manufacturing experience with the products specified in this Section. The manufacturer shall also be represented by a complete sales, installation, and service operation within 60 air miles of Lawrence Berkeley National Laboratory. The installer shall have a minimum of five years documented experience applying the work of this Section. The Subcontractor shall have a service office which has been established for a minimum of five years and is staffed with factory-authorized service technicians capable of servicing all aspects of the crane.

SCHEDULE 6 - PROJECT CONDITIONS PRODUCT DATA SHEET 0 - Examination of Site: The Subcontractor shall examine the site and become familiar with all conditions that may affect the work covered by the specifications. Failure to do so shall not lessen the subcontractor's responsibility or entitle the Subcontractor to additional compensation for work not included in the bid.

SCHEDULE 7 - SCHEDULING PRODUCT DATA SHEET 0 - Schedule shutdowns of utilities in coordination with University. Comply with Division 01 Section "Special Procedures", Part 1.07 - Shutdown.

SCHEDULE 8 - WARRANTY PRODUCT DATA SHEET 0 - Comply with Division 01 Section "General Requirements", Part 1.09 I - Guarantee. 0.1 Free maintenance services shall be provided by the Subcontractor for one (1) year after final system acceptance. These services shall consist of manufacturer's factory-trained representatives providing emergency repair service with on-site response within 24 hours of call, all test equipment and hardware necessary for maintenance and repair work and installation of any hardware modifications designed to improve system performance or eliminate known problems or deficiencies.

PART 2 - PRODUCTS

SCHEDULE 0 - MATERIALS AND SUBSTITIONS PRODUCT DATA SHEET 0 - Materials and Equipment: Materials and equipment shall be uniform throughout the installation. All materials and equipment shall be new and shall be the standard products of manufacturers regularly engaged in the production of such equipment equal to or superior to the material specified, and shall be the manufacturer's latest standard design that complies with the specification requirements. PRODUCT DATA SHEET 1 - Substitutions: Comply with Division 01 Section "General Requirements", Part 1.09 D. 2. Specified Items - Substitutes. Installation of any approved substituted equipment is the Subcontractor's responsibility, and any changes required to work included under other divisions for installations of approved substituted equipment must be made to the satisfaction of the Architect-Engineer and without change in subcontract price. Approval by the ArchitectEngineer of substituted equipment and/or dimension drawings does not waive these requirements.

SCHEDULE 1 - BRIDGE GIRDERS PRODUCT DATA SHEET 0 - The center-to-center dimension of the runway rails shall be approximately 37 feet; 4 inches. This dimension shall be field verified by the Subcontractor prior to manufacturing. PRODUCT DATA SHEET 1 - Bridge girders shall be constructed of A-36 structural steel beams reinforced as necessary or fabricated plate box sections. PRODUCT DATA SHEET 2 - The bridge girders track end stops shall be capable of withstanding the impact of a fully loaded trolley or carrier traveling at 50 percent of the full load speed.

LBNL Facilities Master Specifications Bridge Cranes

412213.13-4

Revised 09/04/09

BUILDING NO. PROJECT NAME PRODUCT DATA SHEET 3 - End truck assemblies shall comply with paragraph 2.03.

SC#

SCHEDULE 2 - TROLLEYS PRODUCT DATA SHEET 0 - Wheel axles shall be precision machined from high strength steel. PRODUCT DATA SHEET 1 - Wheel bearings shall be double row precision ball or taper roller bearings, lubricated and sealed at assembly, and fitted with external grease fittings. Bearings must have minimum B-10 life of 5,000 hours.

SCHEDULE 3 - CRANE DRIVE PRODUCT DATA SHEET 0 - The crane speed shall be controlled through a variable frequency drive from 2 to 80 feet per minute.

SCHEDULE 4 - HOIST CARRIER PRODUCT DATA SHEET 0 - The hoist carrier shall be comprised of two end trucks, structural framing, carrier drive, and electrical controls. PRODUCT DATA SHEET 1 - The carrier speed shall be controlled through a variable frequency drive from 2 to 40 feet per minute.

SCHEDULE 5 - HOIST PRODUCT DATA SHEET 0 - The hoist and appurtenances shall be designed to withstand all stresses imposed under safe operating conditions while handling loads within the rated capacity. Load bearing parts shall be designed such that the static stress, calculated for rated load, shall not exceed 20 percent of the ultimate strength of the material. PRODUCT DATA SHEET 1 - All bearings shall be heavy duty, anti-friction type with a minimum B10 life of 5,000 hours. Motor bearings shall be lifetime lubricated, sealed ball bearings. PRODUCT DATA SHEET 2 - All gearing shall be forged heat treated alloy steel machined for smooth quiet operation. All gearing must meet AGMA quality specifications. No cast gears shall be permitted. PRODUCT DATA SHEET 3 - Bottom block shall be completely shrouded for safety and fabricated from steel. Sheaths must be forged or rolled steel, running on anti-friction bearings. Hooks are to be forged steel supported by anti-friction thrust bearings and permit 360 degree rotation. A latch shall be provided to bridge the opening of the hook for the purpose of retaining slings, chains, etc., under slack conditions. PRODUCT DATA SHEET 4 - Motors shall be totally enclosed, specifically designed for hoist service capable of starting and operating under any condition within the designed capacity and provided with thermal overload protection. PRODUCT DATA SHEET 5 - The hoist shall incorporate an upper plugging type limit switch automatically stopping the hoist motion when the block reaches its highest position. Excessive hook drift shall cause the block to be momentarily reversed. PRODUCT DATA SHEET 6 - Electric hoist controls shall comply with N.E.C. requirements for the application being considered and shall include control circuit breakers and contactors mechanically and electrically interlocked. PRODUCT DATA SHEET 7 - The hoist speed shall be controlled through a variable frequency drive from 2 to 20 feet per minute.

SCHEDULE 6 - HEIGHT DIMENSIONS

LBNL Facilities Master Specifications Bridge Cranes

412213.13-5

Revised 09/04/09

BUILDING NO. PROJECT NAME

SC#

PRODUCT DATA SHEET 0 - The top of the existing crane rail is 17 feet, 9 inches above the finished floor. The bottoms of the existing ductwork and lights are 21 feet, 6 inches above the finished floor. The crane shall have a maximum height of 3 feet, 6 inches from the top of the trolley to the top of the crane rail. The crane lift height shall be long enough to pick loads up off of the floor, 17 feet, 9 inches below the top of the existing crane rail.

SCHEDULE 7 - MOTORS PRODUCT DATA SHEET 0 - All variable speed motors shall be squirrel cage type, totally enclosed. Motor shall be provided with lifetime lubricated anti-friction bearings, unless otherwise specified.

SCHEDULE 8 - ELECTRICAL SCOPE OF WORK PRODUCT DATA SHEET 0 - Provide all materials, labor, equipment and services necessary to provide a fully functioning and tested crane electrical system, complete with pendant and radio control. PRODUCT DATA SHEET 1 - Codes: 1.1 The electrical equipment shall meet NEMA Classification requirements for crane construction except where higher grade devices are specified and all requirements under Article 1.2 References, and Article 1.6 Quality Assurance. 1.2 The design and installation shall conform to the requirements of all applicable California State Industrial Safety Regulations, and the National Electric Code NFPA 70. PRODUCT DATA SHEET 2 - Submittals: 2.1 Submit under Article 1.5 Submittals the Bill of Materials, Manufacturers Brochures and Catalog Cuts, Shop Drawings, Erection Drawings, Wiring Diagrams, Schematics, and an Equipment layout. 2.2 Submit for approval all electrical controls, micro switches, wiring diagrams, schematics, control panels, identification labels, disconnect switches, wire, limit switches, enclosures, contactors, circuit breakers, pendants and buttons, radio control enclosure, master radio transmitter/receiver, hand held transmitter, radio selector switch, collectors and shoes, motors, electric brakes, variable frequency drives (VFD), factory and field default settings for each VFD, and alarm devices. 2.3 Show location and elevation of all electrical controls and panels which shall be placed so that they are available for servicing when the crane is docked at the maintenance platform. PRODUCT DATA SHEET 3 - AC Controls: 3.1 The AC controls shall be provided with an under voltage device which will disconnect all motors from the line on failure of power or brownout and will not permit any motor to be restarted until a reset switch or push-button is operated. 3.2 All magnetic contactors shall be fully rated for their horsepower load and sized for continuous duty. 3.3 All crane components to be designed for a 480V, 3 phase, 3 wire, Delta system. The control voltage shall be 120VAC from a control power transformer with protective circuit breakers. 3.4 The Color Code for 480 VAC wiring is: A = brown, B = yellow, C = purple, Neutral = slate, insulated equipment ground = green. 3.5 Bridge and runway conductors shall be Duct-O-Bar, Insul-8 or equal 3.6 All control wiring shall be 120 VAC, #14 minimum size, MTW or better in conduit or within panels. 3.7 All wiring to be color coded and all terminal strips and wires to be identified with markings consistent with the drawings. 3.8 All wiring between enclosures to terminate on field wiring terminal strips at both ends, except where not practical at small field devices. Field terminal strips aren't required for circuit breakers and large power contactors. Splicing of wires to make connections is forbidden and not acceptable. 3.9 Limit switches shall be installed at both ends of travel on the trolley and the bridge to prevent the trolley or the bridge from striking the bumpers or existing crane. Location of limit switches to be adjustable. Use Heavy Duty limit switches. 3.10 Furnish engraved plastic name plates (to be secured with screws not glue or double back tape) with 1/4" engraved lettering on the exterior of all controller enclosures with the appropriate marking i.e. Main Disconnect, Main Line and Bridge Control, Trolley Control, Hoist Control, etc.. Within the enclosure all components including circuit breakers, contactors, relays, timers, terminal blocks, resistors etc. shall be labeled with 1/8 engraved lettering, firmly attached with metal screws to the equipment.

LBNL Facilities Master Specifications Bridge Cranes

412213.13-6

Revised 09/04/09

BUILDING NO. PROJECT NAME 3.11 3.12 3.13

SC#

All enclosures shall be NEMA type 12, with removable hinged doors with neoprene gaskets, shall be in full compliance with the National Electric Code for size, be readily accessible and doors shall be fully openable to 90 degrees. A 480 VAC lockable crane disconnect switch shall be provided at floor level and shall be the Point of Connection for connection to the LBNL power system. Disconnect switch shall be horsepower and heavy duty rated. A heavy duty, horsepower rated, fused, disconnect switch shall be provided on the crane at the closest entry point to the crane from a maintenance platform that will shut off all power to the crane.

PRODUCT DATA SHEET 4 - Brakes: 4.1 Bridge and trolley shall have electrically operated fail safe magnetic disc type brakes for operation from a dedicated circuit breaker. 4.2 Brakes shall be sized for the full load torque of the motor plus a safety factor. Provide bridge and trolley brake sizing calculations. PRODUCT DATA SHEET 5 - Pendant: 5.1 All crane motions shall be controlled independently by a pendant push-button station and by a radio remote control, only one of which may have control at any one time as selected by a master switch. 5.2 The pendant push-button station shall have an electrified pendant reel which shall be controllable from the radio remote control, a lockable wall mounted switch located at floor level, or pendant push buttons. The pendant reel shall be capable of holding 25 feet of pendant cable. 5.3 Pendant push-button station to include a power on light, twist on & push off switch; three step reversing buttons for infinitely variable bridge, trolley, and hoist VFD control; maintained pressure pendant raise and lower buttons, and a maintained pressure bypass button. 5.4 The pendant shall have complete control of all crane functions including turning power on and off, pendant up/down control, and bypass of trolley and bridge runway limit switches. 5.5 Pendant shall be of such a length that it may be extended to the same level as the hook. 5.6 The pendant cable shall contain 8 spare conductors and be extra flexible. The cable connector connecting the cable to the pendant shall support a minimum of 300 pounds. 5.7 Arrangement of pendant push-buttons shall be as shown on Figure 14633-2. 5.8 The pendant shall be a Telemotive SBP-12-WBTX or equal. PRODUCT DATA SHEET 6 - Radio Control: 6.1 Use isolated relay contacts for the outputs of the radio control which shall be compatible with the VFD inputs. Triac or solid state type contacts are not acceptable. 6.2 Provide a Master switch to select between radio and pendant control. The master switch contacts are to isolate all radio control input and outputs and all pendant controls from each other, and must be easily accessible from the main maintenance entry point onto the crane 6.3 The radio remote control shall use rechargeable Ni-Cad batteries. A spare battery with battery charger shall be provided. 6.4 Radio control to be a pendant type and have the following buttons: key operated power on & off switch, power on/battery monitor light; three step reversing bridge, trolley, and hoist buttons for infinitely variable VFD control; pendant raise and lower buttons; bell button, and bypass button. 6.5 Provide a Bypass switch in the pendant and the radio controls to allow over riding the bridge and trolley limit switches so that docking as close as possible to a maintenance platform is possible. In Bypass the speeds of the trolley and bridge must be limited to a very low speed. 6.6 Provide a Blue Light under the crane which will light whenever the crane is being operated by radio control. The light shall be visible from all directions under the crane. 6.7 The radio remote control shall be a Telemotive Model 10K+16 or equal. PRODUCT DATA SHEET 7 - Electrical Power: 7.1 Electrobar , or equal, inverted V-Bar, fully insulated and supported on insulators and brackets, be CAL OSHA and UL approved. All conductors shall be individually enclosed with spring loaded collector shoes running on the underside. All wire attachments to the collectors shall be fully insulated, protected from harm, and securely attached. 7.2 All electrical wiring shall be in accordance with the latest requirements of the National Electric Code (NFPA 70) and Cal-OSHA Standards, Title 8. All wiring exterior to enclosures shall be in rigid steel conduit with bushings. 7.3 Electrical motor connections to be liquid-tight flexible metal steel conduit with ground wire pulled within and bushings. 7.4 All wiring which interfaces with the LBNL power system shall meet the requirements of Division 16: Electrical. PRODUCT DATA SHEET 8 - Electrical Testing:

LBNL Facilities Master Specifications Bridge Cranes

412213.13-7

Revised 09/04/09

BUILDING NO. PROJECT NAME 8.1 8.2 8.3 8.4 8.5

SC#

Test Hoist, Trolley and Bridge VFD's under full load and no load conditions. Verify that temperature within VFD enclosures are still within tolerance after full load tests. Verify operation of all Pendant and Radio controls. Verify that they operate independently of each other and that they do not interfere with each other. Verify that Pendant and Radio controls both work from the floor level. Verify operation of all limit switches. Verify operation of Bypass controls for limit switches. Verify that electrical maintenance of all control enclosures can be performed from the maintenance platform.

PRODUCT DATA SHEET 9 - Operating Manuals: 9.1 Submit under provisions of 1.08, B, C, & D three ring manuals which include As-Built schematics and wiring diagrams, Bill of Material, spare parts lists, replacement parts guides, lubricant and adjustment manuals, preventative maintenance guides, VFD programming, Radio Control local representatives names and phone numbers. PRODUCT DATA SHEET 10 - Electrical As-Built Drawings: 10.1 At the completion of the installation and after successful testing, Electrical As-Built drawings are to be provided as well as AutoCAD R14 discs containing all schematic, wiring and layout drawing information for the crane and radio controls.

PART 3 - EXECUTION

SCHEDULE 0 - PAINTING PRODUCT DATA SHEET 0 - All material shall be cleaned of loose rust, mill scale and foreign matter. PRODUCT DATA SHEET 1 - The crane bridge, hoist, trolleys, runways and suspension fittings shall be painted one shop coat of primer and two finish coats of manufacturers standard enamel finish paint. PRODUCT DATA SHEET 2 - Equipment must be adequately protected against damage and rust in shipment.

SCHEDULE 1 - SYSTEM MARKING PRODUCT DATA SHEET 0 - Major components of the system shall be marked at the factory so as to assure prompt and proper field identification.

SCHEDULE 2 - CRANE ASSEMBLY AND TEST PRODUCT DATA SHEET 0 - Cranes shall be factory assembled, and a no-load running test of controls and drive machinery performed to ensure proper operation. The crane shall be disassembled only as necessary for shipment.

SCHEDULE 3 - PROTECTION OF EQUIPMENT PRODUCT DATA SHEET 0 - Care shall be exercised during construction to avoid damage or disfigurement of any kind. All equipment shall be protected from dust and moisture prior to and during construction. PRODUCT DATA SHEET 1 - Where required or directed, construct temporary protection for equipment and installations so as to protect same from dust and debris caused by construction. PRODUCT DATA SHEET 2 - All protection shall be substantially constructed with the use of clean canvas, heavy plastic, visqueen and plywood as required, and made tight and dust proof as directed. PRODUCT DATA SHEET 3 - The Subcontractor shall repair by spray or brush painting, after properly preparing the surface, all scratches or defects in the finish of the equipment. Only identical paint furnished by the equipment manufacturer shall be used for such purposes.

LBNL Facilities Master Specifications Bridge Cranes

412213.13-8

Revised 09/04/09

BUILDING NO. PROJECT NAME

SC#

PRODUCT DATA SHEET 4 - Failure of the Subcontractor to protect the equipment as outlined herein shall be grounds for rejection of the equipment and its installation.

SCHEDULE 4 - EXAMINATION PRODUCT DATA SHEET 0 - Verify that systems are ready to receive work. PRODUCT DATA SHEET 1 - Once construction has commenced, the Subcontractor shall be fully responsible for all modifications required to meet the requirements of the Subcontract documents.

SCHEDULE 5 - GENERAL INSTALLATION METHODS PRODUCT DATA SHEET 0 - Seismic Mounting: 0.1 All material and equipment shall comply with Division 01 Section "Lateral Force Procedures".

SCHEDULE 6 - CRANE INSTALLATION PRODUCT DATA SHEET 0 - Install the crane in accordance with the Subcontract documents, manufacturer's instructions, and approved shop drawings. PRODUCT DATA SHEET 1 - The Subcontractor shall touch up of any painted surfaces affected by installation of the crane. PRODUCT DATA SHEET 2 - The Subcontractor shall touch up of any painted surfaces affected by installation of the crane.

SCHEDULE 7 - TESTING PRODUCT DATA SHEET 0 - The Subcontractor shall provide all labor and equipment necessary to perform a comprehensive acceptance test of the crane prior to the acceptance testing witnessed by the University and defined below. The Subcontractor shall complete the testing forms submitted and approved in the Pre-Commissioning Submittals. The Subcontractor shall submit to the Project Manager three (3) copies of all test results, certified in writing, witnessed, signed and dated, within 24 hours of completion of work. PRODUCT DATA SHEET 1 - Under the supervision of the University, the Subcontractor shall provide all labor and equipment necessary to certify the performance of the crane. The Subcontractor shall contact the University to schedule the certification at least two weeks prior to the date of certification testing. PRODUCT DATA SHEET 2 - The crane shall be certified in accordance with ANSI 830.2.0 - 1976; California Administrative Code Title 8, Article 99; and OSHA Title 29, Chapter 17, Part 1910. 2.1 Safety: The crane certification testing shall be performed in accordance with the accepted Safety Plan for this project. 2.2 Crane Inspection: Prior to load testing, the following shall be inspected to verify that they are operative and in like-new condition: A. Hoisting motors and brakes. B. Trolley travel and brakes. C. Bridge travel and brakes. D. hoist limit switch. E. Steel hoisting ropes and hook. 2.3 Holding Brake Load Test: A. Select a location for the load tests where a falling test load will not cause any damage if the brakes do not hold. The location shall also be convenient to make measurements of crane hook movements. B. If there is only one holding brake, the test load shall be 125 percent of the rated capacity of the hoist. If there are two holding brakes, the test load shall be 100 percent of the rated capacity of the hoist. Each holding brake shall be test loaded independently.

LBNL Facilities Master Specifications Bridge Cranes

412213.13-9

Revised 09/04/09

BUILDING NO. PROJECT NAME C.

SC#

D.

E. 2.4 A. B. C. D. E. 2.5 A. B. C. D.

The test load shall first be raised three inches off the load support to check the brake. The test load shall then be raised eighteen inches off the floor, the hoist stopped, and the load checked for downward drift. Record the downward drift of the test load after one minute of the holding brake being set. This test shall be performed twice for each holding brake. The test load shall then be raised thirty-six inches off the floor. The test load shall then be lowered eighteen inches at maximum lowering speed, the holding brake set, and the load checked for downward drift. Record the downward drift of the test load after one minute of the holding brake being set. This test shall be performed twice for each holding brake. If the test load drifts downward more than 1/4 inch within one minute of the holding brake being set during any of the tests, the holding brake shall be adjusted. The tests shall be repeated until the downward drift is less than 1/4 inch within one minute of the holding brake being set, during all tests of all holding brakes. Mechanical Load Brake Test: Select a location for the load tests where a falling test load will not cause any damage if the brakes do not hold. The location shall also be convenient to make measurements of crane hook movements. The test load for the mechanical load brake shall be 125 percent of the rated capacity of the hoist. Make the holding brake inoperative. The test load shall be raised three feet off the floor, the hoist stopped, and the load checked for downward drift. Record the downward drift of the test load after one minute of the hoist being stopped. This test shall be performed twice. The test load shall then be raised five feet off the floor. The test load shall then be lowered two feet at maximum lowering speed, the hoist stopped, and the load checked for downward drift. Record the downward drift of the test load after one minute of the hoist being stopped. This test shall be performed twice. If the test load drifts downward more than 12 inches within one minute of the hoist being stopped during any of the tests, the mechanical load brake shall be adjusted. The tests shall be repeated until the downward drift is less than 12 inches within one minute of the hoist being stopped, during all tests of the mechanical load brake. Operational Tests: The test load for these tests shall be 75 percent of the rated capacity of the hoist. Raise and lower the test load. Verify the hoisting and lowering speeds of the hoist and verify the proper operation of the limit switch. Raise the test load three feet off of the floor and move it transversely from side to side of the building. Verify trolley travel speeds and stops on bridge track rails. Raise the test load three feet off of the floor and move it longitudinally from end to end of the building. Verify bridge travel speeds and stops on crane track rails.

PRODUCT DATA SHEET 3 - The crane will not be accepted until all tests described in this section have been performed to the satisfaction of the Project Manager. Any tests that cannot be performed due to circumstances beyond the control of the Subcontractor shall be exempt from the system acceptance requirements if stated as such in writing by the Project Manager. Such tests shall be performed as part of the crane warranty. PRODUCT DATA SHEET 4 - Any unsatisfactory condition revealed by these test results, or unsatisfactory methods of tests and/or testing apparatus and instruments, shall be corrected by the Subcontractor to the satisfaction of the Project Manager. PRODUCT DATA SHEET 5 - The Project Manager reserves the right to require that the Subcontractor perform and repeat any tests that are deemed necessary to complete or check the tests or the certified records of the Subcontractor at any time during the course of the work. The Subcontractor shall correct any unsatisfactory portion of his work that is revealed by the tests or that may be due to progressive deterioration during this period, unless the item in question was a direct specification.

SCHEDULE 8 - ELECTRICAL TESTING PRODUCT DATA SHEET 0 - Test Hoist, Trolley and Bridge VFDs under full load and no load conditions. Verify that temperature within VFD enclosures are still within tolerance after full load tests. PRODUCT DATA SHEET 1 - Verify operation of all Pendant and Radio controls. Verify that they operate independently of each other and that they do not interfere with each other. PRODUCT DATA SHEET 2 - Verify that Pendant and Radio controls both work from the pit area floor. PRODUCT DATA SHEET 3 - Verify operation of all limit switches. Verify operation of Bypass controls for limit switches.

LBNL Facilities Master Specifications Bridge Cranes

412213.13-10

Revised 09/04/09

BUILDING NO. PROJECT NAME

SC#

PRODUCT DATA SHEET 4 - Verify that electrical maintenance of all control enclosures can be performed from the maintenance platform.

SCHEDULE 9 - OPERATING MANUALS PRODUCT DATA SHEET 0 - Submit under provisions of 1.08, B, C, & D three ring manuals which include As-Built schematics and wiring diagrams, Bill of Material, spare parts lists, replacement parts guides, lubricant and adjustment manuals, preventative maintenance guides, VFD programming, Radio Control local representatives names and phone numbers.

SCHEDULE 10 - ELECTRICAL AS-BUILT DRAWINGS PRODUCT DATA SHEET 0 - At the completion of the installation and after successful testing, Electrical As-Built drawings are to be provided as well as AutoCAD R14 discs containing all schematic, wiring and layout drawing information.

SCHEDULE 11 - CLEANING PRODUCT DATA SHEET 0 - Comply with Division 01 Section "Special Procedures", Part 3.05 - Cleaning.

SCHEDULE 12 - DRAWINGS PRODUCT DATA SHEET 0 - Comply with Division 01 Section "General Requirements", Part 1.09 G - Record Drawings and Division 01 Section "Special Procedures", Part 1.08 - Drawings and Specifications. PRODUCT DATA SHEET 1 - The Subcontractor shall provide all labor and equipment necessary to perform a comprehensive acceptance inspection of all as-built documentation. The inspection shall be performed under the supervision of the University. The Subcontractor shall contact the University to schedule the inspection at least one week prior to the date requested.

SCHEDULE 13 - NOISE AND VIBRATION PRODUCT DATA SHEET 0 - Noise levels shall not exceed ASHRAE recommended noise criteria (NC) for a shop. PRODUCT DATA SHEET 1 - If noise problems are a result of improper material or installation, or exceeds limits determined by Sections 3.15.A, these conditions shall be corrected by the Subcontractor at no cost to the University.

SCHEDULE 14 - TRAINING PRODUCT DATA SHEET 0 - The Subcontractor shall provide 8 hours of training developed specifically for this project. The training sessions shall be given at LBNL on a mutually-agreed upon schedule. Manuals covering the training subject matter shall be submitted at least two weeks prior to each training session. The instructor conducting the training sessions shall be fully proficient in the subject matter. LBNL reserves the right to cancel any training while in session, without loss of training time owed, if it feels that the instructor is not qualified in technical knowledge or ability to teach the subject matter. The training shall be in two sessions as follows: 0.1 Session 1 - Four hours of training shall be provided prior to the proof-of-performance testing. The training shall focus on the overall system design, equipment functions, operation, and the Pre-Commissioning Submittal documentation. 0.2 Session 2 - Four hours of training shall be provided following acceptance of the crane system. The training shall focus on the Project Record Documents and Operating and Maintenance Data. END OF SECTION 412213.13

LBNL Facilities Master Specifications Bridge Cranes

412213.13-11

Revised 09/04/09

Вам также может понравиться

- LeadSolar Gateway Superior v1.0Документ173 страницыLeadSolar Gateway Superior v1.0daviko313Оценок пока нет

- 1 enДокумент32 страницы1 endaviko313Оценок пока нет

- Kiswire General Purpose RopesДокумент28 страницKiswire General Purpose Ropesdaviko313Оценок пока нет

- Simple Pressure VesselsДокумент38 страницSimple Pressure VesselsCristian BorcanescuОценок пока нет

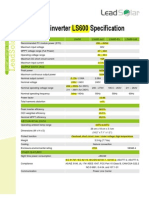

- Microinverter LS600 Specification: Input Data (DC) LS600 LS600-AU LS600-EU LS600-NAДокумент1 страницаMicroinverter LS600 Specification: Input Data (DC) LS600 LS600-AU LS600-EU LS600-NAdaviko313Оценок пока нет

- Column Speaker - T304Документ2 страницыColumn Speaker - T304daviko313Оценок пока нет

- Material Clarification Q345Документ1 страницаMaterial Clarification Q345daviko313Оценок пока нет

- KTS ArДокумент106 страницKTS Ardaviko313Оценок пока нет

- 4 THE OCCUPATIONAL SAFETY AND HEALTH ACT Amendment Fee For FCERTДокумент2 страницы4 THE OCCUPATIONAL SAFETY AND HEALTH ACT Amendment Fee For FCERTdaviko313Оценок пока нет

- Catalogue of Industrial DehumidifierДокумент8 страницCatalogue of Industrial Dehumidifierdaviko313Оценок пока нет

- AirstageДокумент76 страницAirstagedaviko313Оценок пока нет

- Steca TR 0201 Instruction enДокумент40 страницSteca TR 0201 Instruction endaviko313Оценок пока нет

- ASHRAE Workshop Control WilliamYick Part 2Документ48 страницASHRAE Workshop Control WilliamYick Part 2daviko313Оценок пока нет

- HVAC Accurate Load Calcs StrategyДокумент47 страницHVAC Accurate Load Calcs StrategySharon LambertОценок пока нет

- Guide Line For Inspection of Overhead Crane StructureДокумент43 страницыGuide Line For Inspection of Overhead Crane StructurePranoy Barua100% (1)

- Get Started With Solar EnergyДокумент76 страницGet Started With Solar EnergySolar Nation100% (1)

- Sds Eng PDFДокумент8 страницSds Eng PDFdaviko313Оценок пока нет

- Cranes DEMAG CatalogueДокумент160 страницCranes DEMAG Cataloguelcorao100% (1)

- Sds-Bakim Kilavuzu enДокумент24 страницыSds-Bakim Kilavuzu endaviko313Оценок пока нет

- Swisspump Sewage 50hzДокумент92 страницыSwisspump Sewage 50hzdaviko313Оценок пока нет

- Plastic Piping Handbook1Документ359 страницPlastic Piping Handbook1ddadara100% (1)

- VENT AXIA System CalculatorДокумент38 страницVENT AXIA System Calculatordaviko313Оценок пока нет

- 1p5hhays87m8npu234ii PDFДокумент277 страниц1p5hhays87m8npu234ii PDFjwОценок пока нет

- Fire SPRKLR Train ManДокумент81 страницаFire SPRKLR Train ManHESuarezОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Owners: White Cement Concrete and Colored Concrete ConstructionДокумент4 страницыOwners: White Cement Concrete and Colored Concrete ConstructionsonofalexanderОценок пока нет

- StimmungДокумент12 страницStimmungDenzil DelaereОценок пока нет

- Kastner, Jeffrey Wallis, Brian (Ed.) - Land and Environmental ArtДокумент310 страницKastner, Jeffrey Wallis, Brian (Ed.) - Land and Environmental ArtClaudiaRomero90% (10)

- Printed TextilesДокумент10 страницPrinted TextilesManasi PatilОценок пока нет

- Gateways 2018 Entry FormДокумент3 страницыGateways 2018 Entry FormTammy Green FarleyОценок пока нет

- Paul Manes Art Museum of Southeast Texas2Документ7 страницPaul Manes Art Museum of Southeast Texas2Alexandreau del FierroОценок пока нет

- Cultural Cannibalism and Tropicalia An Alternative Modernism in Brazil - EditedДокумент20 страницCultural Cannibalism and Tropicalia An Alternative Modernism in Brazil - EditedDalvin Jr.Оценок пока нет

- Aptitude TestДокумент17 страницAptitude TestChella ManiОценок пока нет

- 'Memories Are Made of This' by Subroto MukerjiДокумент76 страниц'Memories Are Made of This' by Subroto MukerjiSubroto MukerjiОценок пока нет

- Black + White Photography - June 2016 PDFДокумент100 страницBlack + White Photography - June 2016 PDFFery Novianto100% (1)

- Contemporary Artworks - ArceloДокумент7 страницContemporary Artworks - ArceloFrances Clare ArceloОценок пока нет

- Jotun Pioner Topcoat Application Guide - AlkideДокумент4 страницыJotun Pioner Topcoat Application Guide - AlkideChaerul AnwarОценок пока нет

- Handouts L AB Modes in Art and CraftsДокумент9 страницHandouts L AB Modes in Art and CraftsMAAZОценок пока нет

- Process Flow Chart of Knitting: A. Stitch LengthДокумент9 страницProcess Flow Chart of Knitting: A. Stitch LengthAushru HasanОценок пока нет

- 30 06Документ254 страницы30 06pavel ionutОценок пока нет

- Villa Capra "La Rotonda" UNESCO World Heritage SiteДокумент5 страницVilla Capra "La Rotonda" UNESCO World Heritage SitecansuОценок пока нет

- Choosing The Correct Coatings For Cargo TanksДокумент8 страницChoosing The Correct Coatings For Cargo Tanksmp87_ing50% (2)

- Rendering PlasticДокумент20 страницRendering PlasticJamesОценок пока нет

- Mozart Music PaperДокумент6 страницMozart Music Paperapi-253465341Оценок пока нет

- Wolfgang Amadeus Mozart: Online DatabasesДокумент4 страницыWolfgang Amadeus Mozart: Online DatabasessophiabcmОценок пока нет

- A Chinese Artist in Harlem - Quiz PDFДокумент2 страницыA Chinese Artist in Harlem - Quiz PDFLENINAОценок пока нет

- Beyond B1 Plus WB Unit 5 PDFДокумент13 страницBeyond B1 Plus WB Unit 5 PDFlichalopezОценок пока нет

- The Sources of The Young David by Andrea Del CastagnoДокумент10 страницThe Sources of The Young David by Andrea Del CastagnovolodeaTisОценок пока нет

- 5222 SSДокумент2 страницы5222 SSWilliamCondeОценок пока нет

- Paulette Singley - Devouring Architecture - Ruskin's Insatiable GrotesqueДокумент19 страницPaulette Singley - Devouring Architecture - Ruskin's Insatiable GrotesqueJason WeeОценок пока нет

- Adobe Caslon Pro Bold Adobe Garamond Pro Bold Aharoni: Bickham Script Pro RegularДокумент6 страницAdobe Caslon Pro Bold Adobe Garamond Pro Bold Aharoni: Bickham Script Pro RegularNirman KamalОценок пока нет

- Videodrome - PresentationДокумент14 страницVideodrome - PresentationŠtefan SitániОценок пока нет

- Gallery Red - Now We Are FiveДокумент24 страницыGallery Red - Now We Are FiveantcmsОценок пока нет

- Practical Guidelines Inspect Repair HDG Coatings 2008Документ24 страницыPractical Guidelines Inspect Repair HDG Coatings 2008forbeskaОценок пока нет

- Mak Pu Primer: Areas of ApplicationДокумент2 страницыMak Pu Primer: Areas of ApplicationM. K. Petro Products Construction Chemicals ExpertОценок пока нет