Академический Документы

Профессиональный Документы

Культура Документы

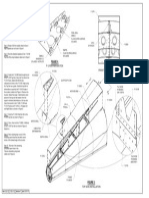

Van'S Aircraft, Inc.: Figure 1: Drilling The Pitot Tube Figure 3: Attaching Pitot Tube

Загружено:

Mark Evan SalutinИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Van'S Aircraft, Inc.: Figure 1: Drilling The Pitot Tube Figure 3: Attaching Pitot Tube

Загружено:

Mark Evan SalutinАвторское право:

Доступные форматы

VAN'S AIRCRAFT, INC.

FWD TAPE HERE 70.0 FF-1202 FF-1201 TOP OF PITOT BLOCK 1 1/4

Step 1: Mark the FF-1202 Pitot Tube by wrapping with masking tape 1 1/4 inches from the aft end as shown in Figure 1. Insert the pitot tube into the FF-1201 Pitot Block up to the edge of the tape. The threaded portion of the pitot block is aft. Flip the pitot tube and pitot block over on a flat surface. Align the most forward point of the pitot tube with the top of the pitot block and make a small scratch to use as an alignment mark on the pitot tube and pitot block as shown in Figure 1. NOTE: The following steps are designed to create a dimple in the FF-1202 Pitot Tube without drilling through the inner wall of the tube. If the tube is breached, see corrective measures detailed in Step 6. Step 2: Install a #36 drill bit into the hole in the top of the FF-1201 Pitot Block. Press the bit down until it contacts the FF-1202 Pitot Tube. Slip enough washers over the bit to cover the flutes on the drill bit. At least one of the washers should be a NAS1149F0332P.

Step 6: Insert the locking screw shown in Figure 3 to "tap" the #36 hole in the FF-1201 Pitot Block. Remove the screw and insert the FF-1202 Pitot Tube through the prop shaft and into the pitot block. Turn the pitot tube until the marks made on the pitot tube and pitot block align. Insert the locking screw as shown in Figure 3 and tighten by hand until it just bottoms on the pitot tube. Check that the front of the tube is properly oriented. The head of the locking screw will not be in contact with the pitot block. A small amount of RTV sealant may be applied to the end of the locking screw before installation if the inner wall of the pitot tube was breached. Check to ensure that the sealant has not blocked the airflow path before proceeding. Step 7: Route the FF-1216 Pitot Line as shown in Figure 4. Cut a one inch piece of .062X3/8 104-0375062 TUBE to make the FF-1217 Pitot Interconnect and slip it over the end of the pitot line and the aft end of the FF-1202 Pitot Tube as shown in Figures 3 and 4. The pitot line and pitot tube should butt against each other.

70.0

MS51957-36 FF-1202

ALIGN MOST FORWARD POINT WITH SURFACE

ALIGNMENT MARK

Slide the drill chuck over the drill bit and press until the drill chuck is firmly seated against the washers. Tighten the drill chuck. Step 3: Remove the drill and bit from the FF-1201 Pitot Block. Remove one of the NAS1149F0332P thin washers from the bit. Insert the drill bit with the remaining washers into the hole in the pitot block and drill #36 the FF-1202 Pitot Tube.

ALIGN DIMPLE WITH SCREW TO SECURE PITOT TUBE FF-1217 FF-1216

FF-1201

FIGURE 1: DRILLING THE PITOT TUBE

Step 4: Remove the FF-1202 Pitot Tube from the FF-1201 Pitot Block and remove the masking tape from the pitot tube. Carefully drill #29 the pilot dimple created in Step 3. Check progress frequently by sighting down the center of the pitot tube. Stop drilling when a small bump appears on the inside wall. NOTE: The FF-1201 Pitot Block may be trimmed if it interferes with the FF-1207 Cooling Shroud. Step 5: Mount the FF-1201 Pitot Block with the hardware called out in Figure 2. The pitot block should be mounted with the threaded half of the pitot block aft. Turn the cap screws until they touch the surface of the washer, turn an additional 1/4 turn and stop. Safety wire the cap screws together as shown in Figure 3.

FIGURE 3: ATTACHING PITOT TUBE (SOME PARTS NOT SHOWN FOR CLARITY)

Step 8: Double wrap safety wire around the FF-1217 Pitot Interconnect as shown in Figure 4.

NAS1149F0432P 4 PLACES FF-1201

FF-1216

FF-1216

FF-1202 FF-1217 SAFETY WIRE

FIGURE 2: PITOT BLOCK INSTALLATION (SOME PARTS NOT SHOWN FOR CLARITY)

PAGE

SCREW M6X25 DH, 2 PLACES

47-02

RV-12

REVISION:

DATE:

09/11/09

FIGURE 4: PITOT LINE ASSEMBLY AND ROUTING

Вам также может понравиться

- Tapco Pro 3 ManualДокумент16 страницTapco Pro 3 Manualacsscruf33% (3)

- Figure 1: Oil Door Assembly Installation: Van'S Aircraft, IncДокумент1 страницаFigure 1: Oil Door Assembly Installation: Van'S Aircraft, IncMark Evan SalutinОценок пока нет

- Figure 1: Separating The: Rudder Pedal Support ChannelsДокумент1 страницаFigure 1: Separating The: Rudder Pedal Support ChannelsMark Evan SalutinОценок пока нет

- CTS-CC-TIGUAN-Q3 CAtchCan InstallationДокумент6 страницCTS-CC-TIGUAN-Q3 CAtchCan Installationranjitv10Оценок пока нет

- Van'S Aircraft, Inc.: Revision: DateДокумент1 страницаVan'S Aircraft, Inc.: Revision: DateMark Evan SalutinОценок пока нет

- SPRINGER GMBH EPOCAST Grouting Chock Resin - BoltingДокумент4 страницыSPRINGER GMBH EPOCAST Grouting Chock Resin - BoltingMachineryeng100% (1)

- Vacon NXS NXP Flange Mounting Kit Installation ManДокумент12 страницVacon NXS NXP Flange Mounting Kit Installation ManTanuTiganuОценок пока нет

- RK2 150PE HF ManualДокумент37 страницRK2 150PE HF ManualMegat AlexanderОценок пока нет

- 2005+ Subaru Legacy/2007+ Outback: Quicklift Installation GuideДокумент4 страницы2005+ Subaru Legacy/2007+ Outback: Quicklift Installation GuideAndrew MillerОценок пока нет

- Van'S Aircraft, Inc.: Making The Mid Cowl HingesДокумент1 страницаVan'S Aircraft, Inc.: Making The Mid Cowl HingesMark Evan SalutinОценок пока нет

- B&W Marine Service: - Technical Service Spare PartsДокумент9 страницB&W Marine Service: - Technical Service Spare PartscocoisolisgmailcomОценок пока нет

- Van'S Aircraft, Inc.: AD-41H, TypДокумент1 страницаVan'S Aircraft, Inc.: AD-41H, TypMark Evan SalutinОценок пока нет

- Figure 2: Cleco The Top Tank Skin: Van'S Aircraft, IncДокумент1 страницаFigure 2: Cleco The Top Tank Skin: Van'S Aircraft, IncMark Evan SalutinОценок пока нет

- Installing T400 Load Sensors: Doc #: 11080 Rev:A T400 InstallationДокумент7 страницInstalling T400 Load Sensors: Doc #: 11080 Rev:A T400 InstallationHusnulKhotimahОценок пока нет

- Figure 3: Separating The Inst Stack Angle: Attaching The F-1201A Assembly (Some Parts Not Shown For Clarity)Документ1 страницаFigure 3: Separating The Inst Stack Angle: Attaching The F-1201A Assembly (Some Parts Not Shown For Clarity)Mark Evan SalutinОценок пока нет

- Mechanical Joint Ductile Iron PipeДокумент4 страницыMechanical Joint Ductile Iron PipemaniaxpdfОценок пока нет

- Multi Stage MechanismДокумент33 страницыMulti Stage MechanismMohd Hazwan ZulkifliОценок пока нет

- FMDV38 Fitting InstructionsДокумент18 страницFMDV38 Fitting Instructionslucaslopes88Оценок пока нет

- Paintball Claymore MineДокумент7 страницPaintball Claymore MineKplopОценок пока нет

- Peugeot 208 Gti InstructionsДокумент13 страницPeugeot 208 Gti InstructionsestaОценок пока нет

- RK2 150PE ManualДокумент37 страницRK2 150PE ManualMegat AlexanderОценок пока нет

- Cameron - Installation ProceduresДокумент110 страницCameron - Installation Proceduresmsu6383100% (8)

- Float Trap: User ManualДокумент2 страницыFloat Trap: User ManualAbhishek VermaОценок пока нет

- Fmdvds3a InstructionsДокумент10 страницFmdvds3a InstructionsMarcio CleberОценок пока нет

- Mini Countryman Atmospheric/Recirculation Dump Valve InstallationДокумент23 страницыMini Countryman Atmospheric/Recirculation Dump Valve InstallationEduardo MendozaОценок пока нет

- BD0425A-57A1 - Bolt Up Procedure For Critical FlangesДокумент22 страницыBD0425A-57A1 - Bolt Up Procedure For Critical Flangesvpkaranam1100% (1)

- Van'S Aircraft, Inc.: J-Stiffener Forward of The F-1208 Frame For Additions LaterДокумент1 страницаVan'S Aircraft, Inc.: J-Stiffener Forward of The F-1208 Frame For Additions LaterMark Evan SalutinОценок пока нет

- CAMERON France S.A.S: Front SheetДокумент27 страницCAMERON France S.A.S: Front SheetkrishnsgkОценок пока нет

- GRP Pipe Adhesive Coupling InstallationДокумент7 страницGRP Pipe Adhesive Coupling InstallationMrinal Kanti BhaduriОценок пока нет

- Positive Displacement Bailer Assembly Procedure 911-213-99 Preparation of The Shear Piston/Bottom Fill Housing SubassemblyДокумент9 страницPositive Displacement Bailer Assembly Procedure 911-213-99 Preparation of The Shear Piston/Bottom Fill Housing SubassemblySergio H. Monje100% (1)

- Intru-Lok Flareless Bite Type FittingsДокумент8 страницIntru-Lok Flareless Bite Type FittingsPartsGopher.comОценок пока нет

- CHEETAH E-SHIFT Pro Series Valve BodyДокумент8 страницCHEETAH E-SHIFT Pro Series Valve BodyhidraulicОценок пока нет

- Inserts Into Aluminum Engine BlocksДокумент3 страницыInserts Into Aluminum Engine BlocksoaszeusОценок пока нет

- 27100-C Air PadsДокумент16 страниц27100-C Air PadsJason MaОценок пока нет

- Van'S Aircraft, Inc.: Figure 4: SwitchДокумент1 страницаVan'S Aircraft, Inc.: Figure 4: SwitchMark Evan SalutinОценок пока нет

- Home Made Paint Grenades: Parts ListДокумент8 страницHome Made Paint Grenades: Parts ListjarfishОценок пока нет

- B8 TFSI Catch Can Kit Installation 034-101-1000Документ7 страницB8 TFSI Catch Can Kit Installation 034-101-1000DedelОценок пока нет

- VDO Gauge InstallationДокумент4 страницыVDO Gauge Installationurule2kОценок пока нет

- V350 Factory Service ManualДокумент7 страницV350 Factory Service ManualCKJJ55@hotmail.cm75% (4)

- HP Lok: 2010 EditionДокумент38 страницHP Lok: 2010 Editiondeema saleemОценок пока нет

- Ensamble de TuberiasДокумент17 страницEnsamble de TuberiasFelicia GlassОценок пока нет

- CB34 Manual 30DG J RIB ManualДокумент100 страницCB34 Manual 30DG J RIB ManualgeracuajinaiОценок пока нет

- Mosley - MP 33 N WARCДокумент19 страницMosley - MP 33 N WARCpepepe78100% (1)

- Figure 3: Rolling The Upper Forward Fuselage Skin: Van'S Aircraft, IncДокумент1 страницаFigure 3: Rolling The Upper Forward Fuselage Skin: Van'S Aircraft, IncMark Evan SalutinОценок пока нет

- Gate Valve Installation InstructionsДокумент20 страницGate Valve Installation InstructionsRomi Kristanto100% (1)

- Coolaire Installation InstructionsДокумент15 страницCoolaire Installation Instructionsgeorgemesfin@gmailОценок пока нет

- Hy Lok Tube Fitting Installation Instruction v2Документ15 страницHy Lok Tube Fitting Installation Instruction v2Wellington AraújoОценок пока нет

- Jet 700 4l60 e Billet Powr ServoДокумент4 страницыJet 700 4l60 e Billet Powr ServoJavier VelasquezОценок пока нет

- Peugeot 208 GTI Atmospheric Recirculation Valve InstructionsДокумент6 страницPeugeot 208 GTI Atmospheric Recirculation Valve InstructionsTadashi Gutierrez100% (1)

- BOLTRIGHT Tightening Procedure 6 - 2500Документ2 страницыBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidОценок пока нет

- Van'S Aircraft, Inc.: Detail A-AДокумент1 страницаVan'S Aircraft, Inc.: Detail A-AMark Evan SalutinОценок пока нет

- Lý thuyết màng thẩm thấu ngược (tiếng Anh)Документ111 страницLý thuyết màng thẩm thấu ngược (tiếng Anh)BajaminhОценок пока нет

- Sanitation Repair InstructionsДокумент179 страницSanitation Repair InstructionsKostasKastrinos0% (1)

- Chapter 14 Installing Soffit and Fascia 2013 PDFДокумент5 страницChapter 14 Installing Soffit and Fascia 2013 PDFAmiraHenilОценок пока нет

- SL - No.04. 4178 - 310Документ2 страницыSL - No.04. 4178 - 310Syed Parveez Alam100% (1)

- BTS3902E WCDMA Quick Installation Guide (01) (PDF) - enДокумент16 страницBTS3902E WCDMA Quick Installation Guide (01) (PDF) - enhungpn84100% (1)

- Figure 1: Snap Bushing Bracket Separation: Van'S Aircraft, IncДокумент1 страницаFigure 1: Snap Bushing Bracket Separation: Van'S Aircraft, IncMark Evan SalutinОценок пока нет

- Block II Tech ManualДокумент19 страницBlock II Tech ManualWilliam James AbercrombieОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Ignition System - Inspection Check PDFДокумент4 страницыIgnition System - Inspection Check PDFMark Evan SalutinОценок пока нет

- Ignition Cables and Igniter Installation PDFДокумент6 страницIgnition Cables and Igniter Installation PDFMark Evan SalutinОценок пока нет

- High Low Tension Ignition Comparison PDFДокумент4 страницыHigh Low Tension Ignition Comparison PDFMark Evan SalutinОценок пока нет

- Ignition System - Inspection Check PDFДокумент4 страницыIgnition System - Inspection Check PDFMark Evan SalutinОценок пока нет

- Agard 406351 Ground Effect MachinesДокумент169 страницAgard 406351 Ground Effect MachinesMark Evan SalutinОценок пока нет

- Poly FIber BR-8600 Blush RetarderДокумент2 страницыPoly FIber BR-8600 Blush RetarderMark Evan SalutinОценок пока нет

- Poly Fiber Reducer R65-75Документ2 страницыPoly Fiber Reducer R65-75Mark Evan SalutinОценок пока нет

- Poly Fiber Poly-SprayДокумент2 страницыPoly Fiber Poly-SprayMark Evan SalutinОценок пока нет

- Poly Fiber Poly-SprayДокумент2 страницыPoly Fiber Poly-SprayMark Evan SalutinОценок пока нет

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingДокумент10 страницSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingMark Evan SalutinОценок пока нет

- Silver Brazing FluxДокумент9 страницSilver Brazing FluxMark Evan SalutinОценок пока нет

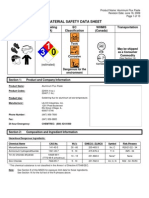

- Material Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationДокумент5 страницMaterial Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationShemi KannurОценок пока нет

- Power CleanДокумент2 страницыPower CleanMark Evan SalutinОценок пока нет

- Sonnen Honing OilДокумент5 страницSonnen Honing OilMark Evan SalutinОценок пока нет

- Sting-X II, Aerosol Certified LabsДокумент4 страницыSting-X II, Aerosol Certified LabsMark Evan SalutinОценок пока нет

- Blue Chalk-Standard MsdsДокумент4 страницыBlue Chalk-Standard MsdsMark Evan SalutinОценок пока нет

- Aluminum Flux PasteДокумент10 страницAluminum Flux PasteMark Evan SalutinОценок пока нет

- Spotcheck Reg Cleaner Remover SKC-HFДокумент3 страницыSpotcheck Reg Cleaner Remover SKC-HFMark Evan SalutinОценок пока нет

- Soldering Flux PasteДокумент9 страницSoldering Flux PasteMark Evan SalutinОценок пока нет

- 1201 Alodine, AKA DX 503Документ7 страниц1201 Alodine, AKA DX 503Mark Evan SalutinОценок пока нет

- Msds For KeroseneДокумент6 страницMsds For KeroseneMahadeva PrasadОценок пока нет

- Al115c Mio Cylinder PDFДокумент2 страницыAl115c Mio Cylinder PDFIwen Tiga BitОценок пока нет

- Hs 342Документ45 страницHs 342Fernando Martinez ContrerasОценок пока нет

- MODEL 670 Drag Chain Conveyor: Installation, Maintenance and Parts ManualДокумент16 страницMODEL 670 Drag Chain Conveyor: Installation, Maintenance and Parts ManualAnand BhiseОценок пока нет

- Elm3320 10344Документ8 страницElm3320 10344georgeОценок пока нет

- MXT Magna MP1528 Transfer CaseДокумент69 страницMXT Magna MP1528 Transfer CaseWilson BuenoОценок пока нет

- Selected Problems Chapters 10 & 12Документ10 страницSelected Problems Chapters 10 & 12assaОценок пока нет

- 997 PDK Oil Change ProcedureДокумент11 страниц997 PDK Oil Change ProcedureEd MoralesОценок пока нет

- Class 800 Steel Check ValvesДокумент2 страницыClass 800 Steel Check Valvesnnaemeka omekeОценок пока нет

- D-11 Chapter 9 Turb Alignment and S P ClearancesДокумент17 страницD-11 Chapter 9 Turb Alignment and S P ClearancesHernan Giraut100% (2)

- D4B80555180-Wheels TyresДокумент12 страницD4B80555180-Wheels TyresjorgebautistagarciaОценок пока нет

- 2 Specification PagesДокумент34 страницы2 Specification PagesRogerОценок пока нет

- Hydro Blowers - OPM-002 - A - JetFan 70 Operators ManualДокумент29 страницHydro Blowers - OPM-002 - A - JetFan 70 Operators ManualvinodОценок пока нет

- SUZUKI - DF25 - DF250 - Small RiggingДокумент110 страницSUZUKI - DF25 - DF250 - Small RiggingJohn PatistasОценок пока нет

- VolvoToothGuide PDFДокумент20 страницVolvoToothGuide PDFCarla Mendez100% (2)

- Fiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICДокумент13 страницFiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICMiguel QueirosОценок пока нет

- Hydraulic Flanges & Components & Dual Seal FlangesДокумент44 страницыHydraulic Flanges & Components & Dual Seal Flangesfernandomachado1992100% (1)

- 7 - The Influence of Nails and Plasterboard On The Racking Resistance of Stud WallsДокумент10 страниц7 - The Influence of Nails and Plasterboard On The Racking Resistance of Stud WallsJulian TumielewiczОценок пока нет

- Planos de Dolly 2 PDFДокумент20 страницPlanos de Dolly 2 PDFerickОценок пока нет

- Clavicle ST LowДокумент20 страницClavicle ST LowEmanuel CortesОценок пока нет

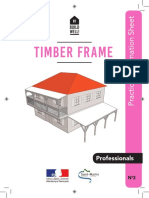

- Timber Frame & Wood Frame DesignДокумент30 страницTimber Frame & Wood Frame Designmokhtar yasserОценок пока нет

- Estimate Gadawara Power Plant, NTPCДокумент420 страницEstimate Gadawara Power Plant, NTPCGopal SudhirОценок пока нет

- RFP - 2023 02 16 17 14 06Документ53 страницыRFP - 2023 02 16 17 14 06Barun kumar paridaОценок пока нет

- BS 10 1962Документ62 страницыBS 10 1962Jignesh PandyaОценок пока нет

- Chapter 2 - Oil ExtractionДокумент42 страницыChapter 2 - Oil Extractionsweetness820% (2)

- Packing ProcedureДокумент12 страницPacking Procedureehsan.m100% (2)

- Earthing Method StatementДокумент2 страницыEarthing Method StatementAndile Cele100% (1)

- Dryer DV5000C WEB EnglishДокумент54 страницыDryer DV5000C WEB EnglishWinstonОценок пока нет

- Is 3757 1985Документ12 страницIs 3757 1985Santosh Kumar100% (2)

- Biomechanical Evaluation of The Screw Preload Values Used in The Plate Placement For Bone FracturesДокумент7 страницBiomechanical Evaluation of The Screw Preload Values Used in The Plate Placement For Bone FracturesBaochun CaiОценок пока нет

- Seaco Premier Dock FloatsДокумент5 страницSeaco Premier Dock FloatsJose MelloОценок пока нет