Академический Документы

Профессиональный Документы

Культура Документы

Mmic 22 PDF

Загружено:

getsweetОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mmic 22 PDF

Загружено:

getsweetАвторское право:

Доступные форматы

Mathematical Models in Engineering and Computer Science

Analysis of Single Phase Moisture and Heat Model of Food Drying

NOR AZNI SHAHARI Universiti Teknologi MARA Department of Mathematics Negeri Sembilan campus MALAYSIA norazni@ns.uitm.edu.my STEPHEN HIBBERD University of Nottingham School of Mathematical Sciences University Park, Nottingham UNITED KINGDOM stephen.hibberd@nottingham.ac.uk

Abstract: Single phase heat and mass models have been widely used to describe the movement of water and heat during drying. In order to reduce the number of parameters and minimise computer time on the problem, reported and non-reported non-dimension numbers have been used. However, very limited research has been done to analyse the sensitivity of these numbers. In this paper, non-dimension analysis of the mathematical model applicable to drying food is discussed. The model combines the principles of mass balance with heat balance for the movement of moisture and heat. Numerical solutions are presented corresponding to one-dimensional food tissues with constant diffusivity. The main nding of the model is the ability of equations with constant properties to represent the movement of moisture and temperature inside the fruit and, consistent with experiment ndings, results providing physical contents are assigned appropriate numerical values. KeyWords: heat, mass, sensitivity, diffusivity.

Introduction

Single phase heat and mass models have been widely used to describe the movement of water and heat during drying. The most common type of single phase modelling in food drying involves one-dimensional heat and mass transfer with empirical values of effective diffusivity. This method has been used by [1, 2, 3, 4] to illustrate drying phenomena. A nitedifference approach [3] or a nite element approach [1, 4] to compute the behaviour of the distribution of heat and mass transfer is widely adopted to solve the resulting equations. Difference between models depends mainly upon assumptions about the surface, such as the use of an equilibrium boundary condition at the surface [5] or convective boundary condition [1]. Dimensionless analysis of the simultaneous heat and mass transfer in food drying has been carried out by Pavon-Melendez et al.[6] and Ruiz Lopez et al. [7]. Pavon-Melendez et al. [6] analysed the transport of moisture and temperature with constant material properties. Non-dimension numbers were obtained and analyses of these non-dimension numbers were used to estimate the mechanisms that control heat and mass transfer during drying but there is no sensitivity of the numbers that were analysed. Ruiz Lopez et al. [7] conducted a similar analysis with variable properties of material during drying. The results obtained by simulation of heat and mass

transfer with variable material properties by experiment were compared with those obtained by analytical solution with equilibrium boundary condition for moisture. However, comparison of the results shows that not all numerical simulations had the same trends in the experiment result but an analytical solution with constant diffusivity reproduces the moisture evolution in an acceptable manner. This demonstrated that variable properties make the system computationally intensive, whereas constant diffusivity can replicate the experiment result. Barati and Esfahani [8] developed onedimensional heat and mass transfer in an innite slab during drying by introducing an analytical solution technique to describe the temperature and moisture evolutions. The result was compared with a set of experiment data found in the open literature. The use of different time scales for moisture and temperature (F om =Dt/L2 , F o=t/L2 ) mean that the moisture and temperature equations cannot be solved simultaneously; this will make the system of equations independent of each other. To make the system of equations dependent on each other, Barati and Esfahani [9], solved the temperature and moisture equation by changing the Fourier number for moisture and temperature at each time step. This is not good practice in terms of model structure not only because of mathematical correctness with regard to the domain, but also the real situation it represents must be the same.

ISBN: 978-1-61804-194-4

137

Mathematical Models in Engineering and Computer Science

The aim of this work was to analyse the nondimension numbers produced in simultaneous heat and mass transfer and conduct sensitivity tests on these numbers. Two different situations were studied, the rst of which was an isothermal condition with negligible latent heat, which gives uncoupled boundary conditions to the mass equation at the surface. In the second model, latent heat effect was considered. This is especially important at the fruit-air interface, where evaporation occurs.

Physical Problem and Mathematical Formulation

air and Csur is the concentration in the form of liquid water lm at the food surface (example see [10]). The fruit sample is a hygroscopic porous media, yet it is assumed to be a ctitious continuum. Weak internal evaporation and transport of vapour within the dehydrated fruits towards the external food surface have not been considered. In the rst instance, we consider models with no shrinkage (x = L0 ) associated with isothermal and non-isothermal diffusion and constant moisture diffusivity (D = D0 ). Non dimensional scaled variables are used: a representative diffusion timescale scaled moisture content, and scaled temperature are dened by M x T T0 D0 t , = and T = . ,M = M L T L2 0 0 air T0 0 (7) The governing equations for diffusion and heat equations as = 2M M = , 2 and 2T T = Le 2 . (8)

The physical problem involves a single slice of food of thickness 2L, initially at a uniform temperature T0 and uniform moisture content M0 . In the case of an innite slab of nite thickness L, the moisture content M (t) across the slab and unsteady temperature T (t) are expressed by the well known system of partial differential equations (PDEs) for moisture and energy transport [4]. During drying, heat is transferred mainly by convection from air to the product surface and by conduction from the surface towards the product centre. Meanwhile, moisture diffuses outwards towards the surface and is vapourized into the air. Such a coupled mechanism provides the basis for a simultaneous moisture and heat transfer model as, s M M = (Ds ); t x x 0 < x < L, (1) (2)

Initial conditions associated with constant conditions are M = 1, and T = 0, at = 0. Taking symmetry boundary conditions in the midplane of the drying slice gives

(

= 0,

and

= 0.

(9)

T T = ( ) ; 0 < x < L. t x x Initial and boundary conditions are at t = 0 : M = M0 , T = T0 , L = L0 ,

At the surface, moisture and temperature boundary conditions of the drying body in contact with drying air become

( ) M = Bim Cair (T sur ) f (M ) 1 , ( ) T M = Bi 1 T sur + .

(10)

(3)

(11)

T = 0, (4) at x = 0 : and x M at x = L : hm (Csur Cair ) = Ds , (5) x T M h(Tair Tsur ) = k Hv Ds . (6) x x In equations (1)-(6) M is local moisture content (dry base), T is local temperature, D represents the effective diffusion coefcient, s is the density of dry solid, Cp heat capacity, k thermal conductivity, x is thickness and t the time. Hv is the heat of vaporization, Tair is air temperature and Tsur is the surface temperature of the fruit, h is the heat transfer coefcient, hm is the mass transfer coefcient, and is thermal diffusivity. Cair is the concentration of moisture in the

ISBN: 978-1-61804-194-4 138

M =0 x

In the above, several dimensionless controlling parameters are dened by hL0 hm L0 , Bi = , Bim = D0 M0 k Hv D0 M0 s Le = , and = . D0 k (Tair T0 ) On the above, D0 represents the constant diffusion coefcient, T0 is initial temperature, M0 is initial moisture. The relationship between aw , moisture content M and the saturated pressure can be found in [2] and used by [11]. In non-dimensional form (T sur ) and f (M ) are given as (T sur ) = A T sur + B T sur + C,

2

(12)

Mathematical Models in Engineering and Computer Science

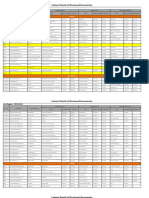

Table 1: Input Parameters used in drying of Mango. Bim =20 Bi=0.3 =0.5 Le=5 Tair =600 C Hv =2345KJ/kg RH =20% s =1080kg/m3

the simulations of M0 =0.8 w.b

4 Results and Discussions

4.1 Experimental validation

Fig. 1 displays the comparison between the experiment results obtained with drying air temperature of 600 C, RH=20% and air velocities=0.5 m/s and the model prediction using Bi=0.3, Bim =20 and Le=5 and =0.5. It was found that there was a close correlation between experimental and predicted values (at 5% level). This Fig. illustrates that the model is able to replicate the trend of experiment moisture evolution of a mango slice during drying. The relative MSE is less than 11%. From this Fig., acceptable agreement is observed.

1

D0 =8x1010 m2 /s h=20250W/m2 K 3 L0 =5mm w =1000kg/m hm =2x106 m/s Cp =2344KJ/kgK =4x109 m2 /s k =0.475W/mK

1

f (M ) = (

M0 E

MD

1 D 1

).

(13)

+MD

A, B, C, D and E are the value of constant was determined experimentally [7]. In equation (13), =2.1667/Cair

Moisture M/M0

0.9

0.8

0.7

3

3.1

Solution Procedure

Numerical Solution

0.6

0.5

The COMSOL Multiphysic program is used to simulate the dehydration process in the drying system, which corresponds to the numerical solution of these model equations. The above system of non linear partial differential equations, together with the described set of initial and boundary conditions, has been solved by Finite Element Method implementation by COMSOL Multiphysic 3.4. The analysis of transport phenomenon presented here is based on the time evolution of variables, i.e. the dimensionless moisture content and temperature at each exposed surface. For drying simulations, the parameters used in the equations for the generic drying condition for mango are listed in Table I.

0.4

15

30 Time (min)

45

60

75

Figure 1: Moisture comparison between model prediction and experiment results for the rst 75 minutes.

4.2 Isothermal solution

In view of non-dimension, the timescale of interest is the time taken for moisture to be diffused to the surface along the thickness of the fruits. The diffusion coefcient of moisture D0 is given for the fruits around 1010 m/s and for fruits with a thickness of 510 mm (0.005-0.01 m). If the drying time to obtain equilibrium is taken as 15000-28000 seconds [40] for the drying of a mango slice, this gives a time scale approximation of 0.36-1.12. We also take the same time scale for temperature, but equation (8) shows that heat transfer by conduction is Le times the mass transfer by diffusion. From the values in Table 1, the value for Le is around 5-100. In this section, the formulation presented above is simplied by assuming that temperature increases rapidly compared to changes in moisture. For cases in which is small, the governing equation for temperature is uncoupled with the governing equation for moisture. The boundary condition for temperature in

3.2

Model verication

Drying experiments were conducted on slices of mango. Before drying, mango were hand peeled and cut into rectangle-shaped slices with thickness of 5mm, width 5 mm and length 10 mm. The initial temperature and moisture content of the product were 300 C and 80%wb (4.0 db) respectively. Mango were dried using conversional hot air drying at air temperature 600 C, 20% RH and air velocities of 0.5 m/s. Food moisture evolution during drying was calculated by regularly measuring the sample weight loss with a balance every 15 min during the rst 75 min. Then, because of the drying rate decrease, measures were taken every one hour until the end of drying.

ISBN: 978-1-61804-194-4

139

Mathematical Models in Engineering and Computer Science

Figure 2: Prole of moisture at time =0.5,1 and 1.5 for different values of Bim

Fig. 2 shows the behaviour of moisture prole, varying the parameter Bim . From Fig. 2, Bim has a great impact, if Bim =1. The results suggest that, at any time during the transient process, it is reasonable to assume a uniform moisture distribution across the food. This is not the case for drying, where the moisture gradient within the foods is signicant (consistent with the experiment ndings for mango [3]). In experiments by [6], when the Bim number is bigger than 30 and change of air velocity is made, the drying curve of moisture is practically overlapped, which shows that drying is by diffusion control. In the simulation in Fig. 2, we also observed that an increase in Bim causes a much faster decrease in moisture and the moisture gradient between the surface and centre is much bigger.

1

equation (11) becomes and T = Bi(1 T ),

Bi =20 0.9

m

at

= 1.

(14)

M/M

0.8 0.7 0.6

Bim=5

Bim=1 Bim=0.5

Bim=0.1

Solutions for the temperature equation can be readily obtained analytically as it is analogous to classic diffusion with surface evaporation (see Crank [12] and Carslaw and Jaeger [13]). The solution can be written as an innite series as 2 Bi cos(n ) exp(n ) T T0 = 1 . 2 + Bi2 + Bi) cos( ) Tair T0 (n n n=1 (15) Where the n s are the positive roots of tan =Bi, the steady state temperature corresponds to T 0, and T 1. This is equivalent to Crank [12]. The time 1 scale for temperature changes is by O( 2 ) and hence >>1 then rapidly compared to change in moisture. At this limit, the boundary condition for the moisture at the surface (equation (10) can be approximated by (T ) = (T = 1) = 1 as

2

0.5 0.4 0.3 0.2 0.1 0 0 1 2 3 4 5 Time (=D0t/L0) 6 7 8

T =

Figure 3: Amount of moisture loss by evaporation at the surface with different values of Bim Fig. 3 shows a plot with different values of Bim , consistent with the graph showing given by Newmann (in Crank [12]) showing residual moisture left at the surface with time; the bigger the Bim number, the faster the moisture equilibrium with drying air.

) ( M = Bim Cair 1 f (M ) 1

4.3 Non-Isothermal solution

Drying is a fundamental process involving simultaneous heat and mass transfer under transient conditions. When the Bi number is large (>>1), coupled heat and mass transfer should be taken into account in the simulation. The isothermal model is modied to solve the heat equation together with the diffusion equation. For this non-isothermal situation, temperature proles will develop inside the material during drying and a differential energy balance is used to determine this temperature prole. More generally, latent heat is an important consideration and moisture and temperature equations must be solved simultaneously. In food-air interfaces, some heat is used for water evaporation (see equation (6)). This gives a coupled governing equation for heat and mass transfer at the surface.

at = 1.

(16) For drying processes with a small Bi number, a uniform temperature prole in the food can be assumed in the simulation and a single mass transfer model can thus be used to describe the drying process [2]. In this case, when temperature is uniform and increases rapidly compared to the loss of moisture, identied as an isothermal condition, the diffusion equations can be solved without consideration of a heat equation. The only parameter that gives effects in this case is Bim . Bim number represents the surface convection mass transfer with respect to the diffusivity of water.

ISBN: 978-1-61804-194-4

140

Mathematical Models in Engineering and Computer Science

Fig. 4 shows the prediction of moisture at the surface and at the centre of the sample. Fig. 4(a) shows the moisture prole through the sample of the fruit with increasing time. Moisture decreased but this was a little slower compared to the isothermal case. Figure 4(b) shows temperature and moisture proles at the surface. The small value of Bi number, Bi=0.3, gives a slower increase in temperature and this affects the moisture prole, which decreased more slowly than in the isothermal case. Figure 6: Prole of temperature and moisture at the surface for different values of Bi (Le=5, Bim =20 and =0.5)

Figure 4: Prole of (a) moisture through the sample, with elapse time =0-3 in step of 0.25 (b) moisture and temperature at the surface and compared with the isothermal case (Bim =20, Bi=0.3 and =0.5)

4.4

Sensitivity Analysis

Based on the thermo-physical values reported in the literature [7], the non-dimension value was around 0.5 for and 0.2-1 for Bi. For this sensitivity study, we xed the values as 0.5 for and 0.3 for Bi.

Figure 7: Prole of temperature at the surface for different values of (Le=5, Bi=0.3, Bim =20)

Figure 5: Prole of temperature and moisture at the surface against time for different values of Le (Bi=0.3, Bim =20 and =0.5) Sensitivity analysis was conducted with a xed value of Bim =20 and an increased value of Le=5-100. Fig. 5(a) shows that the larger the value of Lewis, the quicker the temperature increase. Based on the literature (Pavon Melendez et al.[6]), if the value of Le is more than 100, this gives an interior temperature that is approximately equal to the surface temperature. Fig. 5(b) shows the moisture at the surface with an

increased value of Le. Moisture evaluation at the surface decreased more quickly for a larger value of Le. To see the effect value of and Bi, the simulation was conducted by xing the value of Le and Bim and varying another two parameter properties, and Bi. The rst simulation was conducted with a xed value of =0.5 and varying the value of Bi=0.1-50. As seen in Fig. 6(a), increasing the value of Bi, the temperature increases rapidly and the moisture also decreases rapidly. The second simulation was conducted with a xed value of Bi=0.3 and increased value of =0.1-10. Fig. 7 shows that, when the value of increased, the temperature increased slowly but was relatively at for =5 and 10. This is not the case for drying, where the temperature usually increases nearly the same as the air temperature. Thus, we can conclude that, with the value of Bi=0.3, the approximation of the value of will be between 0.1-1. This is consistent with the ndings of Pavon Melendez et al. [6] that the value of is around 0.5 for fruits. Based on parametric study, the choice of parameters Bim , Bi, Le and depends on the type of fruits and the drying air temperature.

ISBN: 978-1-61804-194-4

141

Mathematical Models in Engineering and Computer Science

Conclusions

[4]

This paper has adopted a simple one-dimensional model of heat and mass transfer that assumes fruit to be a homogenous structure, as discussed by Wang and Brenann [2]. Using numerical simulation, the behaviour of moisture and temperature subject to underlying air ow was calculated for constant diffusivity. With the assumption that a rapidly increasing temperature will generate a uniform temperature prole inside the fruit, the single mass transfer model can thus be used to describe the drying process. This case of moisture transfer by a diffusion process is known as an isothermal model. The results reveal that, with the use of the diffusion process alone, the movement of moisture can simulate the drying process. Taking the Bim number as 20, we may describe the resistance to diffusion within the food as much more than the resistance to convection across the uid boundary layer. This is consistent with experimental ndings by [1] which indicate that the rate of water loss from the fruits appears to be limited by the diffusion of water through the sample but not the rate of evaporation from the surface. However, for typical drying process, it was found that temperature is an important consideration, taking into account a couple of heat and mass transfers in the simulation. This situation applies to the non-isothermal model. Our analysis indicates that an increase in temperature and a decrease in moisture during drying depend on the value of the parameters at the surface boundary, Bim and Bi and latent heat . In general, by changing these parameter values, all these numbers depend upon the type of fruit under study and validation of experiment results. Acknowledgements: The authors wish to thank the Government of Malaysia and Universiti Teknologi MARA, Malaysia for nancial support. Thanks are due to Dr. S. Hill, Dr N. Alias and Dr P. Gajjar for their suggestions and helpful discussions References: [1] L. Zhou, V. M. Puri, R. Anantheswaran, and G. Yeh, Finite element modeling of heat and mass transfer in food materials during microwave heating - model development and validation, Journal of Food Engineering, 25, 1995, pp. 509529. [2] N. Wang, and J. Brennan, A mathematical model of simultaneous heat and moisture during drying of potato, Journal of Food Engineering, 24(1), 1995, pp. 4760. [3] L. Villa-Corrales, J. Flores-Prieto, J. XamanVillasenor, and E. Garcia-Hernandez, Numerical

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12] [13]

and experimental analysis of heat and moisture transfer during drying of ataufo mango. Journal of Food Engineering, 98, 2010, pp. 198206. S. Janjai, N. Lamlert, P. Intawee, B. Mahayothee, M. Haewsungcharern, B. Bala, and J. Muller, Finite element simulation of drying of mango, Biosystem Engineering, 99, 2008, pp. 523531. M.R. Quiroz, and S.A. Nebra, Theoretical and experimental analysis of the drying kinetics of banana, Journal of Food Engineering, 47, 2001, pp. 127132. G. Pavon-Melendez, J. Hernandez, M. Salgado and M. Garcia, Dimensionless analysis of the simultaneous heat and mass transfer in food drying, Journal of Food Engineering, 51, 2002, pp. 347353. I. Ruiz-Lopez, A. Cordova, G.C. RodriguezJimenes and, M. A. Garcia-Alvarado, Moisture and temperature evolution during food drying: Effect of Variable properties, Journal of Food Engineering, 63, 2004, pp. 117124. I. RuizLopez,, , and E. Barati, and J.A. Esfahani, A novel approach to evaluate the temperature during drying of food products with negligible external resistance to mass transfer, Journal of Food Engineering, 114, 2013, pp. 3946 . E. Barati, and J.A. Esfahani, Mathematical simulation of convective drying: Spatially distributed temperature and moisture in carrot slab, International Journal of Thermal Sciences, 56, 2012, pp. 8694 G.J. Dunn, S. K. Wilson, B. R. Duffy, S. David, and K. Seane, The Mathematical Model of the Evaporation of a Thin Sessile Liquid Droplet: Comparison Between Experiment and Theory, Colloids and Surfaces A : Physicochemical and Engineering Aspects, 323(1-3), 2008,pp. 50 55. N. Shahari, and S. Hibberd. Mathematical modelling of Shrinkage Effect during Drying of Food. in Proceding of 2012 IEEE Colloquium on Humanities, Sciences and Engineering Research (CHUSER 2012). 2012. Kota Kinabalu, Sabah Malaysia. J. Crank, The Mathematics of Diffusion, Oxford Sciences Publication, 1975. H.S. Carslaw, and J.C. Jaeger, Conduction of Heat in Solids, 2nd ed. Oxford University Press, 1959.

ISBN: 978-1-61804-194-4

142

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Renewable Theoretical Summary - Mona - MidtermДокумент11 страницRenewable Theoretical Summary - Mona - MidtermgetsweetОценок пока нет

- Solar 2 - Solar Power PlantsДокумент60 страницSolar 2 - Solar Power PlantsgetsweetОценок пока нет

- Review Problems Soln PDFДокумент10 страницReview Problems Soln PDFgetsweetОценок пока нет

- Review Problems Soln PDFДокумент10 страницReview Problems Soln PDFgetsweetОценок пока нет

- Review ProblemsДокумент5 страницReview ProblemsgetsweetОценок пока нет

- Lesson 4 XPДокумент30 страницLesson 4 XPmaglalang_dexter_024Оценок пока нет

- Review ProblemsДокумент5 страницReview ProblemsgetsweetОценок пока нет

- Review ProblemsДокумент5 страницReview ProblemsgetsweetОценок пока нет

- ITEC Application Form 2014-15Документ8 страницITEC Application Form 2014-15Mangalah Gauari MahaletchnanОценок пока нет

- Bearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°Документ1 страницаBearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°getsweetОценок пока нет

- Curriculum Vitae Replace With First Name(s) Surname(s)Документ2 страницыCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- Curriculum Vitae Replace With First Name(s) Surname(s)Документ2 страницыCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- Sustainable BackgroundДокумент111 страницSustainable BackgroundgetsweetОценок пока нет

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemДокумент2 страницыHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

- Proposal Tips HintsДокумент4 страницыProposal Tips HintsAravindan NatarajanОценок пока нет

- Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaДокумент2 страницыEngineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetОценок пока нет

- 6536examples of Air PollutionДокумент50 страниц6536examples of Air PollutiongetsweetОценок пока нет

- Media Lecture Notes S5B1C6Документ17 страницMedia Lecture Notes S5B1C6getsweetОценок пока нет

- General Overview Boilers and FlowДокумент22 страницыGeneral Overview Boilers and FlowLiam MoylanОценок пока нет

- NEWChapter - 3-Mass Balance PDFДокумент10 страницNEWChapter - 3-Mass Balance PDFAbdelhaleem KhaderОценок пока нет

- Problem 01 Problem 02: Community College of Allegheny CountyДокумент1 страницаProblem 01 Problem 02: Community College of Allegheny CountygetsweetОценок пока нет

- Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaДокумент2 страницыEngineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetОценок пока нет

- ST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaДокумент2 страницыST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetОценок пока нет

- Problem 04 Problem 05: Community College of Allegheny CountyДокумент1 страницаProblem 04 Problem 05: Community College of Allegheny CountygetsweetОценок пока нет

- U U U P T: Quick Visit To Bernoulli LandДокумент9 страницU U U P T: Quick Visit To Bernoulli LandAkash SodhaОценок пока нет

- Worksheet Week7Документ2 страницыWorksheet Week7getsweet0% (1)

- Additonal Asgn 02Документ3 страницыAdditonal Asgn 02getsweetОценок пока нет

- Home Soln 8Документ4 страницыHome Soln 8getsweetОценок пока нет

- Chapter 08 2Документ64 страницыChapter 08 2Subhi MohamadОценок пока нет

- Create The Following Solid Models Using Solidworks.: ExerciseДокумент1 страницаCreate The Following Solid Models Using Solidworks.: ExercisegetsweetОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Surface Treatments & Coatings Ref: S. KalpakjianДокумент22 страницыSurface Treatments & Coatings Ref: S. KalpakjianjojoОценок пока нет

- CompressДокумент14 страницCompressAnonymous gfR3btyU0% (1)

- Nil Queries Sheet: S. No. ProcessДокумент24 страницыNil Queries Sheet: S. No. ProcessTarun BhardwajОценок пока нет

- Bodie8ce FormulaSheet PDFДокумент24 страницыBodie8ce FormulaSheet PDFSandini Dharmasena PereraОценок пока нет

- NF en 1317-5 In2Документ23 страницыNF en 1317-5 In2ArunОценок пока нет

- Decisions Made by The DecisionДокумент2 страницыDecisions Made by The Decisionneil arellano mutiaОценок пока нет

- Crew Body Temp: Arrival ArrivalДокумент1 страницаCrew Body Temp: Arrival ArrivalАлександр ГриднёвОценок пока нет

- Sick - Photoelectric 4-180 MM v2Документ7 страницSick - Photoelectric 4-180 MM v2Muhammad SumeetОценок пока нет

- Labour Bureau: Ministry of Labour and Employment, Government of IndiaДокумент1 страницаLabour Bureau: Ministry of Labour and Employment, Government of IndiavinodОценок пока нет

- Final ResearchДокумент6 страницFinal ResearchArenly LongkumerОценок пока нет

- Union Class Dropship 3025Документ1 страницаUnion Class Dropship 3025A KОценок пока нет

- Appendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSДокумент1 страницаAppendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSPau PerezОценок пока нет

- FM Solved ProblemsДокумент28 страницFM Solved ProblemsElisten DabreoОценок пока нет

- Case Study (3 To 5 Months Test Plan) : Test Deliverable Responsibility Completion TimeДокумент1 страницаCase Study (3 To 5 Months Test Plan) : Test Deliverable Responsibility Completion Timepry_kumОценок пока нет

- Galley Steward Knowledge: Free Screening / Interview GuidelineДокумент2 страницыGalley Steward Knowledge: Free Screening / Interview GuidelineAgung Mirah Meyliana100% (2)

- Efqm Success-Story-Book LRДокумент34 страницыEfqm Success-Story-Book LRabdelmutalabОценок пока нет

- Helicopter MaintenanceДокумент347 страницHelicopter MaintenanceJai Deep88% (24)

- Polaris Ranger 500 ManualДокумент105 страницPolaris Ranger 500 ManualDennis aОценок пока нет

- ManualДокумент36 страницManual2009tamerОценок пока нет

- Packages: Khidmatul A'WaamДокумент4 страницыPackages: Khidmatul A'WaamAltaaf IzmaheroОценок пока нет

- WT Notes by Mohammed Ahmed PDFДокумент11 страницWT Notes by Mohammed Ahmed PDFElavarasan MathiОценок пока нет

- SKF BeyondZero White Paper 12761ENДокумент12 страницSKF BeyondZero White Paper 12761ENdiosmio111Оценок пока нет

- Shalina Healthcare JD - Business AnalyticsДокумент2 страницыShalina Healthcare JD - Business AnalyticsMeow bunОценок пока нет

- Writing NuocRut Ver02Документ118 страницWriting NuocRut Ver02thuy linhОценок пока нет

- Huawei Videoconferencing HD Endpoint TE50 Datasheet - 20140221Документ2 страницыHuawei Videoconferencing HD Endpoint TE50 Datasheet - 20140221nuttylОценок пока нет

- General Milling Corp Vs CA (DIGEST)Документ2 страницыGeneral Milling Corp Vs CA (DIGEST)Raima Marjian Sucor100% (1)

- Gcm02-Mt-Ing4 New1 PDFДокумент57 страницGcm02-Mt-Ing4 New1 PDFabdel jabbar67% (3)

- Repair of Small Household Appliances and Power ToolsДокумент315 страницRepair of Small Household Appliances and Power ToolsahmadnawazjaswalОценок пока нет

- Divisional Sec. Contact Details 2019-03-01-UpdateДокумент14 страницDivisional Sec. Contact Details 2019-03-01-Updatedotr9317Оценок пока нет

- A Case Study On Mahindra's Blue Sense Application Project by RohitДокумент43 страницыA Case Study On Mahindra's Blue Sense Application Project by RohitrohitОценок пока нет