Академический Документы

Профессиональный Документы

Культура Документы

Abj Corporate Brochure - Smallsize

Загружено:

umer shafiqueИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Abj Corporate Brochure - Smallsize

Загружено:

umer shafiqueАвторское право:

Доступные форматы

CORPORATE PROFILE

FABRICATION SERVICES AND BEYOND

WELCOME TO ABJ Engineering & Contracting Co.

ABJ Engineering & Contracting Co.

(Canteen)

(Equipment Division)

(Quarantine area)

(Covered shop bays)

(Covered store and supervisor office) (Radiography bunkers)

(Fabricated piping) (Office Building)

(Fabricated piping)

(Pressure vessels assembly) (Duct workshop)

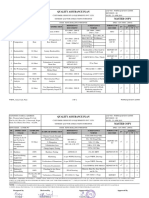

Assets

Profile

Logistics

CONTENTS

Clientele

Products

(Paramedics) (Welding training center) (PW HT Furnace) (Skids assembly)

Accreditations

Plant & Machinery

Services 22

ABJ Engineering & Contracting Co.

(Material storage area)

(Painting/assembly area) (Blasting and painting area)

24

04

08

Our Locations 32

31

30

28

26

ABJ Engineering & Contracting Co.

PROFILE

in nineties to an emerging Global player in the millennium. Today we serve the tailor made needs of a large clientele in Oil & Gas, Petrochemical, Fertilizer, Power, Water, Wastewater, Infrastructure and Industrial Sectors. Our diversified range of products

Over one and half decades ago, Kharafi National, the Kuwait based conglomerate, created ABJ Engineering & Contracting Co. KSCC. ABJ was then perceived to be a structural steel and pipe spool Fabrication Company and that would mainly support the construction projects of the parent, Kharafi National.

4

comprises of Pressure Vessels, The concerted efforts and professional approach yielded in expanding the shops to 30000 sq m in Shuaiba Industrial Area in 1993 to another 200,000 sq m grass root facility in Mina Abdullah Area in 2005. Since then, ABJ has grown by leaps and bounds, developing and launching new products and shifting its stance from an ancillary unit to a Stand-alone profit based entity. The passion to grow exponentially while adopting customer oriented approach could transform the nascent company Columns/Towers, Process Equipment Modules, Modularized Industrial Pipe Racks, Piping & Valve Skids, Shell & Tube Heat Exchangers, Heat Recovery Steam Generators (HRSGs), and Packaged Evaporators & Deaerator units for Desalination Plants, Pre-Fabricated Pipe Spools, Pressurized & Atmospheric Shop Fabricated Storage Vessels/Tanks, and Architectural Roof Structures for International Stadiums. The value added services encompass Refurbishment / Re-Conditioning of Coded Pressure Vessels & Heat Exchangers, Lining & Coating of special material in internal surface of Pressure Vessels and

ABJ Engineering & Contracting Co.

Large Diameter Pipes for corrosion protection, automatic weld overlay on nozzle necks including small bore pipes. The export of its products to Spain, South Africa, Russia, Saudi Arabia, UAE, Iran, Iraq, and Indiareenforces the companys ability to guarantee their clients consistent high quality products at competitive price. Our dedication to quality is reflected in our being ISO 9001:2008 and our shops have been accredited with

ASME U,U2,R,S,P & NB. ABJ is preparing to acquire N Stamp to extend its services to the Nuclear Industry. We own fiduciary responsibility to meet our commitments to health, safety and environment. We believe in building up a high morale of people that would sustain us as a great company.

ABJ Engineering & Contracting Co.

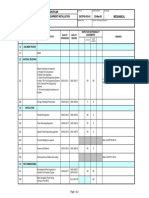

THE JOURNEY CONTINUES AT ICAD III

To support its exponential growth, ABJ, Kharafi Nationals fabrication subsidiary invested substantial amount in purpose built large scale state of art new fabrication facilities in ICAD III Abu Dhabi.

The new facilities of ABJ Industries PJSC are built in Zone Three of the Industrial City of Abu Dhabi (ICAD III) in UAE. The choice of ICAD III was strategic decision. ICAD III enables ABJ to cater for clients in the Oil & Gas, Power, Water, Wastewater and Industrial Infrastructure sectors in Abu Dhabi. The location also enables ABJ to fulfill the customized requirements of the South African, Middle Eastern and Western regions while retaining its cost competitiveness and quality.

The new workshop is just five kilometers from a major sea-port and acquisition of their own Nicolas Hydraulic Trailer means that ABJ Industries PJSC is able to easily handle the logistics of delivering massive fabricated equipments to far-away projects. The fabrication facilities at ICAD III have footprint of over 250,000 square meters. The new facilities at Abu Dhabi is a mirror image of facilities at Kuwait

ABJ Engineering & Contracting Co.

Abu Dhabi

and possess a host of CNC based sophisticated plant and machinery. The facilities at ICAD III have six covered bays with EOT Cranes. The rest of the plants have spaces allocated to facilities that include:

A welders training centre identical

to the training centre in ABJs Kuwait facilities, where the welders will receive hands-on training prior to qualification by a third party.

Radiography bunkers for the

radiographic testing of pre-fabricated pipe spools and structures to ensure an uninterrupted work flow while protecting the health and safety of workers.

Covered storage and a warehouse

for storing bulk materials procured for projects as well as free-issue materials from clients.

Dedicated blasting and painting

areas, both covered and open, for surface preparation.

A post weld heat treatment furnace. A large area for assembly, testing

and pre-commissioning several finished products simultaneously.

The exemplary health & safety

standards, which are undergoing continuous modification in the light of circumstances and are enforced strictly, will be transferred to its operations in Abu Dhabi. The new facilities are operational since December 2010.

ABJ Engineering & Contracting Co.

PRODUCTS Modular Packages / Skids

ABJ Engineering & Contracting Co.

Every year more and more plant owners, engineering consultants, OEMs recognizes the advantages of having all or part of their equipments pre-fabricated on skids. Some time complexity and the size of the equipment can mean that a number of separately built skids (or modules) become necessary. These are simply interconnected at site when delivered to job site. ABJ is specialized in fabrication of these modular skid mounted packages and capable to manufacture several modules simultaneously. These fabricated modules are tested and pre-commissioned in all disciplines including mechanical, electrical & instrumentation for trouble free hook up at site. Some of the typical modules fabricated at ABJ are;

Process Equipments Modules /Skids. Piping & Valve Skids Gas Dehydration Modules Gas Treatment Modules Chemical Dosing Skids Corrosion Inhibitor Skids. Industrial Modularized Pipe Racks. Evaporator Modules Heat Recovery Steam Generator Modules Deaerator Modules.

ABJ Engineering & Contracting Co.

PRODUCTS Pressure Vessels

ABJ has capability to Design, Manufacture and Supply of Pressure Vessels, Reactors, Columns/Towers, Desalter Vessels, Filter Vessels. ABJ Designs and Manufactures these as per ASME Sec VIII Div 1 and ASME Sec VIII Div 2 and authorized to use ASME U and U2 stamps. The welding processes and procedure qualifications have been developed for variety of different grades of materials like Carbon Steel, Carbon Steel NACE/HIC, LTCS, Stainless Steel, Clad Stainless Steel, Clad Inconel etc., Having served clients like Saudi Aramco, ADCO, GASCO, KNPC, KOC, Equate, PIC BAPCO, South Oil Company EPC major players such as Saipem, Tecnimont, Petrofac, SKEC and other International majors. ABJ has an illustrious track record in export to Russia, Spain India in addition to supplies to the Middle East & Africa.

10

ABJ Engineering & Contracting Co.

11

ABJ Engineering & Contracting Co.

PRODUCTS Shell & Tube Heat Exchangers

ABJ has the capability to Design, Manufacture & Supply Shell & Tube Heat Exchangers as per ASME Sec VIII Div 1 and TEMA, authorized to use ASME U stamp. Our shop is self sufficient in drilling and machining tube sheets and flanges using CNC Drilling, Milling & Boring Machines.

12

ABJ Engineering & Contracting Co.

Heat Recovery Steam Generators

ABJ has strategic tie-up with Nooter Eriksen, world renowned Independent designer and supplier of Heat Recovery Steam Generators (HRSGs). Under this agreement ABJ supports and fabricates HRSGs for Nooter Eriksen in the Middle East & North Africa. ABJ shops have acquired S stamp accreditations for their fabrication and assembly of power boilers.

ABJ jointly with Nooter Eriksen have secured the first break-through by getting order for HRSGs from Daelim Industrial Co., Korea for their project of 4th LPG Train at Kuwait National Petroleum Company, Kuwait.

13

Photo by Nooter Eriksen

ABJ Engineering & Contracting Co.

PRODUCTS Desalination Plant Equipments

ABJ diversified into yet another line of business in 2008 commencement of new era of construction, transportation & erection of Evaporators, Deaerators, Water Boxes and associated equipments for Thermal Desalination Plants. The break-through order was supplied to Shuaiba North Desalination Plant and these were built with the design of Fisia Italimpianti Italy. ABJ invested a fortune in building mandatory assets in:

Sophisticated Plant & Machinery for critical drilling, milling,

machining of tube sheets, tube support plates and collar flanges.

Training manpower in fabrication technology Developing critical welding procedures and procedure qualifications (WPS & PQR) to perform critical welds such as Cupro-Nickel to Duplex Steel.

ABJ is fully equipped and geared up to build Modularized Evaporators, Deaerators, Brine Heaters, Steam Transformers and associated equipments for MSF / MED Desalination Plants.

14

ABJ Engineering & Contracting Co.

15

Photo by Fisia Italimpianti

ABJ Engineering & Contracting Co.

PRODUCTS Architectural Roof Structures

16

ABJ Engineering & Contracting Co.

ABJ is one of the few internationally qualified fabricators for Architectural Steel Structural work for Stadium Roofs. The company is honored to have participated in the fabrication of the Roof Structure for two new stadiums namely Nelson Mandela Stadium at Port Elizabeth and Green Point Stadium at Cape Town South Africa. Both stadiums were part of the 2010 FIFA World Cup. ABJ commenced building Stadium Roof Structures in 2007, the first being Jaber Al Ahmed International Stadium in Kuwait.

17

ABJ Engineering & Contracting Co.

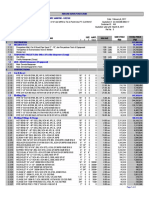

PRODUCTS Pressure and Process Piping

18

ABJ Engineering & Contracting Co.

ABJ has customized facilities for pre-fabricated Pipe Spools for executing large capacity, in excess of 1 Million Inch dia, for mega projects. Our customized facilities include:

ERP based On-line Tracking System to track live status

on fabrication, NDT, Painting, QC release and dispatch.

CNC Plate Cutting Machine installed with SIGMA NEST

software, having compatibility to handle AUTOCAD Drawings for fabrication of large diameter pipes & MITRES from plates. The software optimizes the cutting layout and minimizes wastage.

Dedicated rolling machine for fabrication of pipe spools & mitres from plates. Unique Bar Coding system for segregation and

identification of spools from the incoming materials through to the final dispatch and installation at project site. ABJ has built illustrious track record for the fabrication of pipe spools in exotic materials such as Stainless Steel 304, 304L, 316, 316 L, Duplex / Super Duplex, Titanium, Inconel, Incoloy, 6Mo Steel, Monel. This is in addition to pipe spools in Carbon Steel including service (HIC) requirements, Low Alloy Steel and Low Temperature Carbon Steel.

19

ABJ Engineering & Contracting Co.

PRODUCTS Shop Fabricated Pressurized

ABJ has capability to Design, Manufacture and Supply of Pressurized Storage Vessels such LPG Bullets and Atmospheric Storage Tanks for the core sectors in Oil & Gas, Petrochemical, Fertilizer, Water, Waste Water, Chemical and allied industries. ABJ possess software such TANK, E-TANK & STAAD PRO and as per codes and standard complying with API 650, API 620, AISC & UL 142.

20

ABJ Engineering & Contracting Co.

Storage Vessels and Atmospheric Tanks

21

ABJ Engineering & Contracting Co.

Corrosion Protection Services

SERVICES

ABJ possesses the critical skills to apply internal lining & coatings on the internal surfaces of Pressure Vessels, Tanks and Large Process Piping to mitigate corrosion & enhance the life of the equipments. The following are some of the coating schemes currently practiced in conformance with clients specifications:

Phenolic Epoxy Passive Fire Proofing Glass Flake Resin System Polyester or Vinyl Ester Refractory and Cement Mortar Lining Belzona Metalization (Al, Zn Thermal Spraying)

Re-Conditioning of coded Pressure Vessels and Shell & Tube Heat Exchangers

ABJ Performs weld overlay on nozzle necks for cladded pressure vessels and heat exchangers from small bore 2 to 24 size using an automatic weld overlay machine.

22

ABJ Engineering & Contracting Co.

Bore Cladding and Weld Overlay

ABJ holds the National Board R Stamp for repair and refurbishment of U & U2 stamped Pressure Vessels including re-tubing of Shell & Tube Heat Exchangers. Other typical work tasks include nozzle and man way addition, head repair and replacement etc.

23

ABJ Engineering & Contracting Co.

Assets

ABJ has large work force coming from different nationality and all are trained to be multi skilled to work on several projects simultaneously. We are very conscious of the health & safety of our personnel employed at our facilities. The Company has large number of skilled and qualified welders and many are qualified to weld exotic materials such as Cupro-Nickel, Duplex, Super Duplex, Stainless Steel, Inconel, Incoloy, Alloy Steel, 6 Mo etc.,

Manpower

We believe

Our people are prime assets.

24

ABJ Engineering & Contracting Co.

DESIGN AND ENGINEERING

Welding Training Center

ABJ is self sufficient in Design & Engineering. Our team of Design Engineers and qualified CAD Operators performs engineering functions in-house. The team is well versed in using Industry software such as PVElite, Compress, Ansys, StaadPro, Tekla etc.,

The state of art Welding Training Center is believed to be a mandatory asset to impart training to the welders with regard to the given materials, thickness, welding processes, welding position etc., The center of excellence has 60 booths to train as well as to pre-qualify all welders by a Third Party and / or clients to minimize weld repairs / re-work, optimize the fabrication cycle time and eliminate undue delays in delivery ABJ is one of the few fabrication shops in Middle East region to possess such asset.

25

ABJ Engineering & Contracting Co.

Plant and Machinery

26

Raw Material Storage

Assembly Area

Covered Bays

ABJ Engineering & Contracting Co.

ABJ has an extensive range of some of the most sophisticated fabrication, painting and testing equipment in the Middle East coupled with Welder Training Center, Post Weld Heat Treatment Furnace, Radiography enclosures, Nicholas Hydraulic Trailers.

Mina Abdullah & Shuaiba Shops, Kuwait - Total area 230,000 Sq.M

Machine Shop Painting & Furnace Fabrication Shop

27

ABJ Engineering & Contracting Co.

Logistics

With strategic location of the shops just 5 kilometers away from the sea-port and acquisition of their own remote controlled Nicolas Hydraulic Trailers, ABJ takes care of the inter-model logistics with the ease that builds their Clients confidence in reaching the overdimensional consignments at the door step of far away project destinations.

28

ABJ Engineering & Contracting Co.

29

ABJ Engineering & Contracting Co.

Accreditations

30

ABJ Engineering & Contracting Co.

Clientele

31

ABJ Engineering & Contracting Co.

our LOCATION

www.abjengineer ing.com

32

www.abjindustr ies.c om

ABJ Industries PJSC

KN HEAD OFFICE ICAD

INDUSTRIAL AREA

www.abjengineering.com

KNCCD - ABJ Brochure - Rev 0 - FEB. 2012

Вам также может понравиться

- Epiterma Company Profile 2016 PDFДокумент70 страницEpiterma Company Profile 2016 PDFIna A. PutriОценок пока нет

- MQP - 1 PDFДокумент15 страницMQP - 1 PDFDoita Dutta ChoudhuryОценок пока нет

- Total Project Cost For 2nos. 25KL Tanks and One 40 KL TankДокумент2 страницыTotal Project Cost For 2nos. 25KL Tanks and One 40 KL Tankarajamani78Оценок пока нет

- D & H Secheron Electrodes PVT - LTD.,: Type 5x450 5x350 4x450 4x350 3.15x450 3.15x350 2.5x350Документ3 страницыD & H Secheron Electrodes PVT - LTD.,: Type 5x450 5x350 4x450 4x350 3.15x450 3.15x350 2.5x350Pradyumna Mohapatra100% (1)

- Mahesh Pandit Updated CV 09.01.2021Документ12 страницMahesh Pandit Updated CV 09.01.2021Mahesh PanditОценок пока нет

- Back Weld Repair Procedure QualificationДокумент15 страницBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataОценок пока нет

- WPS PQR 12 PDFДокумент9 страницWPS PQR 12 PDFVinay YadavОценок пока нет

- Line Pipe Material and Manufacturing StandardsДокумент31 страницаLine Pipe Material and Manufacturing Standardsjhon smithОценок пока нет

- Cleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - EngneeringДокумент5 страницCleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - EngneeringVasilica BarbarasaОценок пока нет

- Is 5624Документ9 страницIs 5624jselwyn1980Оценок пока нет

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Документ5 страницA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableОценок пока нет

- ASTM A519 GR 4130 Seamless Pipe QДокумент1 страницаASTM A519 GR 4130 Seamless Pipe QsirjamlesОценок пока нет

- Api-Mip-5lДокумент76 страницApi-Mip-5lVan LinhОценок пока нет

- Scanned Indian Standards ListДокумент30 страницScanned Indian Standards ListJignesh TrivediОценок пока нет

- 7420 0005 250 Esp 005 - 0 Specification For PaintingДокумент23 страницы7420 0005 250 Esp 005 - 0 Specification For PaintingJorge Isaac Lara RamosОценок пока нет

- S-8018 B2Документ5 страницS-8018 B2Abhishek AnandОценок пока нет

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedДокумент2 страницыWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleОценок пока нет

- BGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Документ48 страницBGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Gururaj P KundapurОценок пока нет

- Sor BPCL KochiДокумент79 страницSor BPCL KochiPrafulla PatilОценок пока нет

- Improving Quality of Welding with ISO 3834Документ53 страницыImproving Quality of Welding with ISO 3834AlienshowОценок пока нет

- dpvc-09 Petrobras PDFДокумент47 страницdpvc-09 Petrobras PDFBilly TanОценок пока нет

- S No. Description Quantity: Comparision of RatesДокумент4 страницыS No. Description Quantity: Comparision of Ratesk.sankaranandОценок пока нет

- Cost Effective ConnectionsДокумент14 страницCost Effective ConnectionsMarakan MaranОценок пока нет

- 35 MRJN - Color Code Chart - Rev. 02Документ1 страница35 MRJN - Color Code Chart - Rev. 02احمد حسنОценок пока нет

- Subodh Lab Pricelist Rev1Документ7 страницSubodh Lab Pricelist Rev1anubhavlОценок пока нет

- Astm 1.05Документ3 страницыAstm 1.05asprclms durgapurОценок пока нет

- Allied International Group 2014Документ44 страницыAllied International Group 2014Enoch TwumasiОценок пока нет

- ThyssenДокумент0 страницThyssenAbbas RizviОценок пока нет

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Документ4 страницыProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabОценок пока нет

- Approved ITP 06012023 For WT6Документ1 страницаApproved ITP 06012023 For WT6mohamed irsath100% (1)

- 2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFДокумент22 страницы2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDadaso Baburao JamdarОценок пока нет

- Pressure Test Execution Plan Mar 24 Rev.cДокумент12 страницPressure Test Execution Plan Mar 24 Rev.cAbdullah Al JubayerОценок пока нет

- 1 SATIP-B-019-01 Portable Fire Protection Equip-Rev 1Документ2 страницы1 SATIP-B-019-01 Portable Fire Protection Equip-Rev 1JithuJohnОценок пока нет

- 6 Contractor QC Resume Review ChecklistДокумент1 страница6 Contractor QC Resume Review ChecklistMudabbir HussainОценок пока нет

- 1.1 Welder Test 86,350,000: PackageДокумент2 страницы1.1 Welder Test 86,350,000: PackageAhmad Dzulfiqar RahmanОценок пока нет

- HPCL TenderДокумент214 страницHPCL TenderDayanandSonawaneОценок пока нет

- Contractor QC Supervisor Resume Review ChecklistДокумент1 страницаContractor QC Supervisor Resume Review ChecklistAdnan ArshidОценок пока нет

- Ms. Jennylyn P. PascualДокумент3 страницыMs. Jennylyn P. PascualDarius Frane MarasiganОценок пока нет

- AWWCE Unit Rates For Pipe Work - LegaДокумент24 страницыAWWCE Unit Rates For Pipe Work - LegaMiko Abi0% (1)

- CH EmeticsДокумент1 страницаCH Emeticsrudy_423522658Оценок пока нет

- 6001F Rev 07 Material, Fabrication and Installation StructureДокумент83 страницы6001F Rev 07 Material, Fabrication and Installation StructurePatrickioОценок пока нет

- Steel Structure Design and Fabrication RequirementsДокумент11 страницSteel Structure Design and Fabrication RequirementssbunОценок пока нет

- IQWQ-FT-BSPDS-00-120111 - 0 Packing SpecДокумент27 страницIQWQ-FT-BSPDS-00-120111 - 0 Packing Specjacksonbello34Оценок пока нет

- CV Mechanical Engineer Project Manager 11 Years ExperienceДокумент2 страницыCV Mechanical Engineer Project Manager 11 Years ExperienceDARA SINGHОценок пока нет

- D72307 TC2 PDFДокумент2 страницыD72307 TC2 PDFshivdas bichukaleОценок пока нет

- Product Chemical CompositionДокумент1 страницаProduct Chemical CompositionMohammed HamedОценок пока нет

- PIPING SYSTEM PROJECT FOR GAS DISTRIBUTION FROM HUSKY TO PGNДокумент4 страницыPIPING SYSTEM PROJECT FOR GAS DISTRIBUTION FROM HUSKY TO PGNyuwonoОценок пока нет

- Smart Glass ProcedureДокумент117 страницSmart Glass ProcedureFrancis DhanarajОценок пока нет

- 3 Steel Structure Installation CLДокумент2 страницы3 Steel Structure Installation CLwhah11Оценок пока нет

- Qc&qa AbkДокумент22 страницыQc&qa Abkdosetiadi100% (1)

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCДокумент1 страница22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforОценок пока нет

- 20 Preservation of Piping MaterialsДокумент45 страниц20 Preservation of Piping MaterialsDamar WardhanaОценок пока нет

- PQR - Wps - PWHT P91 To CS: Tunisian Quality EngineerДокумент14 страницPQR - Wps - PWHT P91 To CS: Tunisian Quality EngineerRajeev KhantwalОценок пока нет

- Welder's Master ListДокумент8 страницWelder's Master ListAnonymous rYZyQQot55Оценок пока нет

- SECTION 09960 High-Performance Coatings Rev 0Документ48 страницSECTION 09960 High-Performance Coatings Rev 0rachedОценок пока нет

- The Salt Spray Corrosion of Polymer Coating On Ste PDFДокумент8 страницThe Salt Spray Corrosion of Polymer Coating On Ste PDFrifkifirdausОценок пока нет

- Package 2s E0001 - Jupiter DCR 30-10-2021Документ96 страницPackage 2s E0001 - Jupiter DCR 30-10-2021senthilОценок пока нет

- Electroslag & Electrogas PDFДокумент5 страницElectroslag & Electrogas PDFRobin GuОценок пока нет

- Mechanical Engineer-Syed Zain AliДокумент5 страницMechanical Engineer-Syed Zain AliSyedZainAliОценок пока нет

- Profile of Kadi Contracting Co.Документ33 страницыProfile of Kadi Contracting Co.khan4luvОценок пока нет

- PVAFДокумент3 страницыPVAFVishal BasettiОценок пока нет

- Construction Manual Timber HouseДокумент60 страницConstruction Manual Timber HouseЧавдар ПенеловОценок пока нет

- PVAFДокумент3 страницыPVAFVishal BasettiОценок пока нет

- NPV TableДокумент3 страницыNPV TableAravind Prakash100% (1)

- Prefabricated BuildingДокумент14 страницPrefabricated BuildingSatish PandeyОценок пока нет

- 1english Why Understand Qur AnДокумент128 страниц1english Why Understand Qur AnNor Rizam MazlanОценок пока нет

- Adobe Photoshop Tutorial - Every Tool Explained PDFДокумент130 страницAdobe Photoshop Tutorial - Every Tool Explained PDFumer shafiqueОценок пока нет

- NPV TableДокумент3 страницыNPV TableAravind Prakash100% (1)

- Titman Ch1 3Документ87 страницTitman Ch1 3assabile582083% (6)

- BOSReport PDFДокумент43 страницыBOSReport PDFumer shafiqueОценок пока нет

- 14 - Surat Ibrahim - LinguisticMiracle PDFДокумент29 страниц14 - Surat Ibrahim - LinguisticMiracle PDFmostrom67% (3)

- Sizing Shell and Tube Heat ExchangerДокумент17 страницSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- Beauty of MathematicsДокумент12 страницBeauty of Mathematicsumer shafiqueОценок пока нет

- 10 Steps To Increasing Iman PDFДокумент23 страницы10 Steps To Increasing Iman PDFumer shafiqueОценок пока нет

- Utility Scale Solar Power Plants: A Guide For Developers and InvestorsДокумент204 страницыUtility Scale Solar Power Plants: A Guide For Developers and InvestorsIFC Sustainability94% (18)

- Exterior CladdingДокумент38 страницExterior Claddingumer shafiqueОценок пока нет

- Para 06Документ43 страницыPara 06api-3803246Оценок пока нет

- Prefabrication in Developing Countries: Case Study of India's Growing TrendДокумент6 страницPrefabrication in Developing Countries: Case Study of India's Growing Trendumer shafiqueОценок пока нет

- Solar Photovoltaic Power System HandbookДокумент22 страницыSolar Photovoltaic Power System HandbookGeroldo 'Rollie' L. Querijero100% (2)

- Belief in The Angels PDFДокумент23 страницыBelief in The Angels PDFMohamedTuhamiОценок пока нет

- The Art of TajweedДокумент266 страницThe Art of TajweedAbdullah Rahim Roman0% (1)

- Autocad ShortcutsДокумент13 страницAutocad ShortcutsKriscel CaraanОценок пока нет

- Quran Course BookДокумент120 страницQuran Course BookAnonymous 4u5XkWGOОценок пока нет

- Industrial Development Report 2002-2003Документ203 страницыIndustrial Development Report 2002-2003umer shafiqueОценок пока нет

- Patterns of Manufacturing Development RevisitedДокумент60 страницPatterns of Manufacturing Development Revisitedumer shafiqueОценок пока нет

- Industrial Development Report 2002-2003Документ203 страницыIndustrial Development Report 2002-2003umer shafiqueОценок пока нет

- Public Capital, Infrastructure and Industrial DevelopmentДокумент70 страницPublic Capital, Infrastructure and Industrial Developmentumer shafiqueОценок пока нет

- Stories 20 of 20 The 20 Quran 20 For 20 Children 1Документ113 страницStories 20 of 20 The 20 Quran 20 For 20 Children 1api-219765445Оценок пока нет

- Fundamentals ArabicДокумент87 страницFundamentals ArabicKoos VerwaardeloosОценок пока нет

- Commentary on Surah Yusuf Provides Insights into Prophet Yusuf's LifeДокумент54 страницыCommentary on Surah Yusuf Provides Insights into Prophet Yusuf's LifeLuisa de CesareОценок пока нет

- Pressure & Temp CalculationДокумент3 страницыPressure & Temp CalculationKUNALJAYОценок пока нет

- GE Handbook Guide to Preventing Corrosion in Steam SystemsДокумент19 страницGE Handbook Guide to Preventing Corrosion in Steam SystemsEngr Irfan AkhtarОценок пока нет

- CSI Code Guide for Mechanical, Electrical and Plumbing ProjectsДокумент15 страницCSI Code Guide for Mechanical, Electrical and Plumbing Projectsdelmar02Оценок пока нет

- 500 MW Turbine Design DataДокумент19 страниц500 MW Turbine Design Datasanjay kumar100% (1)

- U.S. Department of Energy Steam System Assessment ToolДокумент43 страницыU.S. Department of Energy Steam System Assessment ToolDiana SoareОценок пока нет

- Design, Operation and Maintenance of LACT UnitsДокумент12 страницDesign, Operation and Maintenance of LACT UnitsDiana Lucía Padilla0% (1)

- Veolia Oil SeparationДокумент8 страницVeolia Oil SeparationbolixinОценок пока нет

- Commissioning Procedure For A Boiler PDFДокумент24 страницыCommissioning Procedure For A Boiler PDFpothan83% (6)

- DBR 300 MW PDFДокумент78 страницDBR 300 MW PDFcynaiduОценок пока нет

- Deaerator Performance TestingДокумент3 страницыDeaerator Performance TestingAbdus Saboor Khalid100% (3)

- TB1-010 Deaerator Design and OperationДокумент2 страницыTB1-010 Deaerator Design and Operationjesus_manrique2753Оценок пока нет

- Refrigeration & Air-Conditioning Interview & Viva Questions With AnswersДокумент23 страницыRefrigeration & Air-Conditioning Interview & Viva Questions With AnswersVăn HoàngОценок пока нет

- 210 MW LMW Turbine EmergenciesДокумент96 страниц210 MW LMW Turbine EmergenciesAshok Rasekar100% (4)

- Heat ExchangerДокумент16 страницHeat Exchangeratulbhogare7100% (1)

- Condensate Cycle SystemДокумент26 страницCondensate Cycle SystemBhumit Sagathiya100% (2)

- Turbine Rolling-Tiroda PDFДокумент11 страницTurbine Rolling-Tiroda PDFs91Оценок пока нет

- New Deaerator For Boiler FeedwaterДокумент6 страницNew Deaerator For Boiler Feedwaterarjmandquest100% (1)

- Glaxo Vol IДокумент164 страницыGlaxo Vol IPrakash WarrierОценок пока нет

- 3 2 4 - LC - D Series PDFДокумент8 страниц3 2 4 - LC - D Series PDFBrLuxy1952Оценок пока нет

- 14 Hot Oil Systems v3Документ14 страниц14 Hot Oil Systems v3sssss100% (1)

- Mex 30201Документ24 страницыMex 30201Yousef Adel HassanenОценок пока нет

- Standards For Air Cooled Condenser-1st Ed-HEIДокумент50 страницStandards For Air Cooled Condenser-1st Ed-HEIalimisaghian6292% (12)

- Softwares Comparison For Thermal Power PlantДокумент6 страницSoftwares Comparison For Thermal Power PlantarjmandquestОценок пока нет

- Aquaanalytics Engineering Notes: Dissolved Oxygen Studies and Deaerator EfficiencyДокумент2 страницыAquaanalytics Engineering Notes: Dissolved Oxygen Studies and Deaerator EfficiencyMohammed YcfssОценок пока нет

- Operating Performance of Large Steam TurbinesДокумент6 страницOperating Performance of Large Steam TurbinesLTE002Оценок пока нет

- Turbine & AuxilariesДокумент64 страницыTurbine & Auxilariesulhatolkargmailcom100% (1)

- Section H3 Traymaster Series Deaerators: Sample SpecificationsДокумент6 страницSection H3 Traymaster Series Deaerators: Sample SpecificationsMOHAMMADОценок пока нет

- UTW CJSC Steam TurbinesДокумент36 страницUTW CJSC Steam TurbinesvamsiklОценок пока нет

- PPCL Training ReportДокумент46 страницPPCL Training ReportAshutosh KumarОценок пока нет

- Unit Normal Shutdown ProcedureДокумент100 страницUnit Normal Shutdown Procedureishak100% (1)