Академический Документы

Профессиональный Документы

Культура Документы

Instructiuni de Utilizare-Intretinere PDF

Загружено:

Alexa AlexandruОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Instructiuni de Utilizare-Intretinere PDF

Загружено:

Alexa AlexandruАвторское право:

Доступные форматы

Cleaning and maintenance of Whr Car Parking Systems

1. Cleaning the Car Parking Systems

1.1 Basic cleaning of the platform surfaces

A regular cleaning of the platform surfaces serves to preserve the unit and is absolutely essential. The platforms driven over by cars are to be cleaned of dirt deposits using a broom, vacuum or wet cloth

Our range of cleaning and maintenance

of Whr Car Parking Systems

Parklifts 1-, 2-, 3-x Economy 2003 Surface 1.1.a) First basic cleaning by customers 1.1.b) Second basic cleaning by customers Parklifts 1-, 2-, 3-x Standard 2003 Surface 1.1.a) First basic cleaning is included when the SIV* (main inspection) is performed 1.1.b) Second basic cleaning is included when the SIV* (secondary inspection) is performed Parking platforms, Turntables, Combilifts Economy 2003 Surface 1.1.a) First basic cleaning by customers 1.1.b) Second basic cleaning by customers Parking platforms, Turntables, Combilifts Standard 2003 Surface 1.1.a) First basic cleaning is included when the SIV* (main inspection) is performed 1.1.b) Second basic cleaning is included when the SIV* (secondary inspection) is performed

Frequency

At least 2 x yearly

1.2 Cleaning in winter

As the winter months cause more heavy wear due to snow, ice, road salt, chippings etc when the platform surfaces are driven over, the following measures are to be observed: 1.2.1 In winter remove any regular condensation in particular below the upper platform(s). 1.2.2 Snow, ice, road salt and dirt deposits are to be removed from the platforms. 1.2.3 Carry out a thorough cleaning of the platforms with broom, vacuum or water jet (domestic water connection up to 5 bar). (Do not use high pressure cleaners.) When droplets form below the upper platform In winter if required several times during the month After the winter season ends, otherwise in addition to basic cleaning 1.2.1 by customers 1.2.2 by customers 1.2.3 by customers 1.2.1 by customers 1.2.2 by customers 1.2.3 by customers for heavy duty use, otherwise see 1.1.a), 1.1.b) 1.2.1 by customers 1.2.2 by customers 1.2.3 by customers 1.2.1 by customers 1.2.2 by customers 1.2.3 by customers for heavy duty use, otherwise see 1.1.a), 1.1.b)

1.3 Basic cleaning of the garage body/pit, unit parts in the pit

1.3.a) Wet clean the pits: Remove snow, rain, surface water etc. in the pits by cleaning e.g. vacuum and then properly dispose of. It is necessary to secure the Car Parking Systems from lowering. 1.3.b) Supports, support bases and support mounts are to be cleaned of dirt deposits. 1.3.c) Dry clean the pits, swept-clean. Caution: Risk to life and limb! Before cleaning the pits it is essential to request your local Whr partner to secure the parking systems At least 1 x yearly, in winter monthly 1 x additionally check and if required carry out At least 2 x yearly 1.3.a) Wet clean: by customers 1.3.a) Wet clean: by customers 1.3.a) Wet clean: by customers 1.3.a) Wet clean: by customers

1.3.b) by customers 1.3.c) Dry clean: Swept clean per parking space (1 x yearly) to be offered by local Whr partner

1.3.b) by customers 1.3.c) Dry clean: Swept clean per parking space (1 x yearly) to be offered by local Whr partner

1.3.b) by customers 1.3.c) Dry clean: Swept clean per parking space (1 x yearly) to be offered by local Whr partner

1.3.b) by customers 1.3.c) Dry clean: Swept clean per parking space (1 x yearly) to be offered by local Whr partner

1.4 Disposal

For the proper disposal the local authorities, such as municipal authorities, environmental protection office or trade supervisory council, are to be informed insofar as residual substances from car oils, batteries or similar have been collected. As required Included in 1.3.b) otherwise by customers Included in 1.1.a), 1.1.b), 1.3.b) otherwise by customers Included in 1.3.b) otherwise by customers Included in 1.1.a), 1.1.b), 1.3.b) otherwise by customers

2. Looking after the Car Parking Systems

Cleaning and looking after As in 02.2004 C023-0007

The unit parts have undergone different corrosion protection measures, depending on their atmospheric or mechanical loading as well as the individual requirements called for by the client. For an effective, long-term protection the following care requirements are to be observed:

2.1 Galvanised plate surfaces

(e.g. in accordance with DIN EN ISO 1461, DIN EN 10 147 or as per DIN EN 10 215) 2.1.1 Zinc oxide (white rust) is caused by damp, poor ventilation or similar. Care measures, if required by means of grinding wool grain A 280 medium fine or brass brush (do not use wire brush!) obtainable from building trade stockists or DIY outlets. Caution: do not use grinding paper or grinding cloth, risk of damaging the surface. If required coat afterwards with a resistant coating material ask your local stockist At least 2 x yearly. Check and if necessary treat during basic cleaning 2.1.1.a) First basic care by customers 2.1.1.b) Second basic care by customers At least 2 x yearly. Check during basic cleaning, and treat if need be Status report by local Whr partner, execution by customers Status report by local Whr partner, execution by customers 2.1.1.a) First basic care by customers 2.1.1.b) Second basic care by customers Status report by local Whr partner, execution by customers Status report by local Whr partner, execution by customers

2.1.2 Iron oxide (rust) caused, for example, by mechanical loading, wear, road salt deposits, insufficient or neglected care. Care measures by means of lightly rubbing down the damaged surface with grinding wool grain A 280 medium fine (obtainable from trade stockists or DIY outlets). Paint treated surfaces ask your trade stockist.

* System maintenance agreement

Cleaning and maintenance of Whr Car Parking Systems

Our range of cleaning and maintenance

of Whr Car Parking Systems

Parklifts 1-, 2-, 3-x Economy 2003 Surface 2.2.a) Performed with the SIV* (main inspection) 2.2.b) Performed with the SIV* (secondary inspection) 2.2.c) Otherwise at least 2 x yearly additionally by customers Parklifts 1-, 2-, 3-x Standard 2003 Surface 2.2.a) Performed with the SIV* (main inspection) 2.2.b) Performed with the SIV* (secondary inspection) 2.2.c) Otherwise at least 2 x yearly additionally by customers Parking platforms, Turntables, Combilifts Economy 2003 Surface 2.2.a) Performed with the SIV* (main inspection) 2.2.b) Performed with the SIV* (secondary inspection) 2.2.c) Otherwise at least 2 x yearly additionally by customers Parking platforms, Turntables, Combilifts Standard 2003 Surface 2.2.a) Performed with the SIV* (main inspection) 2.2.b) Performed with the SIV* (secondary inspection) 2.2.c) Otherwise at least 2 x yearly additionally by customers

2.2 Screws, nuts, washers

When performing basic cleaning of the units immediately check all screws, nuts and washers for correct fit. In the even of rust, brush with a brass brush applying light pressure, clean and spray repair spray after cleaning such as, for example, MULTI-WAX Spray, ask your trade stockist or car workshop.

Frequency

At least 4 x yearly. Check and treat if necessary

2.3 Powder-coated surfaces

Damage due to mechanical or other effects are to be treated as soon as they are detected in order to prevent impairments or infiltration of the powder coating. Care or improvement measures are to be carried out as follows: light rubbing with emery cloth, grain 120 or brass brush (do not use a wire brush!) followed by cleaning and degreasing. Apply the touch-up paint to the damaged points with a brush, such as, for example Polyflex. Touch-up paint RAL 7030 gravel grey, air-dried, Ask your trade stockist At least 2 x yearly. Check during basic cleaning and treat if necessary 2.3 Performed with the SIV* (main and secondary inspection) (2 x yearly) 2.3 Performed with the SIV* (main and secondary inspection) (2 x yearly)

2.4 Disposal

The materials we have named are to be disposed off in accordance with the respective manufacturers recommendations. For proper disposal the local authorities, such as municipal authorities, environmental protection office or trade supervisory council, are to be informed insofar as residual substances from car oils, batteries or similar have been collected. As required 2.4 by customers 2.4 Included for commissioned services, otherwise by customers 2.4 by customers 2.4 Included for commissioned services, otherwise by customers

* System maintenance agreement

3. General remarks

3.1 3.2 The above-mentioned cleaning, care and maintenance work is to be assured, for example, by letting agreements or caretaker services. Please refer to local Whr partner regarding the prices for cleaning and care work: a) Care set for Economy 2003 Surface Protection consisting of: 1 special broom 1 tin of spray-on wax (400 ml) 1 tin of zinc spray (400 ml) 1 tin of zinc touch-up spray (400 ml) 2 brass hand brush 5 pieces of grinding wool grain A 280 medium fine b) Care set for Standard 2003 Surface Protection consisting of: 1 special broom 2 tins of spray-on wax (400 ml) 2 tins of Polyflex touch-up paint RAL 7030 2 brushes 2 brass hand brushes 1 brass-wired brush 5 emery papers grain 120

If parking spaces are occupied during the cleaning and care work, we charge 80% of the respectively commissioned parking space costs. Renewed or more extensive services are to be agreed on a separate basis between the customer and local Whr partner.

Cleaning and looking after As in 02.2004 C023-0007

Please send your queries and orders to your local Whr partner.

W O H R

AUTO PAR K SYS T E M E

We compact parking space

Otto Whr GmbH Postfach 1151 D-71288 Friolzheim Phone Fax +49-70 44-46-0 +49-70 44-46-149

E-Mail: info@ woehr.de Internet: www.woehr.de

Please note: We reserve the right to make design changes. Changes to model details occasioned by technical progress and environmental directives are reserved and also come into force as model change without notice.

Cleaning and looking after As in 02.2004 C023-0007

Вам также может понравиться

- Eurocode 8.6 Part6 - PrEN 1998-6 (ENG)Документ45 страницEurocode 8.6 Part6 - PrEN 1998-6 (ENG)Remus MargineanОценок пока нет

- Eurocode 8.6 Part6 - PrEN 1998-6 (ENG)Документ45 страницEurocode 8.6 Part6 - PrEN 1998-6 (ENG)Remus MargineanОценок пока нет

- prEN1998-3 St34 Jan03 N343 PDFДокумент76 страницprEN1998-3 St34 Jan03 N343 PDFAlexa AlexandruОценок пока нет

- Otel Beton - Proprietati - Echivalente PDFДокумент2 страницыOtel Beton - Proprietati - Echivalente PDFandytuorОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- MCQ - Question-Paper-11 PDFДокумент16 страницMCQ - Question-Paper-11 PDFMuhammad TauseefОценок пока нет

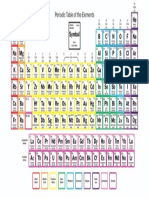

- Periodic Table Labeled GroupsДокумент1 страницаPeriodic Table Labeled GroupsNikFenningÂûОценок пока нет

- Common polyatomic ions and their formulasДокумент16 страницCommon polyatomic ions and their formulasskyline aviationОценок пока нет

- Lecture Notes Air Pollution TechnologiesДокумент27 страницLecture Notes Air Pollution TechnologiesMedo HamedОценок пока нет

- EN FM Flammable GeneralДокумент2 страницыEN FM Flammable GeneralYedersonОценок пока нет

- John Franc Angco - AMTE 216 Assignment Nunber 2Документ5 страницJohn Franc Angco - AMTE 216 Assignment Nunber 2john angcoОценок пока нет

- Fact Sheet - Methane 063011Документ4 страницыFact Sheet - Methane 063011Jn JohnsonОценок пока нет

- Progress in Polyethylene Terephthalate RecyclingДокумент24 страницыProgress in Polyethylene Terephthalate RecyclingyuppeОценок пока нет

- Review of Literature on Aloe Vera and Hand SanitizersДокумент4 страницыReview of Literature on Aloe Vera and Hand SanitizersRamОценок пока нет

- Project Content ChemistryДокумент6 страницProject Content ChemistryPrathmesh MoreОценок пока нет

- Antibacterial Surfaces For Biomedical DevicesДокумент15 страницAntibacterial Surfaces For Biomedical DevicesClever Ricardo ChinagliaОценок пока нет

- Synthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaДокумент3 страницыSynthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDabasish DekaОценок пока нет

- Labreport 4 Biophysical Chem LowryДокумент15 страницLabreport 4 Biophysical Chem LowryJerry CaldwellОценок пока нет

- Constructing Key Questions for PBL in ScienceДокумент3 страницыConstructing Key Questions for PBL in ScienceJboar TbenecdiОценок пока нет

- Vessel Drum Sew DWGДокумент2 страницыVessel Drum Sew DWGSANGEETHAОценок пока нет

- Pop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovalДокумент5 страницPop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovaluserОценок пока нет

- CIL of Preg Robbing GS POXed Slurry For GOLD 100 (FINAL)Документ11 страницCIL of Preg Robbing GS POXed Slurry For GOLD 100 (FINAL)Edgar Barrios JОценок пока нет

- Bass String Diameters and TensionsДокумент6 страницBass String Diameters and Tensionsbonruiz100% (1)

- Name: Ridus Haroon Roll No: 21-10884 Course: Commercialization of Biotechnology Course Code: BIOT305 Section: A Instructor: Z. MehmoodДокумент8 страницName: Ridus Haroon Roll No: 21-10884 Course: Commercialization of Biotechnology Course Code: BIOT305 Section: A Instructor: Z. MehmoodAreeba KhanОценок пока нет

- Cyanide-Free Gold Ore Dressing Agent PDFДокумент13 страницCyanide-Free Gold Ore Dressing Agent PDFAldemar Arciniegas100% (1)

- Acid BassДокумент41 страницаAcid BassRobert Edwards100% (1)

- Queen's University - Mining Engineering - ListДокумент3 страницыQueen's University - Mining Engineering - ListNitinkiet103Оценок пока нет

- Regular chimney inspections extend plant operationsДокумент6 страницRegular chimney inspections extend plant operationstecvidyaОценок пока нет

- Guideline Repeated Dose Toxicity Revision 1 - enДокумент9 страницGuideline Repeated Dose Toxicity Revision 1 - ennimirani2012Оценок пока нет

- Thermal Conductivity Meter: Guarded Heat Flow Test MethodДокумент2 страницыThermal Conductivity Meter: Guarded Heat Flow Test Methodrajesh_rbpОценок пока нет

- Motorized Butterfly Valve With Actuator JJ (WAFN3 - MSEENR)Документ10 страницMotorized Butterfly Valve With Actuator JJ (WAFN3 - MSEENR)hvacvn1984Оценок пока нет

- Chemistry-College 3Документ10 страницChemistry-College 3Subhabrata MabhaiОценок пока нет

- 1000 Error Detection QuestionsДокумент289 страниц1000 Error Detection QuestionsSunil Kumar Jaiswal100% (2)

- Indowud Brochure Revised PDFДокумент10 страницIndowud Brochure Revised PDFsurabhi narangОценок пока нет

- 2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Документ14 страниц2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Vicente SosaОценок пока нет