Академический Документы

Профессиональный Документы

Культура Документы

KEtrix 6S Engl

Загружено:

nhblinhАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

KEtrix 6S Engl

Загружено:

nhblinhАвторское право:

Доступные форматы

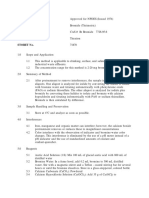

Cold water | Compressed air | Cooling

Triathlon Drinking water (cold)

You have seen the pictures of athletes Clean and uncontaminated water is an

competing in 3 disciplines. essential foodstuff.

The demands are different but the desire Only the best pipe system is sufficient.

to win is the same. Temperature: + 30°C/10 bar

Each discipline is evaluated. + 40°C/ 9 bar

Only the best survive!

Compressed air

Industry-triathlon Pneumatic (up to 16 bar)

Medium for driving, controlling and

Pipe applications other than hot water processing. In all areas of industry.

and heating installations with high

requirements regarding resistance to Chilled water

corrosion, speed of installation and

strength. ( to + 2°C)

Room cooling in accordance with modern

architecture design.

For fan coil systems or cooling pipe work

The winner

in the ceiling. of the industry

The winner in the

industry triathlon

Refrigerants triathlon

(to – 30°C) Quality assurance system

KEtrix® is made of CRYOLEN®, Brine pipelines (e.g. glycol technology) certified by ÖQS

a polyolefine blend. for intensive cooling in the food industry, ÖNORM ISO 9001/EN 29001

A polypropylene alloy with excellent in research and high-tech industries. Reg.Nr.366/0

properties.

Cold water | Compressed air | Cooling

● Resistant to cold temperatures to –30°C The applications

● Elastic at a relatively high rigidity

E-module 1500 N/ mm Pressure rating PN10

● Excellent resistance to chemicals in 20°C nominal pressure 10 bar

the defined area of application – 30°C to + 30°C 10 bar

● Raw material suited for foodstuff + 40°C – 9 bar

(LMG 1975) ON B 5014

● Low specific weight: density of 0.9 Pressure rating PN16

● Four methods of joining for 20°C nominal pressure 16 bar KE KELIT

all applications – 30°C to + 40°C 10 bar Kunststoffwerk GesmbH.

● Complete range of fittings from + 40°C – 10 bar

d 20 – d 110 A-4017 Linz

● Colour: claret with blue stripes Ignaz-Mayer-Straße 17

KEtrix® is unmistakable Austria – Europe

Pipe sizes

● Resistant to corrosion caused

KE KELIT 11/01 eng.

Tel. ++43/73 2/77 92 06-0

by drinking water PN 10 PN 16 Fax ++43/73 2/77 92 06-118

Water

TRI 02 quantity Water

TRI 08 quantity

dxs litre/m dxs litre/m e-mail: office@kekelit.com

20 x 1,9 0,21 20 x 2,8 0,16 www.kekelit.com

©

25 x 2,3 0,33 25 x 3,5 0,25

32 x 2,9 0,54 32 x 4,4 0,42

Testing 40 x 3,7 0,83 40 x 5,5 0,66

50 x 4,6 1,31 50 x 6,9 1,03

KEtrix® is tested as a polypropylene

alloy to the same conditions as

63

75

x 5,8

x 6,8

2,07

2,96

63

75

x 8,6

x 10,3

1,65

2,32

Cold water | Compressed air | Cooling

DIN 8077/78, type PP-B. 90 x 8,2 4,25 90 x 12,3 3,36

A H A ! – KEtrix E.N – 15.10.01

110 x10,0 6,36 110 x 15,1 5,00

The industrial pipe system is

subjected to both internal and The polyfusion welding technology means that there

…innovative Pipesystems

external testing. is no narrowing of the pipe through the fittings.

Cold drinking water The result Compressed air 4 methods

supplies The KEtrix® industry pipe system with

technology Chill technology of joining

many advantages for new building Compressed air is now an integral part

The assured supply of drinking water 1. Polyfusion welding

and renovation projects: of the manufacturing and processing

is an essential part of the quality Range: d 20 – d 110

of modern life. ● Temperature: + 30°C /10 bar industries. Chilled water Refrigerants Pipes and fittings made of identical raw

+ 40°C / 9 bar There are numerous tasks and the solution material. The joint is homogenous and

Pipe systems for chilled water cooling There are only a few types of plastic which requires no extra materials.

The problems ● Range of pipes and fittings for

cold water applications: d 20 – d 110

is often simple. However, the quality of

the piping and its long term properties systems must be safe to use, flexible in are resistant to hammer from refrigerants,

play a decisive role in the safety and the design and quick to install. resistant to corrosion and which have a

Corrosion ● Resistant to both internal and favourable price to quality ratio.

external corrosion from all ions found costs.

● The concentration of ions is increasing. KEtrix® meets all these requirements:

in water or chemicals on the site CRYOLEN® is a polypropylene alloy

The following ions are a particular risk

● No crystallisation points ● The highly secure welding joint (POB = polyolefine blend) and has the

for metal materials: Internal Corrosion - Copper for mineral deposits technology with a safety factor > 3 following properties:

Chlorides: stainless steel

Sulphates: galvanised steel ● Secure joint technology which requires

no additional material ● Resistant to chemicals, aqueous ● Resistant to temperatures

Nitrates: copper solutions and water hammer, down to –30°C

● Even more problematic sources

● Suitable for contact with potable water The requirements also at cold temperatures ● Resistant to all concentrations of

of water are being used for drinking ● Conforms to hygiene regulations

The compressed air can be divided into glycol brines

water supplies ● Low pressure losses as a result ● Resistant to corrosion, even at points

of smooth bore different quality categories which can be where there is unwanted condensation ● Resistant to corrosion even at points

● Acid rain lowers the pH value of classified according to the application. which have fallen below the

surface water and spring water to ● Low noise level temperature of dew point, 2. Threaded joints

The quality depends on many different ● Complete fitting programme which

below 7 (=neutral) ● Easy to install, resistant to impact and at the aggressive temperature Range: d 20 x 1/ 2" – d 75 x 2 1/ 2"-

factors. has been adapted for each application

External corrosive attacks from new ● Easy to handle of + – 0° Threads are manufactured to DIN 2999

The air must be dried or filtered, or the and are made of dezincification resistant

building materials, insulating materials ● Saves on labour costs oil content may need to be changed ● The low weight and easy handling ● No pre-treatment or painting of the brass (MS 63 - CZ 132). They are coated

and installation techniques

● No demountable embedded joints Applications according to the classification. means that many joints can be pipes is necessary with nickel to protect them from stress

pre-manufactured in the workshop. ● Secure welded joint which is very crack corrosion and both male and female

Deposits ● System can be easily drained ● Driving medium for tools such This saves time and costs quick compared to steel/copper/ threads in straight and elbow designs are

● Stringent testing and monitoring as drilling machines, hammer-drive stainless steel available.

● Hard water leads to the formation The pressure dew point

of quality screws, grinding machines, Class Pressure dew point ● KE KELIT pre-manufactures fitting

of deposits on the inside walls of ● Flange connection with EPDM O ring

● Long service life pressure cylinders 1 – 70° C components which are required in

metal materials As a result of the compression of the air seal is resistant to freezing or flat flange

● Pneumatic control systems for machines 2 – 40° C large numbers

the water content in the compressed air for fittings with integrated sealing

This results in rises greatly. Drying the air reduces the 3 – 20° C surface

An important detail ● Driving force for regulating fittings,

solenoid valves, shut-off devices, formation of condensation inside the 4 + 3° C

● Higher friction losses

for drinking water valves ...... system to the minimum possible. The 5 + 7° C

● Reduced flow rate 6 + 10° C

applications ● Purification air at the workplace

pressure dew point is the temperature at

which the water within the compressed air

● Blockages

● Expensive repairs

External Corrosion - Galvanised Steel

Special attention has been paid to the

starts to condense and is categorised in Insulation

different classifications.

● Time-consuming renovation

choice and quality control of Advantages In most cases with cooling systems a

the metal threads.

The solids Max. size Max. concentration specialist insulating contractor will install 3. Flange connection

● Acute supply problems ● Range: d 20 – 110 of particle of particle

Metal threads 3

the insulation with a suitable and approved Range: d 20 – d 110

All the necessary fittings and adaptor Solid impurities found in the air are also Class micro/m mg/m elastomer foam and will ensure that it is

● Dezincification resistant brass The solution for joining to flanged fittings.

(MS 63, CZ 132) for all parts which Pressure rating: PN 16 present in compressed air and must be 1 0,1 0,1 sealed to stop diffusion. Backing ring is joined by polyfusion

transport water ensures a high reduced by filtration. The particle sizes 2 1 1 welding.

● High chemical resistance to

resistance to aggressive water and concentrations are specified in 3 5 5 Straight lengths of pipes are also available

compressor oils

different classifications. 4 15 8 with polyurethane insulation and a spiral

● MS 58 brass for components ● No corrosion. This ensures that pipe covering (made of either aluminium

not in contact with water 5 40 10

the quality of the compressed air or stainless steel). The insulation of the

The solution ● A pore-free, chemically applied, is maintained The oil concentration Oil concentration joints is done by the insulation contractor.

nickel plating prevents stress Class mg/m3

The KEtrix industry pipe system

®

crack corrosion ● Polyfusion welded joints are clean,

Compressors require at least some 1 0,01

for drinking water supplies. leak-proof, secure and homogeneous lubricating oil for the working process.

● The threads are designed to be 2 0,1

resistant to torsion and are suitable ● No energy loss caused by leakage Depending on the application various

Plastics are not "replacement materials". 3 1

for the building site through dried seals procedures must be undertaken to remove

When chosen and applied correctly they this oil from the compressed air. However, 4 5

often provide the better solution for a Plastic threads ● The smooth surface means there 5 25

it must be taken into account that in some

defined problem. The brass in the metal threads is are low friction losses and no narrowing cases a minimum of oil is required in the 4. Electrofusion welding

A H A ! – KEtrix E.N – 15.10.01

Sometimes even the only one. increasingly being replaced by a patented of the cross-section in the fitting. compressed air. Appropriate measures are Range: d 20 – d 110

CRYOLEN® is the answer to the burning high-tech plastic composite thread. As a result of this and the elasticity then taken to add oil to the air. The oil For places which are difficult to access

questions regarding drinking water This is the path to a pipe system made of the material there is a low noise concentration is also divided into different by polyfusion welding KELIT Universal

supplies. Calcite Deposits completely of plastic. transmission categories. E-sockets can be used.

Вам также может понравиться

- Bang Gia Kelen Chuan Binh Minh 2009Документ7 страницBang Gia Kelen Chuan Binh Minh 2009nhblinhОценок пока нет

- PhonEX Eng - UeberseeДокумент28 страницPhonEX Eng - Ueberseenhblinh100% (2)

- Bang Gia Kelen Chuan Binh Minh 2009Документ7 страницBang Gia Kelen Chuan Binh Minh 2009nhblinhОценок пока нет

- KEtrix EK2Документ36 страницKEtrix EK2nhblinh100% (2)

- KELEN HB 07 eДокумент40 страницKELEN HB 07 enhblinh100% (2)

- Installation - Huong Dan Lap Dat Ong PPRДокумент6 страницInstallation - Huong Dan Lap Dat Ong PPRCuong HoangОценок пока нет

- Resistance To Chemical - Phan Ung Voi Cac Loai HoaДокумент5 страницResistance To Chemical - Phan Ung Voi Cac Loai HoaCuong Hoang100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- CH600L Report PDFДокумент53 страницыCH600L Report PDFKatherine May LadoОценок пока нет

- Kopilya 8x80mmДокумент2 страницыKopilya 8x80mmmohamed bakryОценок пока нет

- Bromide Titration MethodДокумент5 страницBromide Titration Methodmaría joséОценок пока нет

- ASME B16.34 Valves Allowed for 13 Cr Stainless SteelДокумент8 страницASME B16.34 Valves Allowed for 13 Cr Stainless SteelInaamОценок пока нет

- ASME B31.8 Wall Thickness CalculationДокумент23 страницыASME B31.8 Wall Thickness Calculationisrar khan100% (2)

- Post Tensioned Concrete Case Study PDFДокумент6 страницPost Tensioned Concrete Case Study PDFShaurya Chauhan0% (1)

- Mueller Indicator PostДокумент16 страницMueller Indicator PostwilfredoruizОценок пока нет

- DLL English 7Документ31 страницаDLL English 7Jocelyn AnavesaОценок пока нет

- Latent HeatДокумент32 страницыLatent HeatAbhijit Kar Gupta100% (11)

- Welding HandbookДокумент368 страницWelding Handbookcahya303Оценок пока нет

- Q-Chem Supplementary Approved Manufacturers List (Saml)Документ4 страницыQ-Chem Supplementary Approved Manufacturers List (Saml)aslam.ambОценок пока нет

- 8301 8310 8312e PDFДокумент16 страниц8301 8310 8312e PDFyuliana zambranoОценок пока нет

- Polymers 10 00825Документ16 страницPolymers 10 00825Özlem YılmazОценок пока нет

- Product Catalogue: ConnectionsДокумент72 страницыProduct Catalogue: ConnectionsRusu AndreiОценок пока нет

- Tetragonal FeSbO4 mineralДокумент2 страницыTetragonal FeSbO4 mineralJorgeBarredaОценок пока нет

- Calculating cement plant production capacityДокумент6 страницCalculating cement plant production capacityIrfan Ahmed100% (1)

- Alternate Fuels For IC EnginesДокумент2 страницыAlternate Fuels For IC Enginesharshasai123456Оценок пока нет

- Final BUA BOQ Tender - OB Plot and Podium - 03.09.21Документ11 страницFinal BUA BOQ Tender - OB Plot and Podium - 03.09.21Jaysukh N SapraОценок пока нет

- Optimization of A Methane Autothermal Reforming-Based Hydrogen Production System With Low CO2 Emission PDFДокумент6 страницOptimization of A Methane Autothermal Reforming-Based Hydrogen Production System With Low CO2 Emission PDFQian Jun AngОценок пока нет

- Mfill 300Документ2 страницыMfill 300Doby YuniardiОценок пока нет

- Pipingmaterials 2Документ23 страницыPipingmaterials 2Godwin MasulaОценок пока нет

- Jain International School 2020 - 2021: A Project For Chemistry On "Study of Constituents & Analysis of An Alloy"Документ15 страницJain International School 2020 - 2021: A Project For Chemistry On "Study of Constituents & Analysis of An Alloy"anmolshubhamОценок пока нет

- DB Injection Moulding1Документ155 страницDB Injection Moulding1bramhananda ukeyОценок пока нет

- Covalence HTLP80: Product Data SheetДокумент2 страницыCovalence HTLP80: Product Data SheetbasukiОценок пока нет

- Concrete Mix, Batching, Mix Design and ProblemsДокумент15 страницConcrete Mix, Batching, Mix Design and ProblemsEng Aidaruos Abdi MatanОценок пока нет

- Chemical Reaction Engineering-II (2170501) : Semester - VII (CHEM) Chapter Name: Catalysis (Chapter 5)Документ11 страницChemical Reaction Engineering-II (2170501) : Semester - VII (CHEM) Chapter Name: Catalysis (Chapter 5)khushbu100% (2)

- BOQ Sample UNDPДокумент20 страницBOQ Sample UNDPharicv019Оценок пока нет

- LR BendДокумент9 страницLR BendGiridharan GanesanОценок пока нет

- Materials Science & Engineering AДокумент10 страницMaterials Science & Engineering AC_rovereОценок пока нет

- Exp 7 Colloids ChemistryДокумент8 страницExp 7 Colloids ChemistryNur Fadhilah100% (1)