Академический Документы

Профессиональный Документы

Культура Документы

Spraymec 1050 WPC 1800045 PDF

Загружено:

vkannan07666Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Spraymec 1050 WPC 1800045 PDF

Загружено:

vkannan07666Авторское право:

Доступные форматы

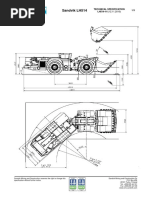

Spraymec 1050 WPC

TI 1800045

DATE 03.07.2012

PAGE 1 / 4

Electro-Hydraulic Shotcreter

Normet Oy

Ahmolantie 6

FI-74510 IISALMI, FINLAND

Tel +358 (0) 17 83 241

Fax +358 (0) 17 823 606

info@normet.f www.normet.f

Spraymec 1050 WPC

TI 1800045

DATE 03.07.2012

PAGE 2 / 4

Electro-Hydraulic Shotcreter

Normet Oy

Ahmolantie 6

FI-74510 IISALMI, FINLAND

Tel +358 (0) 17 83 241

Fax +358 (0) 17 823 606

info@normet.f www.normet.f

Spraymec 1050 WPC

TI 1800045

DATE 03.07.2012

PAGE 3 / 4

Electro-Hydraulic Shotcreter

ENGINE

Deutz TCD2013 L4 2V

120 kW / 2300 rpm

TRANSMISSION

Dana powershift

3 speeds forward and reverse

4-wheel drive

AXLES

Planetary type

Engine end axle oscillation +/- 10

o

TYRES

12.00 - 20 PR 20

BRAKES

Service brake: hydraulically powered dual-circuit oil

immersed multidisc brakes in both axles

Safety/Parking brake: hydraulically

released fail safe -type brake

STEERING

Hydraulic frame steering

Orbitrol type

Frame articulation +/- 40

o

Oscillation +/- 10

o

HYDRAULICS

Steering and boom

210 bar, 95 L/min/2200 rpm

ELECTRICAL SYSTEM

24 V negative ground

Battery 2 X 110 Ah

Alternator 80 A

Lights (2+2) x 70 W

Shotcreting operations:

Working lights 3 x 500 W

PERFORMANCE CURVE

1st gear max. 5 km/h

2nd gear 10 km/h

3rd gear 25 km/h

Max. tractive effort 132 kN

DIMENSIONS

Length 11550 mm

Width 2000 mm

Height 2550 mm

Wheel base 3650 mm

Track 1650 mm

Ground clearance 350 mm

TURNING RADIUS

Outer 7500 mm

Inner 3900 mm

WEIGHT

Operating 15500 kg

SPRAYING BOOM

Boom rotation 270

o

Boom lifting -20

o

...+75

o

Boom folding -60

o

...+165

o

Extension 2200 mm

Nozzle rotation 360

o

Nozzle tilting 105

o

WET CONCRETE PUMP

Electrically operated 4-30 m

3

/h

ACCELERATOR PUMP

Max. pressure 20 bar

Liquid fow 1...20 L/min

ACCELERATOR TANK

Volume 600 L

COMPRESSOR

Electrically powered

Capacity 10m

3

/min

POWER PACK

Electro-hydraulic 400V/50Hz 55 kW

CABLE REEL

Hydraulically driven 100 m

HIGH PRESSURE WASHER

Hydraulically operated

washing effect 180 bar/30 L/min

Max. input water temperature +70

o

C

REMOTE CONTROL

Cable 10 m

WATER HOSE REEL

Manual, 3/4" hose 30 m

FORM OIL SYSTEM

DRIVER'S CABIN

Open 1- man cabin. Non ROPS/FOPS (Optional ROPS/

FOPS approved enclosed cabin enables CE-mark)

Normet Oy

Ahmolantie 6

FI-74510 IISALMI, FINLAND

Tel +358 (0) 17 83 241

Fax +358 (0) 17 823 606

info@normet.f www.normet.f

Spraymec 1050 WPC

TI 1800045

DATE 03.07.2012

PAGE 4 / 4

Electro-Hydraulic Shotcreter

OPTIONAL EQUIPMENT:

690V/50 Hz electrics

1000V/50 Hz electrics

Enclosed cabin for Spraymec 1050 (ROPS/FOPS)

Mercedes-Benz OM 904 LA 110 kW engine

LED driving lights (4 + 2 pcs)

LED working lights on cabin (2 + 2 pcs)

Upgrade Nordozer 900 EH for open canopy models

Upgrade Nordozer 900 EH for enclosed cabin with

extra display

SB 500 radio remote control

Right hand side concrete line assembly

Upgrade 12 cum compressor

Hydraulic driven water hose reel

ADDITIONAL EQUIPMENT:

Soft start system for compressor, 400 V / 50 Hz

Soft start system for compressor, 690 V / 50 Hz

Rock wall washing system 460 bar / 50L

Rock wall washing system 180 bar / 90 L

Cabin heating (enclosed cabin)

Air conditioning for 1050 (enclosed cabin)

Fogmaker extinguishing system (manual)

Fogmaker extinguishing system (automatic)

Ansul extinguishing system (manual)

Ansul extinguishing system (automatic)

Tempus manually actuated (Non CE)

Lubrication system for carrier, boom and pump

(Lincoln)

Fast fuel flling system: Wiggins

1 extra hand held fre extinguisher (12 kg)

1 extra rotating beacon amber

1 extra rotating beacon red

1 extra rotating beacon blue

1 extra strobe light white

Toolbox and maintenance tools

Reversing camera

Spare wheel

Text labels in:

Fin / Por / GB / Swe / Rus / Nor / Ger / Fra /Spa / Ita

LTC SERVICES:

SPARE PARTS

Spare parts package A: Available for 1000 h of use*.

Include periodical service, most common wearing parts

and most critical safety parts.

Spare parts package B: Available for 3000 h of use*.

Include periodical service, most common wearing parts

and most critical safety parts.

* Recommendations are based on average

hours - can vary a lot depending on work site

conditions.

TRAINING SERVICES

Available before delivery, at start up and after

delivery

Product training:

Operation and Maintenance

NorSmart

Foundation of electrics, hydraulics

and mechanics

Audit

Process training:

Concrete spraying

Charging

Process audit

AUDIT SERVICES

To improve performance of the machines

To improve the performance of your processes

To help improve the quality of maintenance operations

SERVICE CONTRACTS

Spare parts supply programmes

Scheduled inspection programmes

Supervision programmes

Periodic maintenance programmes

Machine usage programmes

LINK ONE

Link One electronic spare part manuals

WARRANTY SERVICES

Extended warranty

Normet Oy

Ahmolantie 6

FI-74510 IISALMI, FINLAND

Tel +358 (0) 17 83 241

Fax +358 (0) 17 823 606

info@normet.f www.normet.f

Вам также может понравиться

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- TS410Документ3 страницыTS410Jose Elias VeraguaОценок пока нет

- JD Edwards Enterprise One Financial Management CertificationДокумент3 страницыJD Edwards Enterprise One Financial Management CertificationKholid eFendiОценок пока нет

- Maintenance PDFДокумент632 страницыMaintenance PDFMargaret DaughertyОценок пока нет

- JD Edwards - Address BookДокумент288 страницJD Edwards - Address BookToronto_ScorpionsОценок пока нет

- Technical Overview of InventoryДокумент24 страницыTechnical Overview of InventorynagaravikumarОценок пока нет

- Sap ReferenceДокумент88 страницSap Referenceapi-3856831Оценок пока нет

- Subcontracting Business ProcessДокумент8 страницSubcontracting Business ProcessbiswajitОценок пока нет

- Incorrect Material MovementsДокумент55 страницIncorrect Material MovementsdbedadaОценок пока нет

- Returns and Repairs ProcessingДокумент3 страницыReturns and Repairs ProcessingFabrizio CiavolaОценок пока нет

- FeedAccess-User Guidebook Formulation PDFДокумент17 страницFeedAccess-User Guidebook Formulation PDFTấn Khoa NguyễnОценок пока нет

- Display A List of POs With Outstanding GR or IRДокумент6 страницDisplay A List of POs With Outstanding GR or IRchonchalОценок пока нет

- Commodity Derivatives and Risk Management - AssessmentДокумент4 страницыCommodity Derivatives and Risk Management - AssessmentLokesh manglaОценок пока нет

- Crimp Chart MMДокумент12 страницCrimp Chart MMAlex LevinОценок пока нет

- Enterprise Resource & Planning: Assets ManagementДокумент11 страницEnterprise Resource & Planning: Assets ManagementKumar AjitОценок пока нет

- SAP T-Code FormДокумент1 страницаSAP T-Code FormSudarshan DawОценок пока нет

- CCBPM To BPM en 7.3Документ73 страницыCCBPM To BPM en 7.3Ruben Velasco100% (2)

- 102.20-N1 (1109) SolutionДокумент140 страниц102.20-N1 (1109) Solutionlist16947Оценок пока нет

- Basic User Guide 65Документ1 106 страницBasic User Guide 65SumitОценок пока нет

- RD20 Operation ManualДокумент551 страницаRD20 Operation Manualocto trianto100% (2)

- JDE TablesДокумент3 страницыJDE TablesRaul Islas Tapia0% (1)

- 170 MarkView Overview User GuideДокумент64 страницы170 MarkView Overview User Guide070507wa100% (1)

- 3.1 Materials ManagementДокумент32 страницы3.1 Materials Managementarajesh07Оценок пока нет

- ABAP Debugging - Analyzing Memory Usage of Your ProgramsДокумент8 страницABAP Debugging - Analyzing Memory Usage of Your ProgramsDeadMan BlackHeartОценок пока нет

- End To End S4 Use CaseДокумент5 страницEnd To End S4 Use CaseKaran ChopraОценок пока нет

- 2014 Kit CatalogДокумент1 160 страниц2014 Kit CatalogaleruhoОценок пока нет

- Sis Web User Guide v3-5-1Документ60 страницSis Web User Guide v3-5-1Miguel RodriguezОценок пока нет

- Trane Electric Unit HeatersДокумент48 страницTrane Electric Unit HeatersdanОценок пока нет

- Sanli Spare Parts CatalogueДокумент32 страницыSanli Spare Parts Cataloguekittyhawk88Оценок пока нет

- PurchasingДокумент94 страницыPurchasingapi-3841382100% (1)

- Oracle Purchasing - & - Inventory - Standard - ReportsДокумент19 страницOracle Purchasing - & - Inventory - Standard - Reportsfarhanahmed01Оценок пока нет

- SD - User's Manual STOДокумент11 страницSD - User's Manual STONithin MohanОценок пока нет

- MM - User's Manual PDFДокумент46 страницMM - User's Manual PDFNithin MohanОценок пока нет

- B1 90 TB1000 02 03 Sol PDFДокумент6 страницB1 90 TB1000 02 03 Sol PDFJohn KennedyОценок пока нет

- EDI 997 Functional AcknowledgementДокумент23 страницыEDI 997 Functional AcknowledgementtamtolemolaОценок пока нет

- WM End User DocumentДокумент4 страницыWM End User Document66ANAND66Оценок пока нет

- Transaction Based Pricing - Nirvana For FAOДокумент0 страницTransaction Based Pricing - Nirvana For FAOvijayhegdeОценок пока нет

- List of Stock Items: 55040-Rework ChargesДокумент76 страницList of Stock Items: 55040-Rework ChargesGanesh Sh100% (1)

- A Raid Is Ele MissionДокумент22 страницыA Raid Is Ele Missionjinalshah1012713Оценок пока нет

- 5 Filter Systems and TechnologyДокумент51 страница5 Filter Systems and TechnologyabelsgОценок пока нет

- Minitherm 8 - EnG - V04.2019Документ42 страницыMinitherm 8 - EnG - V04.2019sarag manОценок пока нет

- TCODE - S - ALR - 87012052 Asset RetirementsДокумент3 страницыTCODE - S - ALR - 87012052 Asset RetirementsrajdeeppawarОценок пока нет

- 785 TrucksДокумент7 страниц785 TrucksJavier Pagan TorresОценок пока нет

- SAP SRM TCodes PDFДокумент6 страницSAP SRM TCodes PDFtoabhishekpalОценок пока нет

- Power Sector and ErpДокумент9 страницPower Sector and ErpImran HossainОценок пока нет

- On Road KatalogДокумент81 страницаOn Road KatalogMeowing SteveОценок пока нет

- Microsoft Dynamics AX 2012 R2 FeaturesДокумент9 страницMicrosoft Dynamics AX 2012 R2 FeaturessanthoshinouОценок пока нет

- Here You Find The Complete List of SAP Userexits in SAP R/3 Enterprise 4.7Документ77 страницHere You Find The Complete List of SAP Userexits in SAP R/3 Enterprise 4.7keyur001patelОценок пока нет

- Materials Management ManualДокумент346 страницMaterials Management ManualAddis NurhussienОценок пока нет

- The Changes Made in SAP For Vendor & Customer MasterДокумент9 страницThe Changes Made in SAP For Vendor & Customer Masterpammi veeranji Reddy100% (1)

- Spraymec 6050 WP 100004455Документ4 страницыSpraymec 6050 WP 100004455gasol24Оценок пока нет

- Charmec 6605 B 17008398Документ4 страницыCharmec 6605 B 17008398Christian Sebastian Humeres Rios0% (1)

- Spraymec 6050 WP 100004455 PDFДокумент0 страницSpraymec 6050 WP 100004455 PDFvkannan07666Оценок пока нет

- Specification Jumbo Drill Sandvik DD311D-40EДокумент4 страницыSpecification Jumbo Drill Sandvik DD311D-40ENathania Boas E S50% (2)

- Specification Jumbo Drill Sandvik DD311D-40ECДокумент4 страницыSpecification Jumbo Drill Sandvik DD311D-40ECNathania Boas E SОценок пока нет

- DD310-26 6232sfДокумент4 страницыDD310-26 6232sfRoger TrujilloОценок пока нет

- Technical Specification Sandvik LH514-14Документ3 страницыTechnical Specification Sandvik LH514-14enriquerojoperez_539100% (2)

- Multimec 6600: Normet OyДокумент4 страницыMultimec 6600: Normet OyЕгор ПрохоровОценок пока нет

- Utilift 6605 B: Lifter With BoomДокумент4 страницыUtilift 6605 B: Lifter With BoomDiego GonzalesОценок пока нет

- IR AIR TUGGER WINCHES Manuals and Technical PublicationsДокумент22 страницыIR AIR TUGGER WINCHES Manuals and Technical Publicationsvkannan076660% (1)

- PENT AIR - 1 - SoftFlo PDFДокумент4 страницыPENT AIR - 1 - SoftFlo PDFvkannan07666Оценок пока нет

- Third Generation Air Winch SeriesДокумент6 страницThird Generation Air Winch Seriesvkannan07666Оценок пока нет

- Spraymec 6050 WP 100004455 PDFДокумент0 страницSpraymec 6050 WP 100004455 PDFvkannan07666Оценок пока нет

- Huawei E3131 - USB MODEM To Access Data & Internet Through WirelessДокумент9 страницHuawei E3131 - USB MODEM To Access Data & Internet Through Wirelessvkannan07666Оценок пока нет

- TPLINK TL WR841N 300Mbps Wireless N RouterДокумент18 страницTPLINK TL WR841N 300Mbps Wireless N Routervkannan07666Оценок пока нет

- Case Study - British Rule in IndiaДокумент12 страницCase Study - British Rule in IndiamobilenoОценок пока нет

- 1000 Watt Metal Halide Flood Light FixtureДокумент4 страницы1000 Watt Metal Halide Flood Light Fixturevkannan07666Оценок пока нет

- 348 JCB Telehandler 506CДокумент8 страниц348 JCB Telehandler 506Cvkannan07666100% (1)

- 330D L Excavator-Before OperationДокумент8 страниц330D L Excavator-Before Operationvkannan07666Оценок пока нет

- Marine Main Engine PistonДокумент15 страницMarine Main Engine PistonNandakishore PradeepОценок пока нет

- Service Manual A10 & A12 AAДокумент2 страницыService Manual A10 & A12 AALuisОценок пока нет

- Flyer Oc500 2542 RF DD RevДокумент2 страницыFlyer Oc500 2542 RF DD RevDio YoshitakaОценок пока нет

- Murphy CodigoДокумент4 страницыMurphy CodigoGonzalo VillarroelОценок пока нет

- Jawa MotorsДокумент7 страницJawa MotorsArvind AndrewОценок пока нет

- X44 Electrical ManualДокумент45 страницX44 Electrical Manualbercketowzhenya75% (4)

- Proxima PLUS Z 8541-10541 GBДокумент223 страницыProxima PLUS Z 8541-10541 GBJxyz QwОценок пока нет

- PC300.Testing & AdjustmentsДокумент316 страницPC300.Testing & AdjustmentsBalaram BОценок пока нет

- Sibs 4 Wallchart - Toyota Landcruiser (Rev 1)Документ1 страницаSibs 4 Wallchart - Toyota Landcruiser (Rev 1)Mr.Aidos KОценок пока нет

- Air-Bag: (1) Connector InformationДокумент34 страницыAir-Bag: (1) Connector InformationbakriramziОценок пока нет

- 2019-2020 Mitsubishi Motors Corporation. All Rights Reserved. Gc/PE30C354Mar.19EG Printed in JapanДокумент12 страниц2019-2020 Mitsubishi Motors Corporation. All Rights Reserved. Gc/PE30C354Mar.19EG Printed in JapanMarcelo Daniel Terrazas PintoОценок пока нет

- Manual de Partes 580sm2Документ2 448 страницManual de Partes 580sm2Michel BayardelleОценок пока нет

- Ta 19 V10Документ6 страницTa 19 V10Edgar Rojas EspejoОценок пока нет

- Term Paper On Ford Motor CompanyДокумент6 страницTerm Paper On Ford Motor Companyafduaciuf100% (1)

- Codigos de Falla Qsb6.7Документ8 страницCodigos de Falla Qsb6.7nortonОценок пока нет

- CarburetorДокумент19 страницCarburetorSelazinap LptОценок пока нет

- Catalogues207exarmy PDFДокумент198 страницCatalogues207exarmy PDFKamaldeep SinghОценок пока нет

- 9 Load ControlДокумент25 страниц9 Load ControlJose Manuel Barroso PantojaОценок пока нет

- Excise Duty in IndiaДокумент3 страницыExcise Duty in IndiaKomma RameshОценок пока нет

- HiLoad BrochureДокумент7 страницHiLoad BrochurePrem PatelОценок пока нет

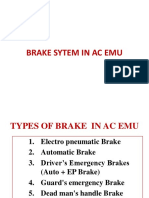

- Brake System (Emu)Документ32 страницыBrake System (Emu)Md Arifullah100% (1)

- Hybrid SystemДокумент20 страницHybrid Systemangganteng13100% (1)

- Full Power For Start-Stop and All Consumer Units in The Car - S5 EFB and S6 AGM From BoschДокумент12 страницFull Power For Start-Stop and All Consumer Units in The Car - S5 EFB and S6 AGM From BoschdekaОценок пока нет

- 15 Cab-N900 Series JMCДокумент42 страницы15 Cab-N900 Series JMCRusonegro100% (1)

- Aprilia RSV Workshop Manual 2004 - 2008Документ309 страницAprilia RSV Workshop Manual 2004 - 2008pichelhuber67% (12)

- 50H EngineДокумент3 страницы50H EngineAmirSyafiqОценок пока нет

- SecmaA5 FINALДокумент9 страницSecmaA5 FINALtruhlei100% (2)

- 03 - 6D107 - Air in FuelДокумент6 страниц03 - 6D107 - Air in FueljoseОценок пока нет

- Clutch: Description and Operation Clutch ComponentsДокумент8 страницClutch: Description and Operation Clutch ComponentsawemetalОценок пока нет

- Gradall 534D-9 PartsДокумент710 страницGradall 534D-9 PartsAlejandro Bonilla100% (3)