Академический Документы

Профессиональный Документы

Культура Документы

Highly Chemical Resistant Epoxy Coating

Загружено:

sudhialakkalОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Highly Chemical Resistant Epoxy Coating

Загружено:

sudhialakkalАвторское право:

Доступные форматы

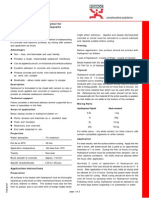

POLYPOXY CR

TDS_Polypoxy-CR_GCC_1011

Che m ic a l res i st ant ep o x y re s in b a se d co a t ing

POLYPOXY CR is a solvent free high build epoxy resin protective coating which provides a chemical resistant surface for concrete and steel.

CHARACTERISTICS

Easy to apply Solvent free

Highly Chemical resistant Water proof and protective coating

Mixing Mix part A (resin) and part B (hardener) separately for 1 minute using a slow speed drill fitted with a paddle. Then add Part B into Part A and mix thoroughly for 2 3 minutes to achieve uniform consistency. Apply immediately after mixing. Application POLYPOXY CR may be applied by brush, squeegee, roller or industrial sprayer. The coating shall be applied @0.3 lt./m2 to achieve a Dry Film Thickness of 300 microns. On horizontal surfaces the coating can be applied in a single coat of 300 microns. As the coating is heavy bodied, on vertical surfaces it shall be applied in 2 coats of 200 microns in each coat to avoid sagging/slumping. Each subsequent coat shall be applied only after the previous coat dries off completely. After application the coating must be back rolled to reduce surface irregularities and improve bonding.

High build Coating

FIELDS OF APPLICATION

Hygienic and easy to clean

Surface preparation New concrete surface to be treated must be 28 days old. Ensure that the moisture content of the surface is less than 5%. The surface shall be free from dust, dirt, curing compound and laitance. The cleaning shall be done by grit/captive blasting or mechanical grinding. The concrete should be sound and any cracks, pot holes to be repaired with POLYPOXY NF and allowed to cure. Prior to the application of the coating make sure that the surface is absolutely dry. Priming Prime the prepared surface with POLYPRIME EP @ 45m2/lt. The coating is applied when the primer is in a tacky to semi-tacky condition. However, in all circumstances, the coating shall be applied within 12 hours of application of the primer. If the primer surface is left open for more than 12 hours, then a fresh coat of primer has to be re-applied.

APPLICATION INSTRUCTIONS

Internal Protection of concrete or metallic storage tank, certain chemicals, oil & fuel Chemical resistant floor and wall coating for manholes, treated sewerage lines, manufacturing units, breweries, etc

Clean all equipments with a POLYSOLVENT immediately after use. Hardened materials can be removed mechanically only. Store in a cool, dry place and keep away from all sources of heat and sunlight. In tropical climates, store in air condition rooms. The shelf life is up to 12 months in un-opened condition and if stored as per recommendations. Excessive exposure to sunlight, humidity and UV will result in the deterioration of the quality of the product and reduce its shelf life. As with all construction chemical products, caution should always be exercised. Protective clothing such as gloves and goggles should be worn. Treat

CLEANING

STORAGE & SHELF LIFE

HEALTH & SAFETY

any splashes to the skin or eyes with fresh water immediately. Should any of the products be accidentally swallowed, do not induce vomiting, but call for medical assistance immediately.

CHEMICAL RESISTANCE

Sulphuric acid (10%) Lactic acid (10%) Nitric acid (10%) Sodium Hydroxide (50%) Diesel Battery water Vegetable oil Formaldehyde (40%) Aviation fuel Sea water Gasoline

Density, [g/cc] Color Solid content, [%] Initial cure [hrs] Full cure [days] Application life [mins] Tack free time [hrs]

PROPERTIES

TECHNICAL SPECIFICATION

1.450.05 Grey 30 6 7 100 12 2 <0.05 VALUES

Adhesion strength, [N/mm2] Water absorption, [%] Abrasion Resistance, [mg]

TDS_Polypoxy-CR_GCC_1011

All values given are subject to 5-10% tolerance

<100

POLYPRIME EP

COVERAGE

POLYPOXY CR

4-5 m2/lt

POLYPRIME EP

SUPPLY

0.3 lt/m2 for 300 micron dry film thickness

POLYPOXY NF

5 lt & 15 lt kit 3 kg kit 3.5 lt kit

POLYPOXY CR

* Refer to website for TDS

The information contained herein, particularly recommendations for the handling and use of our products, is based on our professional experience. As materials and conditions may vary with each intended application, and thus are beyond our sphere of influence, we strongly recommend that in each case sufficient tests are conducted to check the suitability of our products for their intended use. Legal liability cannot be accepted on the basis of the contents of this data sheet or any verbal advice given, unless there is a case of wilful misconduct or gross negligence on our part. This technical data sheet supersedes all previous editions relevant to this product. Manufactured in G.C.C.

Apart from the information given here it is also important to observe the relevant guidelines and regulations of various organisations and trade associations as well as the respective standards. The aforementioned characteristics are based on practical experience and applied testing. Warranted properties and possible uses which go beyond those warranted in this information sheet require our written confirmation. All data given was obtained at an ambient and material temperature of +23C and 50 % relative air humidity unless specified otherwise. Please note that under other climatic conditions hardening can be accelerated or delayed.

P .O. Box 293, Umm Al Quwain, UAE Sales Tel: +971 6 7670777, Fax: +971 6 7670197 Factory Tel: +971 6 7670777, Fax: +971 6 7671669

Henkel Polybit Industries Ltd.

P .O. Box 2230, Al Khobar 31952, K.S.A Tel:+9663 8894110, Fax:+9663 8995313

Henkel Polybit Industries Ltd.(Branch)

Internet: www.henkelpolybit.com E-mail: polybit@henkelpolybit.com

Quality for Professionals

Вам также может понравиться

- Advance Engine Timing with STCДокумент28 страницAdvance Engine Timing with STCLuisPupiales100% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionОт EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionОценок пока нет

- Breakfast Recipes PDFДокумент61 страницаBreakfast Recipes PDFmutton moonswamiОценок пока нет

- Breakfast Recipes PDFДокумент61 страницаBreakfast Recipes PDFmutton moonswamiОценок пока нет

- Water ProofingДокумент30 страницWater ProofingMuhammad Irfan ButtОценок пока нет

- List of BS CodesДокумент33 страницыList of BS Codesnavaneethsparkwest100% (8)

- Underground Drainage SystemsДокумент56 страницUnderground Drainage Systemssudhialakkal100% (1)

- Distillation Lecture Note-2Документ20 страницDistillation Lecture Note-2BasseyОценок пока нет

- Adam Lechter: Resident Course in Confectionery TechnologyДокумент73 страницыAdam Lechter: Resident Course in Confectionery TechnologyJulio KinenОценок пока нет

- Marthon Jotun Marine PaintДокумент5 страницMarthon Jotun Marine PaintNishanthОценок пока нет

- Wastewater Sewer Manual-WavinДокумент92 страницыWastewater Sewer Manual-WavinSankar CdmОценок пока нет

- South Indian FoodДокумент13 страницSouth Indian FoodjaganathorОценок пока нет

- POLYCOATДокумент2 страницыPOLYCOATGeorge TsiamtsourisОценок пока нет

- Polyguard PEДокумент2 страницыPolyguard PEabcd1860100% (1)

- Epoxy Resin Mortar for Concrete ProtectionДокумент2 страницыEpoxy Resin Mortar for Concrete ProtectionsudhialakkalОценок пока нет

- Polypoxy FC(S)Документ2 страницыPolypoxy FC(S)Sam AhmedОценок пока нет

- POLYTEXДокумент2 страницыPOLYTEXDon AlexОценок пока нет

- Polycoat RbeДокумент2 страницыPolycoat RbejovindhaОценок пока нет

- Kanseal Pu.Документ4 страницыKanseal Pu.Sunny SinghОценок пока нет

- Protective Coating System for Aggressive EnvironmentsДокумент3 страницыProtective Coating System for Aggressive EnvironmentsTori SmallОценок пока нет

- Increte Clear SealДокумент2 страницыIncrete Clear SealBrembertОценок пока нет

- Industrial Epoxy Floor Grout: FeaturesДокумент2 страницыIndustrial Epoxy Floor Grout: FeaturesParashuram ChauhanОценок пока нет

- Novolac ScreedДокумент4 страницыNovolac Screedmd_kureshiОценок пока нет

- Carboguard 703 GFДокумент2 страницыCarboguard 703 GFlhanx2100% (2)

- Fosroc Trafficguard UR skid protectionДокумент2 страницыFosroc Trafficguard UR skid protectionSaud PathiranaОценок пока нет

- 21-5 PDS AiДокумент3 страницы21-5 PDS Aiuocmogiandi_aОценок пока нет

- Securea SCДокумент2 страницыSecurea SCAutumn HernandezОценок пока нет

- High-strength non-shrink cementitious groutДокумент2 страницыHigh-strength non-shrink cementitious groutabcd1860Оценок пока нет

- MASTERTOP 1110 - v1Документ2 страницыMASTERTOP 1110 - v1Sumit KiratОценок пока нет

- EcoDem 1Документ2 страницыEcoDem 1lee_cur_van4883Оценок пока нет

- Eco-friendly protective coatingДокумент2 страницыEco-friendly protective coatingRaed Naim KhammashОценок пока нет

- Polyseal PPSДокумент2 страницыPolyseal PPSabc123910Оценок пока нет

- TDS 0004 FlexoPrime 202003Документ3 страницыTDS 0004 FlexoPrime 202003Mearg NgusseОценок пока нет

- Acrylic Plaster PrimerДокумент3 страницыAcrylic Plaster Primerapi-302611547Оценок пока нет

- Dimetcote 9 PDS AIДокумент3 страницыDimetcote 9 PDS AIAmer Y KОценок пока нет

- Jotashield Alkali Resistant Primer Technical Data SheetДокумент3 страницыJotashield Alkali Resistant Primer Technical Data Sheetomda4wadyОценок пока нет

- Durathane TdsДокумент3 страницыDurathane TdsSyawaluddin Fitri AwangОценок пока нет

- Polyprime AC: Acrylic Modified PrimerДокумент2 страницыPolyprime AC: Acrylic Modified PrimerVaittianathan MahavapillaiОценок пока нет

- Crack Bridging Elastomeric PaintДокумент3 страницыCrack Bridging Elastomeric PaintMearg NgusseОценок пока нет

- TDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Документ4 страницыTDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Robert ClarkОценок пока нет

- Megayacht Imperial Antifouling DataДокумент3 страницыMegayacht Imperial Antifouling DatakormatekОценок пока нет

- 05500Документ6 страниц05500khalid764Оценок пока нет

- Nitoseal 125Документ2 страницыNitoseal 125Hantu TuahОценок пока нет

- Interzone 101Документ0 страницInterzone 101hennawijayaОценок пока нет

- TDS - 0063 CapaFilex - 202003Документ3 страницыTDS - 0063 CapaFilex - 202003Mearg NgusseОценок пока нет

- Interclene 5012Документ4 страницыInterclene 5012Trịnh Minh KhoaОценок пока нет

- Amercoat 471 Application May 08Документ2 страницыAmercoat 471 Application May 08Biju_PottayilОценок пока нет

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionДокумент2 страницыRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaОценок пока нет

- Tecnolac 2100 01 UkДокумент2 страницыTecnolac 2100 01 UkvagramОценок пока нет

- Protectosil CIT TDSДокумент2 страницыProtectosil CIT TDSjaga67Оценок пока нет

- Thermaline 450 PDFДокумент2 страницыThermaline 450 PDFNageswara Rao BavisettyОценок пока нет

- Craycoat 30-36 VB-TDSДокумент2 страницыCraycoat 30-36 VB-TDSYASHICA VAITTIANATHANОценок пока нет

- Hydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneДокумент2 страницыHydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneVenkata Raju KalidindiОценок пока нет

- ResiGard SL2Документ4 страницыResiGard SL2fhsn84Оценок пока нет

- Technical Data Sheet for Phenolic/Novolac Epoxy Tank CoatingДокумент5 страницTechnical Data Sheet for Phenolic/Novolac Epoxy Tank CoatingHermanОценок пока нет

- Epiplus 556Документ2 страницыEpiplus 556hareesh13h100% (1)

- Zemin Kaplaması Basf (ENG) - 1Документ3 страницыZemin Kaplaması Basf (ENG) - 1seyfiОценок пока нет

- Nitocote PE135Документ2 страницыNitocote PE135Dejan MicicОценок пока нет

- Waterproof Roof Coating Technical Data SheetДокумент3 страницыWaterproof Roof Coating Technical Data SheetHisham BerrasaliОценок пока нет

- Penguard Primer Datasheet " Azadjotun"Документ3 страницыPenguard Primer Datasheet " Azadjotun"AzadAhmadОценок пока нет

- Sikafloor - 2530 W: 2-Part Water Based Epoxy CoatingДокумент5 страницSikafloor - 2530 W: 2-Part Water Based Epoxy Coatingthe pilotОценок пока нет

- Nitocote EPW100: Water Dispersed Epoxy Coating and SealerДокумент2 страницыNitocote EPW100: Water Dispersed Epoxy Coating and SealerVenkata Raju KalidindiОценок пока нет

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Документ3 страницыChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- 2557datasheetdekguard PUДокумент2 страницы2557datasheetdekguard PUMel AdОценок пока нет

- Fosroc Dekguard PU: Constructive SolutionsДокумент4 страницыFosroc Dekguard PU: Constructive SolutionsganmosesОценок пока нет

- HEMPADUR 15552 Epoxy Primer for Galvanised SurfacesДокумент2 страницыHEMPADUR 15552 Epoxy Primer for Galvanised SurfacesJj OredinaОценок пока нет

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionОт EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionОценок пока нет

- Manualof Green Building MaterialsproductsitstestignfacilitiesДокумент155 страницManualof Green Building MaterialsproductsitstestignfacilitiesSijo JoyОценок пока нет

- Asphalt Pavement TechnologyДокумент88 страницAsphalt Pavement TechnologysudhialakkalОценок пока нет

- Pipe Testing PresentationДокумент36 страницPipe Testing PresentationsudhialakkalОценок пока нет

- Pakistani DishesДокумент1 страницаPakistani DishessudhialakkalОценок пока нет

- SIGMA Flyer enДокумент2 страницыSIGMA Flyer ensudhialakkalОценок пока нет

- Zucchini Thoran Id8163 27144 PrintДокумент1 страницаZucchini Thoran Id8163 27144 PrintsudhialakkalОценок пока нет

- Kerala Aattirachi Curry (Ratings: 0 0Документ1 страницаKerala Aattirachi Curry (Ratings: 0 0sudhialakkalОценок пока нет

- Grundfosliterature 145470Документ16 страницGrundfosliterature 145470sudhialakkalОценок пока нет

- Pakistani DishesДокумент1 страницаPakistani DishessudhialakkalОценок пока нет

- Rice - ItemsДокумент34 страницыRice - ItemsGOVARDHANA RAOОценок пока нет

- Madurai Special Mutton Biriyani Id21162Документ2 страницыMadurai Special Mutton Biriyani Id21162sudhialakkalОценок пока нет

- Piping Design InfoДокумент279 страницPiping Design Infojosediaz141Оценок пока нет

- Weight Loss Print Chicken Tikka Id21739Документ1 страницаWeight Loss Print Chicken Tikka Id21739sudhialakkalОценок пока нет

- Pakistani DishesДокумент1 страницаPakistani DishessudhialakkalОценок пока нет

- Hyderabadi Kheema RecipeДокумент1 страницаHyderabadi Kheema RecipesudhialakkalОценок пока нет

- Ambalapuzha Pal Payasam Id8167 27146 PRДокумент1 страницаAmbalapuzha Pal Payasam Id8167 27146 PRsudhialakkalОценок пока нет

- Roofing Insul Sell Sheet PDFДокумент16 страницRoofing Insul Sell Sheet PDFsudhialakkalОценок пока нет

- Hyderabadi Dum Ka Mutton Biryani Id8339 PDFДокумент2 страницыHyderabadi Dum Ka Mutton Biryani Id8339 PDFsudhialakkalОценок пока нет

- Hyderabadi Biryani Id21972 24732 PrintДокумент1 страницаHyderabadi Biryani Id21972 24732 PrintsudhialakkalОценок пока нет

- Gosht Biryani Id8324 22095 PrintДокумент2 страницыGosht Biryani Id8324 22095 PrintsudhialakkalОценок пока нет

- Chemical Composition (StructualSteel)Документ1 страницаChemical Composition (StructualSteel)sudhialakkalОценок пока нет

- Report GCWДокумент34 страницыReport GCWArchit HaldiaОценок пока нет

- Lec 13Документ5 страницLec 13Ghazy alshyalОценок пока нет

- Organic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Документ3 страницыOrganic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Akira SantosОценок пока нет

- The Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Документ4 страницыThe Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Anonymous hk1fhAkwyОценок пока нет

- 109 Sodium ChlorideДокумент6 страниц109 Sodium Chlorideeng20072007Оценок пока нет

- Nucleic Acids BrochureДокумент2 страницыNucleic Acids BrochureCring-cring NavarroОценок пока нет

- IB Chemistry Molarity, Concentration, Standard Solution and Serial Dilution PreparationДокумент13 страницIB Chemistry Molarity, Concentration, Standard Solution and Serial Dilution PreparationoscarbecОценок пока нет

- Zuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceДокумент2 страницыZuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceJZik SibalОценок пока нет

- Sybron Endo Sealapex Root Canal SealerДокумент7 страницSybron Endo Sealapex Root Canal Sealerenjoy enjoy enjoyОценок пока нет

- HP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced MaterialsДокумент4 страницыHP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced Materialssirjole7584Оценок пока нет

- MN 206 Market Survey CopperДокумент210 страницMN 206 Market Survey CopperArjun MishraОценок пока нет

- ME6008 WELDING TECHNOLOGY Part B IQДокумент1 страницаME6008 WELDING TECHNOLOGY Part B IQVikram mОценок пока нет

- FINALSДокумент8 страницFINALSSeenpai23Оценок пока нет

- Oil Debate Chromatography PPT 2Документ17 страницOil Debate Chromatography PPT 2Eridha TriwardhaniОценок пока нет

- Applied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinДокумент10 страницApplied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinEko RaharjoОценок пока нет

- S1XBIG58 M500 4 Tech InfoДокумент15 страницS1XBIG58 M500 4 Tech InfoFredy DanielОценок пока нет

- 2010 Drug AllergyДокумент78 страниц2010 Drug AllergyEve Methaw100% (1)

- Fosroc Solvent 102 resin cleaning solventДокумент2 страницыFosroc Solvent 102 resin cleaning solventShaikhRizwanОценок пока нет

- ASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire ApparatusДокумент3 страницыASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire Apparatusalin2005Оценок пока нет

- Makrolon® ET3137: Grades / ExtrusionДокумент4 страницыMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroОценок пока нет

- Kimo Kigaz 200 Combustion Gas Analyzer DatasheetДокумент4 страницыKimo Kigaz 200 Combustion Gas Analyzer DatasheetayannathompsoneqsОценок пока нет

- Appchem 1 1Документ18 страницAppchem 1 1Fate SoteroОценок пока нет

- FuelsДокумент22 страницыFuelsADITYA GAURОценок пока нет

- NAK80 MaterialДокумент3 страницыNAK80 MaterialRicky Indra DjunawanОценок пока нет

- Titrimetric Methods of AnalysisДокумент28 страницTitrimetric Methods of AnalysisPraveen Kumar Avvaru100% (2)

- Synthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid DerivativesДокумент4 страницыSynthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid Derivativesmik100% (1)