Академический Документы

Профессиональный Документы

Культура Документы

Agar

Загружено:

fms162Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Agar

Загружено:

fms162Авторское право:

Доступные форматы

Agar: A golden Tree Aquilaria Agallocha(family name Thymelaeaceae), locally known as agar is a moderately tall and erect ever

green tree. At present 50-60 families in Sylhet and Moulvibazar district are engaged in agar processing. Agar oil which is made from agar wood used as a raw material for cosmetics, perfume, and soup etc . There is a massive demand for agar oil all over the world. People in this area usually sell the agar oil to abroad. The processing of collecting oil is something like critical and used their old method to bring out the oil from agar wood. As we know that France is very renowned in perfume sector, there raw material also collecting from agar wood. Here agar in Bangladesh could be a great source for perfume raw material but apologetic matter is that there is no potentially initiative to commercialise this hidden treasure. After surveying there I have come to know that it is very possible to plant this precious tree in other districts also. Since the worth of agar and the availability agar wood in Sylhet we should take initiative to launch a new venture based on agar. Jony khan Shahjalal University of Science and Technology Sylhet

Agar farming sees export markets

Top, Women are cleaning waste agar chips at a factory in Barlekha upazila. Bottom Left, Md Abdul Kabir, secretary of Agar-Atar Kutir Shilpo Rokkha Committee, a platform for the sector, is holding waste agar chips that have been piled up for export to Middle East countries. Right, Inside an agar factory in Rafinagar village. Photo: Iqbal SiddiqueeIqbal Siddiquee, Sylhet

Agar farming by the private sector is changing the lifestyles of many people in the Sylhet region. It is changing the economic landscape of the area and at least 30,000 people are now earning a livelihood in the silently rising sector. Being a profitable form of farming, it is also contributing to reducing poverty. Farmers are now cultivating agar on a commercial basis in regions like Fenchuganj, Beanibazar, Golapganj and Sadar of Sylhet and Rajnagar, Kulaura, Komolganj, Srimangal and Barlekha of Moulvibazar district. The Barlekha upazila is one of the pioneers for growing agar, and the Sujanagar union is well known at home and abroad for it. About 1,000 families in the villages of Sujanagar earn a living by working in the agar factories set up in their homes and around. Some more villages involved in the same work include Saldigha, Bartal, Uttar Sujanagar, Dakshin Sujanagar, Tangortoli and Rafinagar. Md Muhibul Islam Raju of Rafinagar, an industry insider, said despite huge potential, the agar industry is facing numerous challenges like harassment by the law enforcers during transportation, an absence of marketing facilities, a shortage of funds and lack of maintenance.

Md Ziauddin, who runs a factory called Kamrunnahar Agar Factory in Khadimnagar in Sylhet, said an adequate quantity of raw materials is required to cultivate agar, and it is unfortunate that the industry cannot meet demand for a scarcity of raw materials. He, however, supported the planting of saplings on the hilly forest lands and khas lands (government lands) to ensure the availability of raw materials. One good thing about the agar trees is that cattle never eat the plants, he said. "We face a lot of trouble in transporting the agar plants from different upazilas. The law men ask for permits from land, agriculture and forest officials, which are almost impossible to show for a trucker or the labourers." Agar is produced in two ways -- artificially and naturally. Most people adopt the artificial methods as it takes seven to eight years to collect agar. On the other hand, natural methods may take up to 30 years. A handful of agar plants are also present in some of the government institutions. The Agriculture Research Centre at Akbarpur in Moulvibazar has about 30-40 agar trees. Agar is used to make different liquid products, including fragrances, golapjal (scented water), agar bati (incense) and different types of creams. Presently, there are about 121 agar processing factories, including 100 in the Barlekha upazila of Moulvibazar alone. Some other factories are located in Kulaura, Srimangal, Komolganj and in Sylhet. These factories are totally export oriented and highly labour intensive. The industry's contribution to GDP is about Tk 30 crore. Rafiqul Islam Ful, 55, of Rafinagar village has been running his family business of agar and atar for decades now. After spending for 12 years in Dubai, Rafique returned home and started the agar business with his brother Mujahidul Islam. They are not much into production, but they collect the agar trees for processing. They collect agar oil and send to the UAE, where another one of his brothers looks after the business. "The transportation of agar trees from one place to another is a big problem for harassment by police and forest people, which has become a regular affair." Bribing is the only way out, he added. Md Abdul Kabir, secretary of Agar Atar Kutir Shilpo Rokkha Committee, a platform for the sector, told The Daily Star recently that the government should give adequate importance in giving the agar industry a boost as soon as possible. Kabir runs his family business -- BAY OF BENGAL -- at his village home in Shaldigha of Barlekha upazila.

The sector can be boosted quite easily by involving forest and agriculture departments, Kabir said. Adequate training for the farmers is also important, he added. In addition, the agar farmers need loans at low rates of interest, Kabir said. At least 25 agar factories had to be shut down in recent years because of a rise in production costs, especially gas prices, he added. "We are charged industrial rates, but commercial rates should be considered for the sector. Besides, fluctuations in gas pressure cause turmoil for the sensitive heating process." "We had already placed appeals to consider the gas rates and pressure issues, but no action has been taken yet," Kabir said. Upon collecting agar oil from the agar wood chips, what remains has low market value. It is used as a raw material to make agar sticks and others. "We export it to the Middle East," Kabir added. The Export Promotion Bureau has, however, taken steps to stress the production of agar in the Moulvibazar district under their programme -- one district, one product. Bangladesh exports agar oil and chips to Singapore, Saudi Arabia and UAE.

coverCapturing the essenceIt may be near to impossible to find a

person who does not like or use perfumes. Pleasant aroma appeals everyone, be it a baby or an aged person, soothing the senses. However, while wearing the bouquets of our liking, we hardly stop to think where all the beautiful fragrances originate from. Only a few people know the fact that perfumes are produced from herbs; they are not just chemical concoction. The word perfume has derived from Latin per (through) and fumare (to smoke). One of the traditional uses of fragrances has been recorded to be in religious services. Burning

incense and aromatic herbs were used during religious service in ancient times; the tradition is still upheld in some cultures. Odours have a power of persuasion stronger than that of words, appearances, emotions, or will. The persuasive power of an odour cannot be fended off, it enters into us like breath into our lungs, it fills us up, imbues us totally. Perhaps, to reveal this insight of odours, novelist Patrick Sskind wrote his famous novel Perfume: The Story of a Murderer. Later, the film Perfume: The Story of a Murderer by Tom Tykwer, informed us more about the power of odours. Interestingly, the art of perfumery has existed in our country for quite some time. Perfumes are being produced in Bangladesh in the countrys Sylhet Division, and in the Chittagong Hill Tracts (CHT). Families living in that area are devoted to perfumery, holding on to their ancestral tradition and making raw perfumes for many years. It is a legacy; a family tradition. Our ancestors were involved in this profession, and we will continue this industry until we die, says Mongla Monipuri, a perfume producer in Barlekha. Readers may be astonished to learn that perfumes produced in our country are exported to many Arab and European countries, including Saudi Arabia and Turkey. There, these raw perfumes are refined and mixed to make subtle aromas. Skilled perfumers in Barlekha produce raw perfumes from wild herbs, such as agarwood or agar. From a recent visit to Sylhet, this reporter came to know that many farmers are now cultivating agar on a commercial basis in several places within the division. However, Barlekha upazila is one of the pioneers in growing agar, and the Sujanagar union is well known for it. Barlekha has attracted many foreign researchers who are working on the plantation of agar in the Indian Sub-continent. Around a thousand families in the villages of Sujanagar earn a living from the agar factories set up at their homes and surrounding areas. Other villages involved in the industry include Saldigha, Bartal, Uttar Sujanagar, Dakkhin Sujanagar, Tangortoli and Rafinagar. Perfumery is the sole earning source for these villagers. It is somewhat unfortunate that they still have to follow the hand-made steam distillation process to make raw perfumes. According to agar farmers, Sujanagar is a suitable place for plantation because agar is a quick rising plant and a hilly terrain is best for its farming; the tree requires heavy rainfall as well. The entire process of perfume collection is rather brutal: the farmers put iron hooks on the trees for seven to eight years or until they get matured, then the trees are cut into small chips and processed to produce agar oil. The extraction of agar oil is lengthy and costly. However, the plant is not used as firewood. It is widely known that agar oil is a kind of Oleoresin (a semisolid mixture of a resin and essential oil, obtained from certain plants). It is used to prepare atar a non-alcoholic form of perfume that is worn like cologne and

other valuable scents, mainly exported to the Middle Eastern countries. While talking with the farmers about cultivating agar, they said agar oil can be extracted both artificially and naturally. The aforementioned process of collecting the oil is the artificial method; the natural process takes much longer, even up to 30 years. Agar is used to make different liquid products, including fragrances, rose water, agar bati (agar incense) and different types of facial cream. Presently, there are about 121 agar processing factories, including 100 in the Barlekha upazila alone. Some other factories are located in Kulaura, Srimangal, Kamalganj and Sylhet. These factories are export-oriented and highly labour-intensive. According to a research on agar produced in Barlekha, it is found on trees called Fitdkard, growing wild in the jungle. The wood is cut into small pieces and placed in water in a copper vessel and boiled, and from this infusion the perfume is distilled. The research also says that trade in agar-based products is growing rapidly around the world due to their recent adoption as an ingredient in the cosmetics and pharmaceuticals sector. Eaglewood, gaharu and aloeswood are alternative names for agar. It is highly valuable heartwood and is produced from species of the Indomalayan tree genus Aquilaria. Agar trees have been known to grow widely in South and Southeast Asia, especially in Bhutan, Nepal, India, Myanmar, Malaysia, Indonesia, Thailand, Vietnam and Papua New Guinea. The use of agarwood dates back to thousands of years. Historical records show that agar was a key ingredient in Ayurvedic, Tibetan and traditional East Asian medical practice, mainly in Shahih Muslim and Susruta Samhita. Its use as a raw material to produce perfume has been recorded in the Old Testament. Agarwood incense has been burned to produce a pleasant aroma for centuries during important religious ceremonies by Buddhists, Hindus and Muslims. Agar farming has brought change in the lifestyle of many people living in Sylhet as well as the CHT. As a profitable form of farming, it is contributing to reducing poverty, aiding more than 30,000 farmers, according to the villagers in those regions. The farmers now are hoping to get the governments patronisation, considering the growth this industry offers. The seek an easy access to the international market of raw perfume materials, and they believe this business can benefit the nation on a large scale. The farmers hope that the government can recognise the potential of this industry soon enough.

The source of Agarwood is the Aquilaria (agar) tree. This evergreen tree bears flowers that are sweetly scented. Agarwood is highly prized incense that is extremely rare. It has at least a 3000-year history in the Middle East, China and Japan. Agarwood is used in traditional medicine systems such as Ayurvedic, Tibetan and Traditional East Asian medicine and its

fragrance makes it a popular ingredient of perfumes. Agarwood is also burned to create incense for example in India, Japan and the Middle East . Less commonly, it can be used as an insect repellent and as an ingredient in wine. (Ref.: CITES, thirteenth meeting of the Plants Committee, Geneva (Switzerland), 12th-15th August 2003) Agarwood is a remedy for nervous disorders such as neurosis, obsessive behavior and exhaustion. Agrwood is highly psychoactive and is used in spiritual rituals. Chinese medicine uses powdered Agarwood as a treatment for liver, lung and stomach problems. It also acts as a director or focuser for other medicines. Internal use of powdered wood is supposed to enhance chi or body energy. As a perfume ingredient, Agarwood (oud) is sought after and purchased by perfume houses worldwide as an essential component of some of their highclass perfume. Recently aromatherapy using agarwood has become very popular in USA and Europe. (Henry Heauvelling Van Beek, Director-The Tropical Rain forest Project). Agarwood chips and segments may sell for several hundred to several thousand US dollars per kilogram. The price of oil distilled from Agarwood is generally between five and ten thousand US dollars per kilogram, but can be significantly more for Agarwood oil exceptionally high quality.(Ref.: CITES, thirteenth meeting of the Plants Committee, Geneva (Switzerland), 12th-15th August 2003) Current levels of exploitation for forest may be a significant factor in increasing their threat of extinction. For years, trees of the genus Aquilaria have been the principle source of Agarwood, (also called eaglewood, gaharu, aloeswood amongst others), one of the most valuable forest products traded internationally. Trees can produce Agarwood are found throughout South and Southeast Asia from India to as far east as Papua New Guinea. (Ref.: CITES, thirteenth meeting of the Plants Committee, Geneva (Switzerland), 12 th-15th August 2003) It is illegal to harvest agarwood in natural forest. There is a restriction by the international law to trade any part of agar tree. There is no such restriction in trading cultivated agarwood or any part of it. How agarwood is formed in plantations (a) Natural Process: When infected by certain fungi, Aquilaria trees, amongst others, produce Agarwood, the greatest volumes of resin being found in trees aged 50 years or more. However, as only infected trees produce Agarwood; uninfected trees are of negligible commercial value. If Agarwood is present, it exists in unpredictable quantities and qualities that can only be fully determined once the tree has been split open, this result in many trees being felled needlessly thus causing drastic declines in wild populations. (Ref.: CITES, thirteenth meeting of the Plants Committee, Geneva (Switzerland), 12 th-15th August 2003) (b) Traditional method: In various parts of the world even today people try different methods by injuring the tree artificially to obtain Agarwood and Agar oil. These methods make the mortality rate of the plant very high. In Bangladesh, what is traditionally tried by the farmers is the nailing method. But very little, low grade agar oil can be extracted from this method and the harvesting period will be after minimum four years. Besides this method can only be practiced in full monsoon. (c) Scientific Method:

European based TRP has undertaken a project whose concept is people based nature conservation and sponsored by the European Commission. TRP is working on economically and environmentally sustainable Agarwood development. A successful method including of resin formation in young plantation growth trees has been developed and the process is continually being refined and optimized with ongoing research withTRP cooperator and wood microbiologist Prof. Robert Blanchette, University of Minnesota, USA. (Ref.: The rainforest Project www.therainforestproject.net). The name of this research product is CA Kit (Cultivated Agarwood Kit). This is the only scientifically tested and patented technology (Patent No. USA 6848211) available at present. Most importantly, experiments showed that TRP was able to induce Agarwood in planted trees,up to ten-times faster then in nature and in much higher quantities.( Ref.: The rainforest Projectwww.therainforestproject.net). Between November 10th and 15th 2003, Prof. Robert A. Blanchette announced his success in First International Agarwood Conference which was held in Vietnam organized by TRP. Over 80 delegates attended from a multitude of backgrounds and countries. During two days of presentations in Ho Chi Minh City, chemists, forest pathologists, molecular biologists, pharmacologists, business people, government officials, forestry extension and conservation experts, perfumers, incense manufacturers, and aroma therapists exchanged ideas on wideranging topics.(Ref.: The rainforest Project www.therainforestproject.net). Among these 80 delegates, representatives of CITES, IUCN, TRAFFIC, FAO &EC etc. were present. (Henry Heauvelling Van Beek, Director-The Tropical Rain forest Project). Second International Conference was held in Bangkok from March 4 to 11, 2007 at Kasetsart University, organized by TRP and sponsored by CITES, TRAFFIC, IUCN, FAO and EC etc. This conference will follow up on the experience and the feedback of the hugely successful First International Agarwood Conference, held at Viet Nam in November 2003. Also in Second International Agarwood Conference, Agarwood (inducement) production technology (i.e. CA Kit technology) was discussed along with other topics. (Ref.: FAO Corporate Document Repository).

Prof. Robert A. Blanchette presented 1st generation CA Kit in First International Agarwood Conference and improved 2nd generation CA Kit in Second International Agarwood Conference and was discussed. CA Kits has been successfully used in

numerous countries including Bhutan, Malaysia, Thailand, Laos, Papua New Guinea and Vietnam for many years. The CA Kit uses pharmaceutical grade gelatin capsules filled with non harmful inorganic compounds which do not contaminate soil or plants. These compounds are used in many fields including food production and water treatment and meet Europeans, USA, and WHO environmental safety requirements. Henry Heauvelling Van Beek, Director-The Tropical Rain forest Project and Director-CALLC). After several field tests, Prof. Robert Blanchette came up with improved 3rd generation CA Kitwhich was formally announced in a seminar held on 16th May, 2008 at Borolekha, Moulvibazar, Bangladesh.

This inducement technology (CA Kit ) is highest yielding, lowest cost and certified treatment for agar production from trees genus Aquilaria. This technology confirms 100% success anywhere in the world. Prof. Robert A. Blanchette. Agarwood has least timber value so it cant be used in making furniture etc. It cant be used as firewood as well. The only way agarwood is valuable is by forming agar in it by natural process. Formation of agarwood by natural process is very rare and uncertain. This is the reason cultivating agarwood commercially was not popular among the people. As a result invention of this technology has encouraged commercial cultivation of Aquilaria and helped conservation of endangered Aquilaria species, besides more plantations has resulted in environment improvement. Since ages our people has knowledge and experience of agarwood and agar oil in Bangladesh, specially people of Sujanagar union under Borolekha upazila of Moulvibazar district in Sylhet division have been familiar and experienced with agar extraction, chips production and oil extraction in traditional nailing method. Naturally formed agarwood is hardly available as very rarely it is formed in trees. But very little, low grade agar oil can be extracted from any agar tree. Among those who extract agar oil, there is a small group of factory owners who extracts agar oil from white agar wood only. (Note: In such tress neither naturally agar was formed nor any technology had been applied). These factory owners do not fol low the nailing method as their ancestors never did. They consider it to be as an act of sin because agar oil is also used for medicinal purpose. They believe that the rust of iron which is found due to the nailing method actually contaminates the agar oil. After the announcement of 3rd generation CA Kit by Prof. Robert Blanchette, in a seminar held on 16th May, 2008 at Borolekha, Moulvibazar, Bangladesh, several people decided not to apply nailing method to their trees. They are anxiously waiting for CA Kit to be available in the market. Even before the seminar, the local farmers were aware of the CA Kit from sources of BRAC and SQUARE. Also some of the factory owners of Moulvibazar were trying to get the patent of CA Kit. In fact Most of the factory owners and traders travel around South East Asia, Middle East and they have come to know a bout the market demand of CA Kit applied products. At present, extracting agar oil from trees in which nailing method has been applied is practiced by some factory owners. Because, in this way slightly more and a bit better quality agar oil is achieved compared to oil extracted from white agar wood. GOB initiative During the period of 1998 to 2004, the govt. of Bangladesh has experimentally and successfully planted agar trees in 785.67 hectares of land . (Ref. Book-Agar- Experimental Agar production Project-published by Department of Forest under the Ministry of Environment and Forest). Looking at the successful result of previous experimental plantation, another program for planting 6.5 million of agar plants was taken up. (Ref. book-Agar Bonayon- published by Department of Forest under the Ministry of Environment and Forest).

The total amount of money invested in the experimental agar plantation project was Tk.-2.9 crore only. At present the market value of this project is Tk.-380 crore. Presently agar industry provides employment of 10 lac working days. And if there is a planned way of agar plantation then it will provide employment of at least 30 crore working days and will earn foreign currency of at least Tk-500 crore. (Ref. Book-Agar- Experimental Agar production Project-published by Department of Forest under the Ministry of Environment and Forest). Appropriate technology such as CA Kit technology if adopted then employment opportunity and foreign currency earning will increase. Moreover usage of this technology confirms 100% Agar formation in Aquilaria trees. This technology also ensures better quality and more quantity of Agarwood and Agar oil than any other method/technology at present. It reduces the time duration of harvesting such as it takes minimum four years to form agarwood by nailing method where as CA Kit takes within two years.

AGAR: The Liquid Gold & Natures gift to Nagaon Botanists call it Aquillaria Agallocha Roxb. maufacturers call it Agaru, traders call it profit, the poor call it survival, the common man simply calls it agar. It has long been an olfactory prize for discerning noses. Agar oil , is highly valued and universally prized as Otto of Roses. Agar though little known in Assam and the North East is a highly sought after comodity , and the premiums it commands today in the international markets has dramatically transformed the lives of families and economies of areas where its trade exists or where it is procured. One such area that has reaped and flourished from this wonderful resource is the Hojai Subdivision of Nagaon district. The use of agaru is prehistoric.The aromatic Aloe wood mentioned in the Bible was no other but the heartwood of Aquilaria ovata ,or agar.There is mention of the use of Aloe wood(udul-Hind) in Paradise as incense in the famous Ahadith-Sahi Al-Bukhari.Agar also finds a place in the travelouges on ancient Kamrup by Chinese pilgrim Hiuen-Tsang, besides earning a mention in Abhijnanmam Shakuntalam of Kalidasa and Arthashastra of Chanakya. Agar is inextricably linked to Assam s rich cultural heritage. In antiquity, Assam s monarchs employed the used bark of the Sasi Agar tree for chronicling their royal circulars and diktats. The first historical bigraphies in Sanskrit the Harsha Charita written by Bana in 652 AD also chronicles the fact that among the many gifts sent by Assamese king Bhaskara Varman to Harsha,volumes of fine writing in leaves made from aloe bark and balck aloe oil occupied a very prominent place.The Nowgong grant of Balavarman gives a graphic desciption of

Pragjyotishanagara where areca nuts are wrapped in leaves of creeper of betel-plants and Krishnaguru(telegu for Agarwood) or black aloe wood trees were surrounded with cardamom creepers.It is also recorded that after conquering the last king Gaur Gobind in 1348AD ,in Sylhet ,Saint Fakir Ali Shah Jalal and his followers found agar wood and agar attar along with many other valuables in the royal store.This clearly indicates that distillation of agar oil was done as far back as 13th century or even much earlier.Abul Fazal Allami in his Ain-I-Akbari (memiors of Emperor Akbar written in 1590 AD gives a vivid description of agarwood and agar oil along with their manufacturing process and uses.It is also said that the Mughals invaded Assam mainly for agaru..such was it lure.!!. From Kamrup Agaru was exported to the Middle East ,most probabbly by Chinese traders through the Silk Route which extended from China to Middle-east through Kamrup and then India.In those days agaru was the main cosmetic item. Revered Vaishnava saint reformer and literary giant Sri Sankardeva, Vaisnavite saint Shri Madhab Deb also used sheets of the Agar for giving a written expression to their sermons, widely using agar for their sacred scriptures . Sri Sankardeva is also believed to have said that agar and chandana are the two divine trees capable of fulfiilling human desires. Religious puthis and history was also written and copied on specially treated bark of agar trees, known since time immemorial as Sanchipat and puthis, numerous puthis some dating back to as far back as 500 years ago are still preserved in quintessentially Assamese sacred repositories such as Than,Satras and Namgarh. It was during the 1940s that some enterprising families hailing from the erstwhile Sylhet district of Assam,now in Bangladesh, had the expertise to identify agarwood and agar-attar from these trees for commercial ends.But with partition,and a truncated India,the Agar entrepreneurs relocated at Hojai ,who then ventured to build agar business as a cottage indusry.The North east in particular at that time was host to many an agar mahal ,a system of leased forest plantation exclusively for Agar. Today ,numerous families particularly in Hojai are engaged in the extraction of Agar oil from the Agar wood. These families are in the business of wholesaling of agar as well as the wood and the oil. The positive spin-offs on the economy, are there for everyone to see. The magnificent and well-equipped Ajmal Majid Memorial Charitable Hospital , stands out ,in its presence, and the range of facilities it provides. Philanthropy apart, the multiplier effects are tangible.Higher

rates for Agar, translate into more employment for a range of skilled and semi-skilled workers. Higher wages affect buying power and that in turn affects the whole economy and makes it more buoyant. Agar :A High Premium Both natural and man-made factors are responsible for the extraordinarily high premium attributed to Agar. Man-made factors that have contributed to the high premiums are essentially the buying power of Agars chief patronizers and consumers-the Arabs of middle-East. The oil boom of the 70s has greatly enhanced the value that Agar commands. From a rate of Rs50/-per 11.62 grams for Agar oil,, today,the double super quality of agar from Imphal s oil fetches and commands a rate of R s 100-Rs 6000/-per 11.62 grams. Governments revocation of 145% import duty into the country in 1985 has also encouraged the growth of Agar Trade. Natures Value addition It is nothing but a rare fungus that attaches itself to the agar tree that has made agar such a valuable and sought after product. This fungus once it establishes itself on the tree turns the woody trunks into a deep brownish black colour. The darker the woody bark turns due to fungal infection, the more valuable the wood It is the fungus that gives the agar wood its unique aroma, when it is burnt. The oleoresin is usually found where the branches fork out from the stem.Agaru or agarwood is the heavily olereosin impregnated solid chips of wood obtained and processed from the fungus affected part of the trees. Devoid of the fungus, the agar tree in itself has no value. So it is natures value addition to the tree that commands a premium in he market. Where is Agar used? The uses of Agar are many.Its aromatic bark popularly known as Agar Batti is used as incense in many a home. Its by-product Agar oil used as a base for Attars and perfumes. The heavy base notes of the Agar oil lends itself to blend well with other essential oils such as rose,ylang ylang ,and jasmine that collectively power the perfume industry,the world over.Some European perfume houses especially seek out Agar oil to create heavier muskier perfume that have enhanced Agars demand and thereby carved a special niche market for these agar dependant perfumes. Agar Oil also has thereupatic uses as it is used in a large number of Unani and Ayurvedic medicines. Interestingly agar is also used to flavour

common and widely used betel nut prepartions such as Pan Parag and and Baba Zarda Inverted Pricing. Unlike other products that tiltillate the olfactory senses where byproducts are more valuable than the raw products, in the case of agar, it is the raw article or the wood of the infected tree that fetches the highest rate. The Double super variety from areas such as Imphal is highly prized for its intoxicating aroma when burnt. This bark commands the highest premium among Agar wood, and its other derivatives. This dark coloured wood is skillfully cut into smaller pieces, which are sold to be burnt as a kind of room incense especially popular in the Middle East . Its by-product agar oil, which is extracted through a method of crude distillation, in Hojai,is sold at a rate of 100-6000 rupees per tola or 11.62 grams. In economic terms ,its value is pegged at one and half times the price of gold. Process of Oil Extraction.how it is done? Once the Agar wood is procured, t is classified on the basis of quality. The less darker pieces are put into larger water drums to soften. Once these wood pieces soften, they are ground into a powder and are put into vessels called Degs with water. Degs are then heated so as to encourage the ground agar to release the oilwithin it.Once the water inside the Deg reaches a certain boiling temperature then the oil from the wood along with the water vapour reaches a container called the vabka. Before reaching the vabka the water vapour that passes through a steel pipe between the Deg and the vabka is cooled what therefore reaches the Vabka is a combination of water and agar oil,with the oil floating over the water.This oil is carefully extracted with a fine syringe and then stored into a fine glass bottle to be sun dried for the final product the Agar Oil. Research a Must-Save Agar The need for research into this dwindling valuable resource is compelling .Except in Nagland, there is no Agar left in India . Traditional sources are drying up. Reserves in Kalibanthan and Salabasi in Indonesia are also diminishing day by day .Fortunately for traders,new sources have been discovered in Maraoca near Indonesia and Pupua New Guinea , Laos and parts of Java.

Emerging Concerns : Million dollar Questions How does the fungus latch on to the tree ?How does one replicate natures value addition under laboratory condition?Can we inject the agar tree with the fungus .Scientists working for a perfume House in Dubai are quite hopeful that their efforts will be rewarded with fragrance that agar alone emits. This is the story of Agar,the of smell success and Assams very own liquid gold..

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Excel for Beginners GuideДокумент11 страницExcel for Beginners Guidefms162Оценок пока нет

- Guide - Project Management Software Buyers Guide - Checklist PDFДокумент36 страницGuide - Project Management Software Buyers Guide - Checklist PDFfms162Оценок пока нет

- Guide - Project Management Software Buyers Guide - Checklist PDFДокумент36 страницGuide - Project Management Software Buyers Guide - Checklist PDFfms162Оценок пока нет

- Presenting Data Effectively (Chapter 01) - Stephanie D. H. Evergreen - Sage Publications Inc.Документ32 страницыPresenting Data Effectively (Chapter 01) - Stephanie D. H. Evergreen - Sage Publications Inc.fms162Оценок пока нет

- Ambulatory AnesthesiaДокумент45 страницAmbulatory AnesthesiacardiacanesthesiaОценок пока нет

- PreviewДокумент69 страницPreviewMohammed S.GoudaОценок пока нет

- Nursing Psych Exam QuestionsДокумент3 страницыNursing Psych Exam QuestionsLaurie RNtobeОценок пока нет

- Dhaka PDFДокумент121 страницаDhaka PDFfms162Оценок пока нет

- MO L1 Personality Values ULABДокумент29 страницMO L1 Personality Values ULABfms162Оценок пока нет

- The Impact of SERVQUAL Model and Subjective Norms On Customers Satisfaction and Customer Loyalty in Islamic Banks - A Cultural ContextДокумент8 страницThe Impact of SERVQUAL Model and Subjective Norms On Customers Satisfaction and Customer Loyalty in Islamic Banks - A Cultural Contextfms162Оценок пока нет

- Presenting Data Effectively (Chapter 03) - Stephanie D. H. Evergreen - Sage Publications Inc.Документ44 страницыPresenting Data Effectively (Chapter 03) - Stephanie D. H. Evergreen - Sage Publications Inc.fms162Оценок пока нет

- Apply Benford's Law in ExcelДокумент12 страницApply Benford's Law in ExcelHermaz WibisonoОценок пока нет

- Survey Report Guidelines SummaryДокумент2 страницыSurvey Report Guidelines Summaryfms162Оценок пока нет

- Excel2013 Level1Документ17 страницExcel2013 Level1sreekanthОценок пока нет

- Presenting Data Effectively (Flyer) - Stephanie D. H. Evergreen - Sage Publications Inc.Документ6 страницPresenting Data Effectively (Flyer) - Stephanie D. H. Evergreen - Sage Publications Inc.fms162Оценок пока нет

- Excel Learing Sequence PDFДокумент1 страницаExcel Learing Sequence PDFfms162Оценок пока нет

- RFP & ToR - CLS Perception Study 2016 - LatestДокумент5 страницRFP & ToR - CLS Perception Study 2016 - Latestfms162Оценок пока нет

- Quick Guide For Excel 2013 Basics - February 2013 Training: Http://ipfw - Edu/trainingДокумент4 страницыQuick Guide For Excel 2013 Basics - February 2013 Training: Http://ipfw - Edu/trainingColnic AndreiОценок пока нет

- Excel For Beginners - Part IIДокумент15 страницExcel For Beginners - Part IIfms162Оценок пока нет

- Excel For Beginners - Part IIДокумент15 страницExcel For Beginners - Part IIfms162Оценок пока нет

- Statement of Research IntentДокумент2 страницыStatement of Research Intentfms162Оценок пока нет

- Big Chain Stores Are Closing Outlets in USAДокумент3 страницыBig Chain Stores Are Closing Outlets in USAfms162Оценок пока нет

- Minitab17 GettingStarted enДокумент83 страницыMinitab17 GettingStarted enBramantiyo Eko PОценок пока нет

- Key Administrative ResponsibilitiesДокумент1 страницаKey Administrative Responsibilitiesfms162Оценок пока нет

- Supply Demand Lecture MaterialsДокумент6 страницSupply Demand Lecture Materialsfms162Оценок пока нет

- Tourists' Satisfaction With Cultural Tourism FestivalsДокумент10 страницTourists' Satisfaction With Cultural Tourism Festivalsfms162Оценок пока нет

- Excel 2013 Quick Reference PDFДокумент3 страницыExcel 2013 Quick Reference PDFSymphonicОценок пока нет

- Attitudes and Perceptions of Local Residents and Tourists Toward The Protected Area of Retezat National Park, RomaniaДокумент17 страницAttitudes and Perceptions of Local Residents and Tourists Toward The Protected Area of Retezat National Park, Romaniafms162Оценок пока нет

- How Travel Has Changed Our LivesДокумент49 страницHow Travel Has Changed Our Livesfms162Оценок пока нет

- Algebra Worksheet 4 - Indices, Surds, Logs: 1. Simplify The FollowingДокумент2 страницыAlgebra Worksheet 4 - Indices, Surds, Logs: 1. Simplify The Followingfms162Оценок пока нет

- Frozen Food IndustryДокумент9 страницFrozen Food Industryfms162Оценок пока нет

- KolmogorovДокумент11 страницKolmogorovrodelagapitoОценок пока нет

- FIN-453 International Financial ManagementДокумент2 страницыFIN-453 International Financial Managementfms162Оценок пока нет

- The GP Note 2020Документ306 страницThe GP Note 2020firdauseahОценок пока нет

- Ohio Attorney General Mike DeWine's Office Files Suit Against 5 Drug CompaniesДокумент107 страницOhio Attorney General Mike DeWine's Office Files Suit Against 5 Drug CompaniesWCPO 9 NewsОценок пока нет

- Understanding Consumer Preferences for Kids' Health DrinksДокумент13 страницUnderstanding Consumer Preferences for Kids' Health Drinksnaveensingh073Оценок пока нет

- Extraction and Preliminary Phytochemical Screening of Active Compounds in Morinda Citrifolia FruitДокумент4 страницыExtraction and Preliminary Phytochemical Screening of Active Compounds in Morinda Citrifolia FruitnoviОценок пока нет

- Steroid Tapering Guidance for Cancer PatientsДокумент1 страницаSteroid Tapering Guidance for Cancer PatientsAulia AzahrahОценок пока нет

- Growel PharmaceuticalsДокумент27 страницGrowel Pharmaceuticalsprashantgupta11sept100% (1)

- Tafas v. Dudas Et Al - Document No. 211Документ5 страницTafas v. Dudas Et Al - Document No. 211Justia.comОценок пока нет

- Univ. „Ovidius” of Constanța General Medicine InjectionsДокумент18 страницUniv. „Ovidius” of Constanța General Medicine InjectionsNotInterestedОценок пока нет

- Antiflatulents: Labelling StandardДокумент6 страницAntiflatulents: Labelling StandardDavid HosamОценок пока нет

- Acute Confusional State ManagementДокумент18 страницAcute Confusional State ManagementAhmed AbdelgelilОценок пока нет

- Cadillac News 2019 Graduation ScrapbookДокумент7 страницCadillac News 2019 Graduation Scrapbookcn_cadillacmiОценок пока нет

- Pharmacognosy Intro PDFДокумент15 страницPharmacognosy Intro PDFDintakurthi Prasanth0% (1)

- 04 - 02 - Curriculum Design of Med Chem-I - IV SEM-2Документ3 страницы04 - 02 - Curriculum Design of Med Chem-I - IV SEM-2Tamu100% (1)

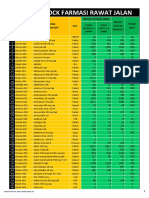

- Farmasi 5B Student Siti Muniroh Lists Various Drug CategoriesДокумент8 страницFarmasi 5B Student Siti Muniroh Lists Various Drug CategoriesArroh NurulaynyОценок пока нет

- Week 1 Introduction To PharmacologyДокумент12 страницWeek 1 Introduction To PharmacologyDino MicaОценок пока нет

- CompusynДокумент68 страницCompusynpicasso544Оценок пока нет

- Leukemia Patient ProfileДокумент2 страницыLeukemia Patient ProfileRN DebaucheryОценок пока нет

- Visions - BCs Mental Health and Addictions Journal - Cannabis-2009Документ32 страницыVisions - BCs Mental Health and Addictions Journal - Cannabis-2009KingstonCompassion ClubSocietyОценок пока нет

- Generalized Solution To Linear, Two-Compartment, Open Model For Drug DistributionДокумент21 страницаGeneralized Solution To Linear, Two-Compartment, Open Model For Drug DistributionChristopher Morales LeonОценок пока нет

- April 07 Us CompendiumДокумент161 страницаApril 07 Us CompendiumTony MarcelОценок пока нет

- RP-HPLC Method for Determining AlprazolamДокумент7 страницRP-HPLC Method for Determining AlprazolamErwin FernándezОценок пока нет

- Moringa Cure Fever PDFДокумент4 страницыMoringa Cure Fever PDFCisco SilvaОценок пока нет

- For Morgellons Disease Patients DR Stricker in San Francisco PrescribedДокумент4 страницыFor Morgellons Disease Patients DR Stricker in San Francisco Prescribedsisterrosetta100% (1)

- Stability of Captopril in Syrspend Sfjulaug2013Документ3 страницыStability of Captopril in Syrspend Sfjulaug2013Beatriz SilvaОценок пока нет

- Molecular modeling's role in drug design and discoveryДокумент6 страницMolecular modeling's role in drug design and discoveryMomaОценок пока нет

- Buffer Stock RJДокумент9 страницBuffer Stock RJardinaОценок пока нет

- ASHP Chapter 29 - Medication Dosing in Patients With Renal DysfunctionДокумент5 страницASHP Chapter 29 - Medication Dosing in Patients With Renal DysfunctionTammyОценок пока нет