Академический Документы

Профессиональный Документы

Культура Документы

BS en 12329 PDF

Загружено:

Senthil Kumar GanesanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BS en 12329 PDF

Загружено:

Senthil Kumar GanesanАвторское право:

Доступные форматы

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

British Standard

A single copy of this British Standard is licensed to

lbocvzr lbocvzr

on March 24, 2002

This is an uncontrolled copy. Ensure use of the most

current version of this document by searching British

Standards Online at bsonline.techindex.co.uk

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BRITISH STANDARD

BS EN

12329:2000

The European Standard EN 12329:2000 has the status of a

British Standard

ICS 25.220.40

NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

Corrosion protection of

metals

Electrodeposited

coatings of zinc with

supplementary

treatment on

iron or steel

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

This British Standard, having

been prepared under the

direction of the Materials and

Chemicals Sector Committee,

was published under the

authority of the Standards

Committee and comes into effect

on 15 June 2000

BSI 06-2000

ISBN 0 580 34345 6

BS EN 12329:2000

Amendments issued since publication

Amd. No. Date Comments

National foreword

This British Standard is the official English language version of EN 12329:2000.

It supersedes BS 1706:1990 which is withdrawn.

CAUTION EN 12329 was approved as a European Standard as it received the

requisite support amongst the 19 member bodies of the European Committee for

Standardization (CEN). The UK therefore has an obligation to implement EN 12329

as its national standard and to withdraw BS 1706 with which it conflicts. However,

attention is drawn to the fact that the UK did not support this standard on the basis

of possible safety implications, these being related to the commencement of heat

treatment as described in clause 6. The UK concern is that once a sub-microscopic

crack forms in the coated article, at present there is no means for its detection and

it cannot be removed. Following the initiation of a sub-microscopic crack no

subsequent heat treatment can repair the damage already sustained. It is essential

therefore that the delay in applying heat treament is as short as practicable. The UK

recommendation therefore was to amend the requirement in clause 6 to heat

treatment shall commence as soon as possible, preferably within 1 h, but not later

than 3 h after plating in accordance with those conditions given in ISO 9588. The

recommendation was not accepted by the CEN Technical Committee responisble

for the development of EN 12329.

The UK participation in its preparation was entrusted to Technical Committee

STI/33, Electrodeposited and related coatings, which has the responsibility to:

aid enquirers to understand the text;

present to the responsible European committee any enquiries on the

interpretation, or proposals for change, and keep the UK interests informed;

monitor related international and European developments and promulgate

them in the UK.

A list of organizations represented on this committee can be obtained on request to

its secretary.

Cross-references

The British Standards which implement international or European publications

referred to in this document may be found in the BSI Standards Catalogue under the

section entitled International Standards Correspondence Index, or by using the

Find facility of the BSI Standards Electronic Catalogue.

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, the EN title page,

pages 2 to 16, an inside back cover and a back cover.

The BSI copyright notice displayed in this document indicates when the document

was last issued.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

EUROPEAN STANDARD

NORME EUROPENNE

EUROPlSCHE NORM

EN 12329

March 2000

lCS 25.220.40

English version

Corrosion protection of metals - Electrodeposited coatings of

zinc with supplementary treatment on iron or steel

Protection contre la corrosion des mtaux - Revtements

lectrolytiques de zinc avec traitement complmentaire sur

fer ou acier

Korrosionsschutz von Metallen - Galvanische

Zinkberzge auf Eisenwerkstoffen mit zustzlicher

Behandlung

This European Standard was approved by CEN on 3 February 2000.

CEN members are bound to comply with the CEN/CENELEC lnternal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,

lceland, lreland, ltaly, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMI TE EUROPEEN DE NORMALI SATI ON

EUROPI SCHES KOMI TEE FR NORMUNG

CentraI Secretariat: rue de Stassart, 36 B-1050 BrusseIs

2000 CEN All rights of exploitation in any form and by any means reserved

worldwide for CEN national Members.

Ref. No. EN 12329:2000 E

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 2

EN 12329:2000

BSl 06-2000

Contents Page

Foreword........................................................................................................................................................... 3

Introduction...................................................................................................................................................... 4

1 Scope........................................................................................................................................... 5

2 Normative references .......................................................................................................... ...... 5

3 Terms and definitions......................................................................................................... ....... 6

4 Information to be supplied by the purchaser.......................................................................... 6

5 Designation................................................................................................................................. 6

5.1 General ........................................................................................................................................ 6

5.2 Heat treatment .............................................................................................................. .............. 6

5.3 Supplementary treatments.................................................................................................... .... 6

6 Heat treatment ................................................................................................................ ............ 6

7 Requirements ............................................................................................................................. 7

7.1 General ........................................................................................................................................ 7

7.2 Appearance................................................................................................................................. 7

7.3 Thickness.................................................................................................................................... 7

7.4 Adhesion..................................................................................................................................... 7

7.5 Corrosion resistance ........................................................................................................ ......... 7

Annex A (informative) Chromate conversion coatings .............................................................................. 10

Annex B (normative) Choice of designation .............................................................................................. 12

Annex C (informative) Examples of designations....................................................................................... 14

Annex D (normative) Measurement of average thickness of coating on small articles........................ 15

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 3

EN 12329:2000

BSl 06-2000

Foreword

This European Standard has been prepared by Technical Committee CEN/TC 262, Metallic and other

inorganic coatings, the Secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by September 2000, and conflicting national standards shall be

withdrawn at the latest by September 2000.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark,

Finland, France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal,

Spain, Sweden, Switzerland and the United Kingdom.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 4

EN 12329:2000

BSl 06-2000

Introduction

Electrodeposited coatings of zinc can be chromate treated in order to retard the formation of corrosion

products on surfaces of coatings exposed to corrosive atmospheres. When corrosion protection is the main

purpose of the coating, the usual practice is to apply a chromate or other conversion coating on top of the

electrodeposited zinc coating. This is particularly effective in retarding the formation of white corrosion

products which form on zinc coatings under certain conditions (see annex A).

Certain types of chromate conversion coating can be coloured in order to facilitate identification of the

treated articles.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 5

EN 12329:2000

BSl 06-2000

1 Scope

This European Standard specifies requirements for electrodeposited coatings of zinc on iron or steel with

supplementary treatment.

This European Standard does not specify chromate finishes which are required only for improving the

adhesion of paints or varnishes.

NOTE This European Standard is not intended to be used alone, but is the complement of EN 1403. It is necessary

for the purchaser to specify the zinc electrodeposited coating in accordance with the designation as specified in EN 1403.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications.

These normative references are cited at the appropriate places in the text and the publications are listed

hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply

to this European Standard only when incorporated in it by amendment or revision. For undated references

the latest edition of the publication referred to applies.

prEN ISO 3497, Metallic coatings Measurement of coating thickness X-ray spectrometric methods

(ISO/DIS 3497:1998).

prEN ISO 3543, Metallic and non-metallic coatings Measurement of thickness Beta backscatter

method (ISO/DIS 3548:1998).

EN 1403:1998, Corrosion protection of metals Electrodeposited coatings Method of specifying general

requirements.

EN ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles Specifications and test

methods (ISO 1461:1999).

EN ISO 1463, Metallic and oxide coatings Measurement of coating thickness Microscopical method

(ISO 1463:1982).

EN ISO 2177, Metallic coatings Measurement of coating thickness Coulometric method by anodic

dissolution (ISO 2177:1985).

EN ISO 2178, Non-magnetic coatings on magnetic substrates Measurement of coating thickness

Magnetic method (ISO 2178:1982).

EN ISO 2360, Non-conductive coatings on non-magnetic basis metals Measurement of coating thickness

Eddy current method (ISO 2360:1982).

EN ISO 2819, Metallic coatings on metallic substrates Electrodeposited and chemically deposited

coatings Review of methods available for testing adhesion (ISO 2819:1980).

EN ISO 3613:1994, Chromate conversion coatings on zinc and cadmium Test methods (ISO 3613:1980).

EN ISO 3892, Conversion coatings on metallic materials Determination of coating mass per unit area

Gravimetric methods (ISO 3892:1980).

ISO 9227, Corrosion tests in artificial atmospheres Salt spray tests.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 6

EN 12329:2000

BSl 06-2000

3 Terms and definitions

For the purposes of this standard the terms and definitions given in EN 1403 apply.

4 Information to be supplied by the purchaser

The information to be supplied by the purchaser shall be as specified in EN 1403. In addition, the purchaser

shall use the designation specified in clause 5.

5 Designation

5.1 General

The appropriate designation according to the severity of service conditions which the coating has to

withstand (see annex B) shall be used.

NOTE Examples of designations are given in annex C.

5.2 Heat treatment

The heat treatment designation as described in EN 1403 shall be used (see clause 6).

5.3 Supplementary treatments

5.3.1 Chromate conversion coatings

The codes for chromate conversion coatings given in annex B shall be used.

NOTE See annex A for more information on chromate conversion coatings.

5.3.2 Other supplementary treatments

Treatments carried out after chromating to enhance corrosion resistance (sealants) or provide colour (dyes)

shall be specified in the designation using the symbols given in EN 1403.

NOTE See the introduction, A.2 and A.5 for more information on sealing and dyeing.

6 Heat treatment

Any heat treatment for the relief of hydrogen embrittlement shall be carried out before a chromate

conversion coating is applied. Heat treatment shall be carried out as soon as possible after coating and in

any case within 4 h.

NOTE 1 Heat treatment procedures and classes are specified in ISO 9587 for stress relieving before processing and in

ISO 9588 for embrittlement relief after processing, but other conditions may be specified by the purchaser.

NOTE 2 Heat treatment in accordance with the recommended conditions can never guarantee complete freedom from

hydrogen embrittlement.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 7

EN 12329:2000

BSl 06-2000

7 Requirements

7.1 General

All tests (including corrosion resistance tests) shall be deferred until the expiry of a period of 24 h after the

chromating process has ended.

NOTE Chromate conversion coatings harden with age by gradual dehydration. They should therefore be handled

carefully for the first 24 h after the treatment.

7.2 Appearance

Over the significant surface, the electroplated articles shall be free from clearly visible plating defects such

as blisters, pits, roughness, cracks or unplated areas. See also 4.1 d) of EN 1403:1998.

Parts which have been given supplementary treatment shall be free from untreated areas on the significant

surface.

7.3 Thickness

7.3.1 Minimum local thickness

When tested in accordance with one of the following standards the minimum local thickness of the zinc

coating on articles having a significant surface area of greater than 1 cm

2

shall conform to that specified in

its designation: EN ISO 1463, EN ISO 2177, EN ISO 2178, EN ISO 2360, prEN ISO 3497, prEN ISO 3543.

NOTE Before using the method specified in EN ISO 2177, it is necessary to remove the chromate or other

supplementary treatment using a very mild abrasive, for example a paste of levigated alumina or magnesium oxide. In

the case of heavy conversion coatings, the results will, therefore, be slightly low.

7.3.2 Average thickness

For articles having a significant surface area of less than 100 mm

2

, the minimum local thickness shall be

deemed to be the minimum value of the average determined by the method specified in annex D.

7.4 Adhesion

7.4.1 Adhesion of zinc coating

When tested by the burnishing test in accordance with EN ISO 2819 the zinc coating shall have good

adhesion.

7.4.2 Adhesion of coloured chromate coating

Coloured chromate coatings shall be tested in accordance with 3.6 of EN ISO 3613:1994.

7.5 Corrosion resistance

When tested in accordance with the neutral salt spray (NSS) test described in ISO 9227 for the times given

in Tables 1 and 2, the test surface shall remain free from red corrosion product (see Table 1) or white

corrosion product (see Table 2) when examined by the unaided eye or corrected vision. Slight staining of the

test surface shall not be a cause of rejection. The test surface shall comprise those parts of the significant

surfaces of the test specimens that can be touched by a ball 20 mm in diameter or as otherwise specified by

the purchaser (see clause 4).

NOTE Red corrosion indicates corrosion of the basis metal and white corrosion indicates corrosion of the zinc

coating.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 8

EN 12329:2000

BSl 06-2000

Table 1 Corrosion resistance of the combined coating (zinc

coating plus chromate conversion coating)

(Partial) designation Service condition

number

Neutral salt spray

test time

(h)

Zn5/A 0 48

Zn5/B

Zn5/F

Zn5/C 1 72

Zn5/D

Zn8/A

Zn8/B

Zn8/F

Zn8/C 2 120

Zn8/D

Zn12/A

Zn12/F

Zn12/C 3 192

Zn12/D

Zn25/A

Zn25/F

Zn25/C 4 360

Zn25/D

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 9

EN 12329:2000

BSl 06-2000

Table 2 Corrosion resistance of the chromate conversion

coating before corrosion of the underlying zinc coating

Chromate

conversion coating

code

Neutral salt spray test time

(h)

Barrel plated parts Rack plated parts

A 8 16

B 8 16

C 72 96

D 72 96

F 24 48

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 10

EN 12329:2000

BSl 06-2000

Annex A

(informative)

Chromate conversion coatings

A.1 General

Chromating solutions are usually acidic and contain hexavalent chromium salts together with other salts

which can be varied to affect the appearance and hardness of the film. Clear, bleached, iridescent,

olive-green and black films on zinc coating can be obtained by processing in appropriate solutions.

Transparent films can also be obtained by bleaching iridescent films in alkaline solutions or in phosphoric

acid. Table A.1 gives the approximate mass per unit area for each type of chromate conversion coating

when measured in accordance with EN ISO 3892.

Table A.1 Chromate conversion coating type, appearance and mass per unit

area

Type Coating mass per unit area

Code Name g/m

2

A

a

Clear 0,5

B

b

Bleached 1,0

C Iridescent > 0,5 to 1,5

D Opaque > 1,5

F Black > 0,5 to 1,0

a

A need not contain chromium in hexavalent form.

b

B is a two-stage process.

A.2 Sealing

In order to give better protection against corrosion, chromate conversion coatings can be post-treated with

sealing agents, by introducing organic products into the chromate film. This operation also enhances the

resistance of the chromate conversion coating to higher temperatures.

Sealing can be carried out by dipping or spraying the conversion coating with polymers in aqueous solutions.

A similar process is based on the addition of suitable organic products to the chromating solution.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 11

EN 12329:2000

BSl 06-2000

A.3 Rinsing and drying

If hot water is used as the final rinse after the chromating process, the time of rinsing should be kept as short

as possible in order to prevent the dissolution of the hexavalent chromium. The drying of the article should

be carried out at a temperature compatible with the type of chromating used in order to prevent cracking due

to dehydration of the chromate coating (in general, the maximum drying temperature is 60 C).

A.4 Processing of parts in bulk

If parts are processed in bulk by electroplating and chromating in barrels, the corrosion resistance of the

chromate coating is reduced by a degree which is reflected in the salt spray test requirements given in

Table 2.

A.5 Dyeing

If required, chromate conversion coatings of types A or B can be dyed with organic dyes to produce coloured

finishes suitable for identification purposes. The process is carried out by dipping in or spraying with

aqueous solutions of the appropriate organic dye (see the introduction).

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 12

EN 12329:2000

BSl 06-2000

Annex B

(normative)

Choice of designation

B.1 Selection

The appropriate designation shall be selected according to the severity of service conditions which the

coating has to withstand (see Table B.1).

Table B.1 (Partial) designation, service condition numbers and service conditions

(Partial)

designation

Service condition

number

Service conditions

Zn5/A 0 Purely cosmetic applications

Zn5/B

Zn5/F

Zn5/C 1 Service indoors in warm dry atmospheres

Zn5/D

Zn8/A

Zn8/B

Zn8/F

Zn8/C 2 Service indoors in places where

condensation may occur

Zn8/D

Zn12/A

Zn12/F

Zn12/C 3 Service outdoors in temperate conditions

Zn12/D

Zn25/A

Zn25/F

Zn25/C 4 Service outdoors in severe corrosive

conditions, e.g. marine or industrial

Zn25/D

NOTE 1 In any particular environment, the protective value of a zinc coating increases with the coating

thickness, but for any particular coating thickness, the corrosion resistance can be enhanced by the use

of appropriate chromate treatments.

NOTE 2 When very long service life is required, as for example on structural steel components, the

thicker zinc coatings required can be applied by hot-dip zinc coating in accordance with EN ISO 1461,

for example.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 13

EN 12329:2000

BSl 06-2000

B.2 Chromate conversion coatings

The code of the chromate conversion coating shall conform to Table B.2.

Table B.2 Chromate conversion coating types and typical appearance

Type Typical appearance

Code Name

A

a Clear Transparent, clear to bluish

B

b Bleached Transparent with slight iridescence

C Iridescent Yellow iridescent

D Opaque Olive-green

F Black Black

a

A need not contain chromium in hexavalent form.

b

B is a two-stage process.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 14

EN 12329:2000

BSl 06-2000

Annex C

(informative)

Examples of designations

EXAMPLE 1 Designation of an electrodeposited coating of 12 mm zinc (Zn12) on iron or steel (Fe) which

has had an iridescent chromate conversion coating (C) applied:

Electrodeposited coating EN 12329 - Fe//Zn12//C

EXAMPLE 2 Designation of an electrodeposited coating of 25 mm zinc (Zn25) on iron or steel (Fe) which

has been heat treated for hydrogen embrittlement relief for 2 h at 190 C (HT(190)2) and has been given a

supplementary opaque chromate conversion coating (D) followed by a sealing treatment consisting of the

application of organic sealant (T2):

Electrodeposited coating EN 12329 - Fe//Zn25/HT(190)2/D/T2

NOTE These examples do not include the standard designation of the basis metal as recommended in

5.2 of EN 1403:1998.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 15

EN 12329:2000

BSl 06-2000

Annex D

(normative)

Measurement of average thickness of coating on small articles

D.1 Materials

Suitable stripping solutions are listed below [items a) to e)].

WARNING Antimony trioxide (Sb

2

O

3

) dissolved in hydrochloric acid and antimony trichloride (SbCl

3

)

are toxic. Avoid contact with the skin.

Stibine (SbH

3

), which is a very toxic gas, may be reIeased during the stripping process when using

either soIution A or B, and stringent precautions shouId be taken to avoid breathing it. Carry out the

stripping process in a fume cupboard.

FormaIdehyde soIution is toxic, irritant and causes burns. Avoid breathing the vapour. Avoid contact

with the skin and eyes.

a) Solution A comprises 2,0 g antimony trioxide (Sb

2

O

3

) dissolved in 800 ml hydrochloric acid

(r = 1,16 g/ml to 1,19 g/ml) and diluted with 200 ml distilled or de-ionized water.

b) Solution B comprises 3,2 g antimony trichloride (SbCl

3

) dissolved in 800 ml hydrochloric acid

(r = 1,16 g/ml to 1,19 g/ml) and diluted with 200 ml distilled or de-ionized water.

c) Solution C comprises 10 ml formaldehyde (solution of mass fraction 30 %) dissolved in

500 ml hydrochloric acid (r = 1,16 g/ml to 1,19 g/ml) and diluted with 500 ml distilled or de-ionized

water.

d) Solution D comprises 300 g/l ammonium nitrate (NH

4

NO

3

).

e) Solution E comprises 1 g propan-2-ol-1 (C

3

H

3

OH) dissolved in 500 ml hydrochloric acid

(r = 1,16g/ml to 1,19 g/ml) and diluted with 500 ml distilled or de-ionized water.

WARNING Do not re-use parts stripped in accordance with annex D.

D.2 Procedure

For articles having a significant surface area of less than 1 cm

2

, take a sufficient number of articles to give a

mass of coating not less than 100 mg. Weigh the articles, to the nearest milligram, and strip off the zinc

coating at room temperature using a suitable stripping solution. When solution A or solution B is used, the

articles shall be removed from the solution as soon as the zinc coating has completely dissolved, i.e. as

soon as the vigorous chemical reaction has ceased.

WARNING The stripping soIutions have hazards associated with them and the precautions given in

D.1 shouId be carefuIIy observed.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 16

EN 12329:2000

BSl 06-2000

Rinse the articles in running water, if necessary brushing to remove any loose dark deposit (of antimony

when using solution A or solution B) from the surface, dry carefully and reweigh, noting the loss in mass.

Calculate the thickness of the zinc coating, G, in micrometres, from the following equation:

r $

P

G

10

3

=

where

P is the loss in mass, in milligrams;

$ is the area of the surface under examination, in square millimetres;

r is the density of the zinc coating, in grams per cubic centimetre, normally 7,1 g/cm

3

.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

blank

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

BS EN

12329:2000

BSI

389 Chiswick High Road

London

W4 4AL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BSI British Standards Institution

BSI is the independent national body responsible for preparing British Standards. It

presents the UK view on standards in Europe and at the international level. It is

incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of British Standards

should make sure that they possess the latest amendments or editions.

It is the constant aim of BSI to improve the quality of our products and services. We

would be grateful if anyone finding an inaccuracy or ambiguity while using this

British Standard would inform the Secretary of the technical committee responsible,

the identity of which can be found on the inside front cover. Tel: 020 8996 9000.

Fax: 020 8996 7400.

BSI offers members an individual updating service called PLUS which ensures that

subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: 020 8996 9001. Fax: 020 8996 7001.

In response to orders for international standards, it is BSI policy to supply the BSI

implementation of those that have been published as British Standards, unless

otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and international

standards through its Library and its Technical Help to Exporters Service. Various

BSI electronic information services are also available which give details on all its

products and services. Contact the Information Centre. Tel: 020 8996 7111.

Fax: 020 8996 7048.

Subscribing members of BSI are kept up to date with standards developments and

receive substantial discounts on the purchase price of standards. For details of

these and other benefits contact Membership Administration. Tel: 020 8996 7002.

Fax: 020 8996 7001.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the UK, of

the publications of the international standardization bodies. Except as permitted

under the Copyright, Designs and Patents Act 1988 no extract may be reproduced,

stored in a retrieval system or transmitted in any form or by any means electronic,

photocopying, recording or otherwise without prior written permission from BSI.

This does not preclude the free use, in the course of implementing the standard, of

necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

If permission is granted, the terms may include royalty payments or a licensing

agreement. Details and advice can be obtained from the Copyright Manager.

Tel: 020 8996 7070.

L

i

c

e

n

s

e

d

C

o

p

y

:

l

b

o

c

v

z

r

l

b

o

c

v

z

r

,

M

a

r

c

h

2

4

,

2

0

0

2

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Вам также может понравиться

- DIN ISO Equivalent FastenersДокумент12 страницDIN ISO Equivalent FastenersGunnie PandherОценок пока нет

- ASCOMETAL Steel Grades ENДокумент8 страницASCOMETAL Steel Grades ENasad144Оценок пока нет

- Iso 228 1 2000Документ9 страницIso 228 1 2000Ulvi NebiyevОценок пока нет

- International Standard: Stainless Steels For Springs - WireДокумент8 страницInternational Standard: Stainless Steels For Springs - WireAfzal ImamОценок пока нет

- BSI BS-1726-1-2002 - Guide To Methods of Specifying Tolerances and Testing - Extension Springs PDFДокумент18 страницBSI BS-1726-1-2002 - Guide To Methods of Specifying Tolerances and Testing - Extension Springs PDFGerald See Toh100% (1)

- Jis G4052-1979Документ39 страницJis G4052-1979RanjithkumarОценок пока нет

- Iso 5145-2014-03Документ44 страницыIso 5145-2014-03Raj KumarОценок пока нет

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledДокумент7 страницFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganОценок пока нет

- BS en Iso 10644-2009 PDFДокумент14 страницBS en Iso 10644-2009 PDFMadheswaran Dharmapuri100% (1)

- Continuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingДокумент12 страницContinuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingudayОценок пока нет

- Technical recommendations for threaded fittings and tapped holesДокумент3 страницыTechnical recommendations for threaded fittings and tapped holesJai Bhandari0% (1)

- Hexagon Socket Button Head Screw With Flange - IsO 7380-2Документ9 страницHexagon Socket Button Head Screw With Flange - IsO 7380-2Corneliu VilcuОценок пока нет

- Standard For FastenersДокумент11 страницStandard For FastenersAmandeep SinghОценок пока нет

- External Metric ISO Thread Table Chart Sizes M20 - M55Документ8 страницExternal Metric ISO Thread Table Chart Sizes M20 - M55dilipОценок пока нет

- Din 8140-1Документ5 страницDin 8140-1main46prairieОценок пока нет

- Din en 13599 - 2014Документ23 страницыDin en 13599 - 2014alferedОценок пока нет

- BS en Iso 9015-2 2016Документ18 страницBS en Iso 9015-2 2016Rahmat Munggaran100% (2)

- Zinc Flake Technology-Technical PDFДокумент1 страницаZinc Flake Technology-Technical PDFKalyan DhakaneОценок пока нет

- BS-919-2-2007-diş Mastar Toleransları PDFДокумент42 страницыBS-919-2-2007-diş Mastar Toleransları PDFalifuat duyguОценок пока нет

- General Tolerances - DIN - IsO - 2768Документ2 страницыGeneral Tolerances - DIN - IsO - 2768Pasca GheorgheОценок пока нет

- Din 6915 PDFДокумент3 страницыDin 6915 PDFa.tabkhi1980100% (3)

- En 10132 - 2000Документ18 страницEn 10132 - 2000Дмитрий ОсинцевОценок пока нет

- DIN 936 DIV 5655: Hexagon Thin Nuts Hexagon Nuts, (H D)Документ3 страницыDIN 936 DIV 5655: Hexagon Thin Nuts Hexagon Nuts, (H D)linijatzОценок пока нет

- BS en 10060 2003Документ12 страницBS en 10060 2003VeraОценок пока нет

- Iso 4042 PDFДокумент25 страницIso 4042 PDFAditya Pratap100% (6)

- En 10270-2Документ20 страницEn 10270-2Bogdan Gabriel100% (3)

- (BS EN ISO 14253-1 - 2013) - Geometrical Product Specifications (GPS) - Inspection by Measurement of Workpieces and Measuring Equipment. Decision Rules For Proving Conformity or NoДокумент26 страниц(BS EN ISO 14253-1 - 2013) - Geometrical Product Specifications (GPS) - Inspection by Measurement of Workpieces and Measuring Equipment. Decision Rules For Proving Conformity or NoRocio Taquire100% (13)

- BS Iso-965-2-1998Документ14 страницBS Iso-965-2-1998Denisse Rodriguez RosasОценок пока нет

- BZ 8002953Документ15 страницBZ 8002953uuur35Оценок пока нет

- Din 50942-96Документ13 страницDin 50942-96RONALD100% (2)

- Iso 7042 2012 PDFДокумент6 страницIso 7042 2012 PDFGuillermo TorresОценок пока нет

- En10083 2Документ2 страницыEn10083 2Sezgin BayrakОценок пока нет

- Worldwide Fastener Standard: Printed Copies Are UncontrolledДокумент2 страницыWorldwide Fastener Standard: Printed Copies Are UncontrolledRasatja Yongskulrote100% (1)

- Material Specification: Specification: Revision Date: Revision LevelДокумент2 страницыMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Iso 965-3 PDFДокумент23 страницыIso 965-3 PDFRitxar DfОценок пока нет

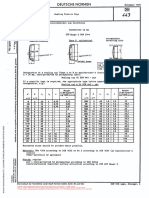

- Din 443 PDFДокумент1 страницаDin 443 PDFLuciano Fontes100% (1)

- DIN 915 EN-1980 Hexagon Socket Set Screws With Dog PointДокумент4 страницыDIN 915 EN-1980 Hexagon Socket Set Screws With Dog Pointthachpn100% (1)

- Supraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilДокумент2 страницыSupraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilHugo RodriguezОценок пока нет

- BS en 00755-4-2008Документ15 страницBS en 00755-4-2008Luis SierraОценок пока нет

- DinДокумент1 страницаDinMelissa SmithОценок пока нет

- Din en Iso 1302Документ51 страницаDin en Iso 1302Akshay Patil100% (1)

- JIS B 0405 General TolerancesДокумент1 страницаJIS B 0405 General TolerancesGiang Nguyễn BáОценок пока нет

- DIN 128 A - Split Spring Washers, Curved, Form AДокумент6 страницDIN 128 A - Split Spring Washers, Curved, Form ASantosh100% (1)

- Low-Carbon Steel Specs and Mechanical PropertiesДокумент9 страницLow-Carbon Steel Specs and Mechanical PropertiescharssxОценок пока нет

- Iso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFДокумент5 страницIso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFMitesh MakvanaОценок пока нет

- 2370 Ed1 ENДокумент5 страниц2370 Ed1 ENanhthoОценок пока нет

- Copper CatalogДокумент2 страницыCopper CatalogYogesh AnapОценок пока нет

- SWG To MM Chart PDFДокумент1 страницаSWG To MM Chart PDFSundara Moorthy100% (1)

- 54SiCr6 Material Spec SheetДокумент1 страница54SiCr6 Material Spec SheetRajaSekarsajjaОценок пока нет

- Iso 16048-2003Документ9 страницIso 16048-2003張曉文100% (1)

- Vdocuments - MX Din 405 Universo For Knuckle Thread Din 405Документ7 страницVdocuments - MX Din 405 Universo For Knuckle Thread Din 405wauwio1906Оценок пока нет

- Din 7500 enДокумент10 страницDin 7500 enCălin Bălăiţă100% (1)

- BS en 12330Документ19 страницBS en 12330OmerfAtaОценок пока нет

- BS en 60974-8Документ25 страницBS en 60974-8Sasa ZivkovicОценок пока нет

- BS 12271-3 Rate of Spread For SealsДокумент8 страницBS 12271-3 Rate of Spread For SealsBindhya RenjithОценок пока нет

- Electric Cables. Calculation of Current Rating. Cable - Unknown - 2001Документ38 страницElectric Cables. Calculation of Current Rating. Cable - Unknown - 2001eero.ylistaloОценок пока нет

- BS en 60974-10Документ21 страницаBS en 60974-10Sasa ZivkovicОценок пока нет

- BS en 12385-6-2004Документ28 страницBS en 12385-6-2004Leon MarcoОценок пока нет

- EN 50272-3-2002 - enДокумент20 страницEN 50272-3-2002 - enMiahsaheb RafeeqОценок пока нет

- WeatherpdfДокумент3 страницыWeatherpdfSenthil Kumar GanesanОценок пока нет

- Ryton Pps Thermal PropertiesДокумент8 страницRyton Pps Thermal PropertiesSenthil Kumar GanesanОценок пока нет

- JIS Kanto Loam Z8901 - Class 7 8 11 2015Документ1 страницаJIS Kanto Loam Z8901 - Class 7 8 11 2015Senthil Kumar GanesanОценок пока нет

- Techtron PPSДокумент5 страницTechtron PPSSenthil Kumar GanesanОценок пока нет

- NORYLДокумент1 страницаNORYLSenthil Kumar GanesanОценок пока нет

- Techtron & Ryton PpsДокумент2 страницыTechtron & Ryton PpsSenthil Kumar GanesanОценок пока нет

- Plastic MaterialДокумент8 страницPlastic MaterialSenthil Kumar GanesanОценок пока нет

- Technical Information: Moulding CompoundДокумент2 страницыTechnical Information: Moulding CompoundSenthil Kumar GanesanОценок пока нет

- Technical Information: Moulding CompoundДокумент2 страницыTechnical Information: Moulding CompoundSenthil Kumar GanesanОценок пока нет

- Noryl GTX®: FeaturesДокумент4 страницыNoryl GTX®: FeaturesSenthil Kumar GanesanОценок пока нет

- Techtron & Ryton PpsДокумент2 страницыTechtron & Ryton PpsSenthil Kumar GanesanОценок пока нет

- Ryton Mechanical PropertiesДокумент12 страницRyton Mechanical PropertiesClaudia MmsОценок пока нет

- Techtron & Ryton PpsДокумент2 страницыTechtron & Ryton PpsSenthil Kumar GanesanОценок пока нет

- Techtron & Ryton PpsДокумент2 страницыTechtron & Ryton PpsSenthil Kumar GanesanОценок пока нет

- Noryl GTX®: FeaturesДокумент4 страницыNoryl GTX®: FeaturesSenthil Kumar GanesanОценок пока нет

- Alvania r3Документ7 страницAlvania r3Senthil Kumar GanesanОценок пока нет

- BS 970 Part 2 1988Документ16 страницBS 970 Part 2 1988Senthil Kumar GanesanОценок пока нет

- BS en 10087Документ26 страницBS en 10087Erik RochaОценок пока нет

- Alvania r3Документ2 страницыAlvania r3Senthil Kumar Ganesan75% (4)

- Astm E505 - 1Документ3 страницыAstm E505 - 1Senthil Kumar GanesanОценок пока нет

- 9975 2Документ5 страниц9975 2Senthil Kumar GanesanОценок пока нет

- ISO 1940-2-1997 Mechanical VibДокумент20 страницISO 1940-2-1997 Mechanical VibJavad Monfared100% (3)

- Is - 2062Документ9 страницIs - 2062Prakash SinghОценок пока нет

- Alvania r3Документ2 страницыAlvania r3Senthil Kumar Ganesan75% (4)

- BS en 12329 PDFДокумент21 страницаBS en 12329 PDFSenthil Kumar GanesanОценок пока нет

- BS en 12329 PDFДокумент21 страницаBS en 12329 PDFSenthil Kumar GanesanОценок пока нет

- E155-00 Aluminum & Magnesium CastingsДокумент4 страницыE155-00 Aluminum & Magnesium Castingschitti409Оценок пока нет

- Is 1079 2009Документ13 страницIs 1079 2009Kings ParkОценок пока нет

- BS PD 970-2005Документ50 страницBS PD 970-2005vpmohammed100% (3)

- 3601 Specification of Tubes PDFДокумент30 страниц3601 Specification of Tubes PDFSenthil Kumar GanesanОценок пока нет

- Chemical Content of FertilizersДокумент22 страницыChemical Content of FertilizersJohn DAcquisto, D.Sc.100% (1)

- StatProb11 Q4 Mod3 RegressionAnalysis v4Документ21 страницаStatProb11 Q4 Mod3 RegressionAnalysis v4ALEX SARAOSOS100% (4)

- Andhra Pradesh Land Reforms (Ceiling On Agricultural Holdings) (Amendment) Act, 2009Документ3 страницыAndhra Pradesh Land Reforms (Ceiling On Agricultural Holdings) (Amendment) Act, 2009Latest Laws TeamОценок пока нет

- MAST20026 Real Analysis With Applications, August 10, 2011. This Document Was Produced by Steve Carnie and Adapted by Alex GhitzaДокумент2 страницыMAST20026 Real Analysis With Applications, August 10, 2011. This Document Was Produced by Steve Carnie and Adapted by Alex Ghitzavanessa8pangestuОценок пока нет

- Προσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςДокумент20 страницΠροσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςARISTEIDIS VIKETOSОценок пока нет

- 2.2 Access CT Networking Rev20150728Документ5 страниц2.2 Access CT Networking Rev20150728F CОценок пока нет

- Micom P139: Feeder Management and Bay ControlДокумент376 страницMicom P139: Feeder Management and Bay ControljjcanoolivaresОценок пока нет

- Huntersvsfarmers 131204084857 Phpapp01Документ1 страницаHuntersvsfarmers 131204084857 Phpapp01Charles BronsonОценок пока нет

- Course Contents: Academic Session 2020-21 B.A. LL.B. (Hons.) Tenth SemesterДокумент52 страницыCourse Contents: Academic Session 2020-21 B.A. LL.B. (Hons.) Tenth SemesterShashank PandeyОценок пока нет

- The Bedford Clanger May 2013 (The Beer Issue)Документ12 страницThe Bedford Clanger May 2013 (The Beer Issue)Erica RoffeОценок пока нет

- Logiq 180 UsuarioДокумент414 страницLogiq 180 UsuariolaboratorioelectroОценок пока нет

- Exam Progam May 2023 Pnle (Nursing)Документ4 страницыExam Progam May 2023 Pnle (Nursing)marisavillaruzОценок пока нет

- NCP Ineffective Breathing PatternДокумент1 страницаNCP Ineffective Breathing PatternMarc Johnuel HumangitОценок пока нет

- Display PDF PDFДокумент7 страницDisplay PDF PDFSandeepОценок пока нет

- Planning For Good AcousticsДокумент1 страницаPlanning For Good Acousticsa_j_sanyal259Оценок пока нет

- Design and Construction of Water Supply SchemeДокумент126 страницDesign and Construction of Water Supply SchemeShreyansh SharmaОценок пока нет

- Hofa Iq Limiter Manual enДокумент8 страницHofa Iq Limiter Manual enDrixОценок пока нет

- Delivering Large-Scale IT Projects On Time, On Budget, and On ValueДокумент5 страницDelivering Large-Scale IT Projects On Time, On Budget, and On ValueMirel IonutОценок пока нет

- 280Документ6 страниц280Alex CostaОценок пока нет

- Philippine Constitutional Commissions Powers and FunctionsДокумент36 страницPhilippine Constitutional Commissions Powers and Functionssharlica1990Оценок пока нет

- Advance NewsletterДокумент14 страницAdvance Newsletterapi-206881299Оценок пока нет

- Noam Chomsky Propaganda Modela Critical EvaluationДокумент24 страницыNoam Chomsky Propaganda Modela Critical Evaluationsatyanarayana vuyyapuОценок пока нет

- Industrial Tour Report (JEWEL - MANAGEMENT-CU)Документ37 страницIndustrial Tour Report (JEWEL - MANAGEMENT-CU)Mohammad Jewel100% (2)

- 3 IT18 Information Assurance and Security 2 Prelim ExamДокумент2 страницы3 IT18 Information Assurance and Security 2 Prelim Examsarah miinggОценок пока нет

- PT-E - Fundamentals of Process Plant Layout and Piping DesignДокумент14 страницPT-E - Fundamentals of Process Plant Layout and Piping DesignNofrizal HasanОценок пока нет

- Rift Valley University Office of The Registrar Registration SlipДокумент2 страницыRift Valley University Office of The Registrar Registration SlipHACHALU FAYEОценок пока нет

- Innovative Uses of Housing Lifting Techniques-JIARMДокумент16 страницInnovative Uses of Housing Lifting Techniques-JIARMPOOJA VОценок пока нет

- EE5 Writing Revision Unit1-5Документ8 страницEE5 Writing Revision Unit1-5Chuc VuОценок пока нет

- Data Sheet ECU-TESTДокумент2 страницыData Sheet ECU-TESTmeetbalakumarОценок пока нет

- Netflix AccountsДокумент2 страницыNetflix AccountsjzefjbjeОценок пока нет