Академический Документы

Профессиональный Документы

Культура Документы

Bus Duct Design

Загружено:

hani_pilevar3778Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bus Duct Design

Загружено:

hani_pilevar3778Авторское право:

Доступные форматы

http://www.slideshare.

net/STUPIDPANDEY/bus-duct-fabrication

BUS DUCTS

INTRODUCTION

Bus ducts or bus bars arc used to carry very h.igh. current between

the generator and associated transfonncrs. in the power stations. In

the power stations the generator voltages vary from 12 KV to 24

KV wllereas auxiliary supply voltages are 3.3 KY. 6.6 KY. or 12

KY.

Bus bars arc thick. metal oonnectors. usually of aluminium. wh.ich.

carry large current up to 10 KA for 2001250 MW sets and around

20 KA for 500 MW set. llle oonductors are metal enclosed.

usually aluminium to provide safety and reliable operation.

Considering tile cost of ooppcr and aluminium. the later lias been

found to be an economical choice as oonducting

Resistance-Temp oocfficient per centigrade degree

0.00403 0.00381

Density gm. per IT 2.95 8.9

Relative density I 3.29

material for h.igller current bu s ducts. Aluminium Ilas been used for

the enclosure. as well as to reduce magnetic losses.

TIle enclosures and conductors are provided welded joints as for as

possible to give reduced maintenance. Bolted joints are provided

wllere opening is necessary during operation.

Aluminium is being used increasingly as busbar material. in power

stations. distribution boards. switchgear. etc. one of tile main

,

reasons for th.is is tltat it is ch.eapcr to use lIlan ooppcr and making

allowance forthe light metal's.

TYPES OF BUSDUCTS

I. Isolated pllase busduct

2. segregated busduct

ISOLATED PHASE BUSDUCT

INTRODUCTION:

Busduct fonns lIle electrical link between generator. transformers

and associated cquipments such. as LAVT cubicle. UAT cubicle.

NG cubicle etc. I t is an assembly of busbars with. associated joints

.oonncctions and supponing insulators with.in a grounded metal

enclosure.

In Isolated Ph.a.<;c Bus duct each. pllase oonductor is enclosed by an

individual metal h.ousing and separated from adjacent pltase

oonductor OOusing by an air space. In lIle oontinuous I. P.Busduct

various sections are so intcroonnccted lIlat low resistance path. for

lIle induced circulating current is provided from one ph.a.<;c

enclosu re to other pltase enclosu re.

,

DESIGN ASPECTS AND CRITERIA

lllc design of bus duct is governed by following Typical values

for parameters 3 X 210 MW Tenugh.at Proposal (ICB) is given

below:

a) Rated Continuous Current for main bus I<xx)

Amps

b) Rated Continuous Current for Tap-offbus 1600 I 800

Amps

e) Rated Voltage 15.75 KV

d)

e) SIlort time Current for main bus

f) Soon time Current forTap-offbus

-78 KA rms for 3Sec.

\225 KAP

150 KA nTIS for 3

sccl420 KAP

g) Tempcrarure rise allowed for bus enclosure 20 deg. C

Over 50 deg.C

g) Temperature rise allowed for bus Conductor - 40 deg.( Plain

boltejoint)

Over SOdeg.C

55 deg. C(Silver

plated joint)

lllc bus duct is designed to meet tile above requirements and

following are tile design out puts:

IlBus har :

a) Material and grade

Alloy

l\bin t L ~

AI. Alloy

Tap-off

AI.

Grade 19501 Grade63401

b) Sllapc

c) Size (Dia. & th.ickncss)

II l Bus Enclosure :

a) Material and grade

3lLXXl

b) Sllapc

c) Size (Dia. & th.ickncss)

III) Phase to Phase spacing

mm

Round Square

450 OlD . 15 Tk.

I 52.4A1F.8.ITk.

Box ch.anncl condo

AI. Alloy

Grade 19500

Round

AI. Alloy

Grade

Round

1000 0 / D.6.35 Tk.

780 0 f D4.78Tk.

1250 mm tolX)

,

IV) Phase to earth clearance (min.) 220 mm 220

mm

V) Type of cooling

VI) Degree of Protection

tests as per Appendix 'F'

AirNatraul

Air and Water tigh.tncss

of IS :8084

CONSTRUCTIONAL ASPECTS

lllc busduct enclosure is made of aluminium alloy slleet and

supplied in lengtll upto 6-7 meters. It is furtller reinforced with.

aluminium cllannel rings at intervals wh.ich. are also used for

enclosure and insulator mounting. Scaled openings are provided in

tile busduct run ncar insulator for inspection and maintenancc.lllc

tIlree ph.ase enclosures are interconnected effectively at tile ends to

pennit now of current. Different sections of each. ph.ase are

generally connected togetller by aluminium make up pieces at site.

It is provided at Bus duct tenninations and in tile run of bus duct if

route lengtll is more titan 30 to 35 mtr .. to take care of mach.ine

vibrations . alignment and expansion f contration due to

temperature variations. Furtllcr . it insulates tile termination

cquipments connecting to bus duct and thus do not let toc bus

enclosu re currents to flow in th.e connecting cqu iprrcnts.

HEXIIILES :

Copper !lexibles are provided at bus duct tcnninations i.e at

Generator end. Generator trans(orrrcr end. LA VT Cubicle. NG

Cubicle and oth.er oonnccting cquiprrcnt end. Aluminium flexiblcs

are provided in toc run of bus duct to take care o( alignrrcnt

variation in bus bar lengths due to temperature variations.

Epoxy Seal off bushings are provided at Power house wall and at

Generator tennination end to restrict toc propogation o( fire in case

of accident. For air prcssuriscd job's, Sea! ofT bushing is also

provided at Generator transformer end to (orm a close loop (or

oompresscd air.

AIR PRESSURI SATION I-:DUIPl\U:NT. :

To avoid th.e ingress of dust. moisturcs etc. inside toc bus duct. air

at a pressure slightly above th.e atmospheric pressure 25 to 40 mm

WC is flown in th.e busduct with toc oclp of Air Pressurisation

Equiprrcnt.

,

HOT AIR IILOWt: R :

After prolonged sllutdown. to improve tile IR value of Bus duct.

Hot air is blown inside tile bus duct witll tile IIelp of Hot Air

Blower_

Isolated Phase Bus-Duct

----.

SEGREGATED PHASE BUSDUCT

INTRODUCTION:

Busduct fonns the electrical link between generator. transformers

and associated equipmcnts such. as LA VT cubicle. UA T cubicle.

NG cubicle etc. It is an assembly of busbars with. associated joints

.connections and supponing insulators with.in a grounded metal

enclosure.

In Segregated Phase Bus duct all the tllrec ph.ase conductors are

housed in a metal enclosure with. segregation between tile phases

by means of a metallic' insulating barriers. Th.is arrangement

reduces possibility of ph.a.<;! fault s and also Ilelps in reducing

temperature rise.

DESIGN ASPECTS AND CRITERIA

llle design of bus duct is governed by following parameters.

Typical values for 250 MW Power Plant is given below:

II) Rated Continuou s Current for main bus

Amps

I) 2000

II ) 2500 Amps

Ill) 4000 Amps

i) Rated Voltage 6.6 KV

'"

j ) Soon time Current for 40 KA rms for I

Sec.l102 KAP

k) Tempcrarure rise allowed for bus enclosure - 20 deg.C

Over 50 deg. C

I) Tempcrarure rise allowed for bus Conductor - 40 deg.C

(her 50 deg. C

lllc bus duct is dcsigned to meet tile above requirements and

following arc tile

design out puts:

I)Bushar :

a) Material and grade

b) Sllapc

c) Size

2000A I 2500 A

AI. Alloy

Grade 63401

Square

4000 A

Al Alloy

Grade63401

Square

2XI27 AlF.8.01 tk.

2x I 77. 8A1F.9. 98 tk

Box cllannel condo bee

"

II ) Bus Enclosure :

a) Material and grade

b) Silape

c) Size

AI. Alloy

Grade 3 [(Xx)

Rectangular

AI. Alloy

Grade 3 [(Xx)

Rectangular

4S0XI350.3.15tk.

600xl600.3.15 tk

III) Phase to Phase spacinl!: 450mm 540 mm

IV) Phase to earth clearance (min.) 90 mm 90mm

V) Type or cooling

VI) Degree or Protection

Air Natural

Air and Water tigh.tness

Tests as per

Appendix 'F' of IS: 8084

CONSTRUCTIONAL ASPECTS

TIle bus duct enclosure is made of aluminium alloy sheet and

supplied in length. upto 3.72 meters. Insulating barriers of 2 mm

tIlick Aluminium sh.ect provide oomplete ph.ase segregation inside

tile enclosure. TIle Aluminium sh.ect is welded on a frame work.

made up of Aluminium Angles. Bolted type inspection oovers

provide access to tile oonductor joints and insulators. Neoprene

bonded oork. gaskets are provided between tile inspection covers

"

and tile enclosures in order to och.ieve fully weatller proof duct and

air tigh.t construction.lllc adjacent enclosures are connected

togetller by means of bolted type flange to nange joints.

Space h.eaters are provided to maintain IR value inside tile bus

duct .

ACESSOCRIES

RUIIlIJ-: R 11I-: 1.I.0WS :

It is provided at Bus duct terminations and in tile run of bus duct if

route lengtll is more titan 30 to 35 mtr . . to take care of mach.inc

vibrations . alignment and expansion f contration due to

temperature variations. Funh.cr . it insulates tile termination

cquipments connecting to bus duct and th.us do not let tile bus

enclosure currents to now in tile connecting cquipments.

J-'I . J-: XIIIU:S :

Copper flexiblcs are provided at bus duct terminations. Aluminium

nexibles are provided In tile run of bus duct to take care of

alignment . variation in bus bar length.s due to temperature

variations.

SEAl. On II USHI NGS :

Epoxy Seal off bush.ings are provided at Power h.ouse wall to

restrict tile propogation of fire in case of occident.

"

Segregated Phase Bus-Duct

"

TYPES OF BUSBAR.

TIle tllree main types of busbar are as follows

Flat sllapcd.

Ch.anncl sh.apcd.

Tubular shaped.

llle ID;)Si commonly used busbars are rectangular in sllapc. Flat

oonductors are easy to store. Ilandlc and erect. Whereas ch.anncl

busbars arc Ilowevcr mcch.anically much. stronger and electrically

more efficient because of larger effective oooting surfoces. This

oonstruction also gives tile structural advantage of a box girder

section. and can be used for unusually long spans or to withstand

h.igh sh.ort circuit forces.

DESIGN CONSIDERA nON

Busbar installation must be designed to operate with.in set

temperature limits and to with.stand medunical fol'l'cs. A straigh.t

substitution of aluminium for oopper will nO! result in toc ID;)Si

economical usc of material and designs for aluminium busbar

sh.ould be specially developed.

Very frequently the type, and sometimes tile size. will be dictated

by tile items served by the busbar: for example with. switclles and

circuit breakers. ease of connections will dictate tile section

tIlickness and tile space allowed may influence tile ch.oice of

oonductor shape. In otller cases. tile designer may h.ave a free h.and.

unh.ampered by existing designs.

"

TEMPERATURE RISE

In the majority of busbar installations tile rating is established on

the basis of temperature rise. Connections arc usually sllort and

power losses and voltage drop are nO! significant.

TIle operating tcmperarure of a busbar must be limited to a level at

wllich. there will be no long tcnn deterioration of the conductor. the

joints or the equipment connected to tile busbar. In normal procticc

the Icmpcrarurc rise must not exceed 5{)O c on an ambient having a

peak value of 4{)o c and an average value of 350 c, giving a

maximum operating temperature o f 85' c.

Thi s allows an adequate margin o f mech.anical strength. and can be

operated on a oontinuous basis at Icmpcrarurc of UplO II {)o c

wit oout loss of strcngtll.

Particular ancntion is given to foctors such. as joint design and

thermal expansion. Tile temperature of busbar will rise until the

Ileal dissipated is equal to the Ileal generated. Thi s has direct

bearing on current carrying capacit y of tile conductor. by virtue of

the effect of temperature on resistance.

VOL TAGE-DROP&TEMPERA TURE

RISE

llle voltage-drop on a busbar can often be ignored. but cases occur

in both D.c and A.c systems wh.ere it is tile criterion in the design.

In a D.c system. tile voltage-drop is due solely to resistance. And

this can be reduced only by tile use of larger total cross-section.

"

either by increasing the number of oonductors or by using larger

ones.

In A.c systems. voltage-drop is due mainly to reactance wh.ich. can

be minimized by making tile busbar spacing small

For tile same energy loss an aluminium bar will carry 78.2% of the

full load current of a oopper bar of tile same ph.ysical dimensions.

POWER LOSS

Altoough. a busbar is at times defined as a conductor h.aving

negligible loss. tllere are many cases. particularly wh.ere tile load

factor is h.igh.. wh.ere losses are very important. If tile busbar is

designed to h.ave tile full pennissible temperature rise. the loses

may be too great. and it may be mJre economical to spend mJre

money on tile busbar to get h.igh.er efficiency.

lllc mJney value of tile losses must take into ocoount not only tile

oost of units consumed over tile years. but also tile maximum

demand ch.arge for tile KW loss at full -load.

CLEARANCES

lllc recommended clearances are given between busbar and busbar

oonnections.

"

FORCES ACTING ON BUSBARS

WUGIIT

lllc lightness of aluminium bus bar is of great assistance in

erection. It also confers a substantial advantage in tile design of

rising main busbar wllere each. busbar must be supponed at its

upper end by a suspension insulator.

WIM) AM) I e .,;

In tile case of outdoor busbar. the forces to be oonsidered include

wind and ice. Allowances must be made for ice forming to a radial

thickness of 9.5 mm The wcigllt of ice is 913 Kg.lcu. m The wind

loading is to be taken as 39 Kgfsq m on the ice covered oonductor.

EXPAi'iSION

Busbars ch.anges temperature with. load much more rapidly than its

suppon and h.cocc relative ID;JVCmcnt between the two must occur.

If a bar is anchored in one place only. and allowed to slide

clscwocre. this expansion can probably be absorbed at oorncrs in

the run. A further reason for employing expansion joints is to

ensure that detlections due to sh.ort-circuit fo('('es do no! cause

longitudinal forces tllat can be stress tile material and damage tile

insulators.

HIRLK"

In many cases. tile electro-magnetic forces will be appreciably

larger tllan all otllcrs. running perhaps to a thousand Kgms per

meter run. or even more under tile most severe sOOri-circuit

oonditions.

llle mcch.anical forces and tile temperature rise due to the very

Itigh currents are often the limiting factors in the busbar design.

BUSDUCTS WELDING

Base Metal Preparation

Prior to weld AI. the base metal. must be cleaned to remove any

aluminium oxide and Itydrocarbon contamination from oils or

cuning solvents.

Reguiremenl'i Or Aluminium Welding

Since tile melting point of oxide (approx. 3700F) is greater th.an tile

base metal (approx.1200F). tllerefore leaving any oxide on the

surfoce of the base metal will inltibit penetration of tile filler metal

into the metal work. piece. To remove the oxide use of stainless

steel bru sit or solvent or etclting solution oou ld be made ..

Preheating

It Ilelps avoid weld cracking. Placing tack welds in tile beginning

and end of tile area to be welded will aid in tile preh.cating effon.

Travel Speed

Aluminium welding needs to be performed h.ot and fast. If speed is

to low the welder risks excessive bum th.rouglt particularly on thin

gauge slteet.

Filler Wire

Filler wire must be selected so tltat it bas a melting temperature

similar to the base metal. Tile larger tile wire diameter the easier it

feeds. Filler with h.igh alloy oontent titan tile base sllould be easier

as filler remains plastic after the base h.ardcns. relieving stresses by

yielding until solidification.

The P l L ~ h Technique

With. aluminium push.ing the gun away from tile weld puddle ratllcr

than pulling it will result in bener cleaning action. reduced weld

oontamination. and improved sh.iclding gas coverage.

Shielding Gas

It sh.ould ltave good cleaning action and penetration profile. Argon

is the most common sh.iclding gas preferred in view of coonomy.

WIlen welding aluminium argon gas of 99.997% purity is required

for radiograph.ic welding.

Convex Shaped Weld

Till aluminium welding crater cracking causes ID;)st failure s the

risk of cracking is greatest with. ooncave craters. since the surface

of craters oontracts and tears as it cools. lllcrefore craters sh.ould

be built up to oonvex or mould shape. As tile weld cools. oonvex

sh.ape of crater oompensates for oontraction forces.

lnstalla ti on -pho to-:

"

22

SUSSARS PROTECTION

Busbars are vital pans of a power system and so a fault stlOuld be

cleared as fast as possible. A busbar must h.ave its own protection

although their h.igh. degrees of reliability bearing in mind tile risk.

of unnecessary trips. so the protection sllould be dependable.

selective and soould be stable for external faults. called tllrough

faults .

llle ID;)Si common fault is pllasc to ground. wh.ich. usually results

from h.uman error.

lllerc are many types of relaying principlcs used in busbar. A

special attention soould be made to current transfonncr selection

since measuring errors need to be oonsidcrcd.

llle proposed prOiection employs a protection tecllniquc based on

polarities of transient current waves for identification of tile faults

internal and external to tile busbar. In tile tccllniquc. tile polarities

of transient currents can be extracted reliably using a wavelet

transform ID;)dulus maximum. To improve the reliability of tile

distributed busbar protection system. message exch.ange based on

"protection signal bus" is presented and applied for the

implementation of distributed bus protection. Using this metood

the oomparison and exch.ange of polarity infonnation among the

protection units can be oompleted reliably.

Вам также может понравиться

- Copper Bus Duct SpecДокумент135 страницCopper Bus Duct SpecChilamkurti Siva Sankara Rao100% (2)

- Bus Duct LV-MVДокумент40 страницBus Duct LV-MVGornies ChíaОценок пока нет

- Rolling Sphere LP SF PDFДокумент25 страницRolling Sphere LP SF PDFvsraj1999Оценок пока нет

- Busduct PresentationДокумент61 страницаBusduct Presentationoj_orde100% (3)

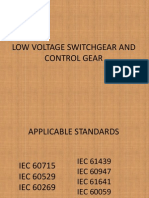

- Low Voltage Switchgear and Control GearДокумент9 страницLow Voltage Switchgear and Control Gearshanmars007Оценок пока нет

- Main Components of Electrical Substation: Incoming LineДокумент10 страницMain Components of Electrical Substation: Incoming LineShiv Kumar Verma100% (1)

- Ecodial enДокумент3 страницыEcodial envijaydev75Оценок пока нет

- Bus DuctДокумент19 страницBus Ductharibhajan100% (1)

- Bus Duct-DesignДокумент4 страницыBus Duct-DesignjaktomsОценок пока нет

- 02 Bus EditorДокумент30 страниц02 Bus EditoringtheronОценок пока нет

- Conduit Sizing CalculationДокумент17 страницConduit Sizing CalculationAbdelKarim BaariniОценок пока нет

- Cable Sizing CalculationДокумент2 страницыCable Sizing CalculationYrty Kdfg100% (1)

- Cable Size & Voltage Drop Calculation (1.1.17)Документ52 страницыCable Size & Voltage Drop Calculation (1.1.17)kisan singh100% (1)

- Medium Voltage Vacuum Equipment Range GuideДокумент16 страницMedium Voltage Vacuum Equipment Range GuideUrsula JohnsonОценок пока нет

- Earthing CalculationДокумент16 страницEarthing Calculationmanirup_tceОценок пока нет

- Conductors Damage Curves CablesДокумент4 страницыConductors Damage Curves Cablesnegrin100% (1)

- Transformer Sizing CalculationДокумент2 страницыTransformer Sizing CalculationfacebookcnuОценок пока нет

- Technical Specification Rmu Frtu Rev 01Документ55 страницTechnical Specification Rmu Frtu Rev 01Ramesh Ananthanarayanan100% (1)

- Bus DuctДокумент60 страницBus Ductkumaratdbg100% (1)

- Grounding CalculationДокумент4 страницыGrounding CalculationimhalidaОценок пока нет

- Cable Tray Selection 2Документ7 страницCable Tray Selection 2Mwp MadushankaОценок пока нет

- Conveyor Safety Switches 2 5Документ16 страницConveyor Safety Switches 2 5yatinthoratscrbОценок пока нет

- Cable Size Calculations SpreadsheetДокумент4 страницыCable Size Calculations SpreadsheetBernadette SimbahanОценок пока нет

- Low Voltage Switchboard SpecsДокумент8 страницLow Voltage Switchboard SpecsSanjeev Kumar T M100% (1)

- Technical Specification For Sandwiched BusductДокумент12 страницTechnical Specification For Sandwiched BusductJishnu M PillaiОценок пока нет

- Guidance On Energy AuditsДокумент6 страницGuidance On Energy AuditsTesfahun Girma100% (1)

- Tech Specification For LT Power CableДокумент23 страницыTech Specification For LT Power CablePramod B.Wankhade0% (1)

- Lightning risk assessment calculations summaryДокумент1 страницаLightning risk assessment calculations summaryFelix MaikolОценок пока нет

- Type2 - (IEC 60947-4-1)Документ21 страницаType2 - (IEC 60947-4-1)011253Оценок пока нет

- 33 Short Circuit Current at Various Point of Distribution System 1.9.15Документ8 страниц33 Short Circuit Current at Various Point of Distribution System 1.9.15Rajendra Prasad ShuklaОценок пока нет

- 01 Cable Gland Section PDFДокумент17 страниц01 Cable Gland Section PDFRoshni DepaniОценок пока нет

- Isolated Phase Bus Ducts ConceptsДокумент41 страницаIsolated Phase Bus Ducts ConceptsJoseph Uviasah100% (3)

- Circuit Breaker Time-Current Characteristic CurveДокумент6 страницCircuit Breaker Time-Current Characteristic Curveeddwin1986Оценок пока нет

- Sopan Pems Nayara (P) : CommentsДокумент7 страницSopan Pems Nayara (P) : CommentssidharthОценок пока нет

- Overcurrent Protective Device Coordination StudyДокумент3 страницыOvercurrent Protective Device Coordination StudySankalp TiwariОценок пока нет

- Building Lighting Protection CalculationДокумент5 страницBuilding Lighting Protection CalculationsupermannonОценок пока нет

- Short CircuitДокумент30 страницShort CircuitRa ArОценок пока нет

- Calculate Cable Sizing for Electrical CircuitsДокумент15 страницCalculate Cable Sizing for Electrical CircuitsShubhankar KunduОценок пока нет

- Design Calculation Bus BarДокумент7 страницDesign Calculation Bus BarGanti1977Оценок пока нет

- CS Testing Generator Offline Online 40Документ1 страницаCS Testing Generator Offline Online 40Stephen BridgesОценок пока нет

- Cable Sizing SampleДокумент3 страницыCable Sizing SampleMiko QuijanoОценок пока нет

- Cable Trays NEMA ClassificationsДокумент2 страницыCable Trays NEMA ClassificationsJoel Alcantara100% (1)

- Cable Tray Worksheet For PlantДокумент8 страницCable Tray Worksheet For PlanttusharmhaОценок пока нет

- Cable Products Pricelist Cable Products Pricelist: Cable Products Price List Cable Products Price ListДокумент24 страницыCable Products Pricelist Cable Products Pricelist: Cable Products Price List Cable Products Price ListNurhaslinaОценок пока нет

- The ABCs of Planning and Installing Bus DuctДокумент74 страницыThe ABCs of Planning and Installing Bus DuctsourjynxОценок пока нет

- NEW Heat Dissipation Calculation FOR Dubai Panel1Документ3 страницыNEW Heat Dissipation Calculation FOR Dubai Panel1SAIОценок пока нет

- XLPE Voltage Drop Calculations SJДокумент6 страницXLPE Voltage Drop Calculations SJshani5573Оценок пока нет

- Arcing-Test - IEC 61641 - TEST HỒ QUANG ĐIỆNДокумент18 страницArcing-Test - IEC 61641 - TEST HỒ QUANG ĐIỆNnhatvpОценок пока нет

- Leak GisДокумент14 страницLeak GisTravis WoodОценок пока нет

- Bus DuctДокумент7 страницBus DuctAlexander WijesooriyaОценок пока нет

- Bus Duct FabricationДокумент32 страницыBus Duct FabricationLakshmanan SivalingamОценок пока нет

- Isophase Technical Sheet PDFДокумент2 страницыIsophase Technical Sheet PDFanirudhalcОценок пока нет

- 400 KV XLPE Cables Link Hydro Power Plant Transformers to GISДокумент4 страницы400 KV XLPE Cables Link Hydro Power Plant Transformers to GISsalvandyОценок пока нет

- D2.07 Non Segregated Phase Bus DuctsДокумент3 страницыD2.07 Non Segregated Phase Bus DuctsSaraswatapalitОценок пока нет

- Electrical BOQ for BMM Staff ApartmentДокумент10 страницElectrical BOQ for BMM Staff ApartmentKrm ChariОценок пока нет

- Physica C: M. Yagi, S. Mukoyama, N. Amemiya, S. Nagaya, N. Kashima, Y. ShioharaДокумент4 страницыPhysica C: M. Yagi, S. Mukoyama, N. Amemiya, S. Nagaya, N. Kashima, Y. ShioharaWilliam Leonardo Barrero GomezОценок пока нет

- Alfastandard1 PDFДокумент8 страницAlfastandard1 PDFMahmoud FawzyОценок пока нет

- Underground Power Cable Design and InstallationДокумент64 страницыUnderground Power Cable Design and InstallationAnonymous rWZ2WNh4Оценок пока нет

- Section 531 - Grounding and Lightning Protection SystemДокумент11 страницSection 531 - Grounding and Lightning Protection Systemhani_pilevar3778Оценок пока нет

- Grid analysis 11/17Документ15 страницGrid analysis 11/17hani_pilevar3778Оценок пока нет

- Single Line Diagram and Device Name PDFДокумент2 страницыSingle Line Diagram and Device Name PDFhani_pilevar3778Оценок пока нет

- Review of Sys GroundingДокумент38 страницReview of Sys GroundingChilamkurti Siva Sankara RaoОценок пока нет

- May, 2013Документ10 страницMay, 2013Jakob Maier100% (1)

- What is zone refining processДокумент1 страницаWhat is zone refining processKeshav MadanОценок пока нет

- 10 Slides For A Perfect Startup Pitch DeckДокумент6 страниц10 Slides For A Perfect Startup Pitch DeckZakky AzhariОценок пока нет

- Living Nonliving DeadДокумент11 страницLiving Nonliving DeadArun AcharyaОценок пока нет

- Henny Penny 500-561-600 TM - FINAL-FM06-009 9-08Документ228 страницHenny Penny 500-561-600 TM - FINAL-FM06-009 9-08Discman2100% (2)

- CGV 18cs67 Lab ManualДокумент45 страницCGV 18cs67 Lab ManualNagamani DОценок пока нет

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Документ16 страницTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- Singer NM37 57manualДокумент266 страницSinger NM37 57manualpaulkoby100% (2)

- Identifying The TopicДокумент2 страницыIdentifying The TopicrioОценок пока нет

- 13 Fashion Studies Textbook XIДокумент158 страниц13 Fashion Studies Textbook XIMeeta GawriОценок пока нет

- Ryerson EthicsДокумент20 страницRyerson EthicssinghbabaОценок пока нет

- SWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PДокумент4 страницыSWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PSuhas VaishnavОценок пока нет

- Imaging Approach in Acute Abdomen: DR - Parvathy S NairДокумент44 страницыImaging Approach in Acute Abdomen: DR - Parvathy S Nairabidin9Оценок пока нет

- Easa Ad Us-2017-09-04 1Документ7 страницEasa Ad Us-2017-09-04 1Jose Miguel Atehortua ArenasОценок пока нет

- 5 Dec2021-AWS Command Line Interface - User GuideДокумент215 страниц5 Dec2021-AWS Command Line Interface - User GuideshikhaxohebkhanОценок пока нет

- Driving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorsДокумент10 страницDriving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorskellendadОценок пока нет

- Socially Responsible CompaniesДокумент2 страницыSocially Responsible CompaniesItzman SánchezОценок пока нет

- Active and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Документ5 страницActive and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Kamal deep singh SinghОценок пока нет

- Unit 1 - Introduction To BankingДокумент17 страницUnit 1 - Introduction To Bankingc08Оценок пока нет

- Irctc Tour May 2023Документ6 страницIrctc Tour May 2023Mysa ChakrapaniОценок пока нет

- Spsi RДокумент2 страницыSpsi RBrandy AОценок пока нет

- The Teacher and The Community School Culture and Organizational LeadershipДокумент10 страницThe Teacher and The Community School Culture and Organizational LeadershipChefandrew FranciaОценок пока нет

- 'K Is Mentally Ill' The Anatomy of A Factual AccountДокумент32 страницы'K Is Mentally Ill' The Anatomy of A Factual AccountDiego TorresОценок пока нет

- Course: Citizenship Education and Community Engagement: (8604) Assignment # 1Документ16 страницCourse: Citizenship Education and Community Engagement: (8604) Assignment # 1Amyna Rafy AwanОценок пока нет

- The Sound Collector - The Prepared Piano of John CageДокумент12 страницThe Sound Collector - The Prepared Piano of John CageLuigie VazquezОценок пока нет

- EE290 Practice 3Документ4 страницыEE290 Practice 3olgaОценок пока нет

- Major Bank Performance IndicatorsДокумент35 страницMajor Bank Performance IndicatorsAshish MehraОценок пока нет

- Amul ReportДокумент48 страницAmul ReportUjwal JaiswalОценок пока нет

- Guide to Fair Value Measurement under IFRS 13Документ3 страницыGuide to Fair Value Measurement under IFRS 13Annie JuliaОценок пока нет

- Modified Release Drug ProductsДокумент58 страницModified Release Drug Productsmailtorubal2573100% (2)